Toe structure of all-steel radial tire with inner tube

A technology for radial tires and toes, which is applied in the field of toe structures of all-steel radial tires with inner tubes, can solve the problems of low flex resistance, large bead structure deformation, and blasting, and achieve improved deformation resistance and dispersion capabilities , Reduce the effect of tire damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

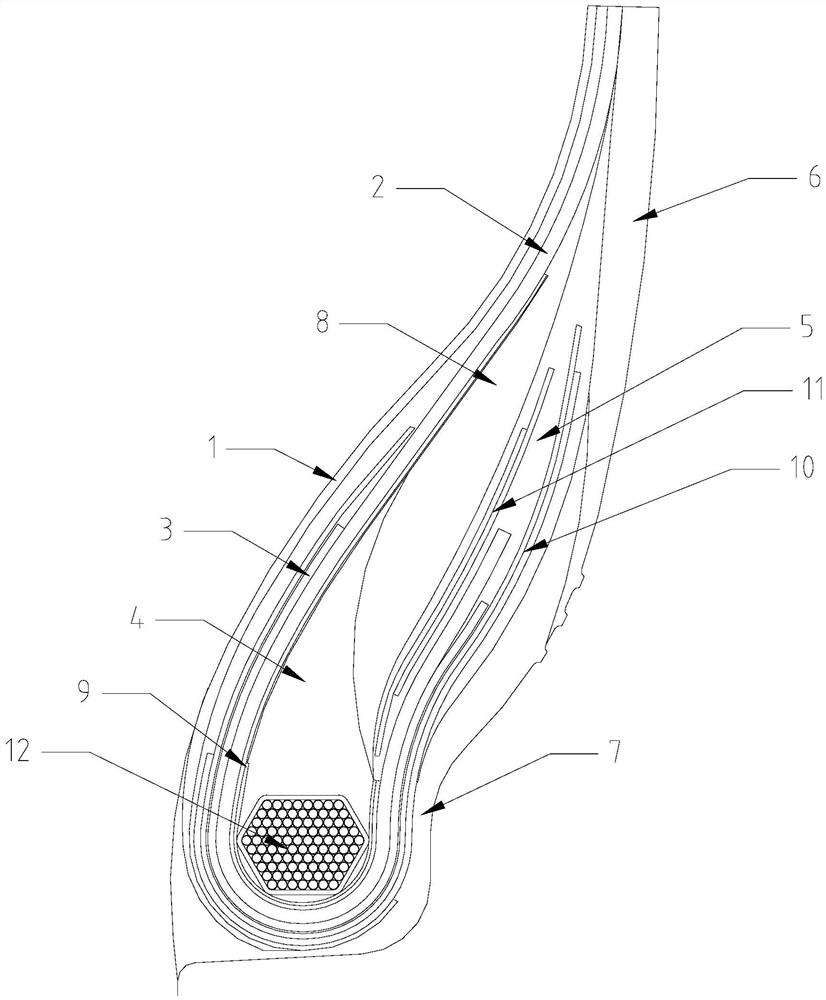

[0016]An inner tire-tire-steel moon tire tire toe structure, including the inner rigid triangle core 4, the outer soft triangle film 8, tire skeleton 2, toe strengthening layer 3, external nylon protective layer 10, Nylon protection Layer 11, the neutral core 4 and the soft triangle core 8 are sequentially by the tire skeleton 2 from the inner to the outside, the toe port reinforcement layer 3 is a U-shaped package, the outer side of the tire skeleton 2 The upper end end of the soft triangular core 8 is located below the end of the tire skeleton 2, respectively, and the outer nylon protective layer 10 is located outside the soft triangular film 8, respectively. The lower end end of the outer nylon protective layer 10 is located between the outer end of the tire skeleton 2 and the toe port reinforcing layer 3, and the upper end end of the outer nylon protective layer 10 is lower than the upper end end of the soft triangle core 8, and Nylon. The protective layer 11 is located outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com