Fabric antibacterial treatment liquid and preparation method thereof

A technology for treating liquids and fabrics, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve problems such as human body and environmental hazards, and achieve the effects of improving distribution structure, improving performance, and enhancing bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

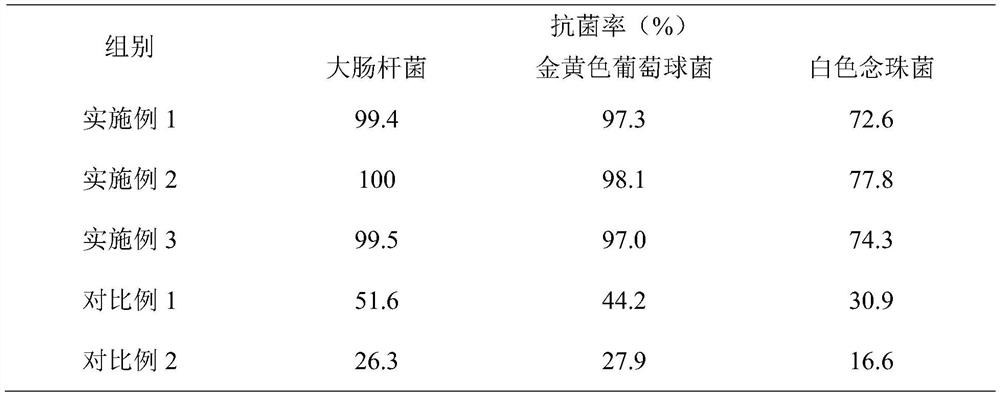

Examples

Embodiment 1

[0020] A preparation method of fabric antibacterial treatment liquid, the steps are: hydrolyzing and dissolving chitosan in water, adding active agent, stirring evenly, then adding sodium alginate and auxiliary agent (leveling agent), stirring until sodium alginate Dissolve completely to obtain fabric antibacterial treatment solution;

[0021] Wherein, the activating agent is made by mixing monoleptin and honeycomb powder according to a mass ratio of 1:50, and the mass ratio between chitosan, water, activating agent and sodium alginate is 8:15:6:8;

[0022] The preparation steps of the honeycomb powder are as follows: take the honeycomb and dry it and grind it into a powder. The particle size of the honeycomb powder is 5nm. Disperse for 0.5h, then heat the solution to 60°C, and carry out stirring reaction, the speed of stirring reaction is 600r / min, stirring time is 24h, then filter, put the filtered powder at 80°C, vacuum dry and activate 4h, that is, honeycomb powder.

Embodiment 2

[0024] A preparation method of fabric antibacterial treatment solution, the steps are: hydrolyzing and dissolving chitosan in water, adding active agent, stirring evenly, then adding sodium alginate and auxiliary agent (antistatic agent), stirring until sodium alginate Dissolve completely to obtain fabric antibacterial treatment solution;

[0025] Wherein, the activating agent is made by mixing monoleptin and honeycomb powder according to a mass ratio of 1:100, and the mass ratio between chitosan, water, activating agent and sodium alginate is 10:25:8:10;

[0026] The preparation steps of the honeycomb powder are as follows: take the honeycomb and dry it and grind it into a powder. The particle size of the honeycomb powder is 30nm. The powder is added to the coupling agent / ethanol solution with a volume concentration of the coupling agent of 1%. Disperse for 0.8h, then heat the solution to 65°C, and carry out stirring reaction, the speed of stirring reaction is 700r / min, stirr...

Embodiment 3

[0028] A preparation method of fabric antibacterial treatment solution, the steps are: hydrolyzing and dissolving chitosan in water, adding an active agent, stirring evenly, then adding sodium alginate and auxiliary agent (hydrophobic agent), stirring until the sodium alginate is completely Dissolve to obtain fabric antibacterial treatment solution;

[0029] Wherein, the activating agent is made by mixing monoleptin and honeycomb powder according to a mass ratio of 1:200, and the mass ratio between chitosan, water, activating agent and sodium alginate is 12:30:10:12;

[0030] The preparation steps of the honeycomb powder are as follows: take the honeycomb and dry it and grind it into powder. The particle size of the honeycomb powder is 50nm. Disperse for 1 hour, then heat the solution to 70°C, and carry out stirring reaction, the speed of the stirring reaction is 800r / min, the stirring time is 12h, then filter, put the filtered powder at 90°C, vacuum dry and activate for 2.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com