Uniform pressure distribution type anchor cable

A type of layout and anchor cable technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as different elongation values, intensified unevenness of anchor cable steel strands, scrapped anchor cables, etc., to achieve overall The effect of uniform stress state, good long-term anchorage performance, and uniform distribution of shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

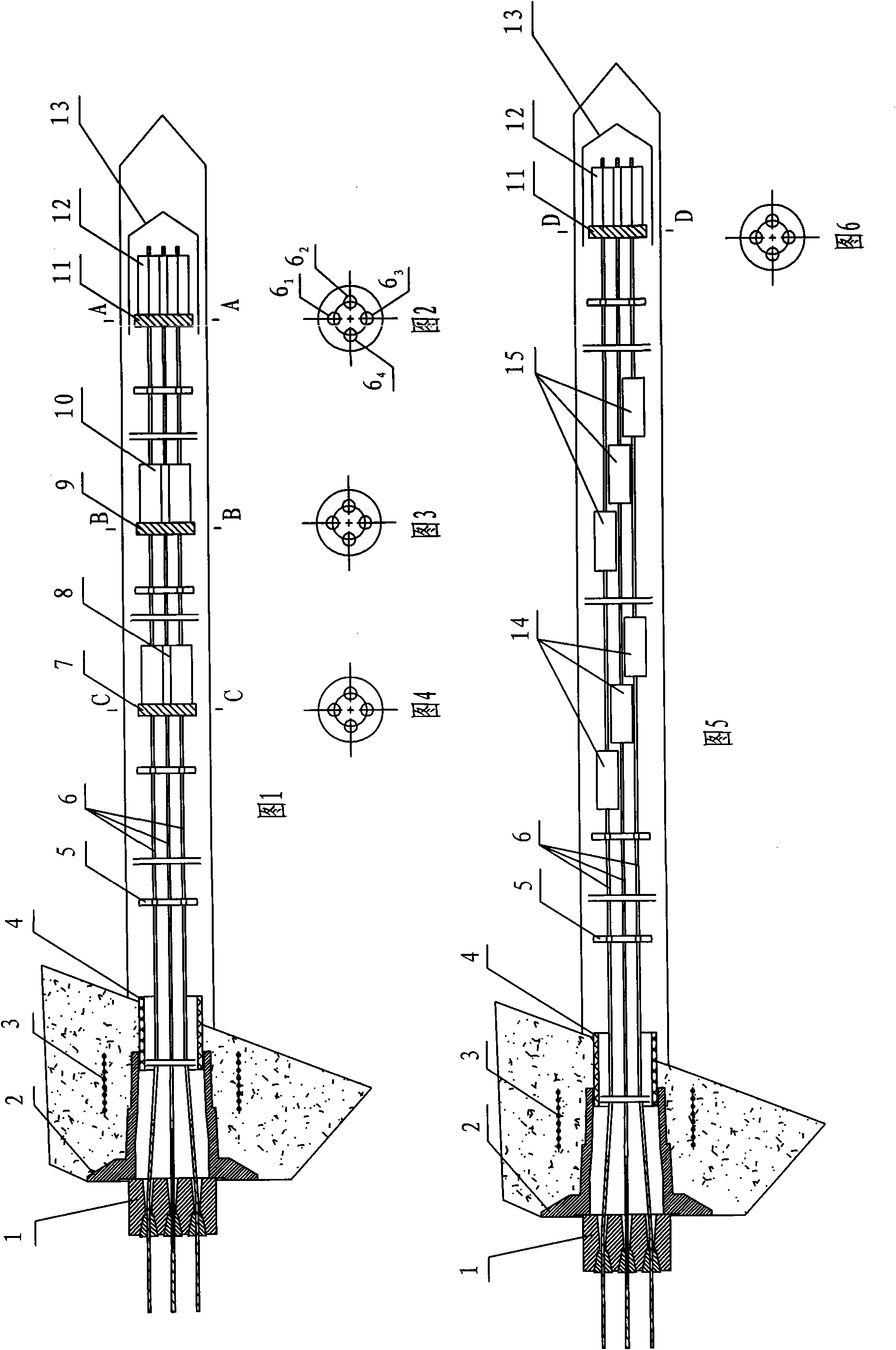

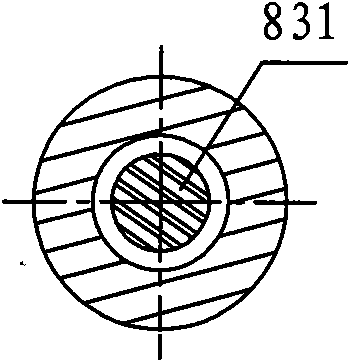

[0032] A pressure-distributed anchor cable, including an outer anchor head part and an inner anchor section composed of an anchor 1, an anchor backing plate 2, a spiral rib 3, a pre-embedded pipe 4, and an isolation frame 5, and the inner anchor section includes an anchor cable Cable body and multi-stage cable body load-bearing structure, the first-stage load-bearing structure is a permanent load-bearing structure composed of extruded anchorage 12 and pressure-bearing plate I11, and the second-level load-bearing structure of the cable body is composed of pressure-bearing plate II9 and pressure relief The pressure-yielding bearing structure of the anchorage 10, the third-level bearing structure is a pressure-yielding bearing structure composed of the pressure-bearing plate III7 