Oxygen barrier material in tungsten-rhenium thermocouple anti-oxidation coating structure, and application thereof

A technology of anti-oxidation coating and barrier material, applied in coatings, thermoelectric devices, metal material coating processes, etc., can solve the problems of use restrictions, no actual use of products, increase in volume and weight of thermocouple armor, etc. Achieve anti-oxidation ability guarantee, good stress dispersion, ensure the effect of stress dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the oxygen barrier material of the above-mentioned tungsten-rhenium thermocouple anti-oxidation coating structure comprises the following steps:

[0045] (1) Select the absolute value of the difference between the thermal expansion coefficient and the thermal expansion coefficient of the tungsten-rhenium thermocouple substrate to be no more than 6×10 -6 K -1 The material or mixture of materials is used as an oxygen barrier material, and the first layer of oxygen barrier material is prepared on the surface of the tungsten-rhenium thermocouple substrate by chemical vapor deposition, thermal spraying or sol-gel method;

[0046] (2) Change the material type of each layer in turn, or do not change the material type, and gradually adjust the concentration ratio of different materials in each layer, and deposit layer by layer in the direction away from the tungsten-rhenium thermocouple substrate according to the same method as step (1). , so that the...

Embodiment 1

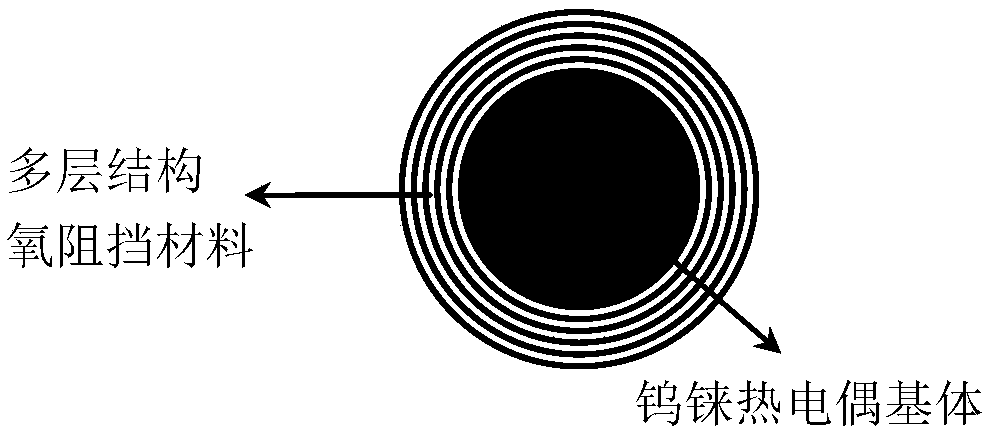

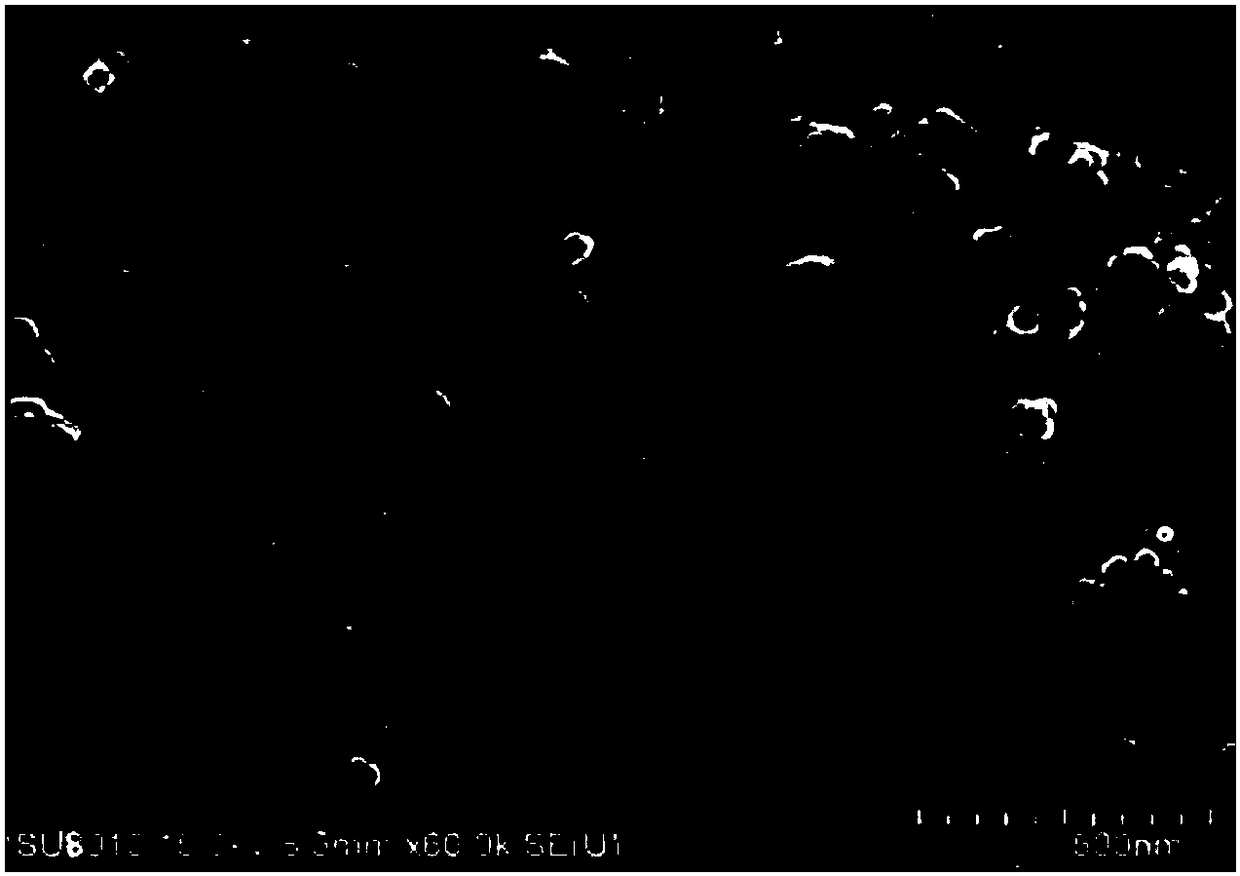

