Graphene high-thermal-conductivity material

A graphene, high thermal conductivity technology, applied in the field of graphene, can solve the problems of product brittleness, low thermal conductivity, easy cracking, etc., and achieve the effect of reducing the usage amount, improving the distribution structure, and improving the cohesion of the adhesive layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

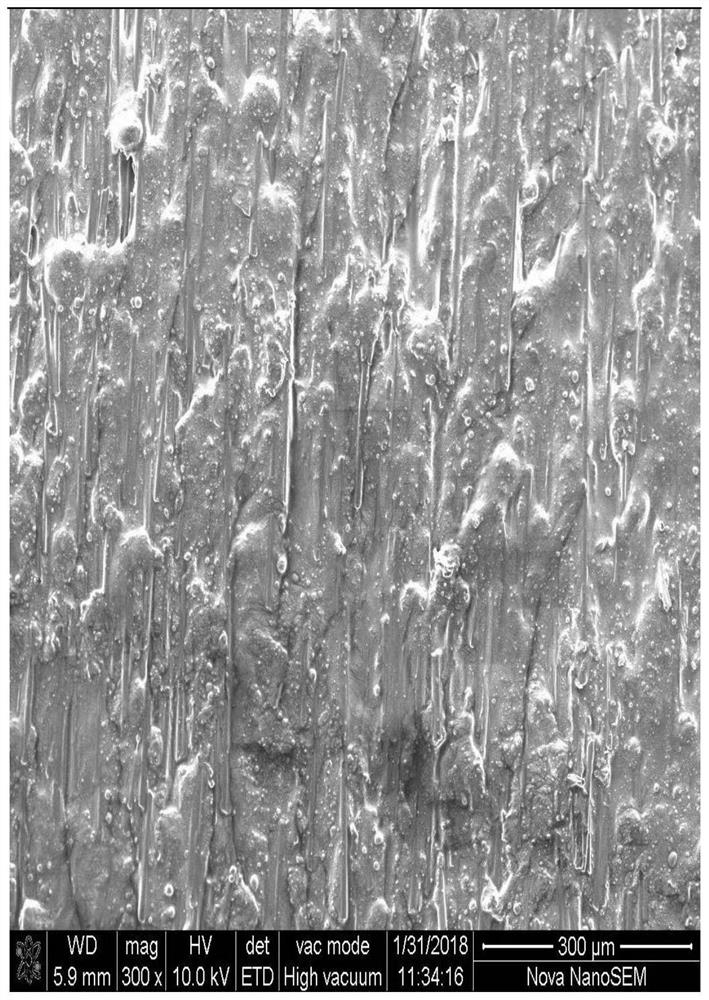

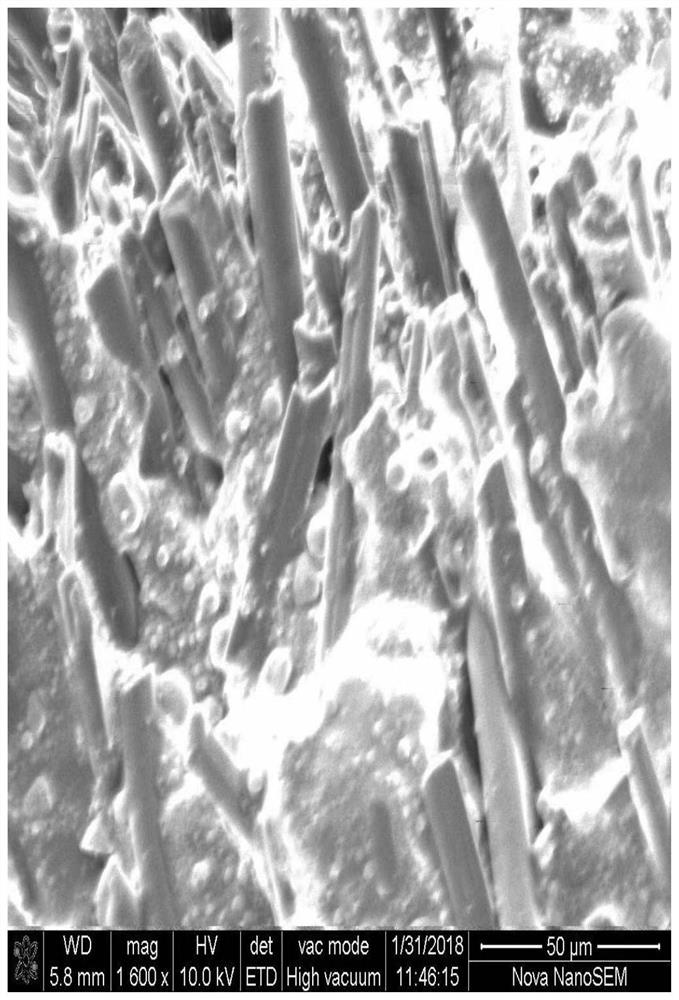

Image

Examples

Embodiment Construction

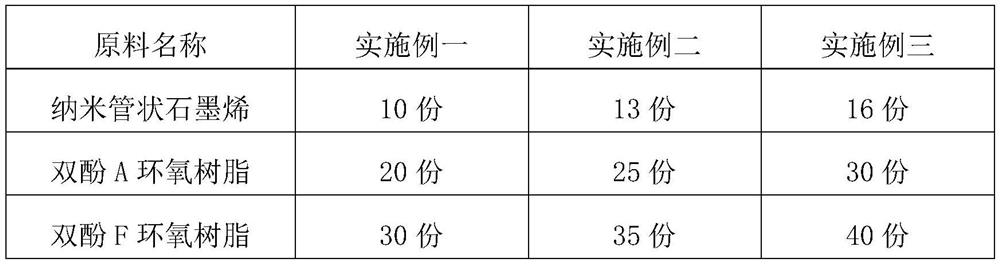

[0024] The raw material component (every component=1g) of a kind of graphene heat-conducting material in embodiment one~three is as follows:

[0025]

[0026]

[0027] The preparation steps of above-mentioned a kind of graphene heat-conducting material are as follows:

[0028] Step 1: add nanotubular graphene, bisphenol A epoxy resin and bisphenol F epoxy resin in double planetary mixer, by double planetary mixer with the rotating speed of 3000r / s, to bisphenol A epoxy resin and bisphenol F The epoxy resin was stirred for 2 hours to dehydrate, heated to 90°C during the stirring process, and evacuated to 0.1MPa to form the first mixture;

[0029] Step 2: Add the modified mercaptan curing agent to the first mixture, and stir the first mixture and the modified mercaptan curing agent for 1 hour to dehydrate the first mixture and the modified mercaptan curing agent through a double planetary mixer at a speed of 3000 r / s, and heat to 90°C, and vacuum 0.1MPa to form the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com