A kind of cathode material for high-capacity lithium secondary battery and preparation method thereof

A lithium secondary battery and cathode material technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of precursor and ternary cathode material design, the impact of equipment and product quality, and the difficulty of industrialized production. Low environmental moisture requirements, cost saving, and long-term high-temperature cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

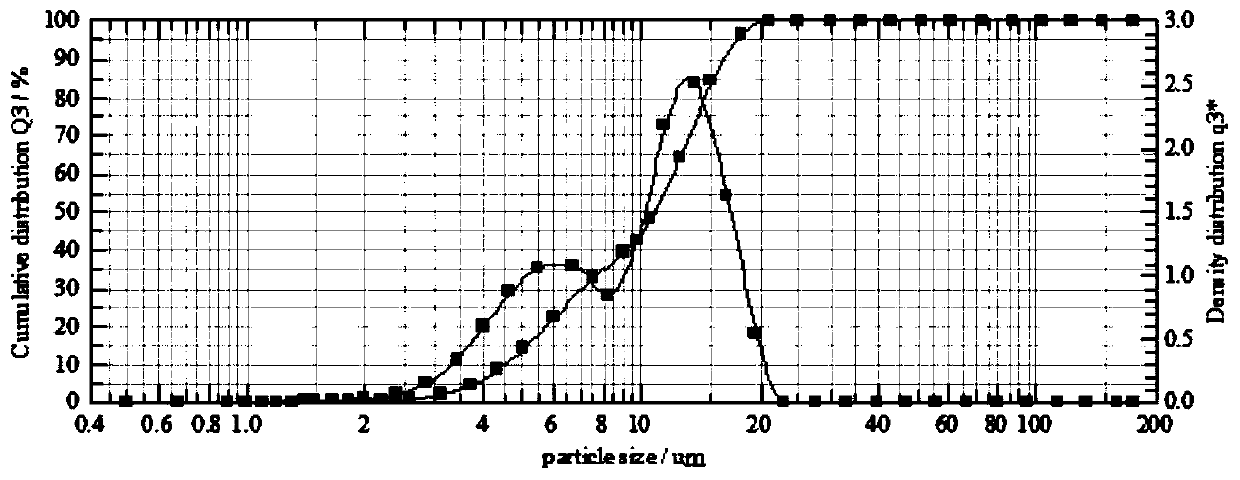

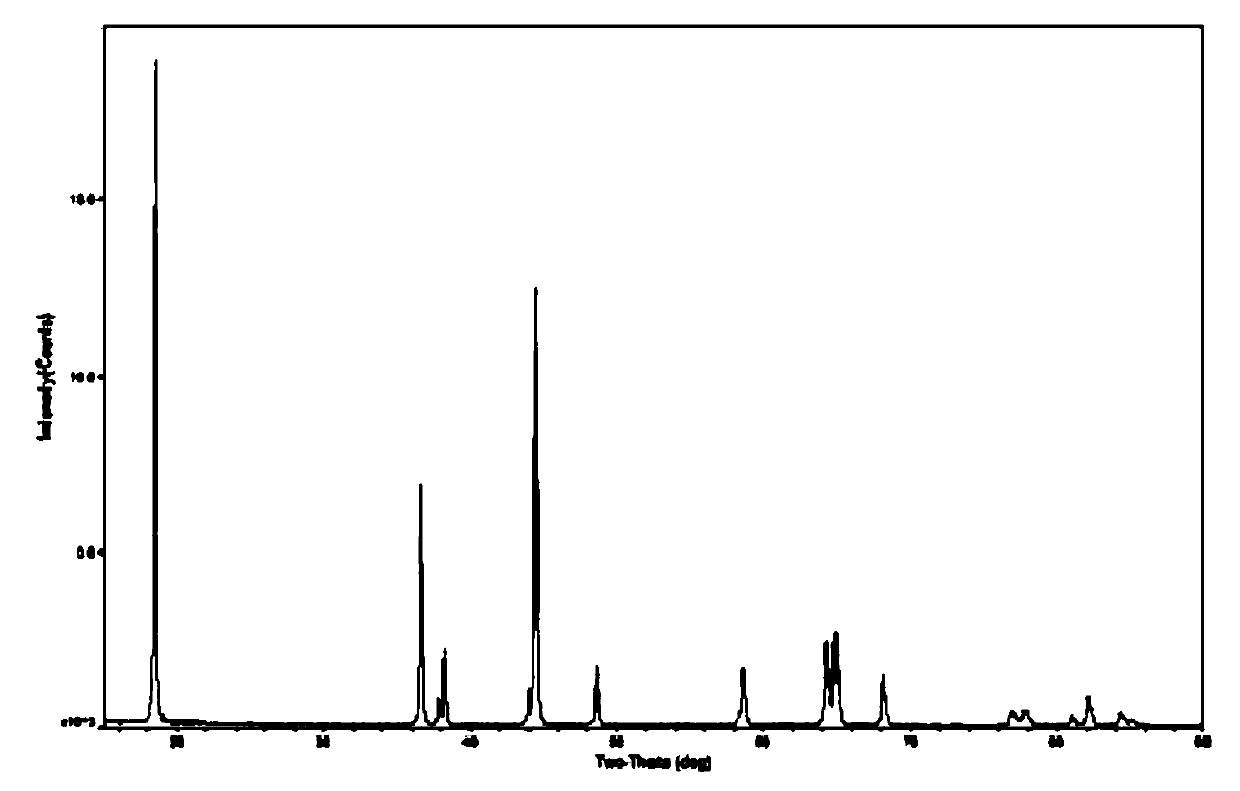

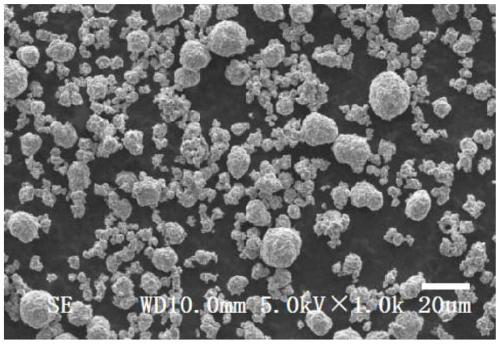

[0041] (1) mixing: mix D 50 4.0µm and D 50 14.0μm nickel cobalt manganese hydroxide precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 Accurately weigh and add high-speed mixer according to the mass ratio of 3:7, and accurately weigh lithium carbonate according to lithium metal ratio (Li / Me=1.05) simultaneously, according to B, W, Al being 500ppm respectively, F being the amount of 1055ppm at high speed Add AlF to the mixer at the same time 3 , Na 2 B 4 o 7 10H 2 O, WO 3 , mixed for 30min;

[0042] (2) Firing: The mixed powder prepared in step 1 is accurately loaded into the crucible according to the set weight of 4.5kg and entered into a 40m roller kiln with 2m / area. The kiln uses a single-layer