Active touch sensor

A tactile sensor, active technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc. , cumbersome lithography methods, etc., to achieve the effects of good sensitivity and response time, wide selection of materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

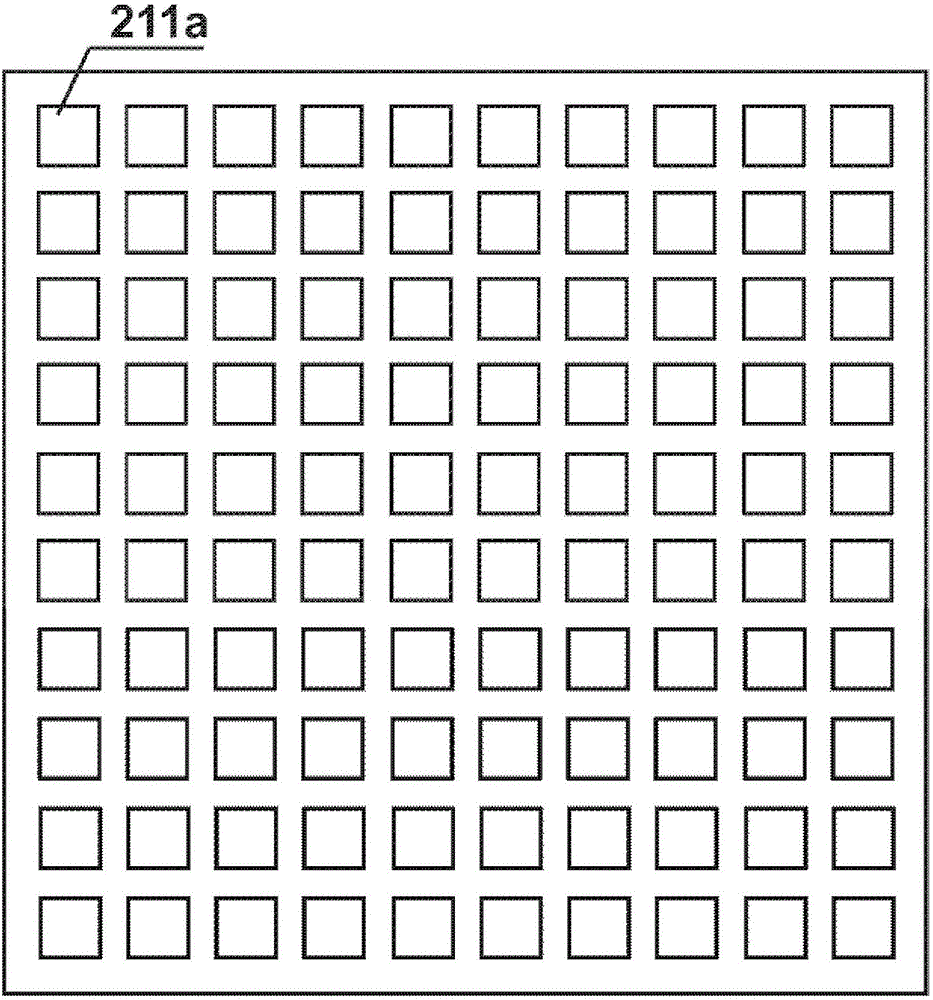

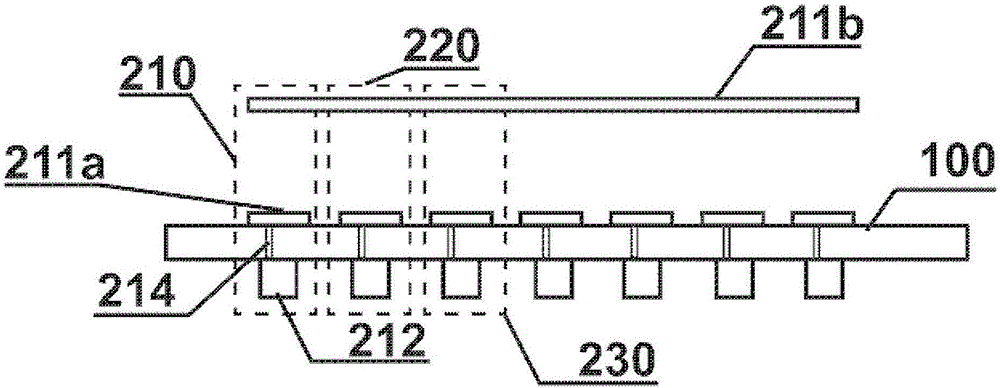

Image

Examples

Embodiment Construction

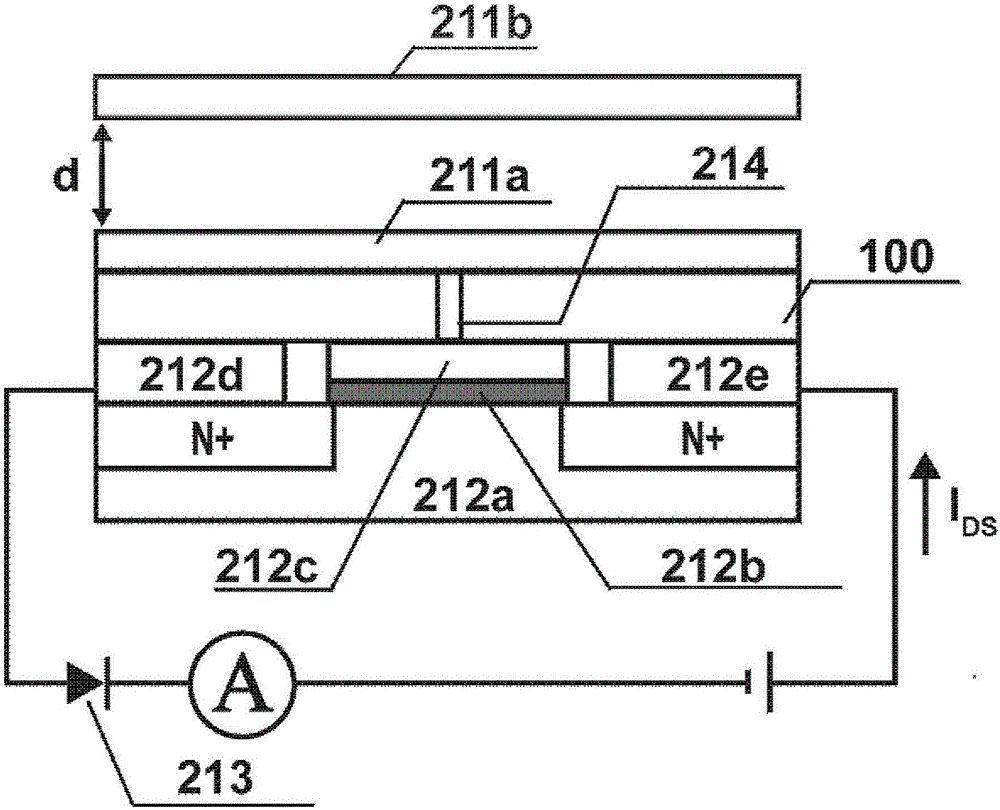

[0029] The triboelectric nanogenerator proposed by Professor Wang Zhonglin's research group provides a new idea for the preparation of active tactile sensing systems. The working principle of this generator is based on the coupling of friction electrification and electrostatic induction. Two polymer materials coated with electrodes and having different charging characteristics are pasted together, and mechanical deformation is generated under the action of external mechanical force, so that the two The materials rub against each other. Since the two materials have different electronic gain and loss capabilities, charge separation will occur on the contact surface of the two materials to form a built-in potential difference. The two plated electrodes generate induced charges on the surface through electrostatic induction, and are driven by the frictional electrostatic potential. A current flows through an external circuit. In addition to directly utilizing the triboelectric na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com