Graphene nano three-proofing adhesive and preparation method thereof

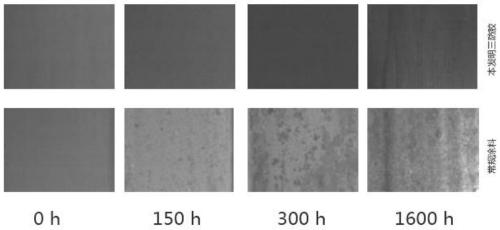

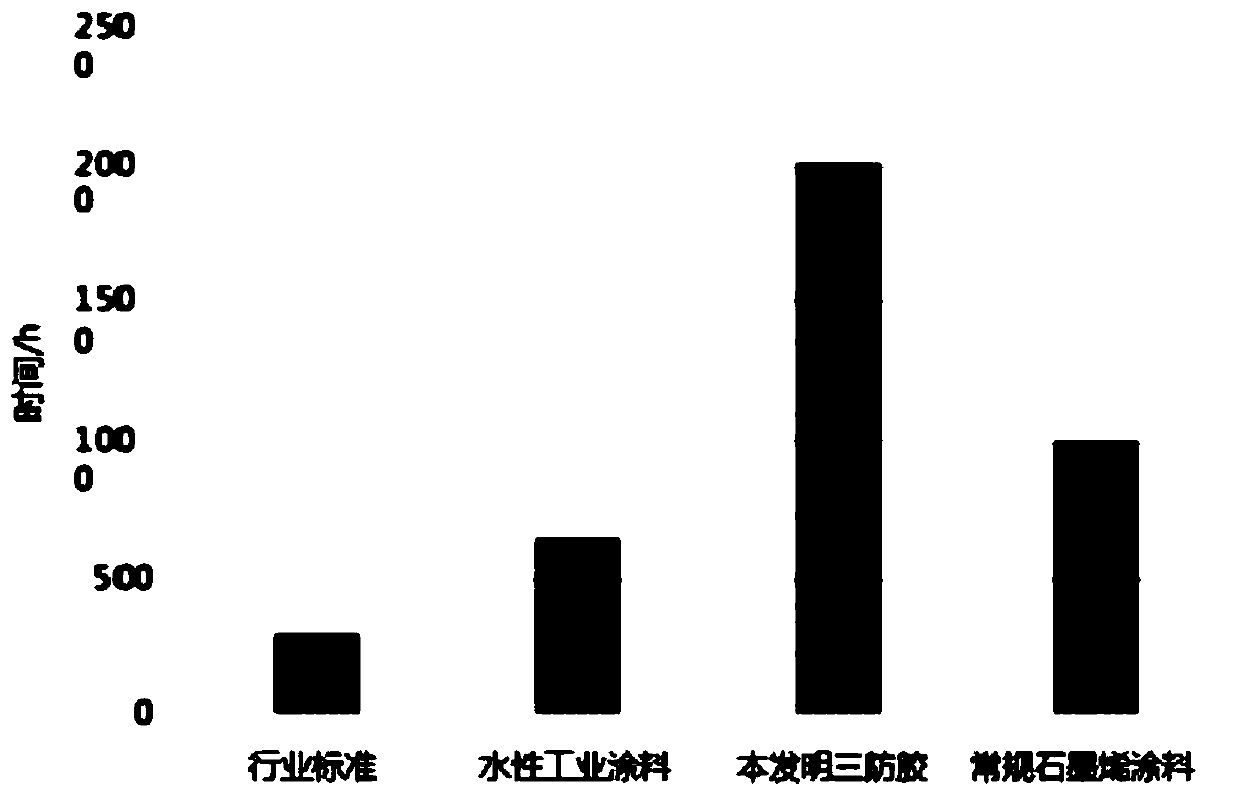

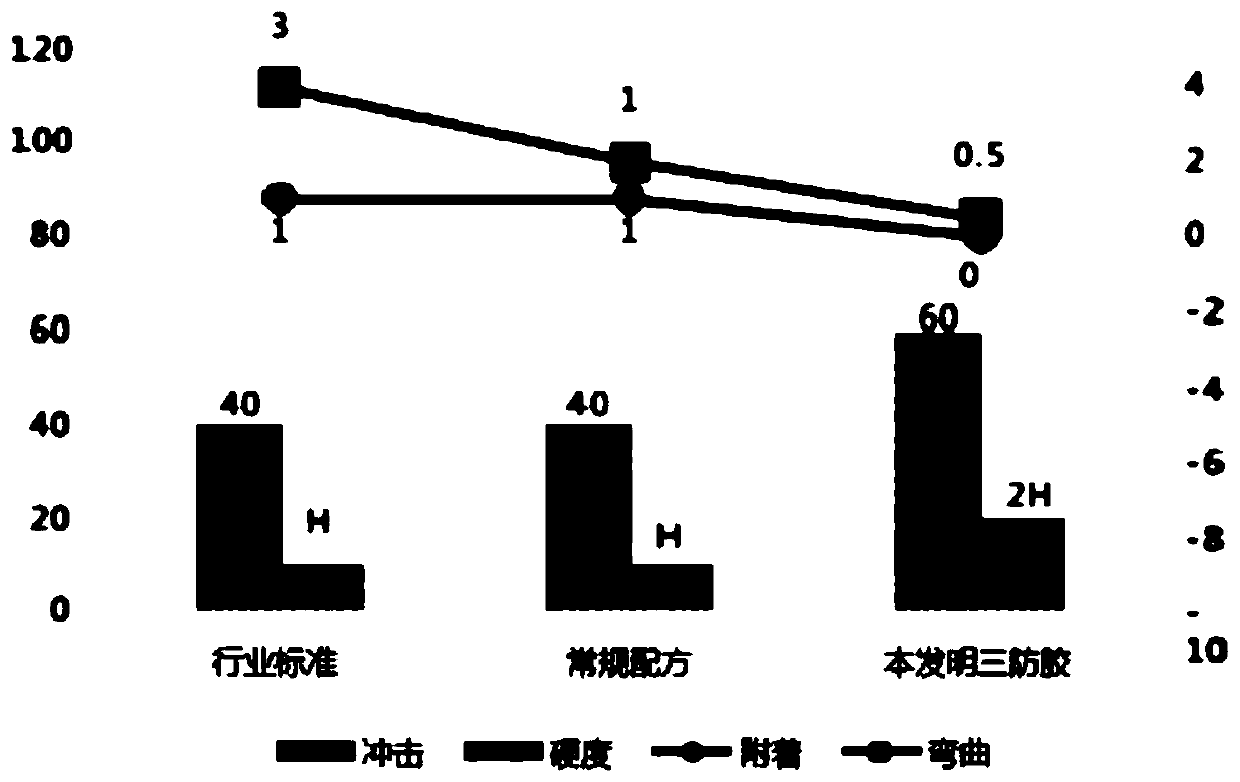

A graphene, three-proof adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of low bonding strength, large environmental impact, poor resistance to friction and scratches, etc. It achieves excellent effects such as internal compactness and surface scratch resistance, salt spray resistance and physical protection performance, and scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A graphene nano three-proof adhesive, comprising the following mass percentage components: modified polyurethane resin: 26%; functional two-dimensional nano-sheet graphene: 28%; polyurethane curing agent MDI: 23%; defoamer: 2 %; Hydrophobic fumed silica: 1%; Graphene dispersant: 20%. When preparing the graphene nano three-proof glue, first prepare the materials according to the above mass percentages of each component; then add the prepared modified polyurethane resin into the double planetary stirring tank, and add graphite in three times when the temperature is raised to 50-55°C Olefin dispersant and functional two-dimensional nano-sheet graphene, fully stirred in a double planetary stirring tank for 2-3 hours, then cooled to 20-25 °C, and then added hydrophobic meteorological silica, defoamer, Polyurethane curing agent MDI, fully stirred and mixed for 2 hours to obtain the finished product, and tested for packaging. Among them, when the graphene dispersant and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com