Composite pressure-resistant casing and molding method thereof

A technology of pressure-resistant shells and composite materials, applied in the direction of ships, etc., can solve the problem of not being able to go to deep water and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

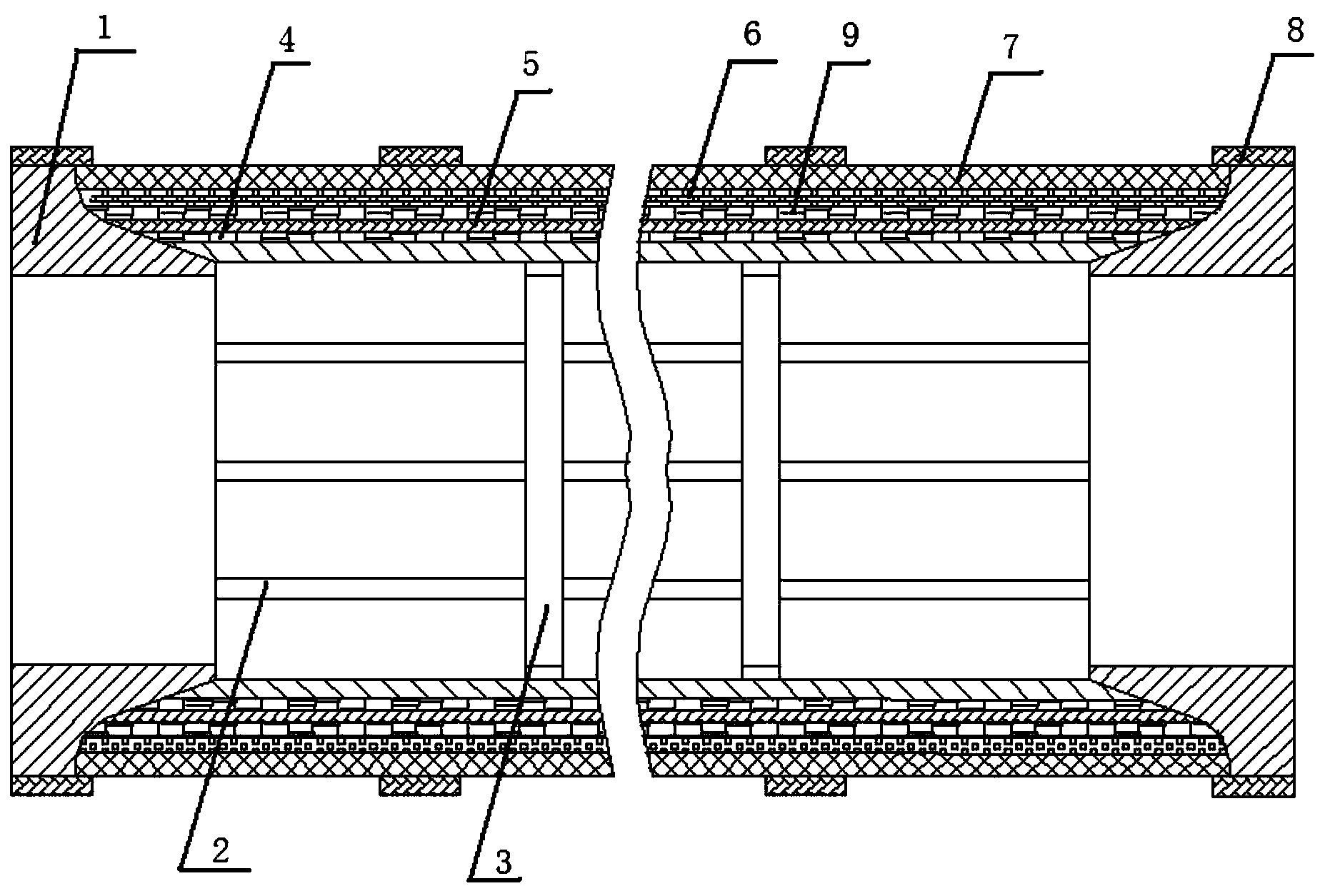

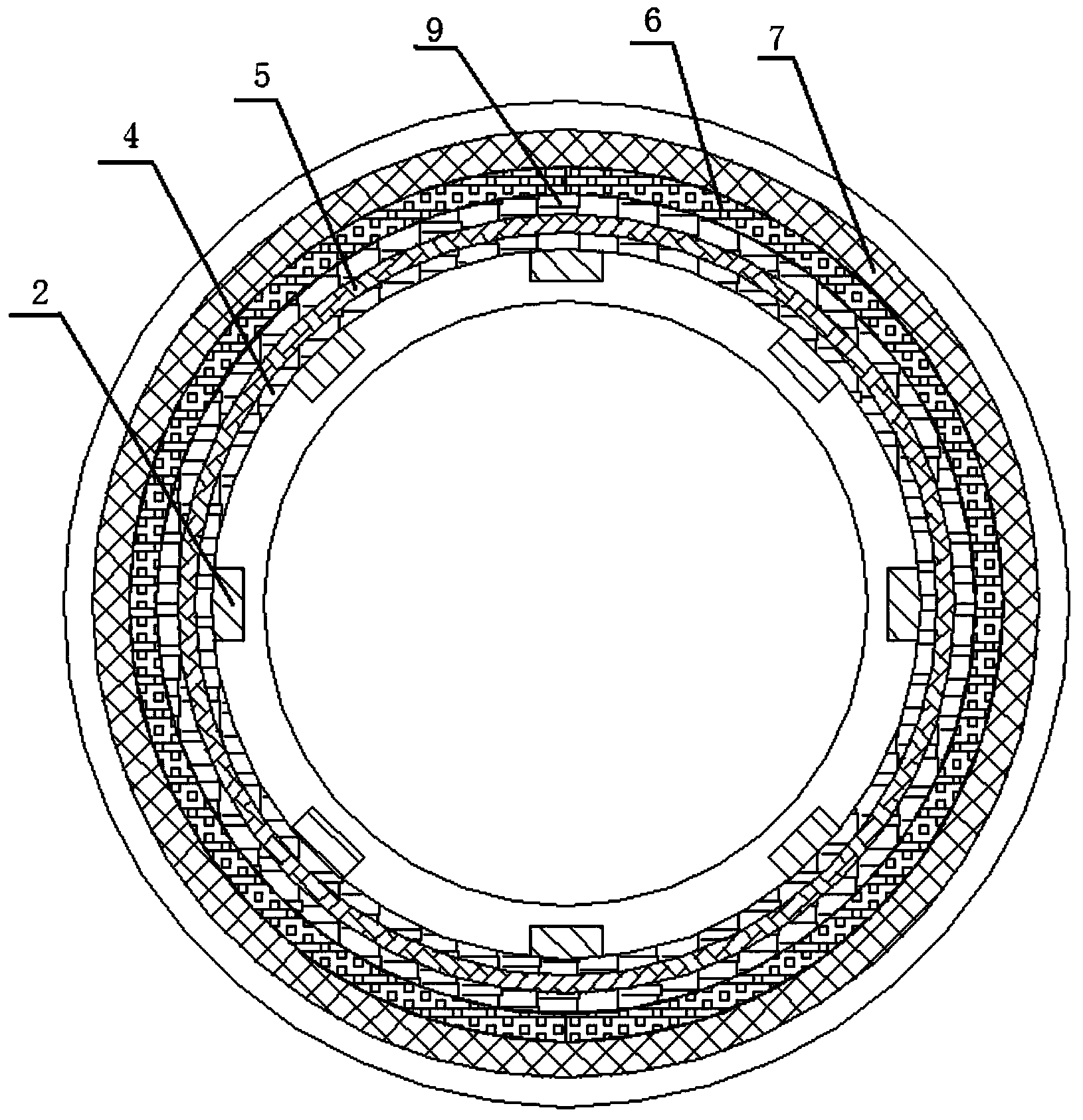

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] This embodiment provides a pressure-resistant shell of an underwater vehicle made of composite materials and its forming method. The shell is used as an installation platform for underwater detection equipment or other instruments and equipment that require isolation from water, and can withstand 40MPa (water pressure). Under 4000m) external pressure capability, and under the conditions of use, it is light in weight and has a certain impact resistance.

[0028] In this embodiment, the requirements for the physical size of the pressure-resistant shell are: the outer diameter is 760mm, the length is 1500mm (large volume), and the weight is required to meet the conditions of use; the working environment: work in seawater, and can withstand 40MPa external pressure Ability, at the same time have a certain impact resistance.

[0029] Based on the above cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com