Heat exchanger

a heat exchanger and heat exchanger technology, applied in the direction of heat exchanger fastening, lighting and heating apparatus, stationary conduit assemblies, etc., can solve the problem of increasing the design space of the inlet pipe, and achieve the effect of improving the refrigerant distribution structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077]Reference will now be made in detail to the embodiments of the present disclosure, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout.

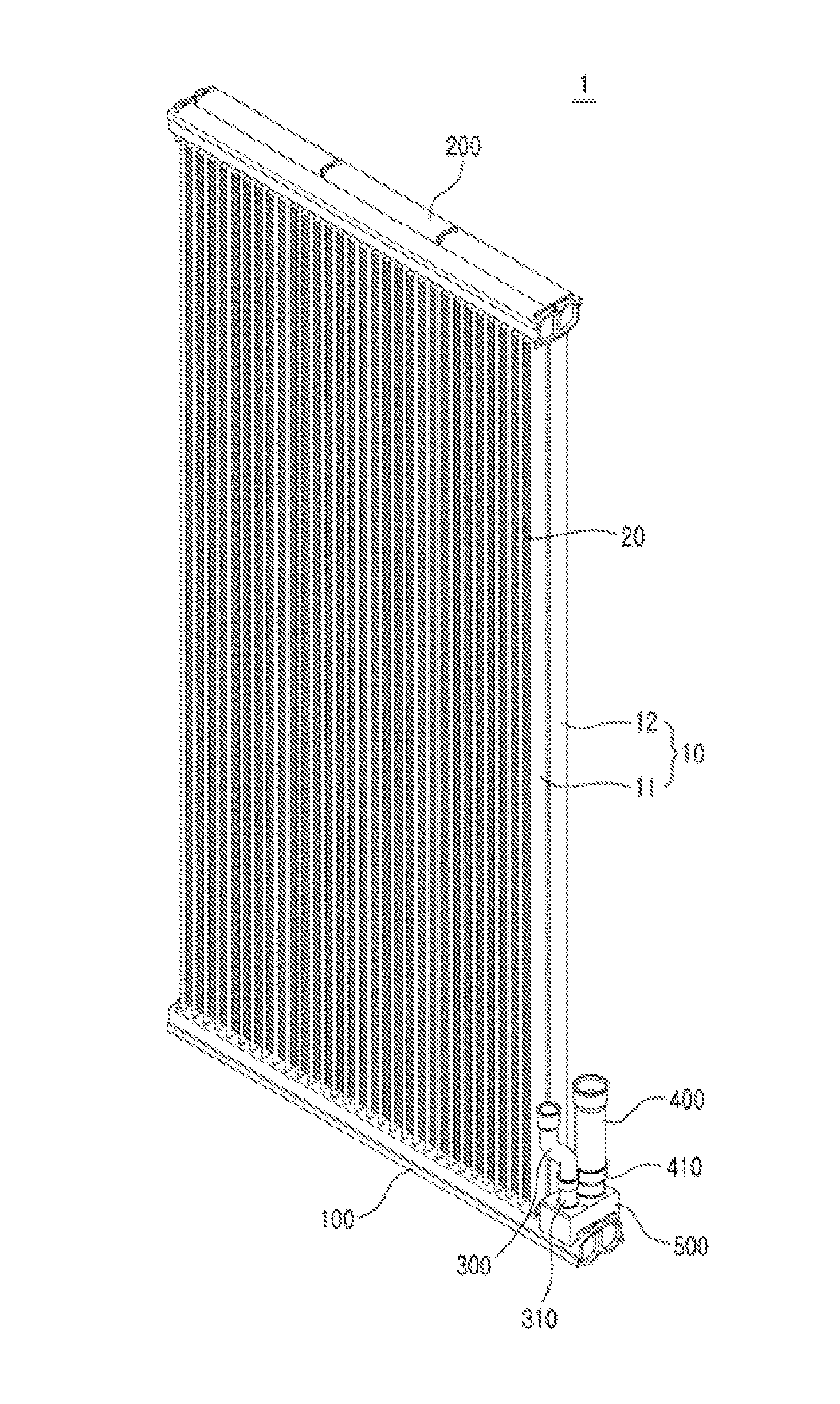

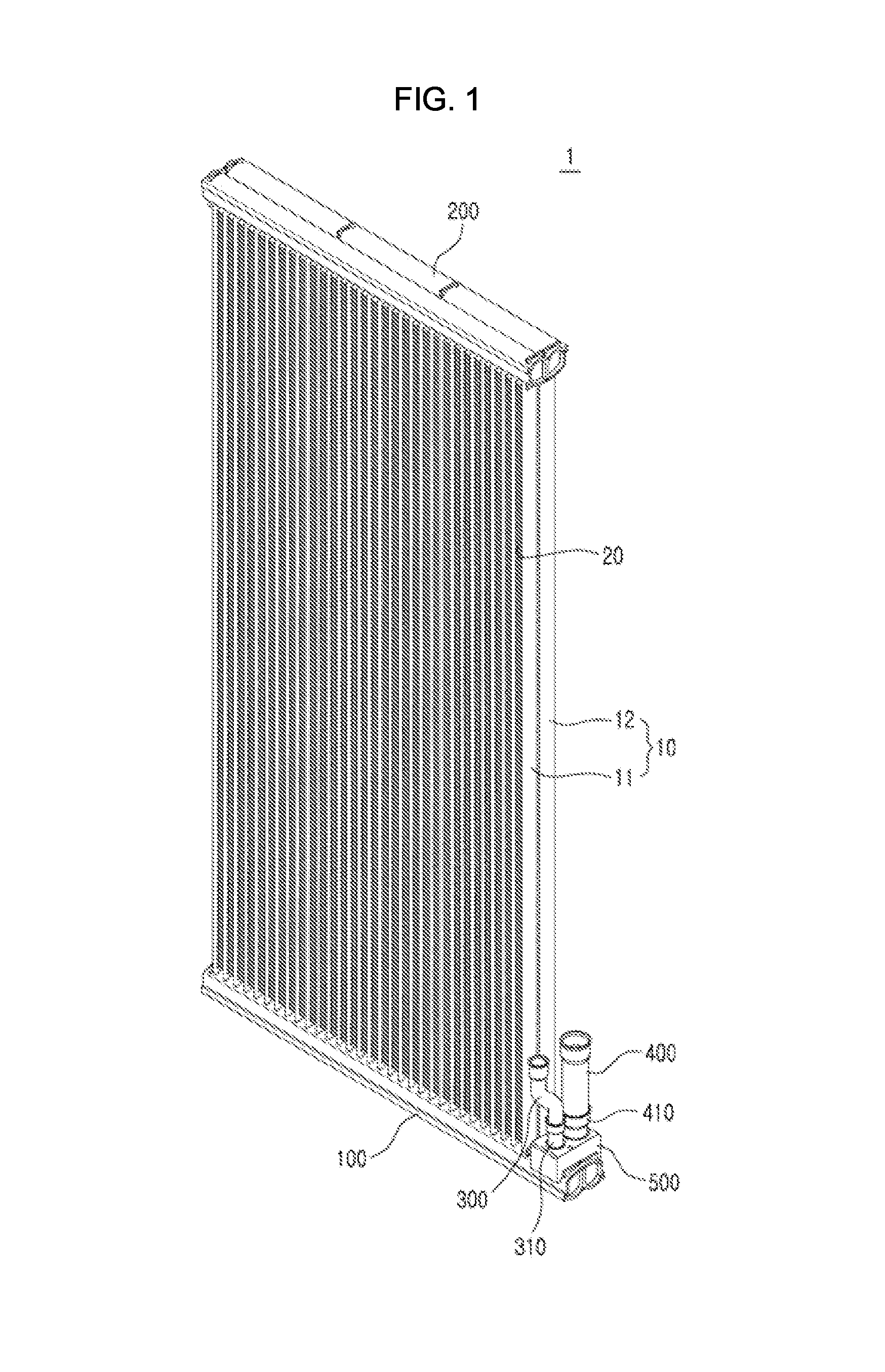

[0078]FIG. 1 is a perspective view illustrating the exterior of a heat exchanger according to an embodiment of the present disclosure.

