A fuel droplet ignition temperature measurement device for visualization experiments

A temperature measuring device and experimental technology, applied in the direction of measuring devices, combustion and ignition, and electric devices, etc., can solve the problems of not being able to observe the relevant parameters of the sample projection status, resistance wires affecting the effect of observation, and affecting the accuracy of experimental results, etc. To achieve the effect of ensuring uniform stability, high stability and reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

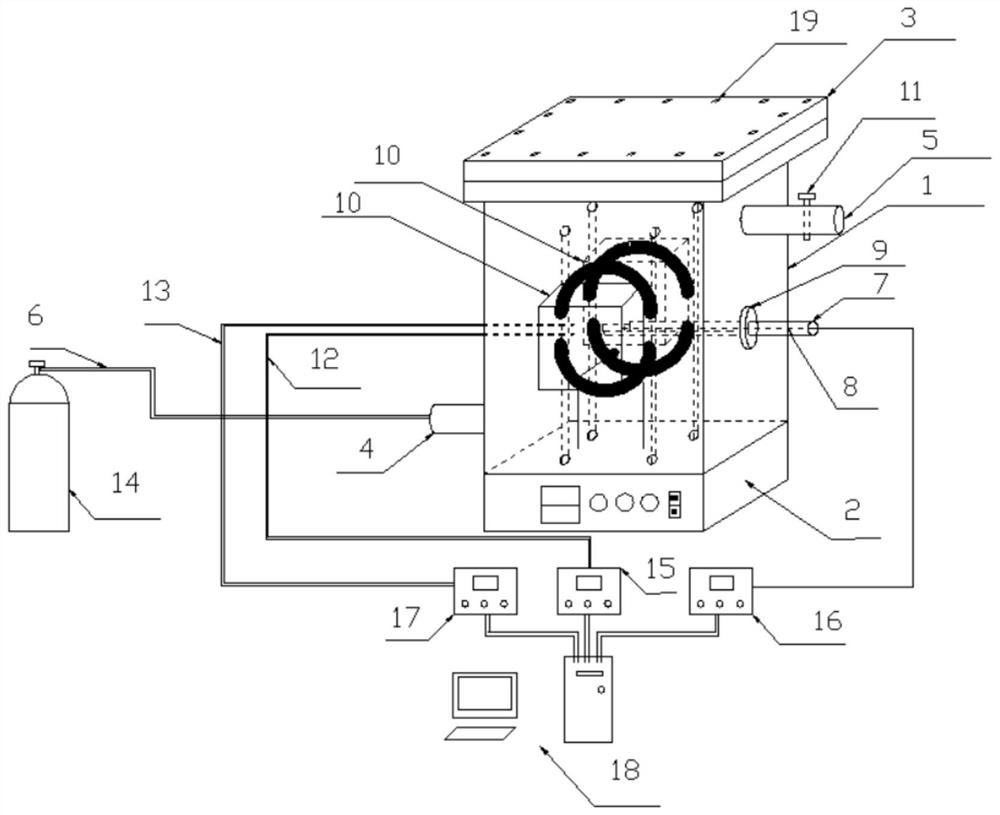

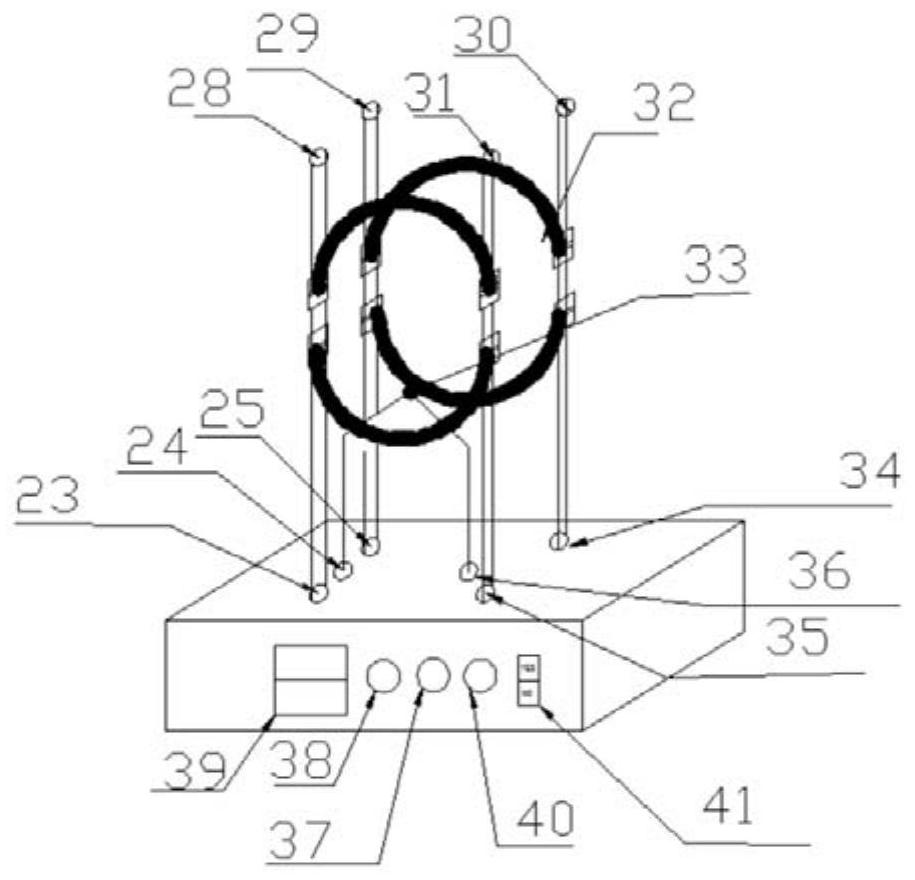

[0037] combine Figure 1-Figure 4 As shown, a fuel droplet ignition temperature measurement device for a visualization experiment in this embodiment includes a combustion chamber 1, a combustion sample pushing mechanism and a data collection and processing mechanism, and the fuel to be tested is pushed into the combustion chamber 1 through the combustion sample pushing mechanism Carry out the combustion test, and use the data acquisition and processing mechanism to collect, process and analyze the parameters of the fuel combustion process, such as smoke composition, pressure, temperature, etc. Wherein, the first ignition column 28, the second ignition column 31, the third ignition column 30 and the fourth ignition column 29 are provided with symmetrical distribution in the combustion chamber 1, and these four ignition columns surround and form a rectangular structure (located at the apex of the rectangle respectively). position), each ignition column is provided with two ignit...

Embodiment 2

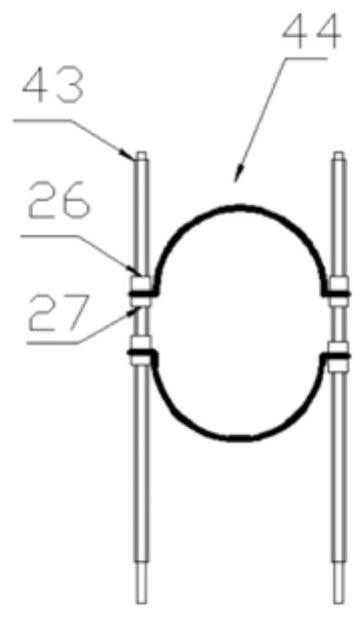