[0050] An oxygen barrier material in a tungsten-rhenium thermocouple high-temperature oxidation-resistant coating structure, the oxygen barrier material is directly set on the tungsten-rhenium thermocouple substrate, that is, the surface of the tungsten-rhenium thermocouple wire with a diameter of about 0.5mm, that is, the oxygen barrier material is Antioxidant coatings for the tungsten-rhenium thermocouple, such as figure 1 As shown, the anti-oxidation coating has five layers in total, the first layer is made of ZrB2 material, and the coefficient of thermal expansion is 6.5×10 -6 K -1 , the thickness is 10 μm; the second layer is ZrB2-5% SiC material, the thickness is 10 μm; the third layer is ZrB2-10% SiC, the thickness is 10 μm; the fourth layer is ZrB2-15% SiC, the thickness is 10 μm; the fifth The layer is ZrB2-20% SiC, the coefficient of thermal expansion is 9×10 -6 K -1 , with a thickness of 10 μm. The total thickness of the oxygen barrier material of the multilayer...

Embodiment 2

[0055] An oxygen barrier material in a tungsten-rhenium thermocouple high-temperature oxidation-resistant coating structure, the oxygen barrier material is directly set on the tungsten-rhenium thermocouple substrate, that is, the surface of the tungsten-rhenium thermocouple wire with a diameter of about 0.5mm, that is, the oxygen barrier material is It is the anti-oxidation coating of the tungsten-rhenium thermocouple. The anti-oxidation coating has six layers in total. The first layer is SiC material with a thermal expansion coefficient of 4.5×10 -6 K -1 , the thickness is 20μm; the second layer is SiC-20%HfC material, the thickness is 20μm; the third layer is SiC-40%HfC, the thickness is 20μm; the fourth layer is SiC-60%HfC, the thickness is 20μm; The layer is SiC-80%HfC with a thickness of 20μm; the sixth layer is HfC with a thermal expansion coefficient of 6.7×10 -6 K -1 , with a thickness of 20 μm. The total thickness of the oxygen barrier material of the multilayer st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com