Multi-material variable-diameter screw extrusion 3D printing device

A variable-diameter screw and 3D printing technology, applied in coating devices, processing drive devices, manufacturing auxiliary devices, etc., can solve the problem of inability to realize active mixing and precise control of multi-materials, complex structure and operation of multiple nozzles, and the number of nozzles configured Limited and other problems, to achieve the effect of convenient and precise regulation, ensuring uniformity and stability, and improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

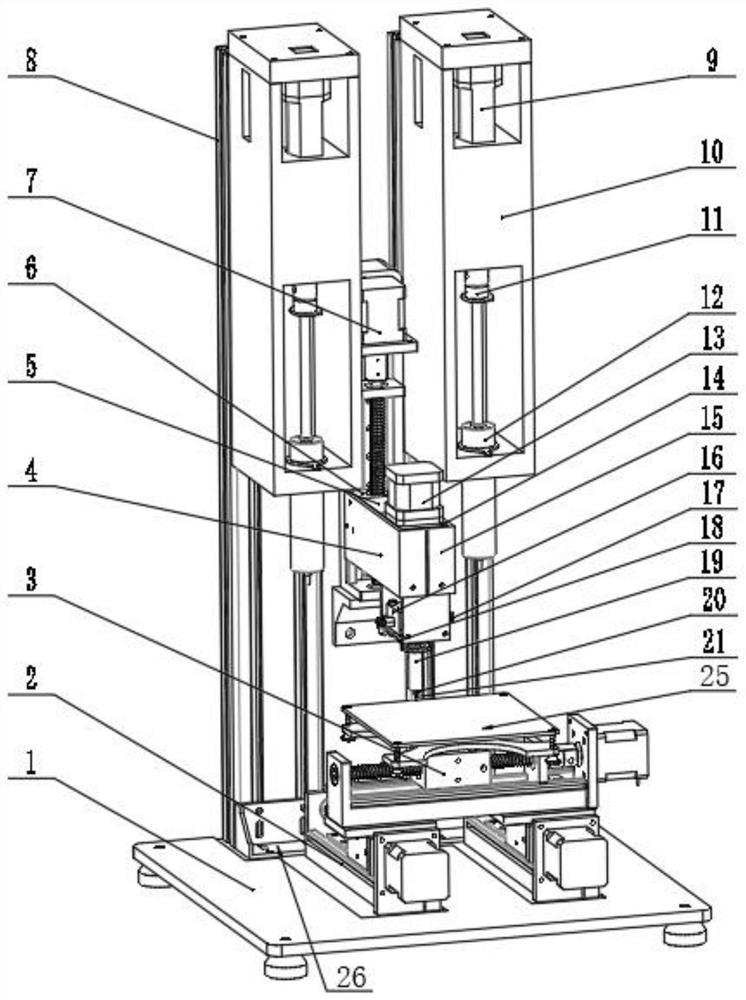

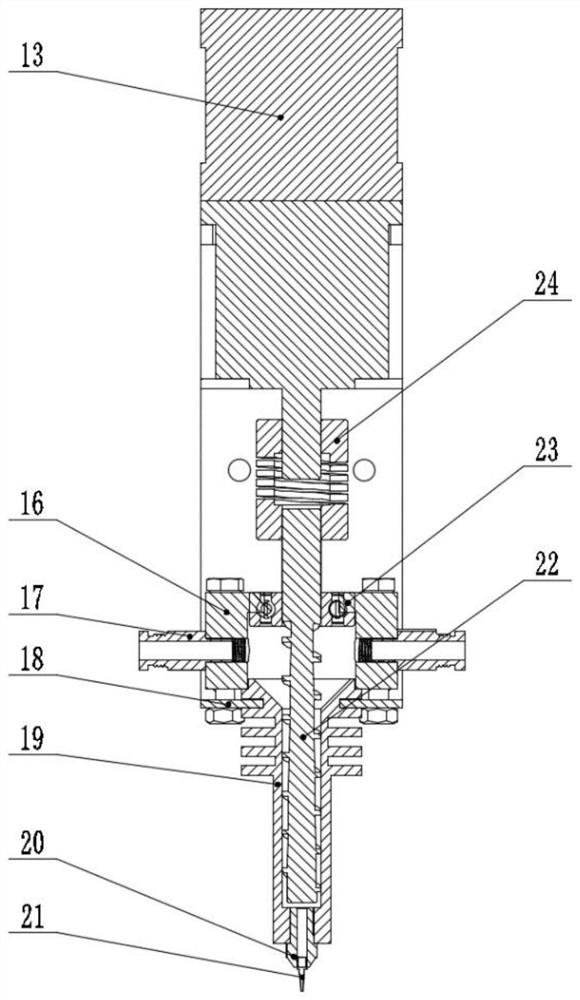

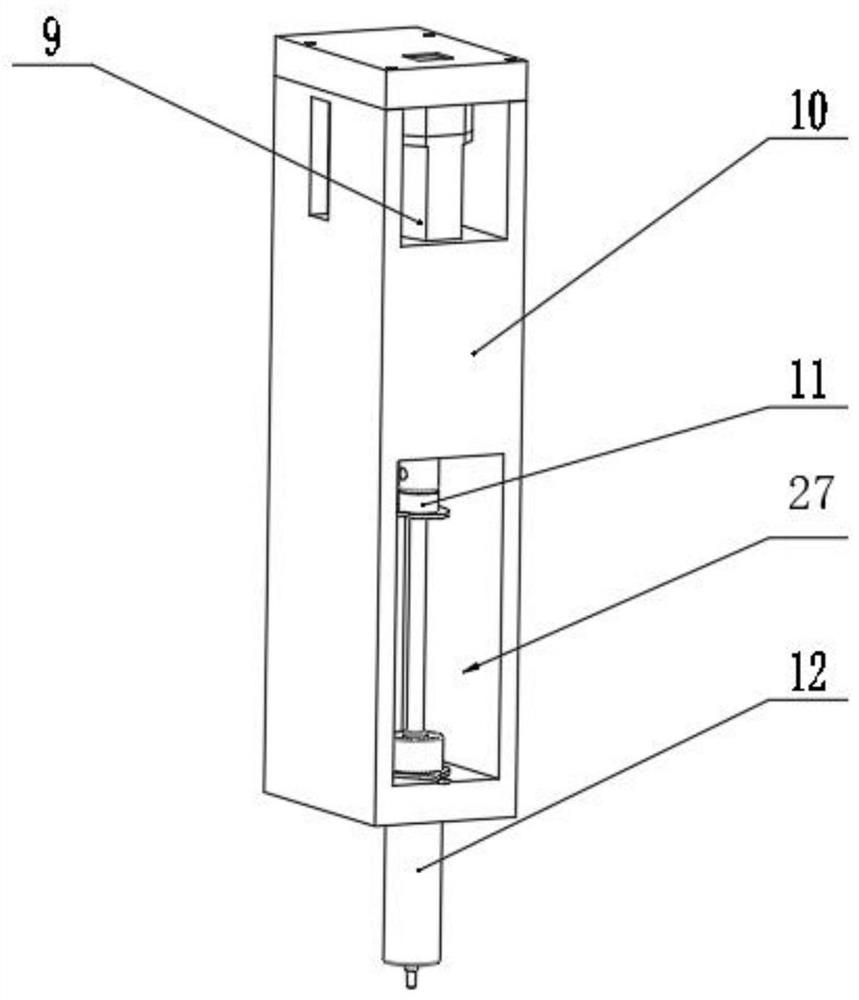

[0026] A multi-material variable-diameter screw extrusion 3D printing device, which is innovative in that it includes a base plate 1 and a vertical plate 8 vertically arranged on the base plate 1, and the base plate 1 is provided with an X-axis drive unit, and the X-axis A Y-axis drive unit is arranged on the drive unit, and a printing platform 25 is connected above the Y-axis drive unit, and the X-axis drive unit and the Y-axis drive unit drive the printing platform 25 to move horizontally; There is a feeding unit and a Z-axis driving unit, the Z-axis driving unit is connected with a printing unit, the feeding unit is connected with the printing unit, and the Z-axis driving unit drives the printing unit to vertically lift.

[0027] The numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com