High-thermal-conductivity modified polyphenyl ether material and preparation method thereof

A polyphenylene ether, high thermal conductivity technology, applied in the field of polyphenylene ether preparation, can solve the problems of low reliability and low practicability, and achieve the effects of reducing preparation cost, improving compatibility, and improving ductility and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

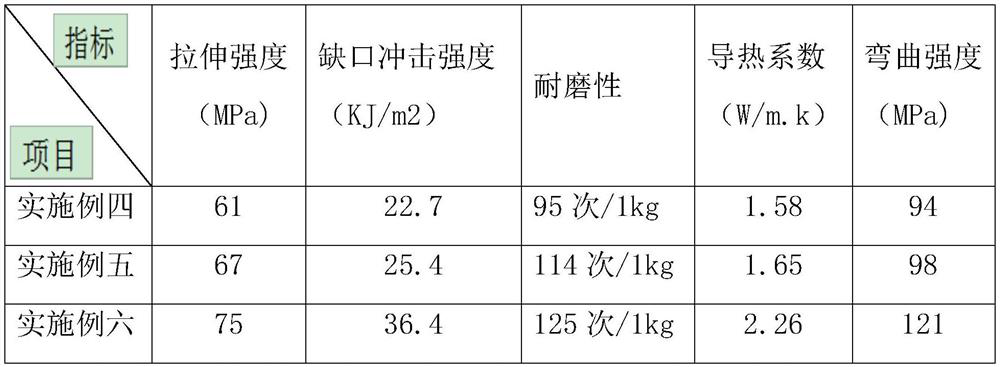

Examples

Embodiment 1

[0023] A modified polyphenylene ether material with high thermal conductivity, comprising the following raw materials in parts by weight: 10 parts of nano-zinc oxide, 20 parts of nano-copper powder, 0 parts of nano-tubular graphene, 20 parts of bisphenol A epoxy resin, bisphenol F 30 parts of epoxy resin, 5 parts of acrylated polyphenylene ether, 0.5 part of carborane heptamethylcyclotetrasiloxane compound, 0.5 part of aluminum hydroxide, NMP organic solvent, tris(triphenylphosphine) chloride 1 part of rhodium catalyst, 5 parts of amine-containing curing agent, 1 part of tri-n-butylamine and triphenylphosphorus mixture, 5 parts of polytetrafluoroethylene powder, and 5 parts of decabromodiphenylethane.

Embodiment 2

[0025] A modified polyphenylene ether material with high thermal conductivity, comprising the following raw materials by weight: 15 parts of nano-zinc oxide, 25 parts of nano-copper powder, 10 parts of nano-tubular graphene, 25 parts of bisphenol A epoxy resin, bisphenol F 35 parts of epoxy resin, 35 parts of acrylated polyphenylene ether, 0.6 part of carborane heptamethylcyclotetrasiloxane compound, 0.7 part of aluminum hydroxide, NMP organic solvent, tris(triphenylphosphine) chloride 2 parts of rhodium catalyst, 35 parts of amine-containing curing agent, 2 parts of tri-n-butylamine and triphenylphosphorus mixture, 30 parts of polytetrafluoroethylene powder, and 10 parts of decabromodiphenylethane.

Embodiment 3

[0027] A modified polyphenylene ether material with high thermal conductivity, comprising the following raw materials by weight: 20 parts of nano-zinc oxide, 30 parts of nano-copper powder, 16 parts of nano-tubular graphene, 30 parts of bisphenol A epoxy resin, bisphenol F 40 parts of epoxy resin, 50 parts of acrylated polyphenylene ether, 0.1 part of carborane heptamethylcyclotetrasiloxane compound, 0.1 part of aluminum hydroxide, NMP organic solvent, tris(triphenylphosphine) chloride 3 parts of rhodium catalyst, 50 parts of amine-containing curing agent, 3 parts of tri-n-butylamine and triphenylphosphorus mixture, 45 parts of polytetrafluoroethylene powder, and 25 parts of decabromodiphenylethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com