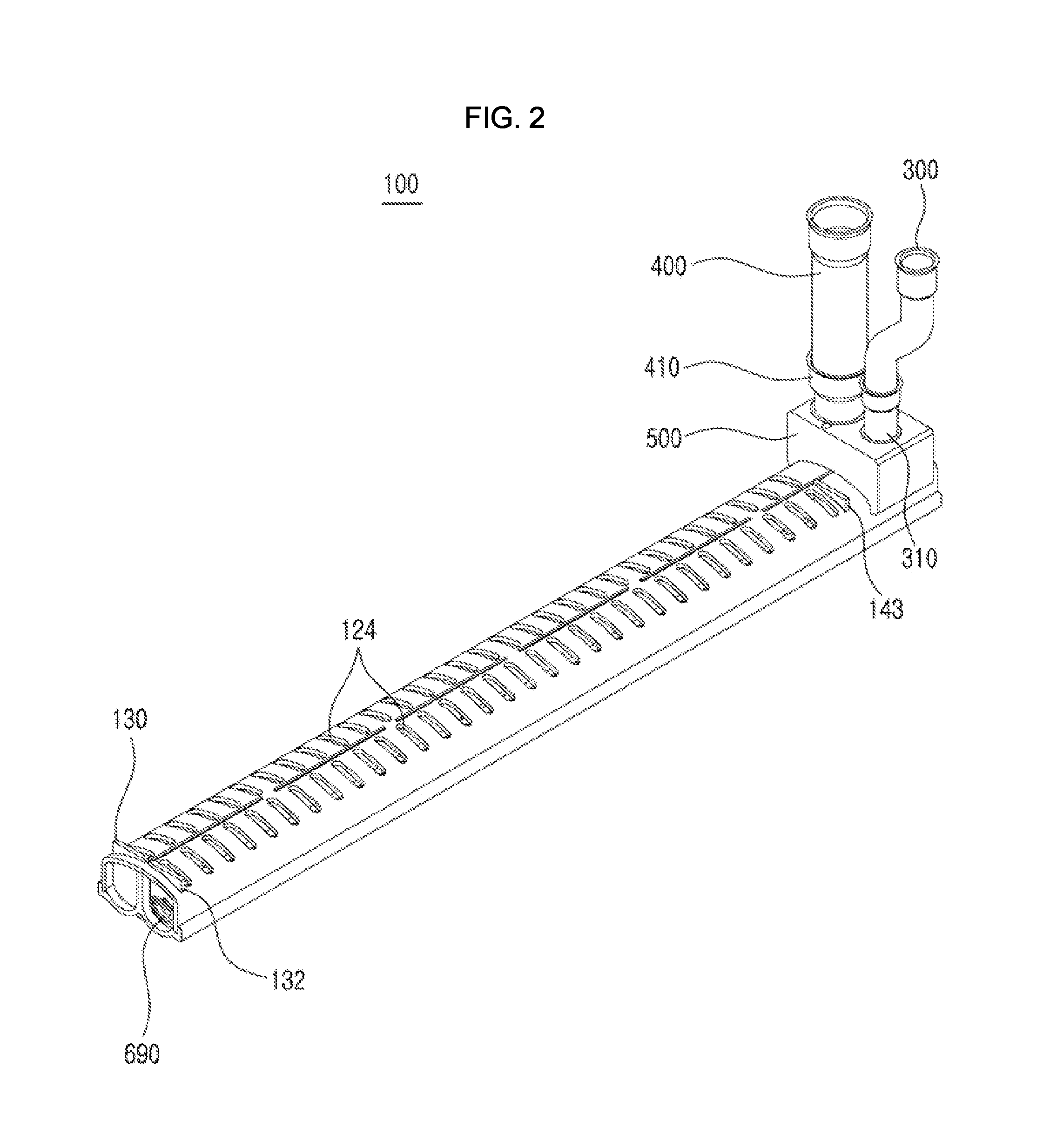

[0079]Referring to FIG. 1, a heat exchanger 1 according to an embodiment of the present disclosure includes a plurality of tubes 10 in which a refrigerant flows and is heat-exchanged with air outside the heat exchanger, heat-exchanging fins 20 that contact the plurality of tubes 10 to increase a heat transfer area with air outside the heat exchanger 1, a first header 100 and a second header 200 in which the plurality of tubes 10 communicate with one another, an inlet pipe 300 through which a refrigerant outside the heat exchanger 1 flows into the heat exchanger 1, an outlet pipe 400 through which the refrigerant flows out of the heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com