High-temperature mechanical property in-situ tension test system and method for small-sized monocrystalline silicon test piece

A high-temperature mechanics and testing system technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of large differences in small-sized structures, and achieve the effect of easy implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is an in-situ tensile testing system and method for high-temperature mechanical properties of a small-sized monocrystalline silicon specimen, and its specific implementation is as follows:

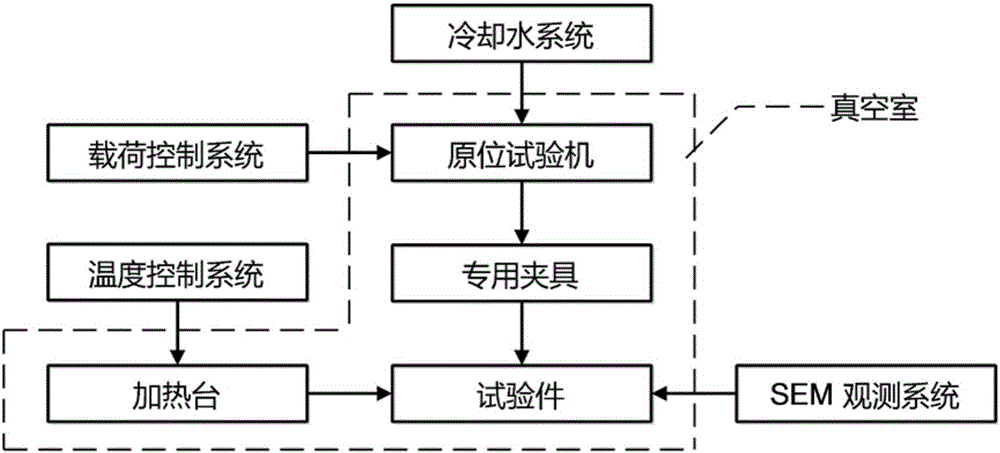

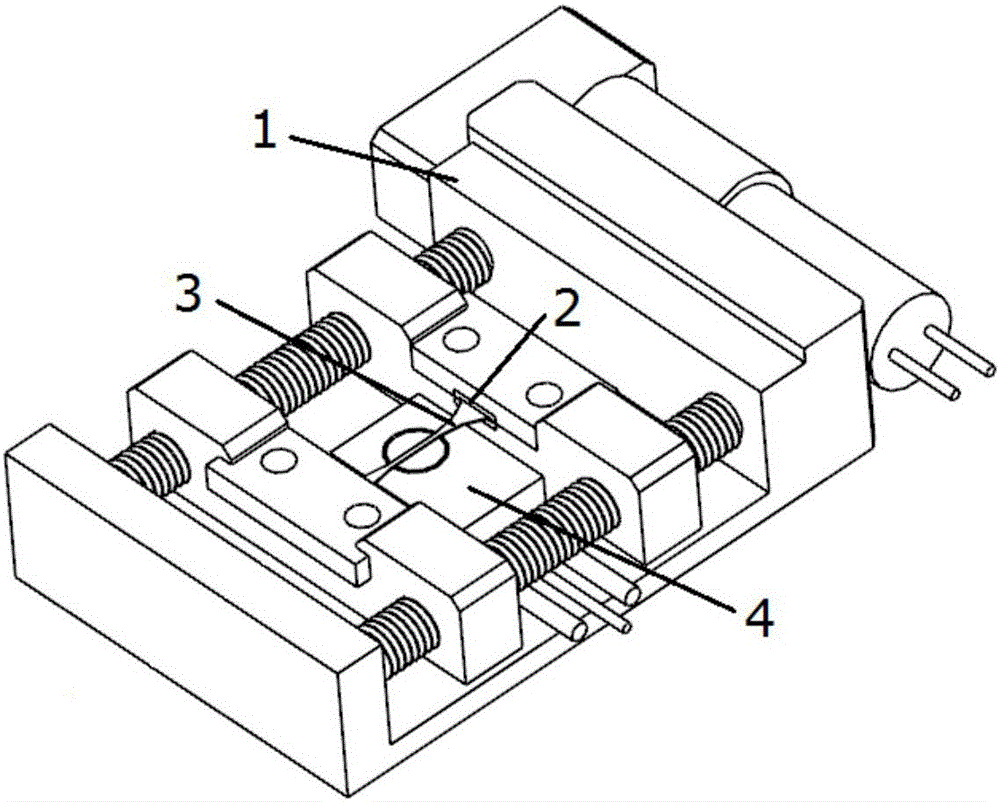

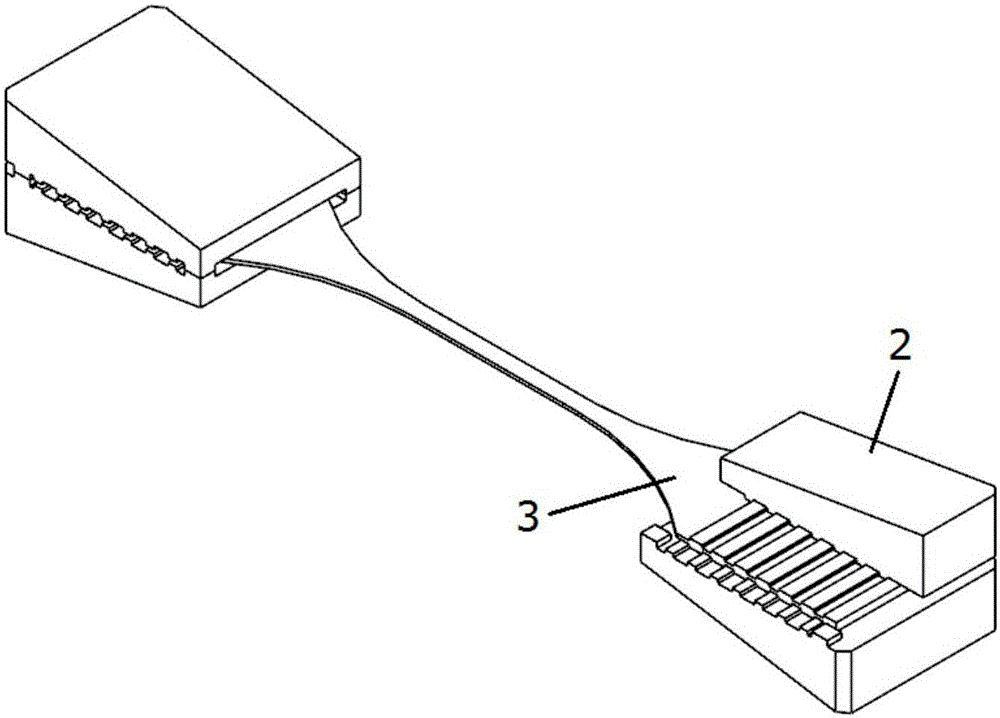

[0027] Such as figure 1 As shown, the system of the present invention consists of a load control system, an in-situ testing machine 1, a special fixture 2, a special test piece 3, a temperature control system, a heating table 4, a cooling water system, and an SEM observation system. The special test piece 3 is specially designed and fixed on the in-situ testing machine 1 through the special fixture 2. The in-situ testing machine 1 is connected to the load control system through the data line; the heating table 4 is connected to the temperature control system through the data line, and is mechanically fixed on the On the in-situ testing machine 1 and below the special test piece 3, heat the special test piece 3; the water cooling channel inside the heating table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com