Jacking pipe cushioning material, and jacking pipe

A buffer material and pipe technology, applied in the direction of pipes/pipe joints/fittings, pipe protection, pipe laying and maintenance, etc., can solve the problem of reduced buffer performance, and achieve the effect of improved buffer effect, high stress dispersion effect, and easy positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

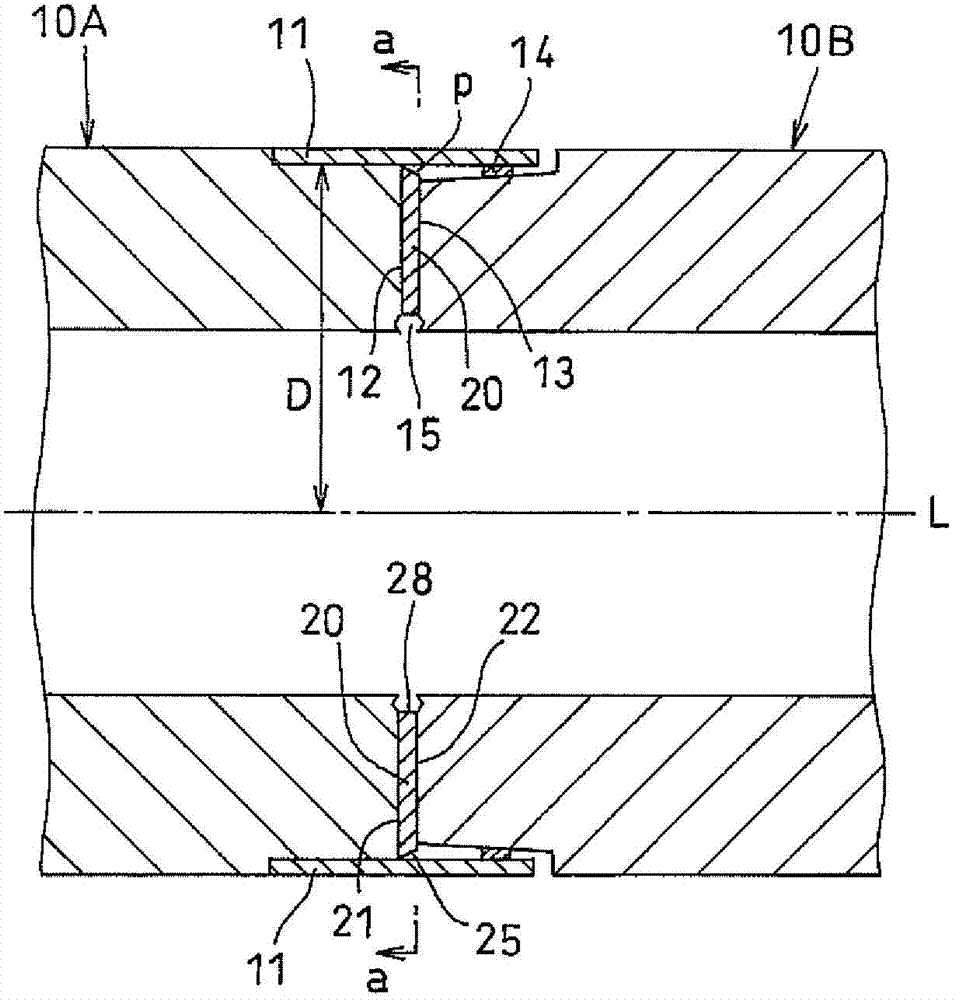

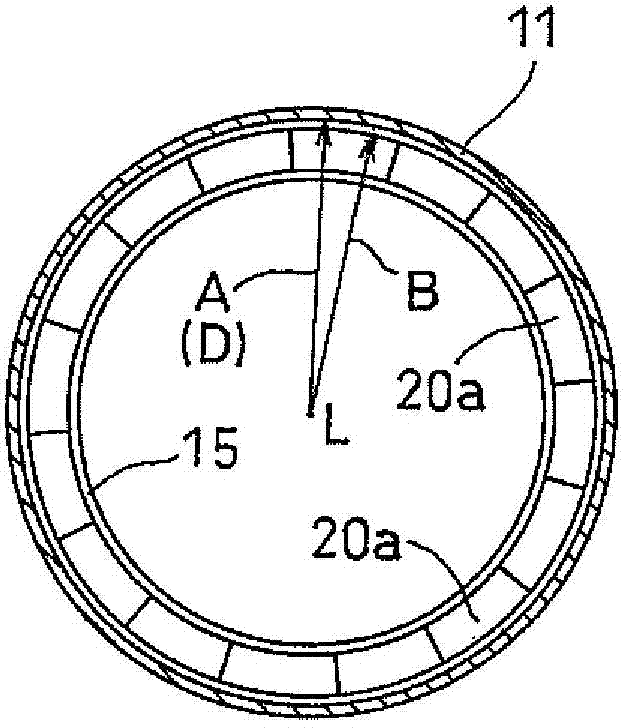

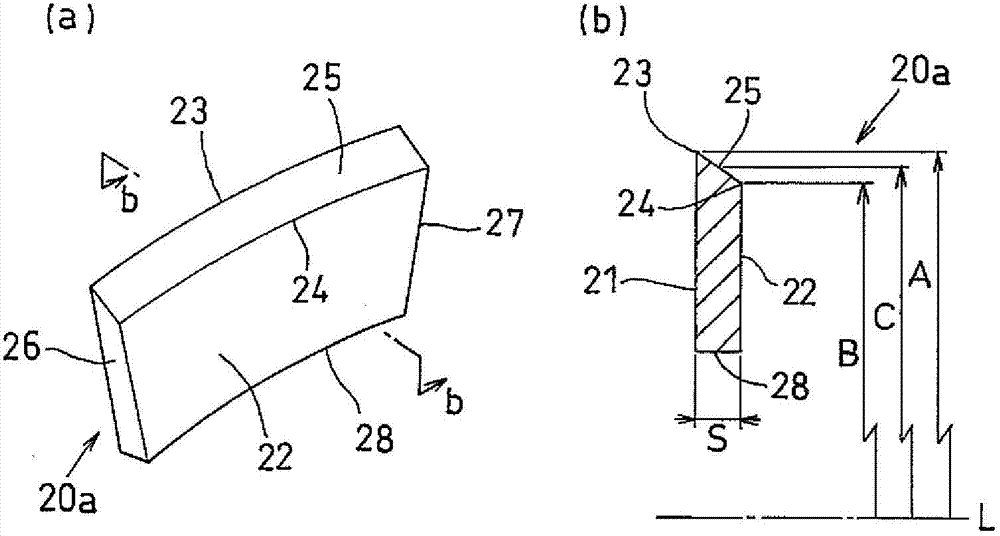

[0029] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0030] exist figure 1 Among them, 10 is, for example, a cylindrical jacking pipe made of concrete, and L is a central axis. A cylindrical ferrule 11 made of steel plate or the like is mounted on the rear end portion (the receiving port side) of the push pipe 10A on the front side, and the slightly reduced diameter front end portion (the insertion port side) of the push pipe 10B on the push rear side is installed. side) into the above ferrule 11. On the rear end surface 12 of the front jacking pipe 10A, an annular cushioning material 20 for jacking is pasted with an adhesive or the like so that the central axis becomes the above-mentioned central axis L. When pushing, the rear jacking pipe 10B As described above, the front end portion enters the ferrule 11 , and the front end surface 13 is in contact with the cushioning material 20 for pipe jacking. In addition, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com