A powder toughening and anti-gas channeling agent for well cementing

A technology of anti-gas channeling agent and powder, which can be used in drilling compositions, chemical instruments and methods, etc., can solve the problem of oil leakage and damage; on the other hand, the problems of interlayer isolation failure, etc. The probability of occurrence, the effect of ensuring uniform stability, and enhancing impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 1 part by weight of styrene-butadiene powder material, 0.04 part by weight of organosilane surfactant, 0.05 part by weight of sodium metasilicate pentahydrate, and 0.2 part by weight of polycarboxylate dispersant, mix uniformly to make powder Toughening anti-air channeling agent, coded with G01. (All medicines used are commercially available)

[0020] The evaluation method of anti-gas channeling performance adopts the method described in the industry standard oil well cement admixture evaluation method Part 5: anti gas channeling agent SYT5504.5-2010.

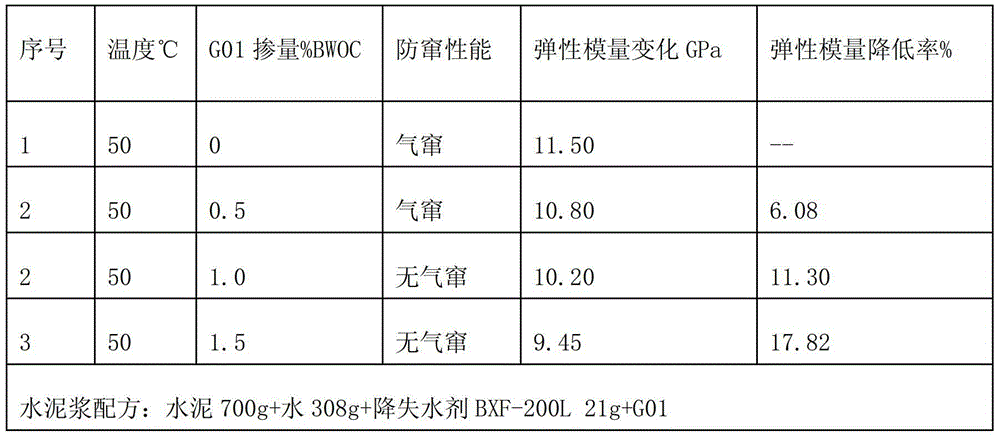

[0021] Table 1 Anti-gas channeling effect and mechanical properties of different dosages of G01 at 80°C

[0022]

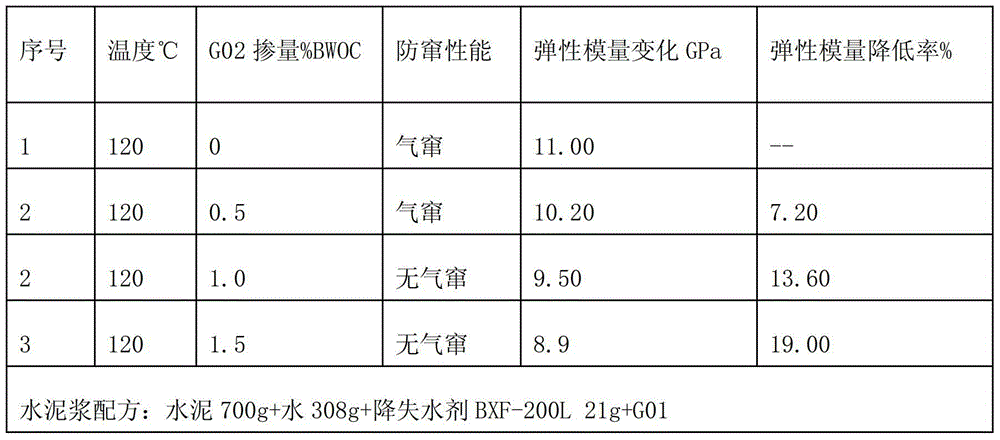

[0023] Table 2 Anti-gas channeling effect and mechanical properties of different dosages of G01 at 120°C

[0024]

Embodiment 2

[0026] Weigh 1 part by weight of styrene-butadiene powder material, 0.05 part by weight of organosilane surfactant, 0.01 part by weight of sodium metasilicate pentahydrate, and 0.1 part by weight of polycarboxylic acid dispersant, and mix them evenly to make powder Toughening anti-air channeling agent, coded with G02.

[0027] The evaluation method of anti-gas channeling performance adopts the method described in the industry standard oil well cement admixture evaluation method Part 5: anti gas channeling agent SYT5504.5-2010.

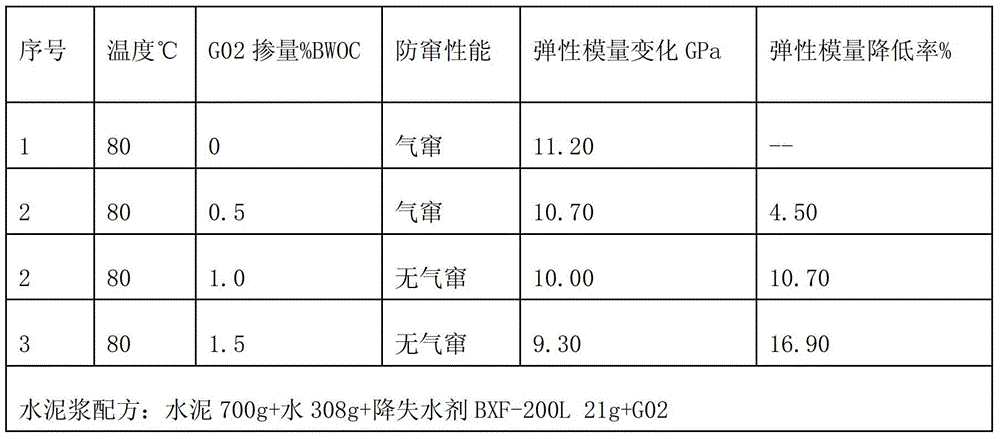

[0028] Table 3 Anti-gas channeling effect and mechanical properties of different dosages of G02 at 80°C

[0029]

[0030] Table 4 Anti-gas channeling effect and mechanical properties of different dosages of G02 at 120°C

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com