Finite element calculation method for temperature fields of multiple cross-linked polyethylene insulated cables during trench sharing

A cross-linked polyethylene, insulated cable technology, applied in the field of power cables, can solve the problems of large amount of calculation, poor adaptability to complex areas, and many boundaries of boundary element method, achieve high calculation accuracy, improve the distribution structure of cable trenches, and calculate speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

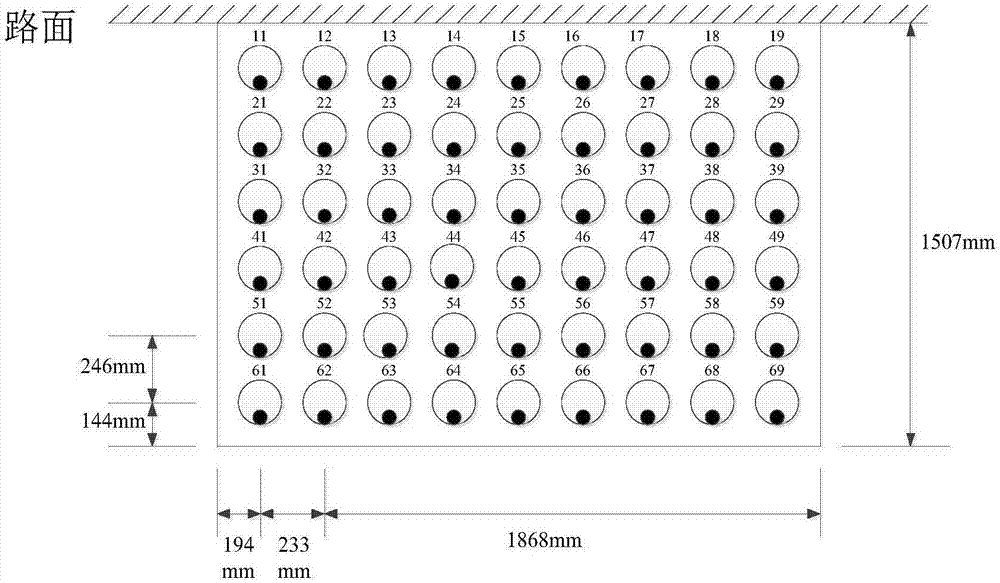

[0037] Below will further illustrate the specific embodiment of the present invention in conjunction with accompanying drawing, concrete steps are as follows:

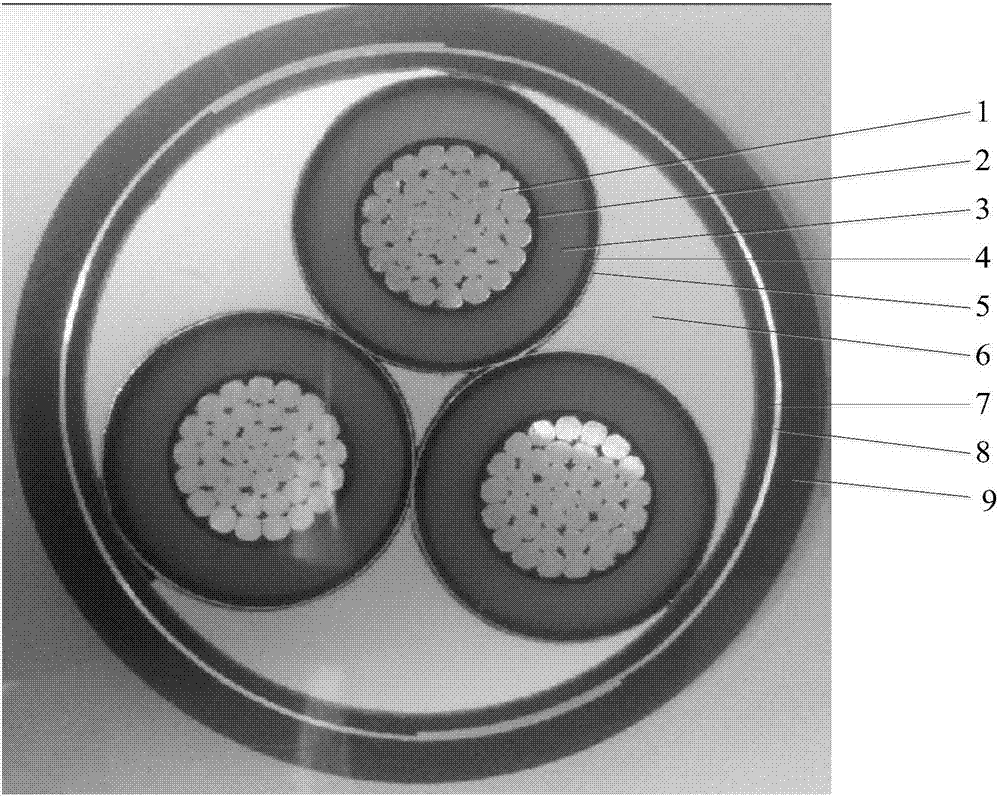

[0038] A, the 10kV model is YJV22-8.7 / 15-3*240mm 2 The XLPE armored three-core power cable is the research object, and the relevant parameters of the cable are calculated based on the IEC 60287 standard. For the structure of the cable see figure 1 , the three conductors are respectively insulated and wrapped in the armor layer 8, and the outer sheath 9 is wrapped outside. The specific parameters of the cable body are shown in Table 1.

[0039] Table 1 Dimensional parameters of the three-core cable body

[0040]

[0041] The calculation of the relevant parameters of the cable is as follows:

[0042] (1) Calculation of AC resistance of cable conductor

[0043] The cable conductor is located in the innermost layer of the cable structure, i.e. figure 1 The neutral wire core 1 is used to transfer current. The AC r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com