Supporting bracket for bridge engineering and construction method thereof

A technology for supporting brackets and bridge engineering, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., which can solve problems such as difficulty in guaranteeing construction quality, low operating efficiency, and difficulty in dismantling, and achieves convenient and quick installation, low cost, and structural Reasonable and reliable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

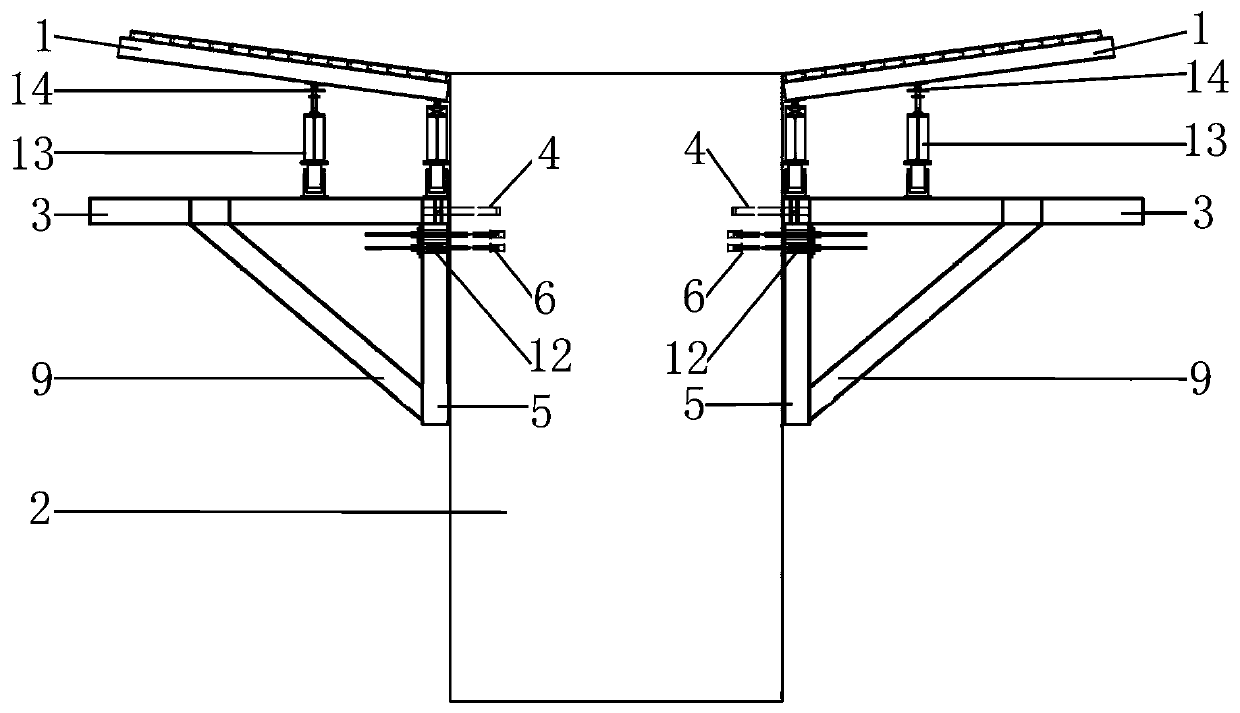

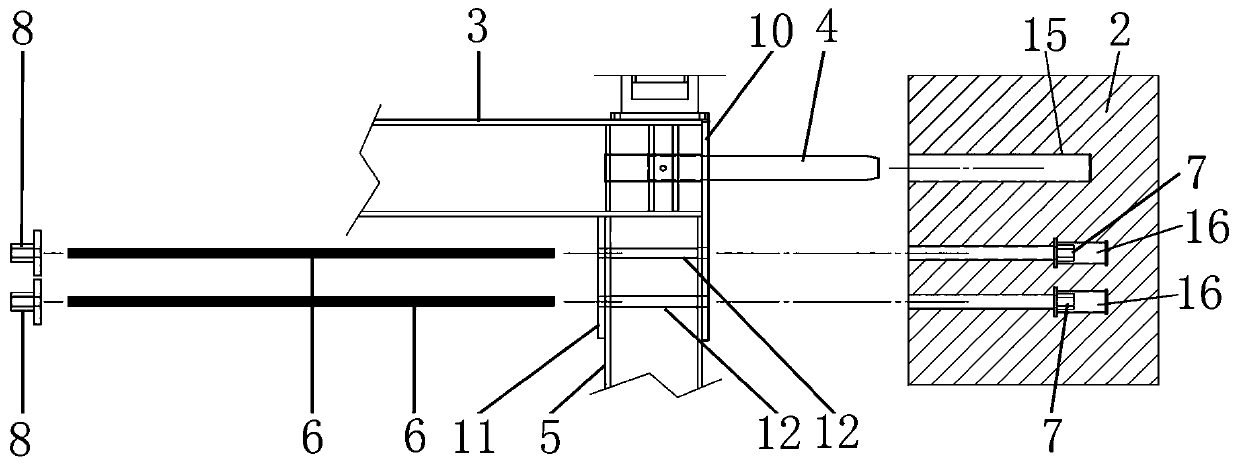

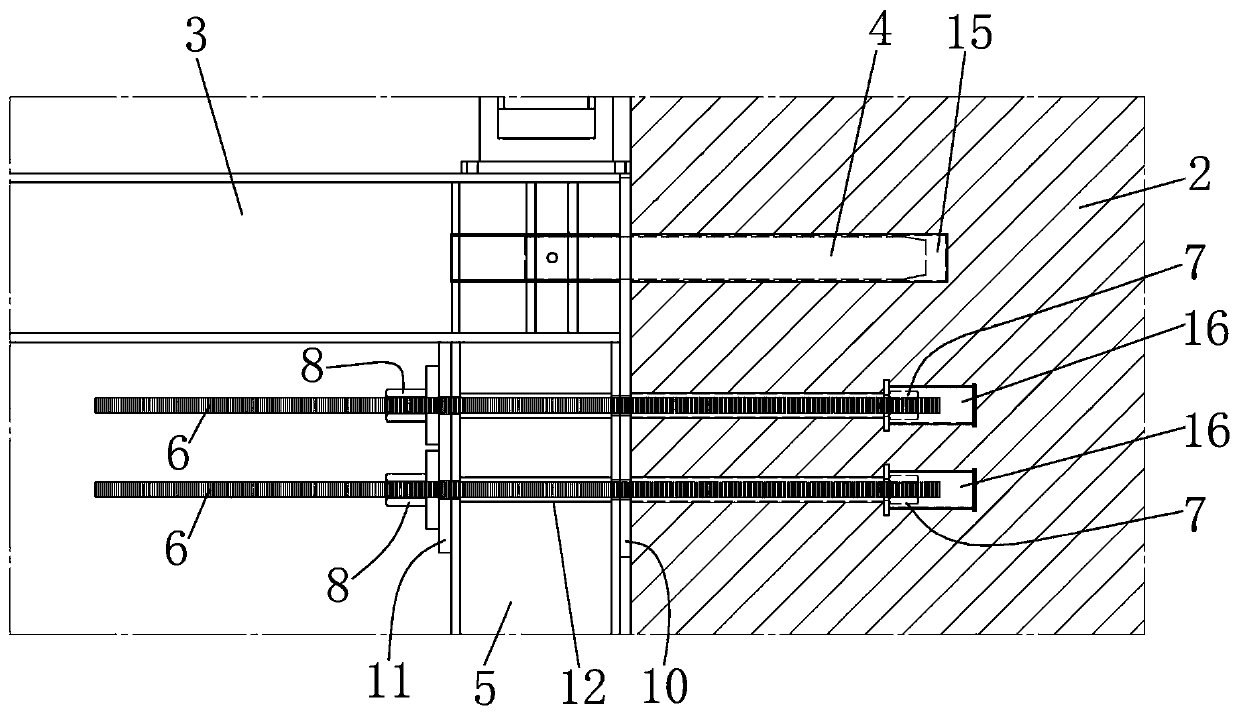

[0022] A support bracket for bridge engineering, comprising a load-bearing beam 1 and a bridge pier 2; the side of the bridge pier 2 is provided with a circular structure and horizontally placed support plate 3, and the inner surface of the support plate 3 is extended with several pieces inserted into the interior of the bridge pier 2 The first steel bar 4 is fixed coaxially on the lower surface of the support plate 3 with a support tube 5 that is placed close to the side of the pier 2. The side wall of the support tube 5 is perforated with a number of second steel rods with external threads in the radial direction. rod 6, the inner end of each second steel rod 6 is inserted into the inside of the pier 2, and the outer end passes through the outer surface of the support tube 5; An inner lock nut 7 and an outer lock nut 8 which is arranged close to the outer surface of the support cylinder 5; several oblique support rods 9 placed obliquely are arranged between the lower surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com