Recombined bamboo timber composite board and processing method thereof

A processing method and technology of composite boards, which are applied in wood processing equipment, sugarcane mechanical processing, chemical instruments and methods, etc., can solve the problems of short available length of bamboo tips, stains on the cutting surface, and high density of bamboo joints, etc. Achieve the effect of improving the utilization rate of bamboo, not easy to absorb water, and high fiber density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

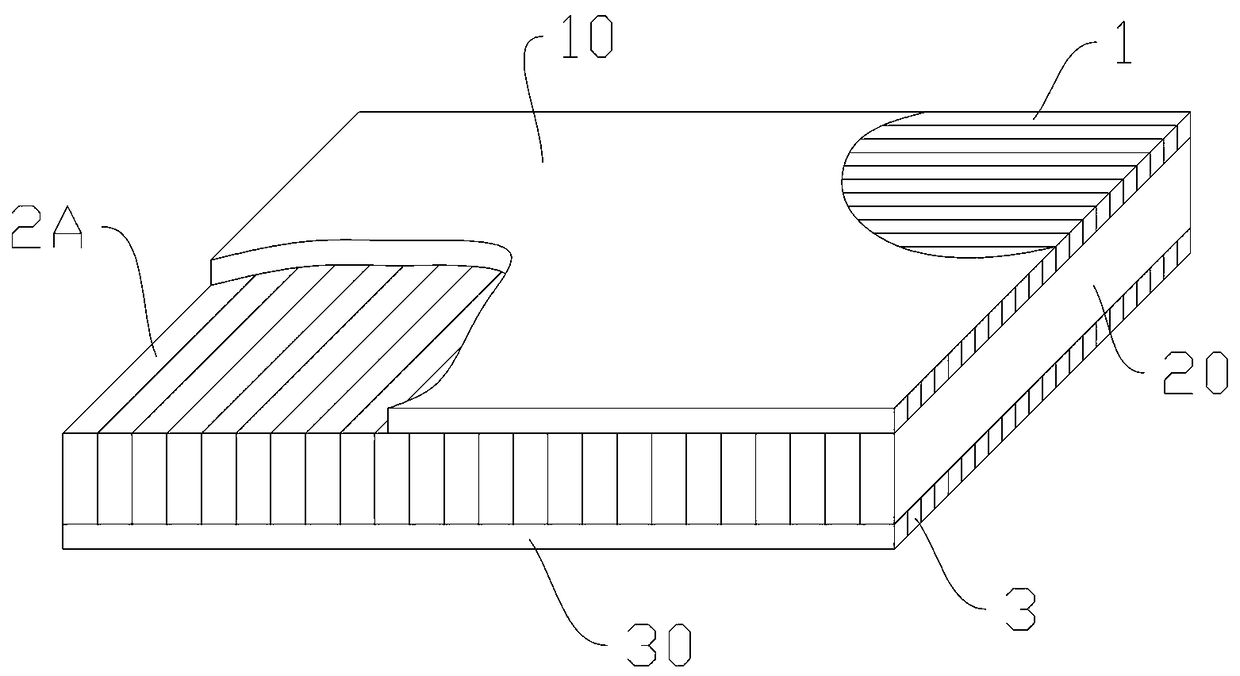

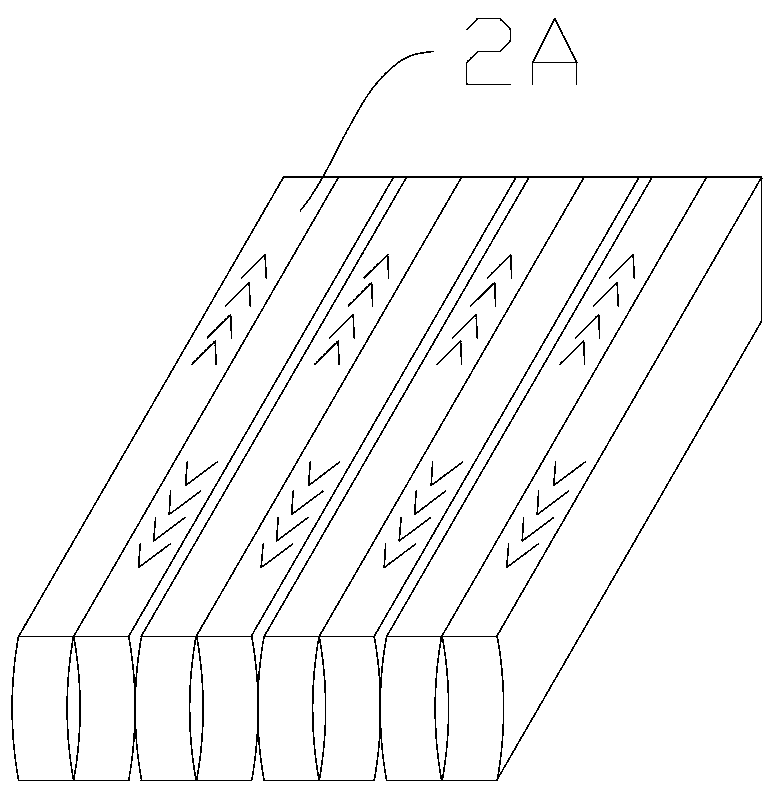

[0041] Example one: such as Figure 1-2 As shown, a recombined bamboo composite panel includes a panel 10, a core panel 20, and a bottom panel 30. The panel includes bamboo filaments 1 arranged in parallel, the bottom panel includes a second bamboo strip 3 that is spliced in parallel, and the core panel includes a second bamboo strip that is spliced in parallel. One bamboo strip; the bamboo silk is made of the material of the middle section of the bamboo, the second bamboo strip is made of the green part of the middle section of the bamboo; the first bamboo strip includes the bamboo tip strip 2A made of the material of the bamboo tip section.

