Oil cooler formed by staggered dotting oil cooler pipes

A technology of oil cooler and pipe body, which is applied in the field of automobile radiator components, and can solve the problems of inability to realize the cooling effect of lubricating oil, unfavorable requirements for energy saving of automobiles, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

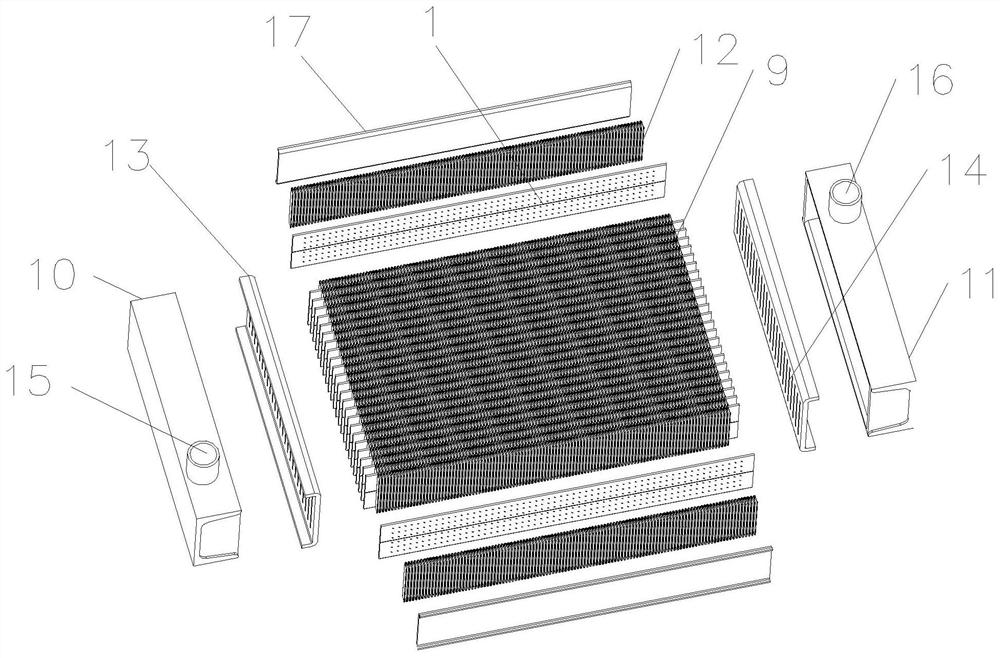

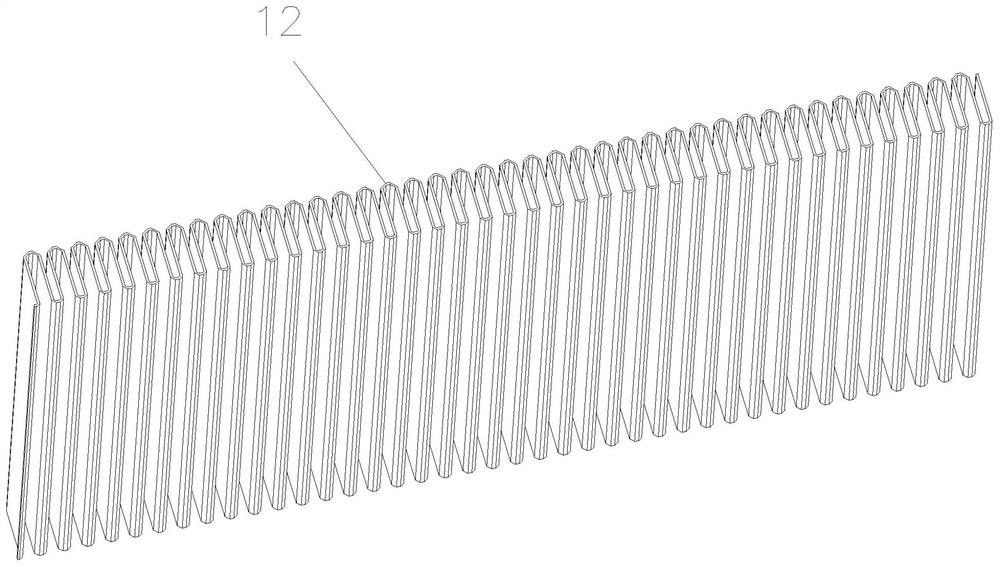

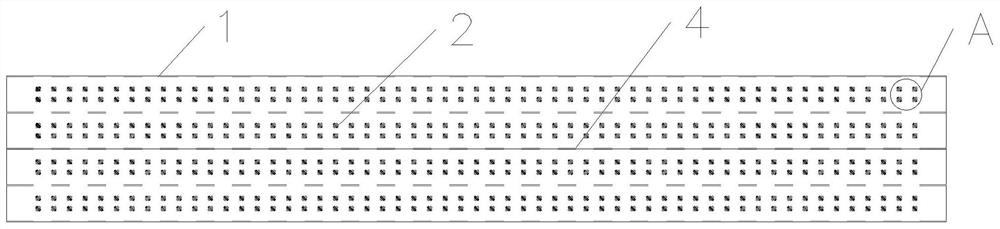

[0048] Such as Figure 1-4 As shown, the oil cooler made of misplaced oil cooler tubes in this embodiment includes a body, and the body includes a core 9 , an oil inlet chamber 10 and an oil outlet chamber 11 . The core 9 includes alternately arranged heat dissipation strips 12 and oil cooler tubes, the number of heat dissipation strips 12 is one more than that of the oil cooler tube, and the two outermost heat dissipation strips 12 on the core 9 are welded with shielding The plate 17 and the two ends of the core 9 are welded with a main piece 13, and the main piece 13 is provided with an oil hole 14 at a position corresponding to the oil cooler tube. An oil inlet chamber 10 and an oil outlet chamber 11 are respectively welded on the other side of the main piece 13 at both ends of the core 9 , the top of the oil inlet chamber 10 is provided with an oil inlet 15 , and the top of the oil outlet chamber 11 is provided with an oil outlet 16 . The heat dissipation strip 12 used in...

Embodiment 2

[0053] Such as Image 6 As shown, the difference between this embodiment and embodiment 2 is that the inner walls of both sides of the tube body 1 are provided with reinforcing pieces 5 , and the thickness of the reinforcing pieces 5 is equal to the wall thickness of the tube body 1 .

Embodiment 3

[0055] Such as Figure 7-8 As shown, the difference between this embodiment and Embodiment 1 is that the pipe body 1 is formed by bending a piece of sheet body, the bending part of the sheet body is provided with a first bending part 6, and the two free ends of the sheet body A second bent portion 7 and a third bent portion 8 are respectively provided. The first bending part 6 is formed by folding three layers of a sheet body, and the second bending part 7 and the third bending part 8 are formed by folding three layers of two free ends of the sheet body into the tube body 1 , and the heights of the second bending portion 7 and the third bending portion 8 are half of the height of the first bending portion 6, the first bending portion 6, the second bending portion 7, and the third bending portion 8 The thickness is the same after folding. The second bending portion 7 and the third bending portion 8 are closed by high frequency welding.

[0056] Working principle: The working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com