Floating brake pad

A brake pad, floating technology, applied in the direction of brake type, brake components, mechanical equipment, etc., can solve problems such as support failure, and achieve the effect of stress averaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

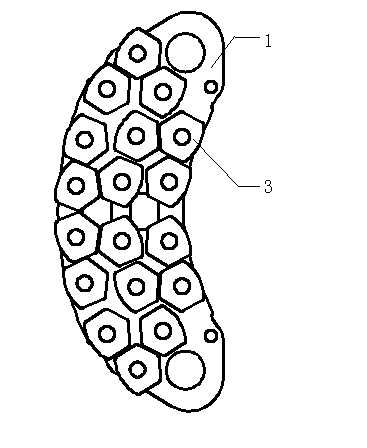

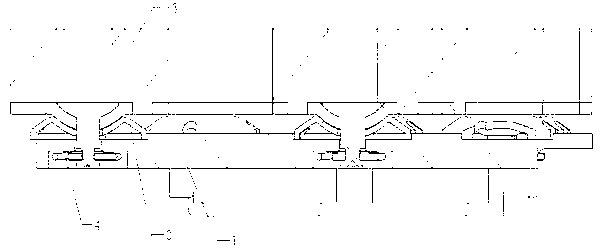

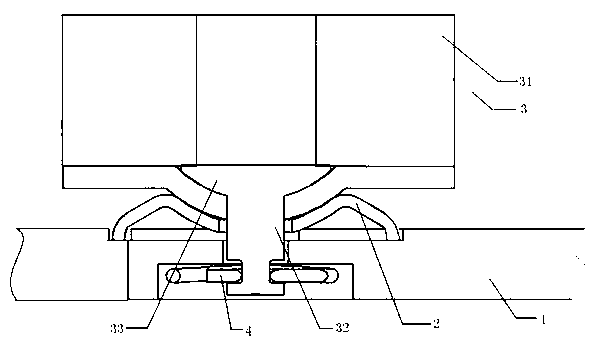

[0036] Such as Figure 1-8Shown is the floating brake pad of the present invention, which includes: a brake pad back plate 1 formed with a plurality of positioning holes 11; several friction blocks 3, which include friction parts 31 inserted into the positioning holes 11 The positioning part 32 and the support part 33 arranged between the friction part 31 and the positioning part 32, the support part 33 is a spherical structure, and the spherical surface of the support part 33 protrudes in the direction of the positioning part 32; Several circlips 4, the circlips are clamped on the positioning part 32, and the friction block 3 is connected to the brake pad back plate 1 with a certain floating amount; The elastic support piece 2 between the block 3 and the brake pad back plate 1, the elastic support piece 2 includes: a spherical support surface 21, which is attached and connected with the support part 33, and the bottom of the spherical support surface 21 is provided There is ...

Embodiment 2

[0046] The structure of this embodiment is basically the same as that of Embodiment 1, and the difference is that:

[0047] Such as Figure 9 As shown, in this embodiment, the spherical support surface 21 is composed of a section of spherical surface, and the spherical support surface 21 is in surface contact with the support portion 33 of the friction block 3, instead of the edge in the first embodiment. The spherical part c and the bottom spherical part d form the spherical supporting surface 21. In this embodiment, the arrangement of the spherical supporting surface 21 makes the processing of the elastic supporting sheet more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com