[0042] The arrangement lines of the bamboo threads are perpendicular to the splicing lines of the first bamboo strips, and the splicing lines of the first bamboo strips and the second bamboo strips are perpendicular to each other.

[0043] A method for processing reorganized bamboo composite board includes the following steps:

[0044] The...

Embodiment 2

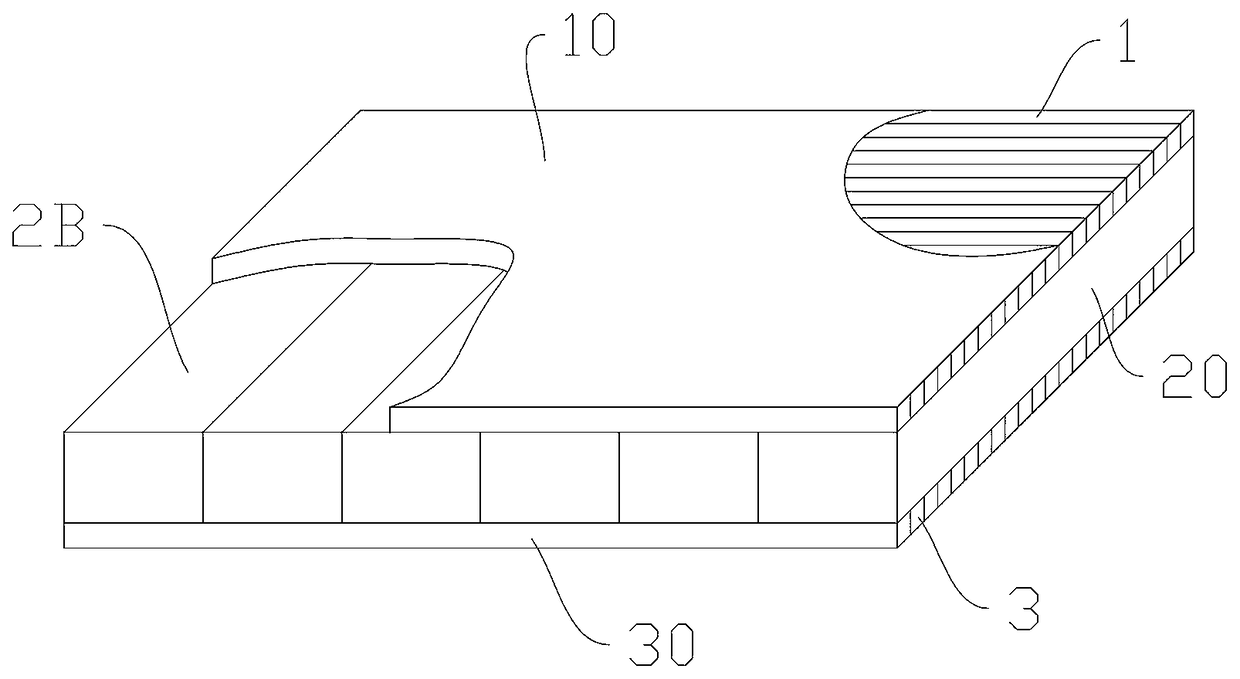

[0052] Embodiment two: such as Figure 3-4 As shown, a recombined bamboo composite panel includes a panel 10, a core panel 20, and a bottom panel 30. The panel includes bamboo filaments 1 arranged in parallel, the bottom panel includes a second bamboo strip 3 that is spliced in parallel, and the core panel includes a second bamboo strip that is spliced in parallel. One bamboo strip; the bamboo silk is made of the material of the middle section of the bamboo, the second bamboo strip is made of the green part of the middle section of the bamboo; the first bamboo strip includes the bamboo root strip 2B made of the material of the root section.

[0053] The arrangement lines of the bamboo threads are perpendicular to the splicing lines of the first bamboo strips, and the splicing lines of the first bamboo strips and the second bamboo strips are perpendicular to each other.

[0054] A method for processing reorganized bamboo composite board includes the following steps:

[0055] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com