Anti-skid high-strength exposed concrete and preparation method thereof

A concrete and explicit technology, applied in the field of concrete, can solve problems such as poor anti-skid performance and mechanical strength, achieve the effect of improving poor strength, improving anti-skid performance and mechanical strength, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

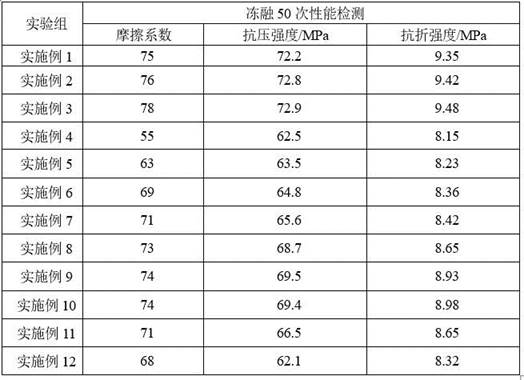

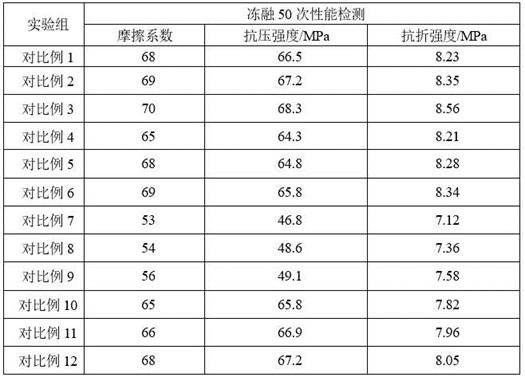

Examples

preparation example 1

[0034] Mix 450mL 75% ethanol solution with 10mL tetraethyl orthosilicate, adjust the pH to 3.0 with 0.1mol / L nitric acid, and stir for 2 hours to obtain sol solution A; then take 450mL 75% ethanol solution and 20g aluminum chloride Place in an Erlenmeyer flask, stir and mix, and hydrolyze at room temperature for 2 hours to obtain sol solution B; take 20g of propylene oxide, 150mL of sol solution A and 250mL of sol solution B, place them in a stirring device, stir and mix to obtain mixed sol solution 1;

[0035] Take 20 g of calcium carbonate particles with a particle size of 6 μm, 1 mL of silane coupling agent, and 200 mL of mixed sol solution 1 in a mortar, grind and disperse them and pass through a 200-mesh sieve to collect the sieving liquid; weigh 45 mL of the sieving liquid , 55mL of deionized water, 3g of sodium citrate, 6g of sodium gluconate and 1g of sodium tripolyphosphate were placed in a stirring tank, stirred and mixed at 55°C until the viscosity was 25Pa·s, and th...

preparation example 2

[0037] Mix 475mL 75% ethanol solution with 11mL tetraethyl orthosilicate, adjust the pH to 3.0 with 0.1mol / L nitric acid, and stir for 2 hours to obtain sol solution A; then take 475mL 75% ethanol solution and 22g aluminum chloride Place in an Erlenmeyer flask, stir and mix, and hydrolyze at room temperature for 2 hours to obtain sol solution B; take 20g of propylene oxide, 175mL of sol solution A and 275mL of sol solution B, place them in a stirring device, stir and mix to obtain mixed sol solution 1;

[0038] Take 22g of calcium carbonate particles with a particle size of 7 μm, 1mL of silane coupling agent and 250mL of mixed sol solution 1 and place them in a mortar, grind and disperse them and pass through a 200-mesh sieve to collect the sieving liquid; weigh 47mL of the sieving liquid respectively , 57mL of deionized water, 4g of sodium citrate, 7g of sodium gluconate and 1g of sodium tripolyphosphate were placed in a stirred tank, stirred and mixed at 57°C until the viscos...

preparation example 3

[0040] Mix 500mL 75% ethanol solution with 12mL tetraethyl orthosilicate, adjust the pH to 3.0 with 0.1mol / L nitric acid, and stir for 3 hours to obtain sol solution A; then take 500mL 75% ethanol solution and 25g aluminum chloride Place in an Erlenmeyer flask, stir and mix, and hydrolyze at room temperature for 3 hours to obtain sol solution B; take 20g of propylene oxide, 200mL of sol solution A and 300mL of sol solution B, place them in a stirring device, stir and mix to obtain mixed sol solution 1;

[0041] Take 25g of calcium carbonate particles with a particle size of 8 μm, 2mL of silane coupling agent and 300mL of mixed sol solution 1 and place them in a mortar, grind and disperse them and pass through a 200-mesh sieve to collect the sieving liquid; weigh 50mL of the sieving liquid respectively , 60mL deionized water, 5g sodium citrate, 8g sodium gluconate and 2g sodium tripolyphosphate were placed in a stirred tank, stirred and mixed at 60°C until the viscosity was 28Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com