Detecting unit of coriolis quality flow meter

A technology of mass flowmeter and detection unit, which is applied in direct mass flowmeter, mass flow measuring device, measuring device, etc., to achieve the effects of improving distribution structure, accurate motion state, and ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

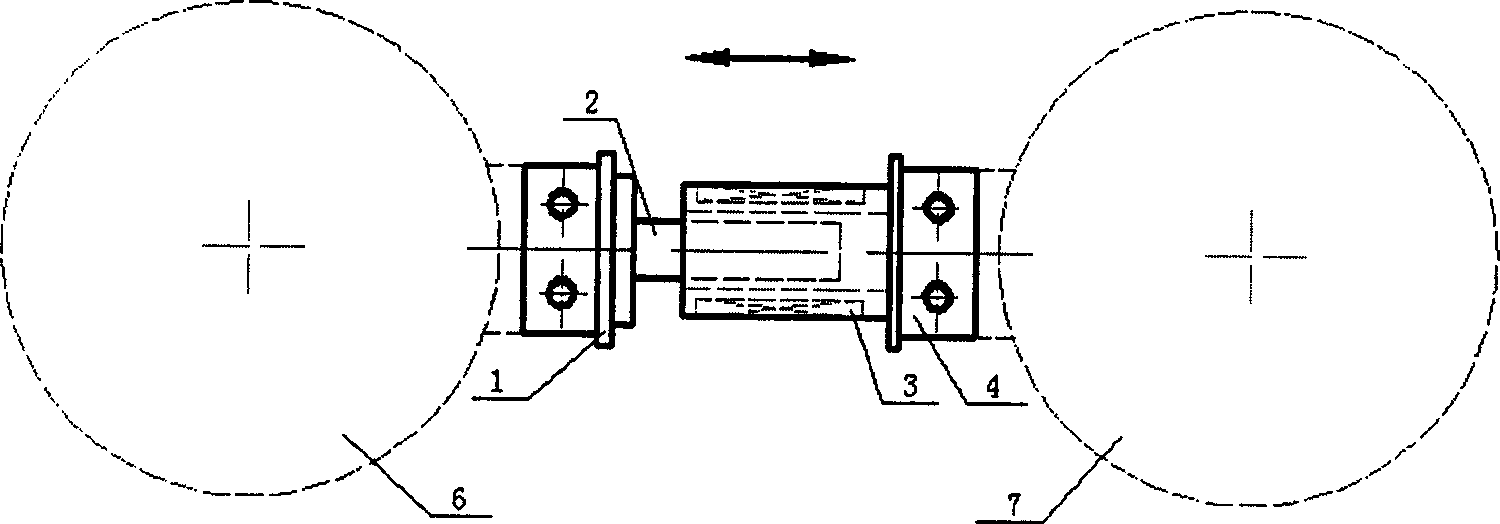

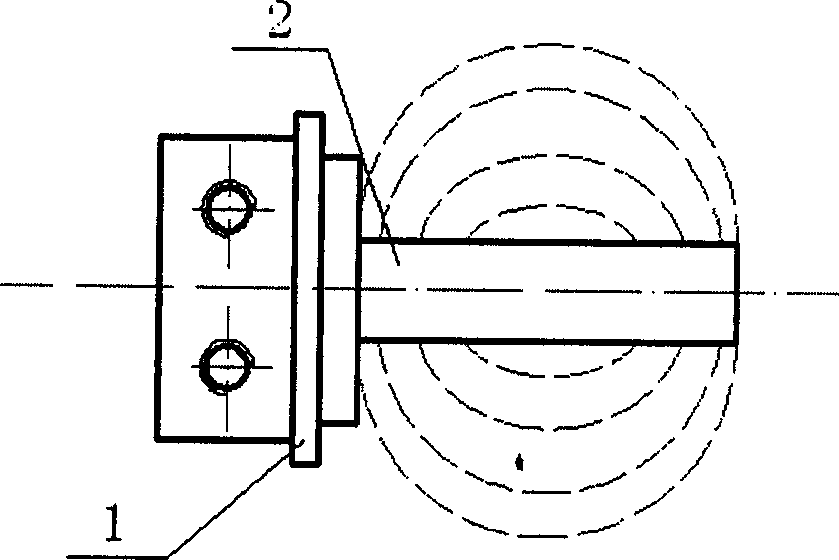

[0014] Such as image 3 As shown, the present invention is composed of two parts: a magnetic steel part and a coil part. The magnetic steel part includes a base 1, an annular magnetic steel 2 and a central magnetizer 3, and the magnetic steel part is installed on the measuring tube 6 through the base 1 as a whole. In the positioning