Resin foam body and foam member

一种树脂发泡体、树脂的技术,应用在合成树脂层状产品、薄膜/薄片状的粘合剂、化学仪器和方法等方向,能够解决没有发泡体应力分散性公开或启示等问题,达到高应力分散性、耐热性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

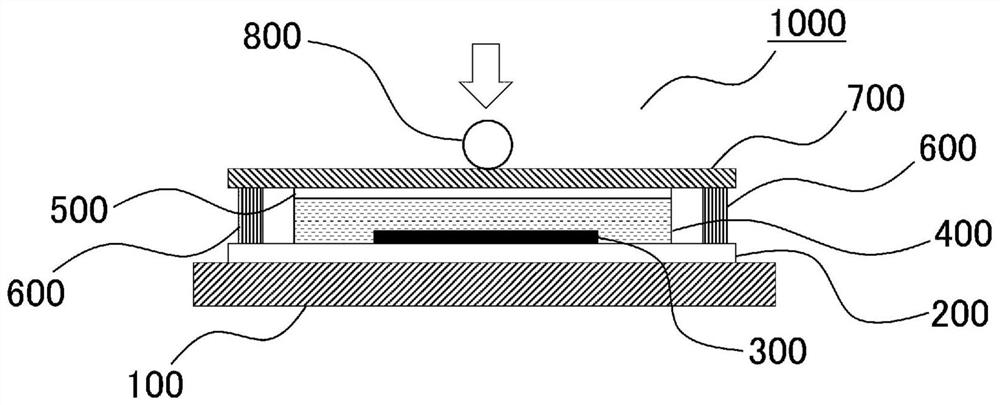

Image

Examples

Embodiment approach 2

[0121] As one Embodiment 2 which forms the resin foam of this invention, the form which makes a resin composition foam with a foaming agent, and forms a foam is mentioned. As the foaming agent, a foaming agent generally used in foam molding can be used, and it is preferable to use a high-pressure inert gas from the viewpoint of environmental protection and low pollution to the foamed body.

[0122] As the inert gas, any appropriate inert gas can be used as long as it is inert to the resin composition and can be impregnated. As such an inert gas, carbon dioxide, nitrogen, air, etc. are mentioned, for example. These gases can also be used in combination. Among these, carbon dioxide is preferable from the viewpoint of a large amount of impregnation into the resin material (polymer) and a high impregnation rate.

[0123] The inert gas is preferably in a supercritical state. That is, it is particularly preferable to use carbon dioxide in a supercritical state. In the supercriti...

Embodiment 1

[0168] Polypropylene [melt flow rate (MFR) (230° C.): 0.40 g / 10 min]: 50 parts by weight, polypropylene [melt flow rate (MFR) (230°C): 2.40g / 10min]: 25 parts by weight, polyolefin elastomer [trade name "THERMORUN 5850N", manufactured by Mitsubishi Chemical]: 35 parts by weight, magnesium hydroxide: 100 parts by weight (trade name "KISUMA 5P" manufactured by Kyowa Chemical Industry Co., Ltd.), carbon (trade name "Asahi #35", manufactured by Asahi Carbon Co., Ltd.): 10 parts by weight, and monoglyceride stearate: 1 part by weight were kneaded at a temperature of 200°C Finally, it is extruded in the form of strands, and shaped into pellets after water cooling. The pellets were charged into a single-screw extruder manufactured by Nippon Steel Works, Ltd., and carbon dioxide gas was injected at a pressure of 13 (12 after injection) MPa in an atmosphere of 220°C. Carbon dioxide gas was injected in a ratio of 3.5 parts by weight with respect to 100 parts by weight of the resin. Aft...

Embodiment 2

[0171] A resin foam A was obtained in the same manner as in Example 1. The said resin foam A was passed between the rolls (gap between rolls) of a pair of roll heated to 200 degreeC by one roll, and the resin foam B of thickness 0.15mm was obtained. In addition, the space|gap (gap) between rolls was set so that the resin foam B with thickness 0.15mm could be obtained.

[0172] For this foam, its apparent density is 0.18g / cm 3 , 650°C residue is 36%, tensile modulus is 2.1MPa, and stress retention rate is 66%. Table 1 shows the evaluation results for the resin foam B including these results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| apparent density | aaaaa | aaaaa |

| bubble diameter | aaaaa | aaaaa |

| apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com