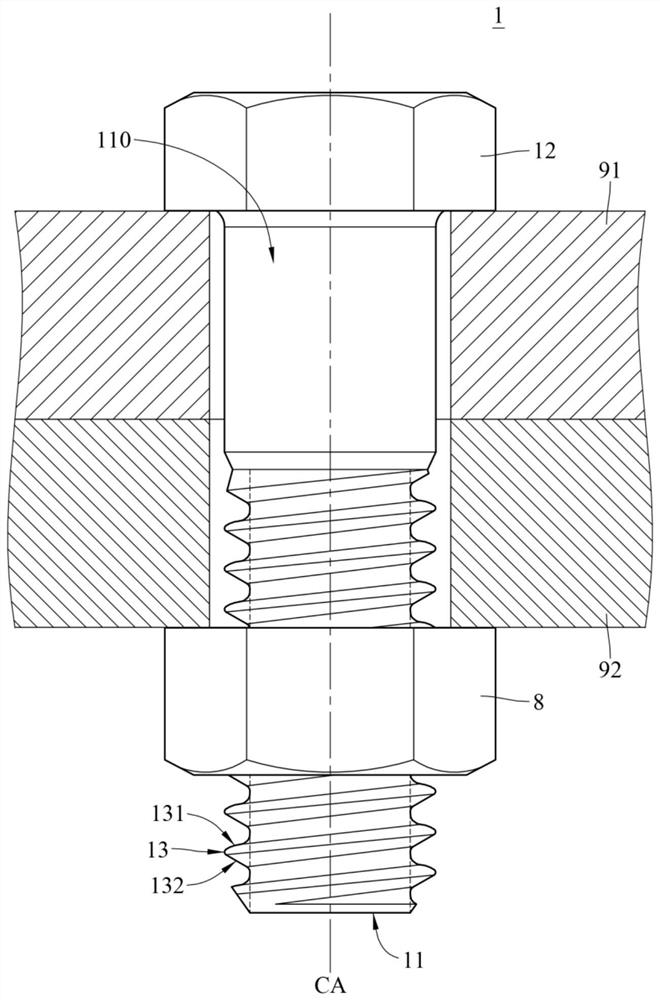

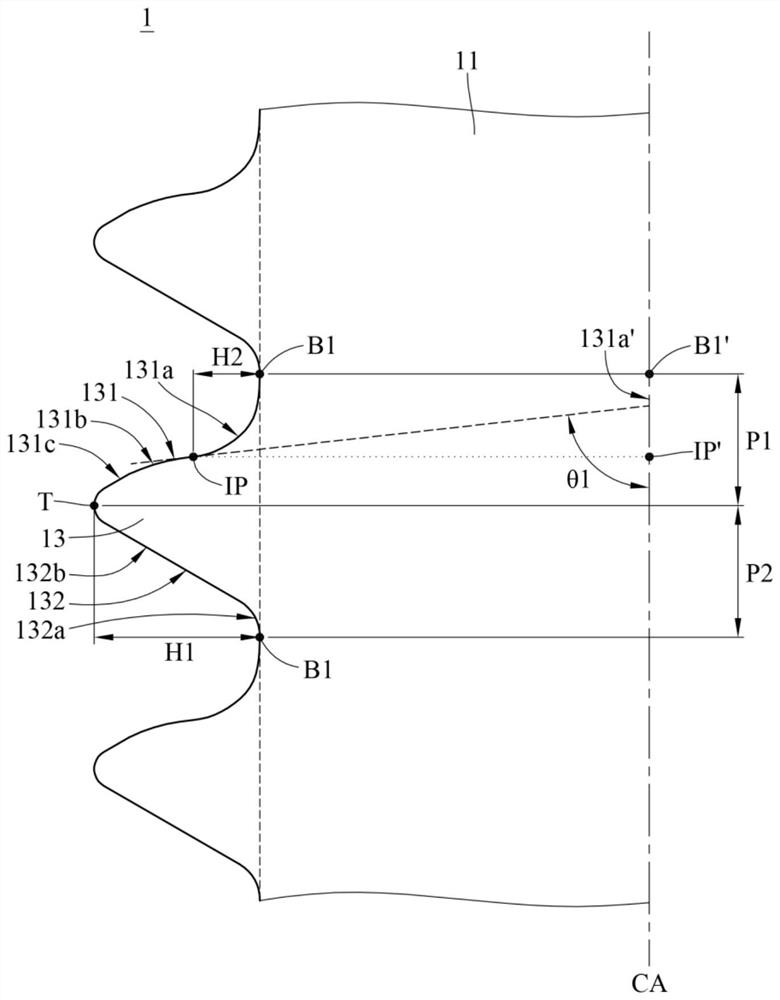

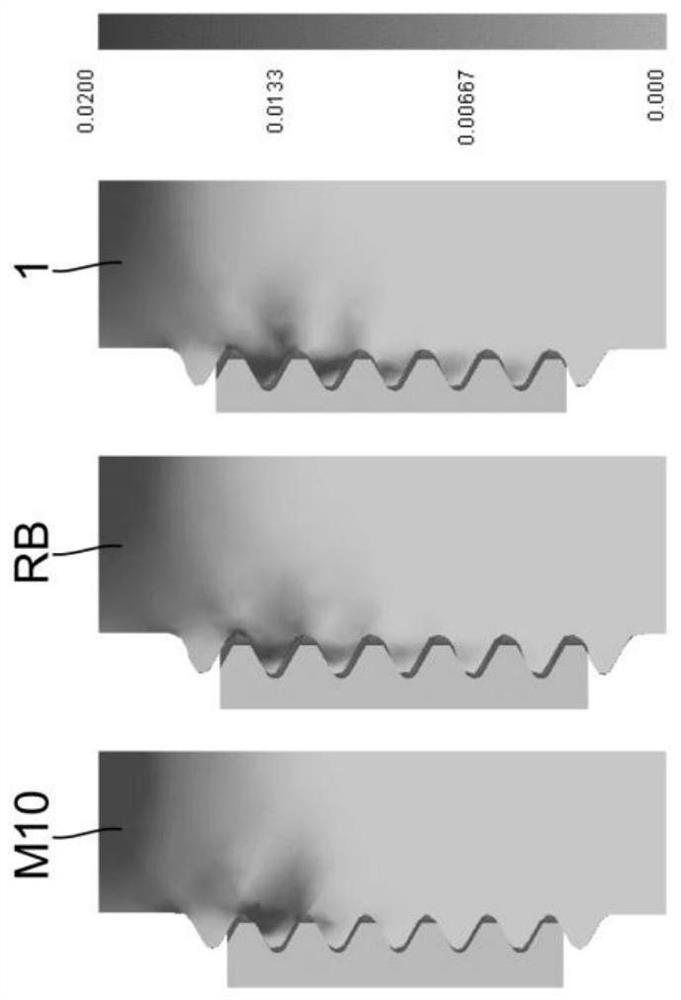

bolt

A technology of bolts and threaded parts, applied in the field of anti-loosening and anti-collapsing bolts, can solve the problems of excessive load force, collapse of screw teeth, increased local stress, etc., to prevent bolts from loosening, increase friction, prevent tooth chipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The following described in detail features and advantages of embodiments of the present invention in detail in the embodiment, the contents of which is sufficient to enable anyone skilled in the art understand the technical contents of the embodiment of the present invention and accordingly embodiment, and based on the contents disclosed in this specification, the claim requirements and drawings, anyone skilled in the art can easily understand the relevant objectives and advantages of the present invention. The following examples further aspect of the present invention described in more detail, but not to limit the scope of the invention in any of the views.

[0079] A schematic view of the present specification called, due to illustrate the case may have a more exaggerated size, scale and angle, etc., but the present invention is not limited thereto. In the case of not departing from the gist of the present invention is capable of various modifications. Longitudinal vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com