Radial tire bead

A radial tire and bead technology, applied in the field of radial tire bead and all-steel radial tire bead, can solve problems such as vehicle overloading, blasting, and higher requirements for vehicle tires, so as to improve stress dispersion ability and improve support performance. , Improve the effect of flexural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below through non-limiting examples and in conjunction with the accompanying drawings:

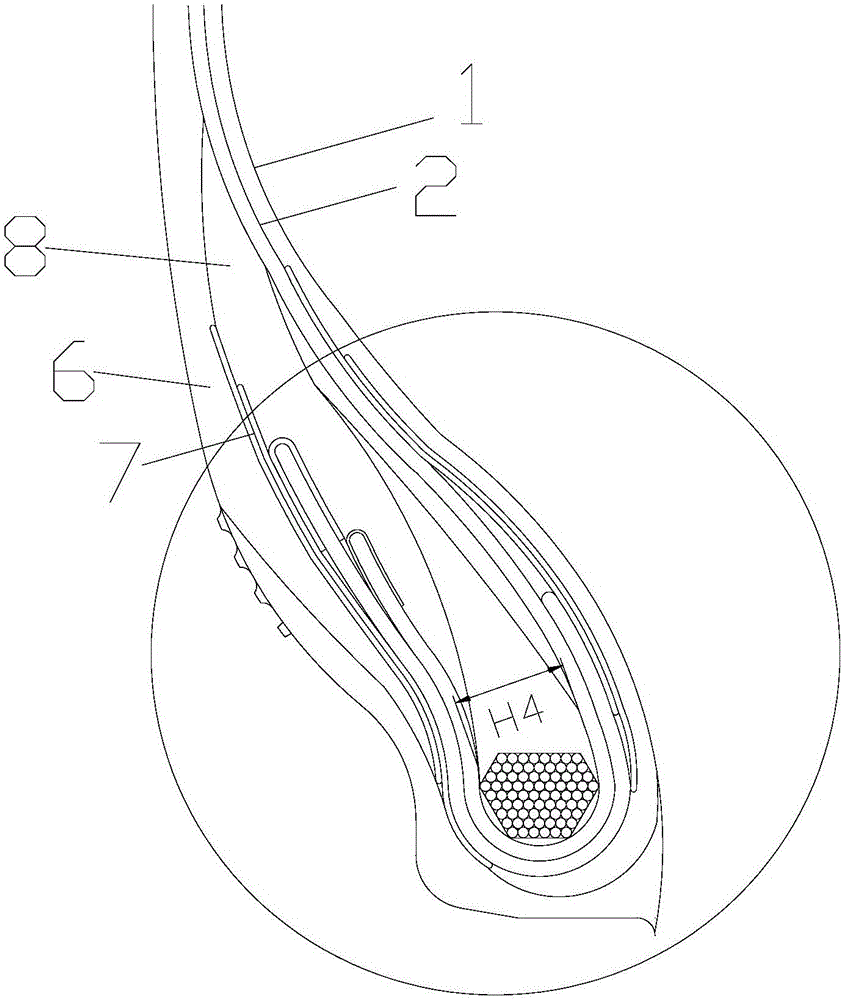

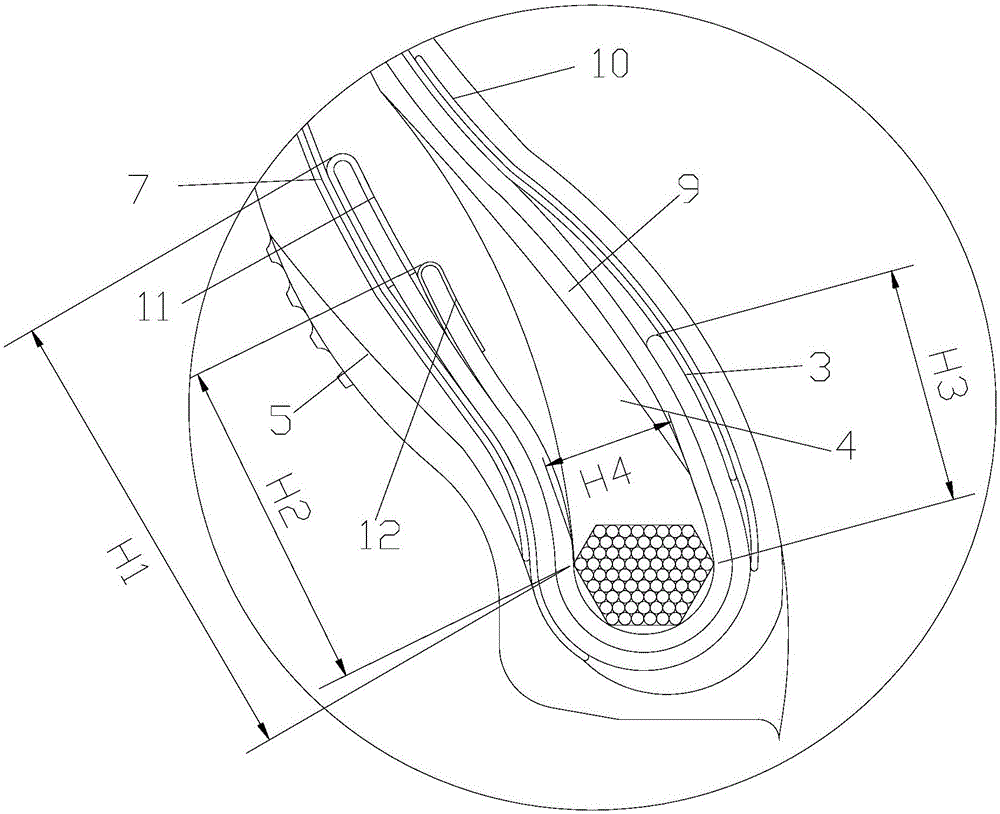

[0019] As shown in the attached drawings, a radial tire bead includes an inner liner 1 , a carcass cord 2 , a reinforced steel cord fabric 3 , a three-composite rubber core, a nipple rubber 5 and a sidewall rubber 6 . The three composite rubber cores include a filling rubber core 9, a hard apex rubber core 4, and a soft apex rubber core 8, wherein the hard apex rubber core 4 is located on the inner side, the soft apex rubber core 8 is located on the outer side, and the filling rubber core 9 is located in the hard apex rubber core. On the side of the core 4 close to the inner side of the bead, the filling rubber core 9 , the hard apex rubber core 4 and the soft apex rubber core 8 are sequentially wrapped by the carcass cord 2 and the reinforced steel cord 3 from the inside to the outside. The inner liner 1 is wrapped on the inner side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com