and the pressure-yielding anchor 8, and one end of each prestressed tendon that constitutes the anchor cable body is respectively The extruded anchor 12 is extruded and anchored on the bearing plate I11, ...

Embodiment 2

[0034] A pressure-distributed anchor cable, such as Figure 5 ~ Figure 6 As shown, its basic structure is the same as that of Embodiment 1, including the anchor cable body and the multi-stage cable body bearing structure. The number is the same, and the first-stage load-bearing structure is a permanent load-bearing structure composed of extruded anchors 12 and bearing plates I11. Anchored under pressure on the pressure bearing plate I11, the difference from Embodiment 1 is that the rest of the load-bearing structures at all levels are all pressure-bearing structures composed of pressure-yielding anchors 8, and the pressure-bearing structures on each prestressed tendon The setting spacing of the pressure-bearing structure is different, which facilitates the assembly of the cable body and improves the overall mechanical performance. Its structure is as Figure 5 ~ Figure 6 shown.

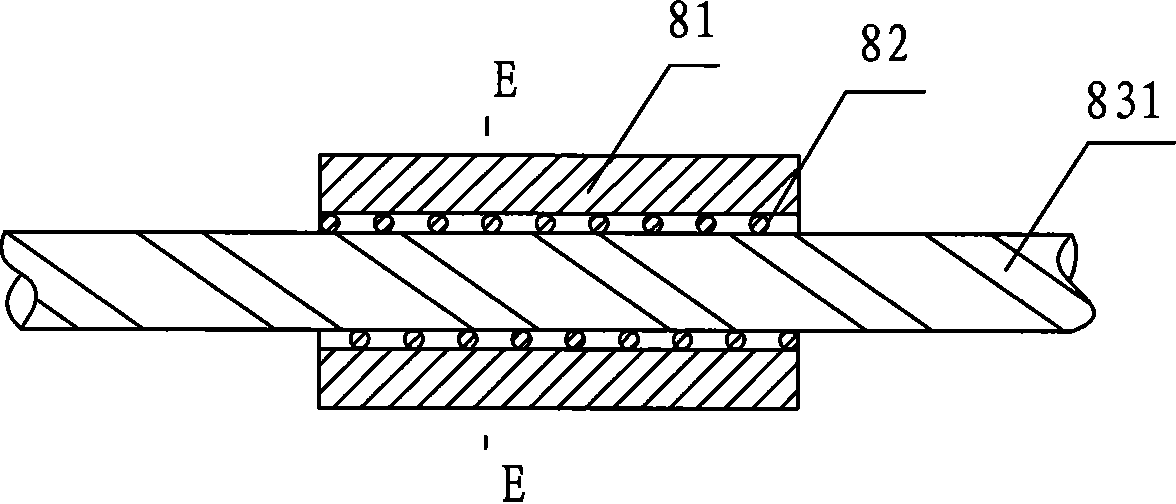

[0035] In Embodiment 1 and Embodiment 2 of the present invention, the pressure yielding anchor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com