Double-layer knitted mooring rope

A double-layer weaving and cable technology, applied in the field of cables, can solve the problems of potential safety hazards, short service life, poor wear resistance of cables, etc., and achieve the effects of prolonging service life, reducing resistance and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not limited only to the following embodiments.

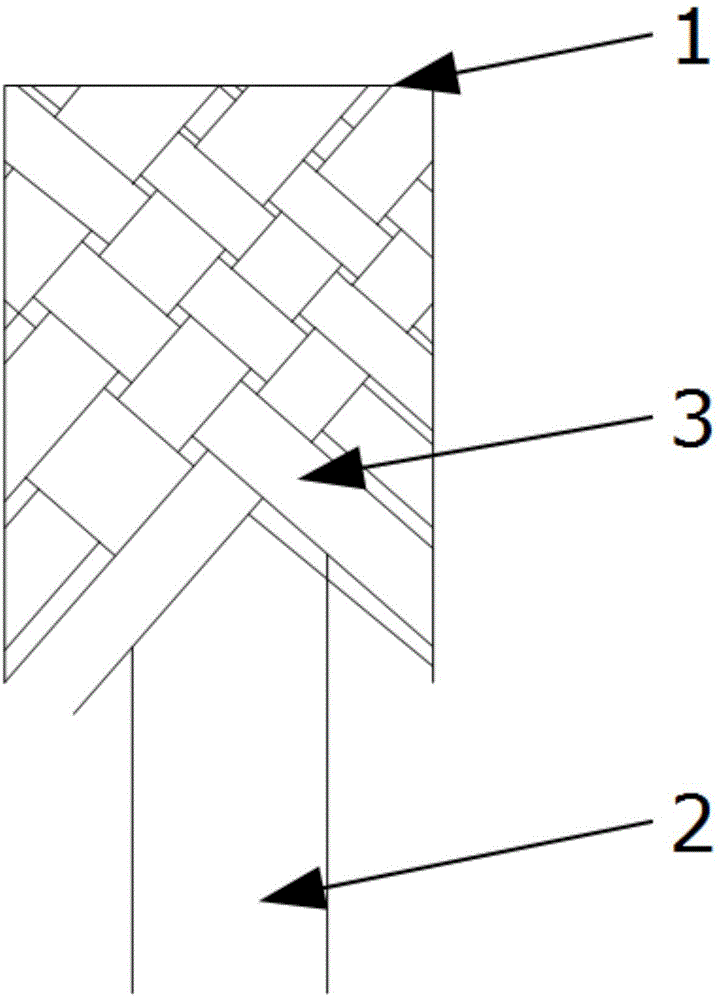

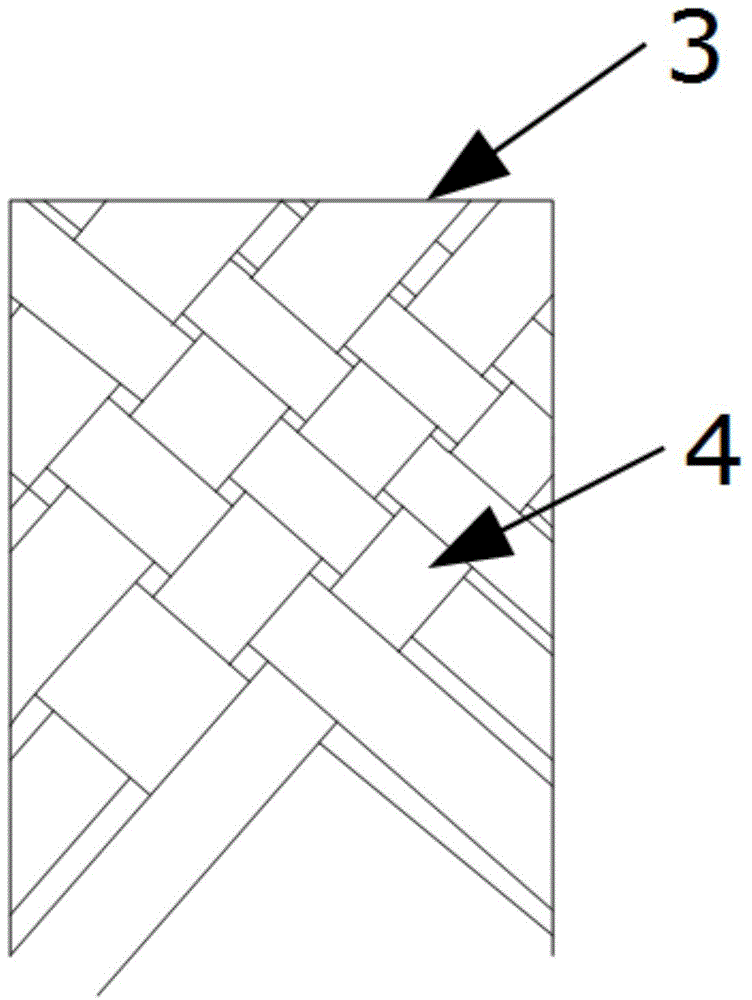

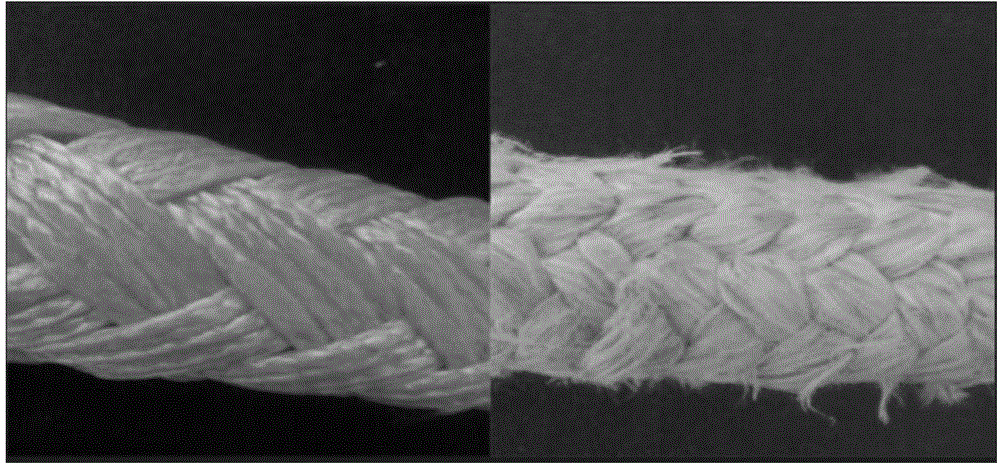

[0015] Such as figure 1 , 2 As shown, this double-layer braided cable includes a rope core 2 and an outer cladding 1, the outer cladding 1 is wrapped in the outer layer of the rope core 2, and the outer cladding 1 is formed by cross-braiding a plurality of thin ropes 3, so Said thin rope 3 is formed by cross braiding of multiple fiber strands 4 .

[0016] In a preferred embodiment of the present invention, four thin ropes 3 are arranged side by side to form a thin rope group, and 12 strands of thin rope groups are cross-braided so that the outer covering layer 1 is wrapped around the rope core 2 formed by twisting and forming 6 fiber strands.

[0017] The cable designed by the present invention is mainly suitable for high-altitude wind power generation. High-altitude wind power gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com