Cup body of soybean milk maker without filter screen

A soymilk maker and cup technology, which is applied to milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems that have not been proposed, can not meet the beating and fine grinding effect, and achieve the effect of easy cleaning and high efficiency of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

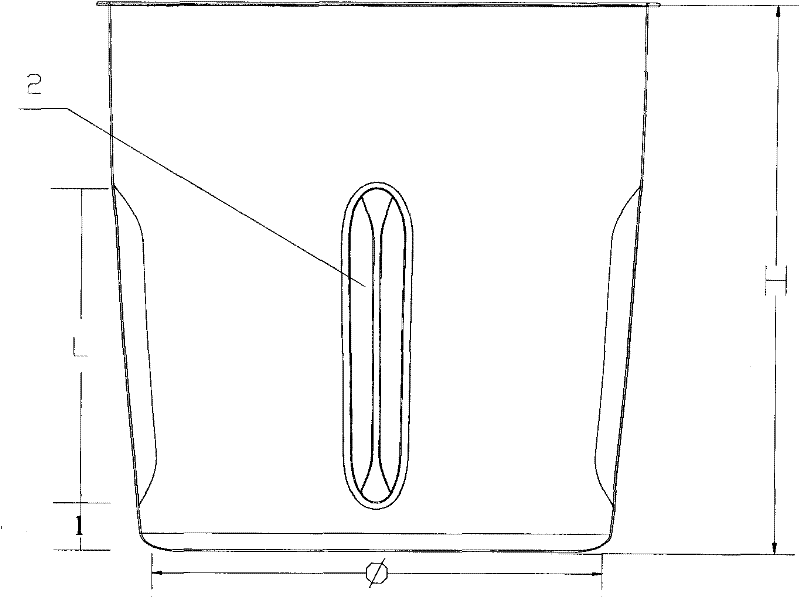

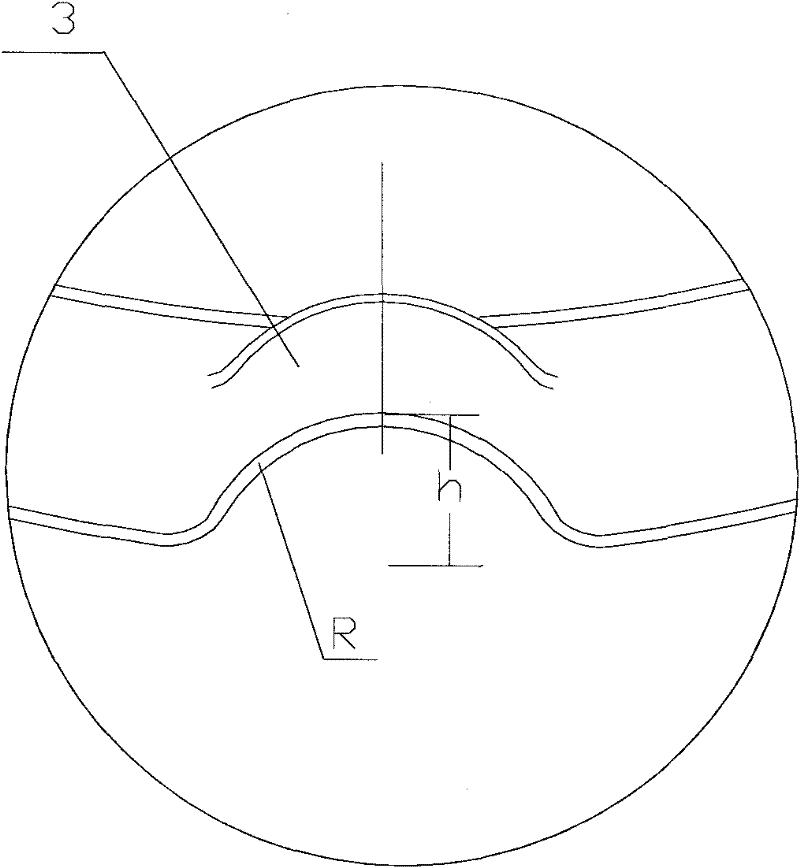

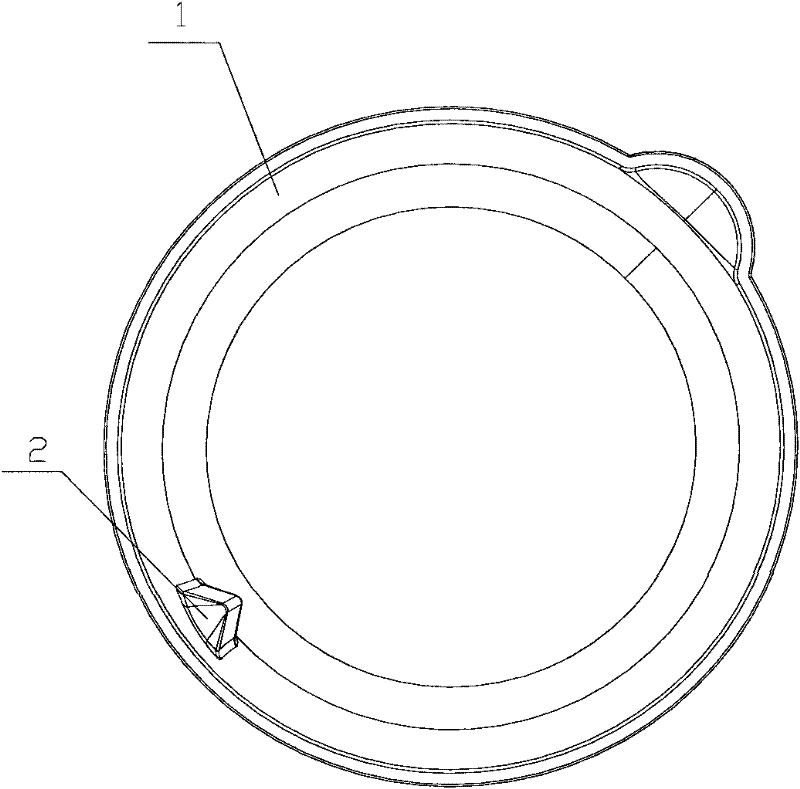

[0036] Such as Figure 1 to Figure 4 As shown, the present invention discloses a cup body of a non-net soymilk machine. The cup body is made of metal material, and several ribs 2 are arranged on the inner surface 1 thereof. The included angle α of the inner surface 1 is 120°-145°. Here, the angle between the two surfaces of the flow blocking surface 3 and the inner surface 1 passes through the tangent of the inner surface 1 at the intersection of the flow blocking surface 3 and the inner surface 1, and the top of the flow blocking surface 3 and the flow blocking surface 3 and the inner surface 1 The angle between the connecting chords of the intersection points is determined, such as Figure 7 shown.

[0037] The installation position of the soya-bean milk maker cutter is located at the central axis of the cup body and close to the bottom position, which is the installation position of the general existing soymilk maker cutter. Under the agitation of the cutter placed on th...

Embodiment 2

