Internal mixer for V belt production and V belt capable of reducing dynamic heat generation

An internal mixer and internal mixing technology, applied in belts, applications, household appliances, etc., can solve the problems of lowering the quality of V-belt products, shortening the service life, and odor of rubber belts, so as to save energy consumption and improve the filtering effect , the effect of reducing noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

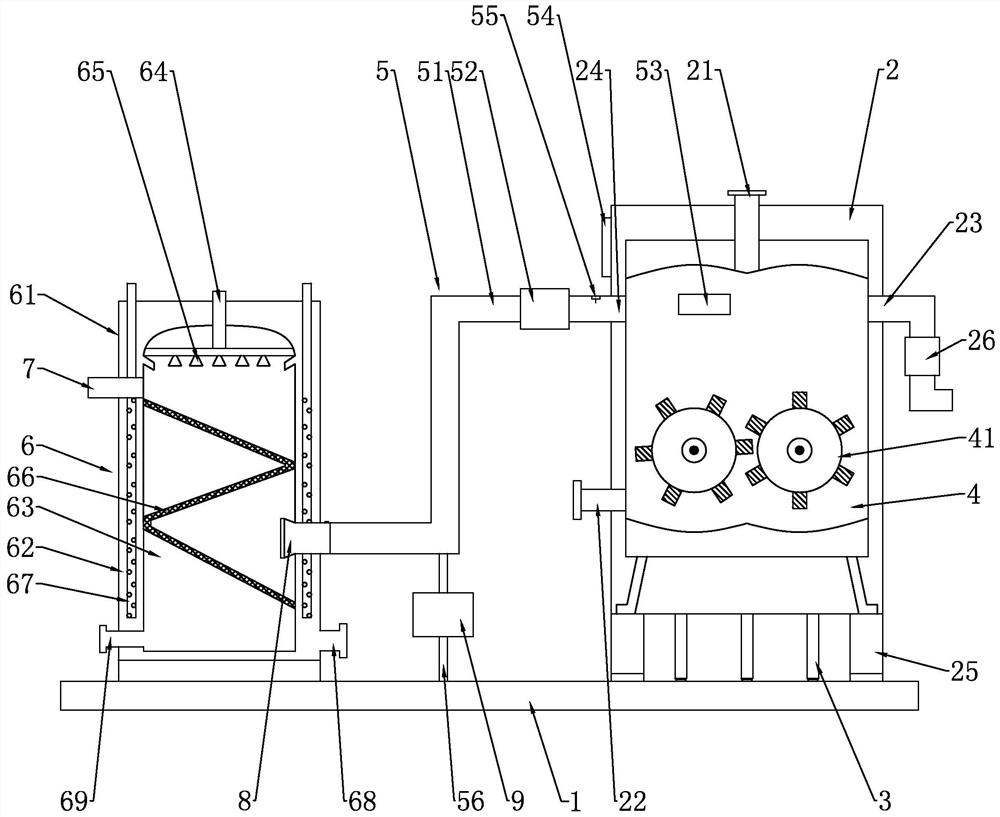

[0081] like Figure 1 to Figure 5 As shown, the embodiment of the present application provides an internal mixer for V-belt production, including:

[0082] bottom plate 1;

[0083] Internal mixer body 2, the internal mixer body 2 is provided with a feed port 21, a discharge port 22, a first air inlet 23 and a first air outlet 24, and the bottom of the internal mixer body 2 is provided with feet 25 and a number of reducers. shock element 3;

[0084] booster pump 26;

[0085] Mixing chamber 4, a rotor 41 is arranged in the mixing chamber 4;

[0086] Exhaust system 5, the exhaust system 5 is used to discharge the waste gas in the mixing chamber 4;

[0087] Filter system 6, the filter system 6 is used to filter exhaust gas;

[0088] Among them, the internal mixer body 2 and the filter system 5 are both arranged on the bottom plate 1, the internal mixer cavity 4 is set in the internal mixer body 2, and both the feeding port 21 and the discharging port 22 are communicated with ...