device, it is fixedly connected by screws. The coil part includes a coil 4 and a coil frame 5. The coil 4 is evenly wound in the fixing groove of the coil frame 5. The coil frame 5 is installed in the positioning device of the measuring tube 7 and fixedly connected by screws. The annular magnetic steel 2 is made of samarium cobalt SmCo rare earth permanent magnet material, and the base 1 and the central magnetizer 3 are made of high magnetic permeability MnZn ferrite material.

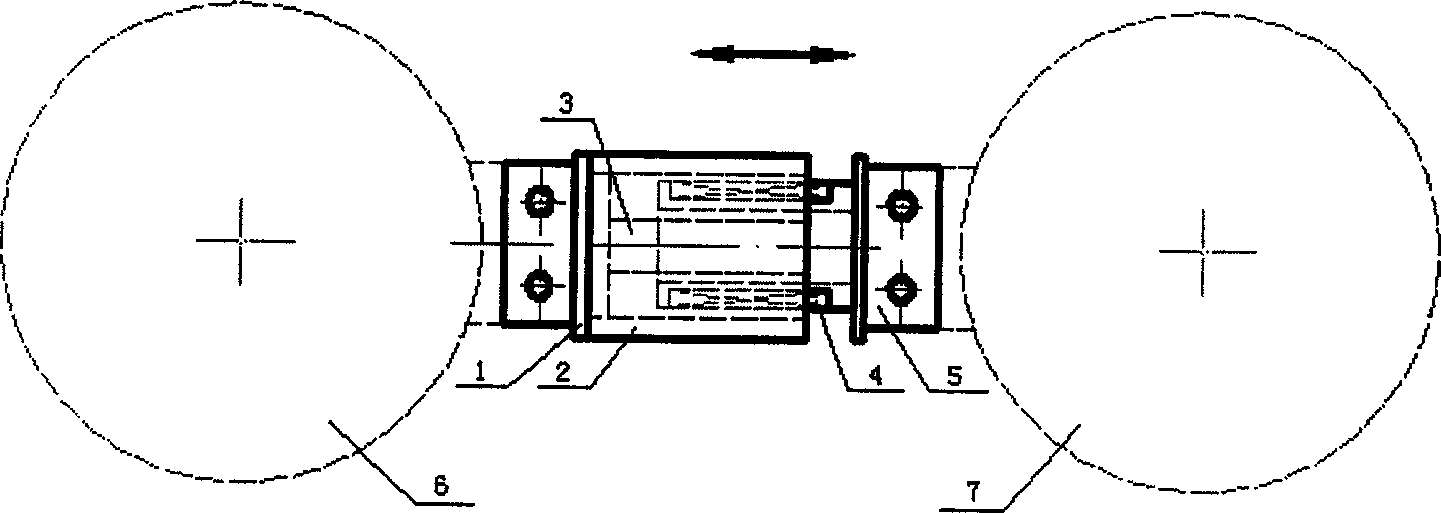

[0015] As shown in Fig. 4, the magnetic steel part of the present invention is made of base 1, annular magnetic steel 2 and center magnetizer 3, and central magnetizer 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com