four-row crucible with a size of 320mm*320mm*100mm. The temperature is raised to 120°C at a rate of 2.5°C / min, and the temperature is kept at 120°C for 3 hours. After that, the temperature is continued to rise at a rate of 2.5°C / min. Insulate at 500°C for 3 hours, then raise the temper...

Embodiment 2

[0046] (1) mixing: mix D 50 3.0μm and D 50 12.0μm nickel cobalt manganese hydroxide precursor Ni 0.7 co 0.15 mn 0.15 (OH) 2 Accurately weigh and add to the high-speed mixer according to the mass ratio of 2:8, and simultaneously accurately weigh lithium carbonate according to the lithium metal ratio (Li / Me=1.04), according to B, W, Al being 1000ppm respectively, and F being 2110ppm at high speed Add AlF to the mixer at the same time 3 , Na 2 B 4 o 7 10H 2 O, WO 3 , mixed for 30min;

[0047] (2) Firing: The mixed powder prepared in step 1 is accurately loaded into the crucible according to the set weight of 4.0kg and entered into a 40m roller kiln with 2m / area. The kiln uses a single-layer four-row crucible with a size of 320mm*320mm*100mm. The temperature is raised to 120°C at a rate of 2.0°C / min, and the temperature is kept at 120°C for 3 hours. After that, the temperature is continued to rise at a rate of 2°C / min. Insulate at 500°C for 4 hours, then raise the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com