Wheel suspension for a vehicle

A suspension and vehicle technology, applied in the direction of suspension, vehicle spring, elastic suspension, etc., can solve problems such as packaging problems and increasing space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

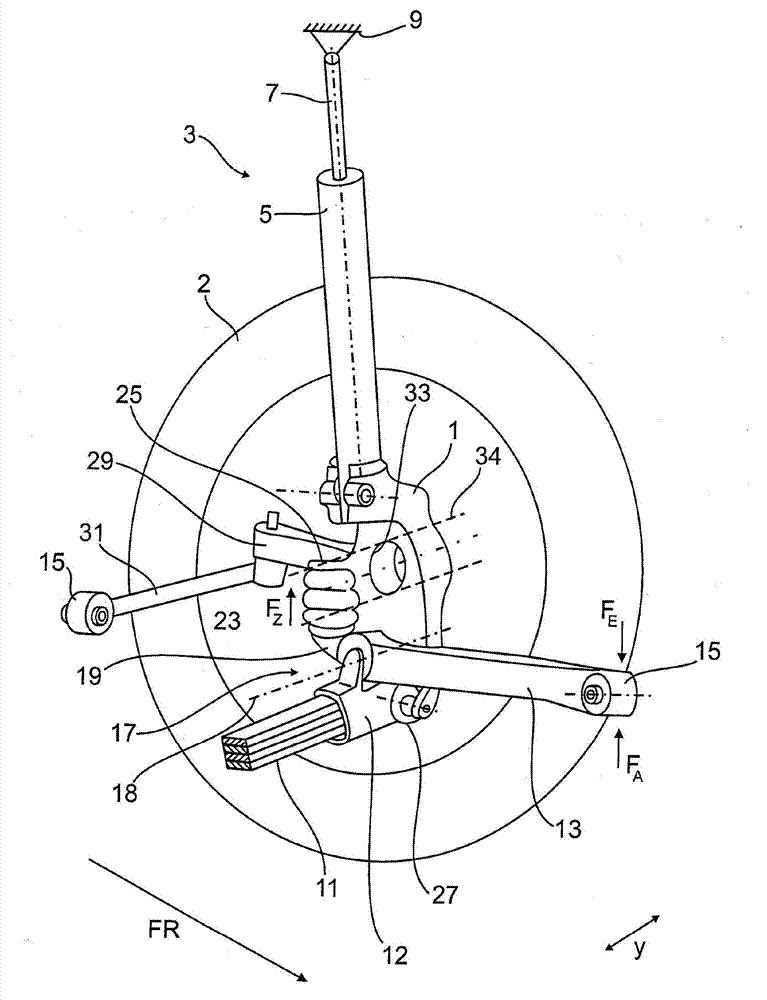

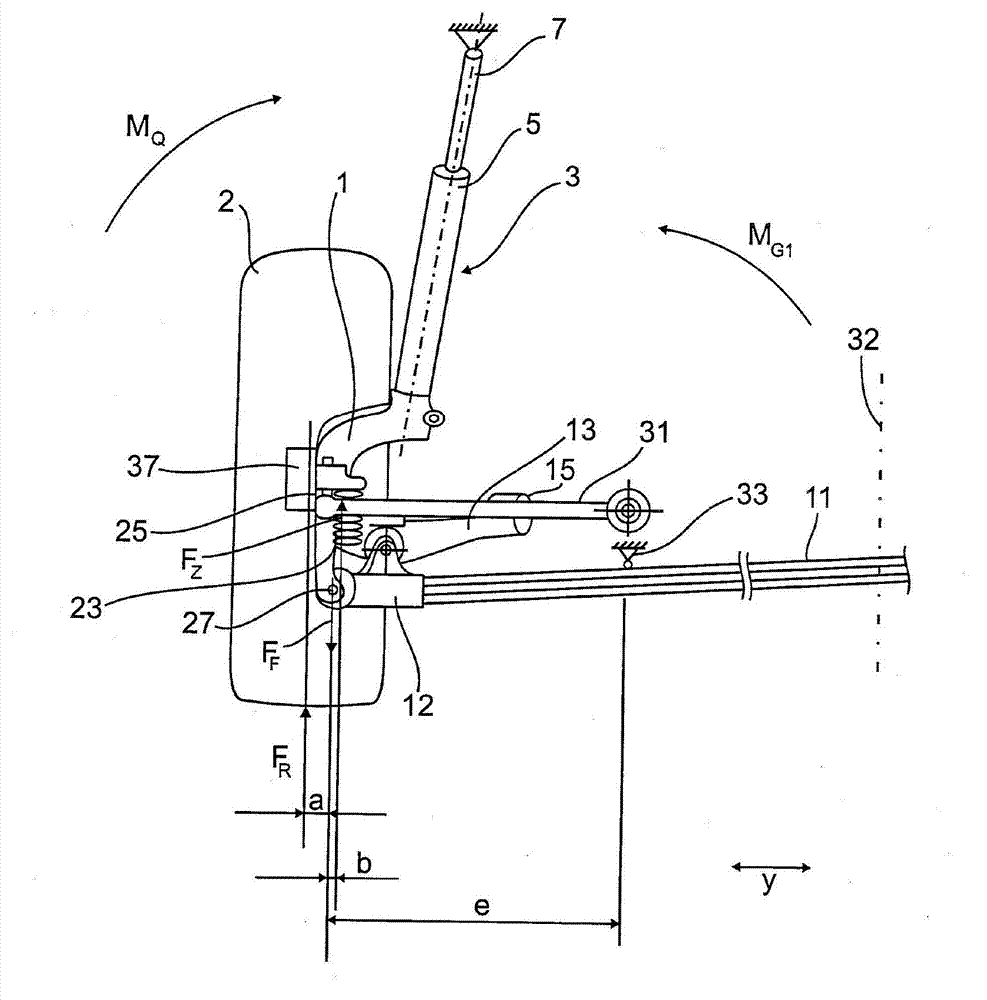

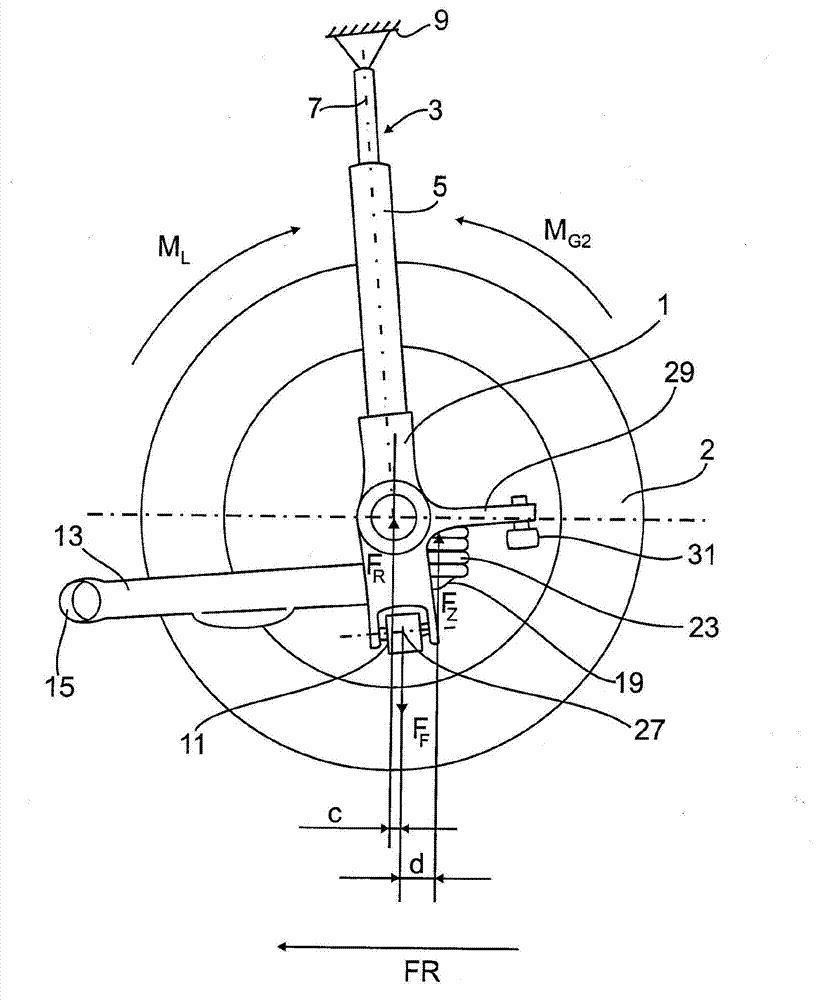

[0017] figure 1 shows a wheel suspension arrangement according to a first exemplary embodiment for a rear axle with a rear wheel drive not shown. The wheel suspension has a MacPherson suspension with a half-shell hub carrier 1 for the rear wheel 2 . Screwed onto the upper end of the hub carrier 1 is a substantially vertically arranged damper strut 3 comprising a damper tube 5 and a piston rod 7 guided in the damper tube 5 . The free upper end of the piston rod 7 is hinged to the body 9 .

[0018] The hub carrier 1 is articulated to the body 9 via a control arm assembly which lies essentially in the plane of the lower control arm. according to figure 1 , the control arm assembly has a leaf spring or bending spring 11 extending in the vehicle transverse direction y, the leaf spring end piece 12 of which, in the form of a transverse control arm, is at the bottom at the connection point 27 on the wheel carrier side Hinged on the hub bracket 1. The leaf spring 11 , which consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com