[0046] This embodiment is further limited on the basis of Embodiment 1, specifically, the included angle α between the flow blocking surface 3 of the rib 2 and the inner side surface 1 of the cup is 125°-135°. Utilizing the turbulence effect of the ribs 2 described in Embodiment 1 and the direction of rotation of the bean grains, this embodiment further accurately positions the bean grains hitting the knife when they rebound from the choke surface 3 . In this embodiment, when the included angle between the choke surface 3 and the inner surface 1 is 125°-135°, under the action of the rib 2 choke surface 3, if the direction of rotation of the liquid flow is counterclockwise, the bean grains will To the central position of the cutter, which greatly increases the probability of bean grains colliding with the cutter and improves the turbulence effect.

Embodiment 3

[0048] This embodiment is further limited on the basis of Embodiment 1, specifically, the number of ribs 2 is 3 to 4, such as Figure 5 shown. In this embodiment, the number of ribs 2 is set at 3 to 4, and they are evenly distributed on the side surface 1 of the cup body. It is driven to move in the circumferential direction for the next step of disturbing the flow, which improves the defect that the flow disturbance efficiency of only one rib is not too high, and also improves the fact that when there are five ribs, the beans can only be hit near the cutter without being hit. Can not hit the defect in the center of the tool, so this embodiment can greatly improve the effect of turbulence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height h | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com