Plastic sheet glue brushing device for blister package flocking

A technology for blister packaging and plastic sheets, which is applied to devices and coatings for coating liquid on the surface, and can solve the problems of reducing the quality of plastic sheet gluing, dripping glue from glue spray nozzles, and lack of protection measures. Achieve the effects of enhancing work stability, ensuring uniform stability, and simple and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

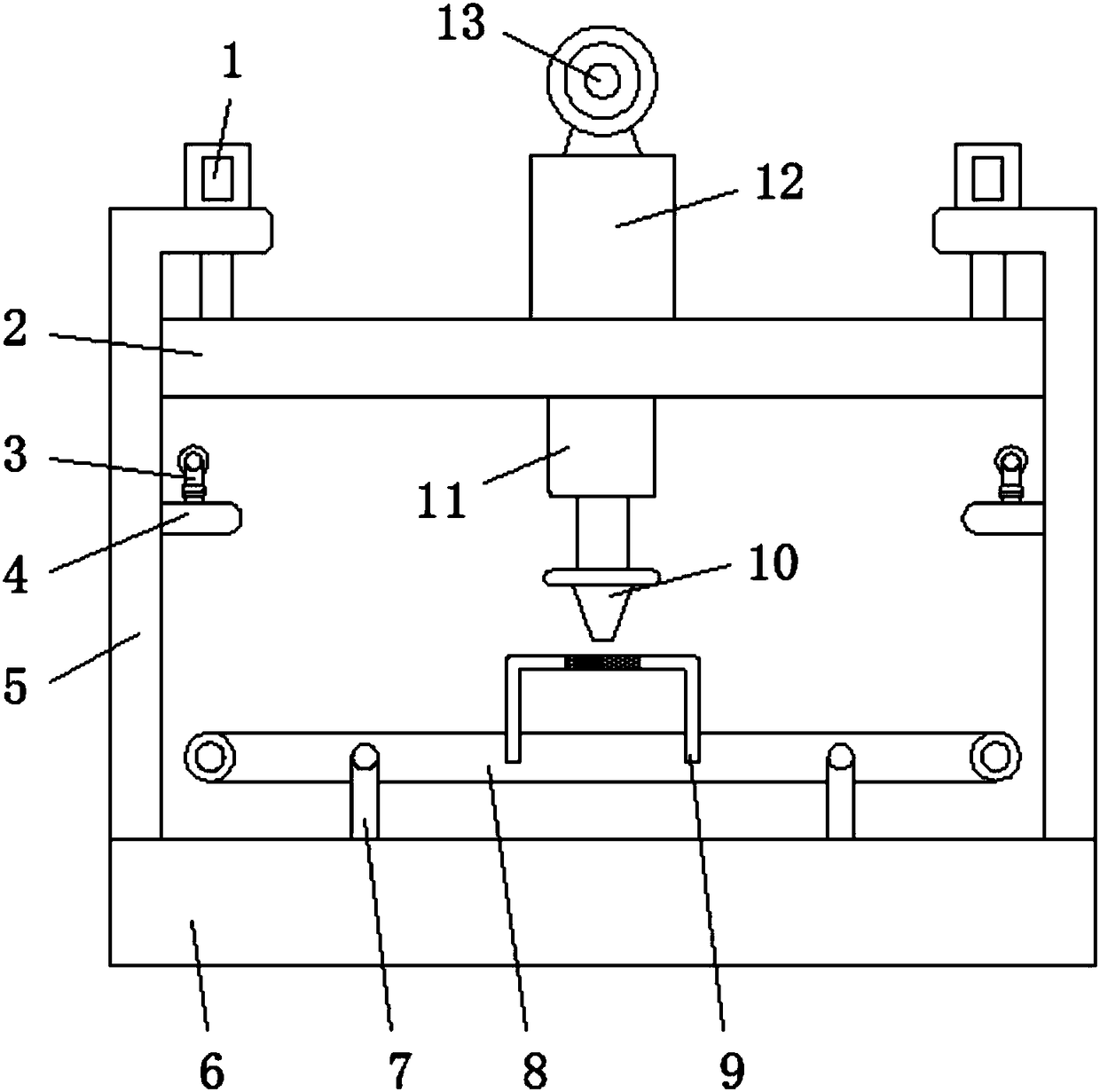

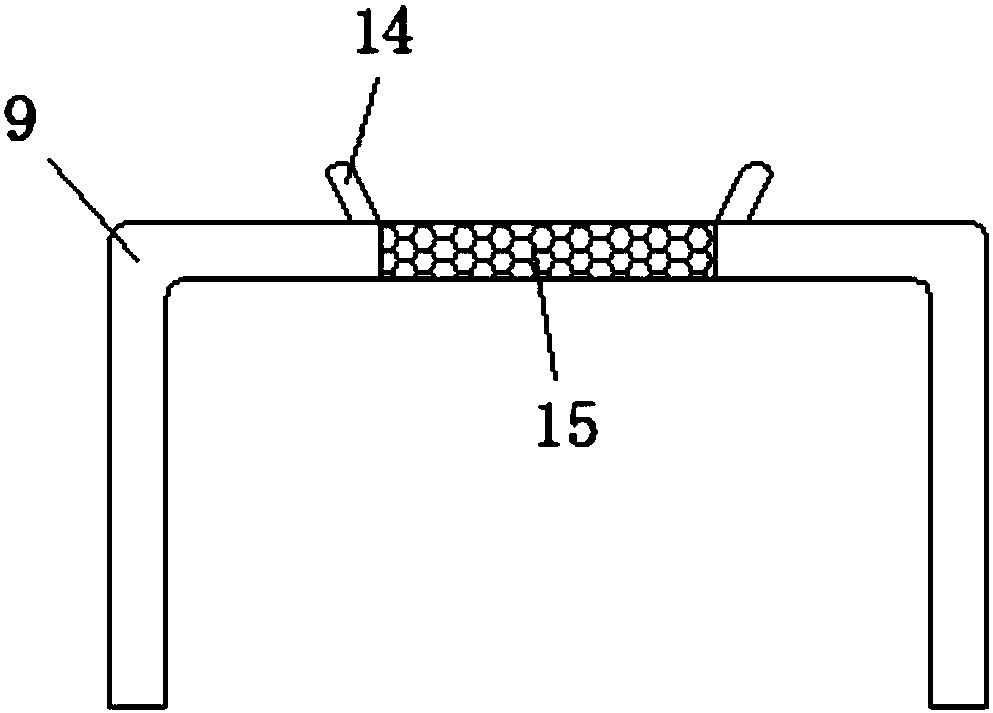

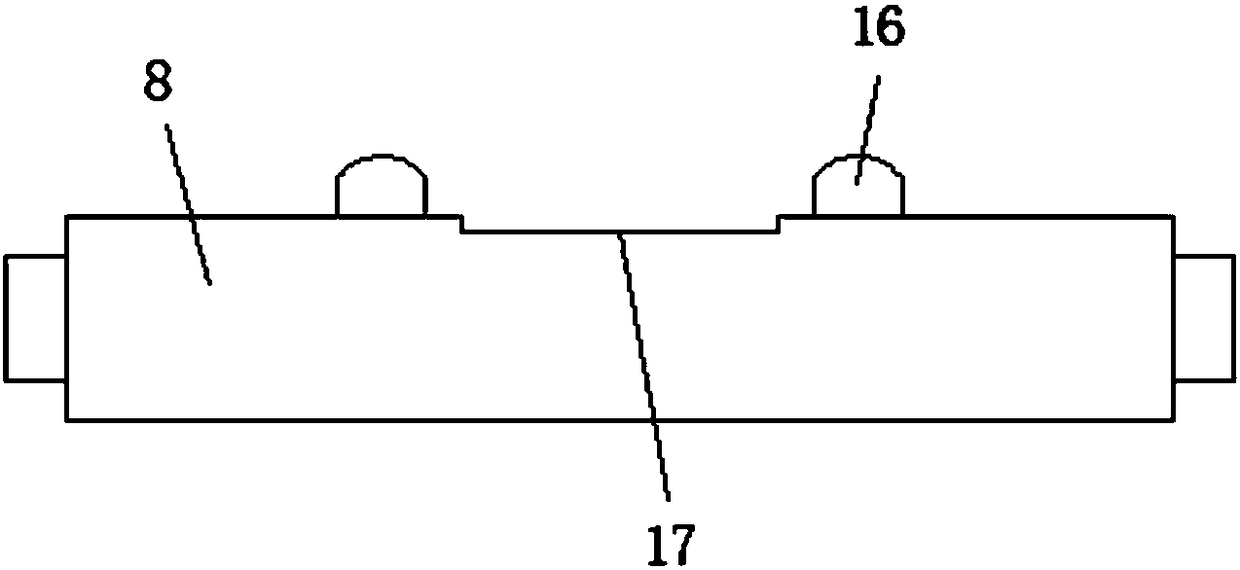

[0022] refer to Figure 1-3 , a plastic sheet glue brushing device for blister packaging flocking, comprising a base 6, connecting rods 7 are welded symmetrically on both sides of the upper surface of the base 6, and a conveyor belt 8 is welded on the top of the connecting rod 7, and the top of the conveyor belt 8 There is a groove 17 at the center of the surface, and a connecting frame 9 is welded symmetrically on both sides of the outer wall of the conveyor belt 8. An elastic mesh cover 15 is arranged inside the horizontal end of the connecting frame 9, and the horizontal end of the connecting frame 9 is located on the elastic mesh cover 15. Protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com