Roller of roll type crusher

A roller crusher and roller technology, applied in grain processing and other directions, can solve the problems of cracking of the roller sleeve, the size of clinker crushing becomes larger, and it is not conducive to the production of the next process, and achieves the effect of improving efficiency and improving firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

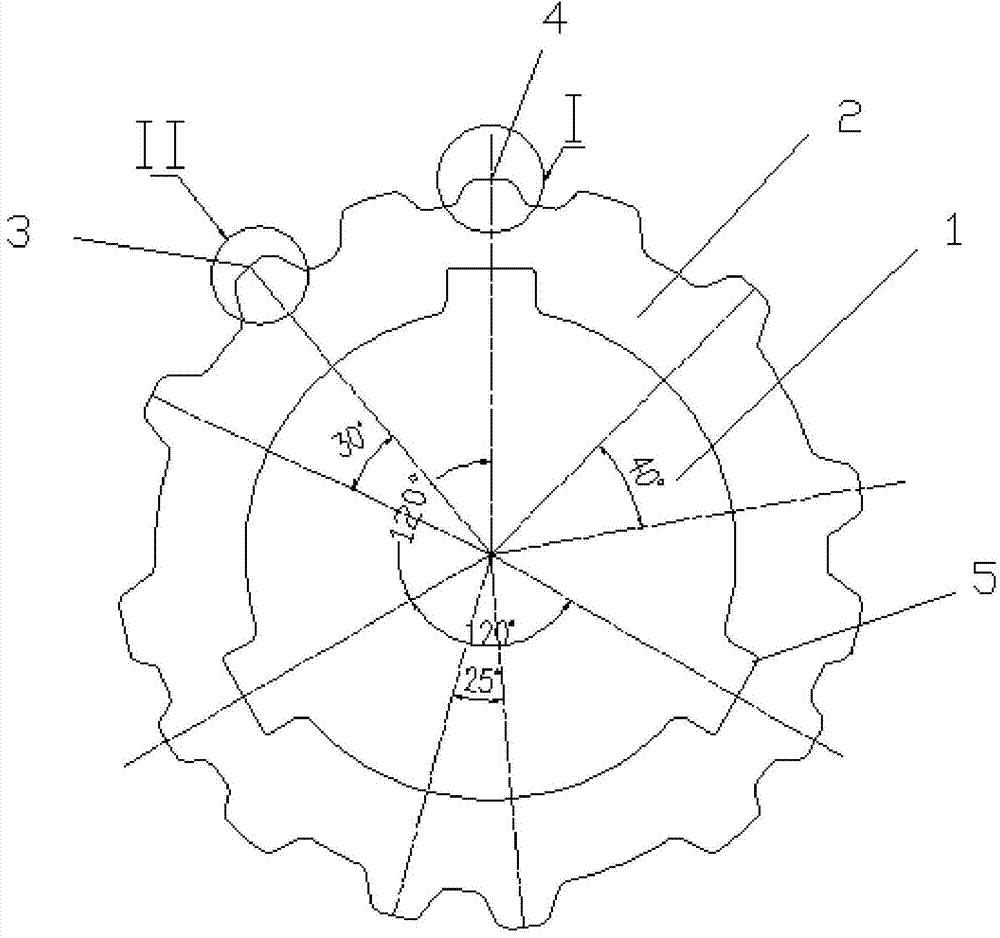

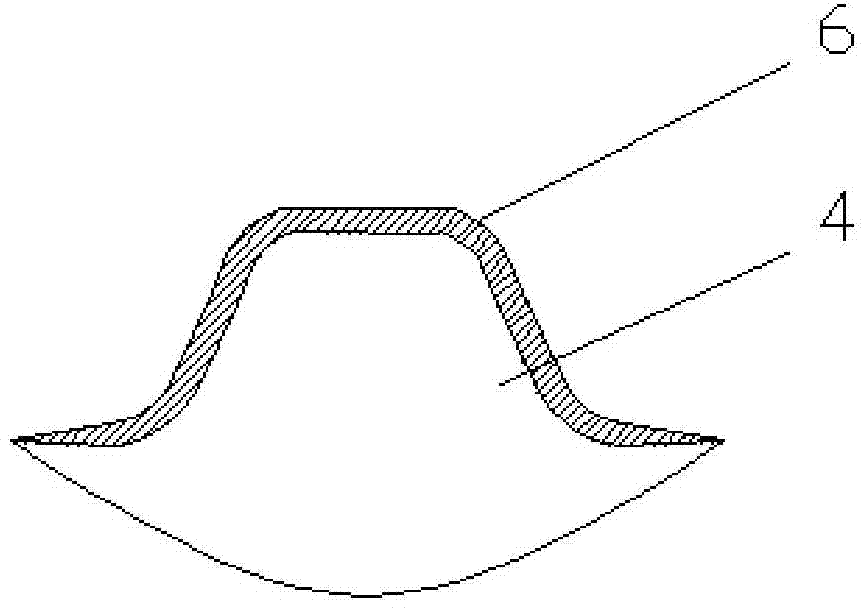

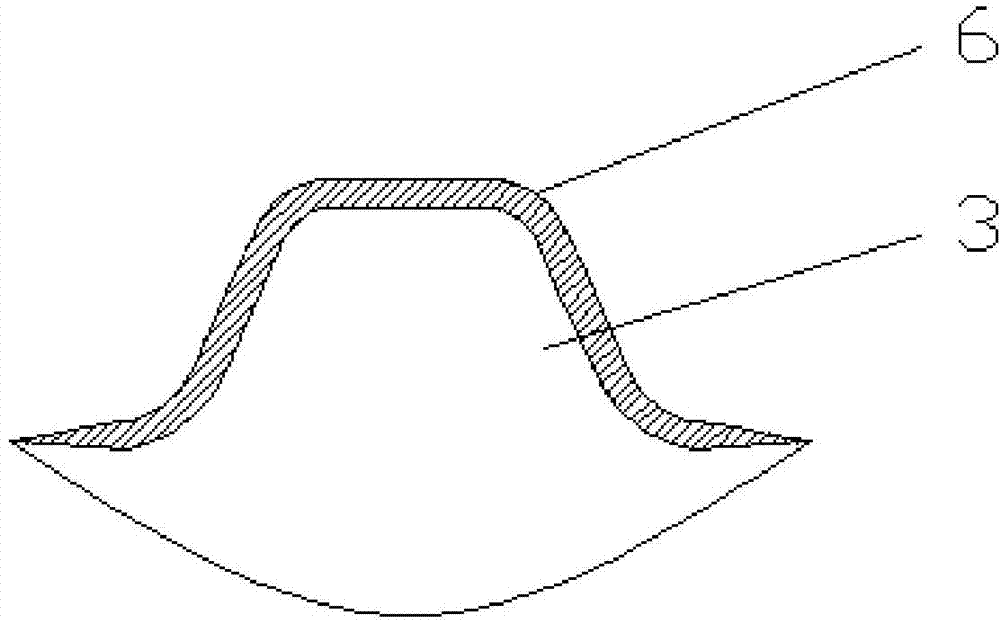

[0016] Such as figure 1 As shown, the roller of the roller crusher of the present invention includes a roller hole 1, a roller surface 2, a large roller tooth 3, a small roller tooth 4 and a keyway 5, and the roller hole 1 is arranged at the center of the roller surface 2, and the size The roller teeth 3 and 4 are arranged on the outer edge of the roller surface 2; the said key grooves 5 are provided with three, arranged in the roller hole 1, and the angle between the adjacent key grooves 5 is 120 degrees; the said small roller teeth 4 are arranged There are three, and the angle between adjacent small roller teeth 4 is 120 degrees, and corresponds to the position of the keyway 5; there are multiple large roller teeth 3, and the distribution is uneven.

[0017] During installation and operation, every two sets of rollers are a crushing unit, and every two sets of rollers ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com