Embodiment 2

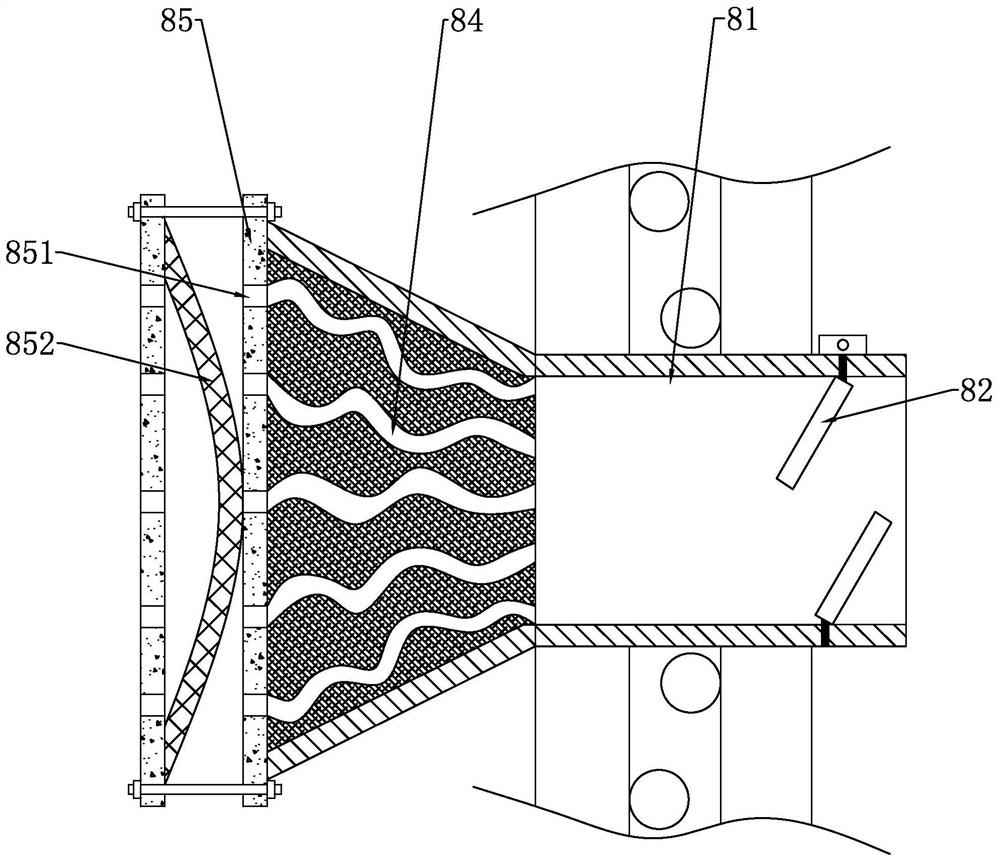

[0091] In this embodiment, in addition to including the structural features of the preceding embodiments, the further filter system 6 also includes:

[0092] The filter tower 61 is provided with a cooling chamber 62 and a filter chamber 63 in the filter tower 61;

[0093] The water inlet pipe 64 is provided with a shower head 65;

[0094] filter plate 66, the filter plate 66 is arranged in the filter cavity 63;

[0095] The cooling water pipe 67, the cooling water pipe 67 is arranged in the cooling chamber 62;

[0096] the first water outlet pipe 68;

[0097] The second water outlet pipe 69;

[0098] smoke exhaust pipe 7;

[0099] The cooling chamber 62 is arranged in the tower wall of the filter tower 61, the water inlet pipe 64 is located at the top of the filter tower 61 and the shower head 65 is located in the filter chamber 63, the first water outlet pipe 68 is communicated with the cooling chamber 62, and the second water outlet pipe 69 communicates with the filter ...

Embodiment 3

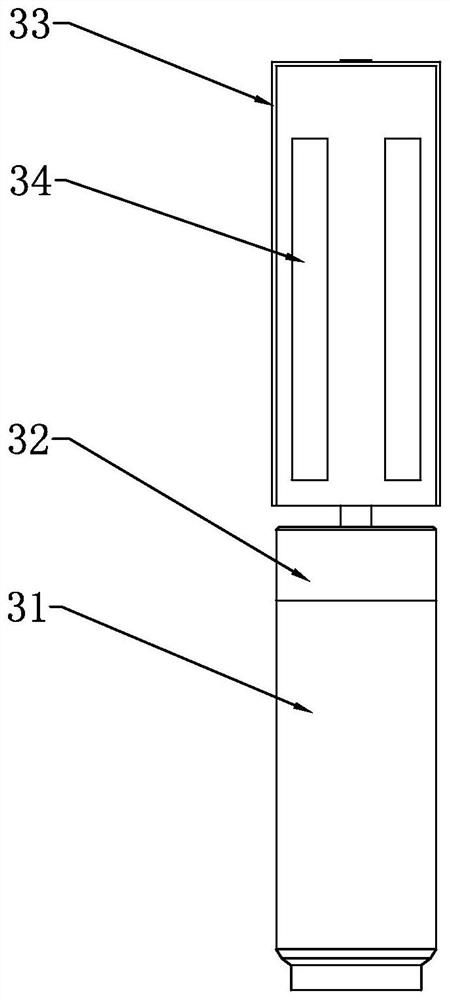

[0102] In this embodiment, in addition to including the structural features of the previous embodiments, the further shock absorbing member 3 further includes:

[0103] The hydraulic shock-absorbing column 31, the top of the hydraulic shock-absorbing column 31 is provided with a first magnet 32;

[0104] The protective cover 33, the inner wall of the protective cover 33 is provided with a plurality of second magnets 34;

[0105] Rubber pad 35;

[0106] Among them, a plurality of second magnets 34 are evenly spaced along the circumference of the inner wall of the protective sleeve 33. The magnetic poles of the first magnets 32 and the second magnets 34 repel each other. The lower end of the shock column 31 is connected to the upper surface of the bottom plate 1 , the upper end of the hydraulic shock column 31 is connected to the bottom surface of the mixer main body 2 through the protective sleeve 33 , and the rubber pad 35 is connected to the bottom end of the support foot 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com