[0040] A fuel droplet ignition temperature measuring device for a visualization experiment of the present embodiment is basically the same in structure as that of Embodiment 1, and its difference mainly lies in: combining Figure 1-Figure 3 , the ignition column in this embodiment is made of stainless steel, and the area above the upper ignition wire fastening device, the area below the lower ignition wire fastening device and the area between the two fastening devices on each ignition column are all set There is a detachable insulating ceramic cover 43, and the ignition column at the installation position of the ignition wire fastening device is in an exposed state (there is no ceramic cover 43). The above-mentioned ignition wire fastening device includes an upper rotating piece 26 and a lower rotating piece 27 that cooperate with each other, and the end of the arc-shaped ignition wire 32 is fastened to the bare part of the ignition column through the fastening device. like ...

Embodiment 3

[0043] A fuel droplet ignition temperature measuring device for a visualization experiment of this embodiment is basically the same in structure as that of Embodiment 2, and the difference mainly lies in: Figure 4 As shown, the combustion sample pushing mechanism of this embodiment includes a sample pushing rod 7, a sealing plug 42 and a sealing ring 9. The inside of the sealing plug 42 is processed with a through hole for the sample pushing rod 7 to pass through. The sample pushing rod 7 is installed in the opening on one side of the combustion chamber 1 and sealed by the sealing ring 9, and the sample pushing rod 7 is provided with a slot at one end of the combustion chamber 1, through which the solid sample can be directly held, If the sample is liquid, hang it directly on the thermocouple, and put it in the slot as for the mixed sample.

[0044] Therefore, through the structural design of the combustion sample pushing mechanism, on the one hand, the combustion test requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com