Double layer co-extrusion method for extremely micro air-blowing optical cable, and the extremely micro air-blowing optical cable

A double-layer co-extrusion and air-blowing technology, which is applied in the field of optical cable manufacturing, can solve the problems of pressure resistance performance limiting the wall thickness of the loose tube, the size of the structure cannot be well satisfied, and the size of the loose tube diameter is limited. Achieve the effect of reducing production and post-maintenance costs, solving the shortage of pipeline resources, and improving environmental resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

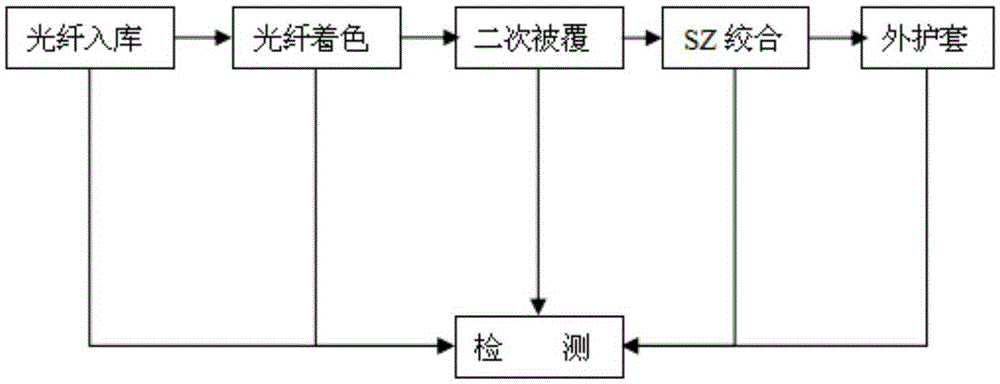

[0032] Such as figure 1 As shown, this embodiment discloses a double-layer co-extrusion method for ultra-miniature air-blown optical cables. Compared with the conventional secondary coating production process, this method adopts a new type of loose tube material and a double-layer co-extrusion extrusion process.

[0033] Specifically include the following procedures:

[0034] Fiber warehousing: Screen the warehousing optical fibers, and select optical fibers with qualified transmission performance and tension.

[0035] Optical fiber coloring: The standard full color spectrum is used to mark the optical fiber. The marked optical fiber does not fade under high temperature and is easy to identify when splicing.

[0036] Secondary coating: The secondary coating adopts double-layer co-extrusion extrusion process to make loose tube; PC material and PBT material are dried and extruded through different extruder units respectively, and passed through different distribution cones in t...

Embodiment 2

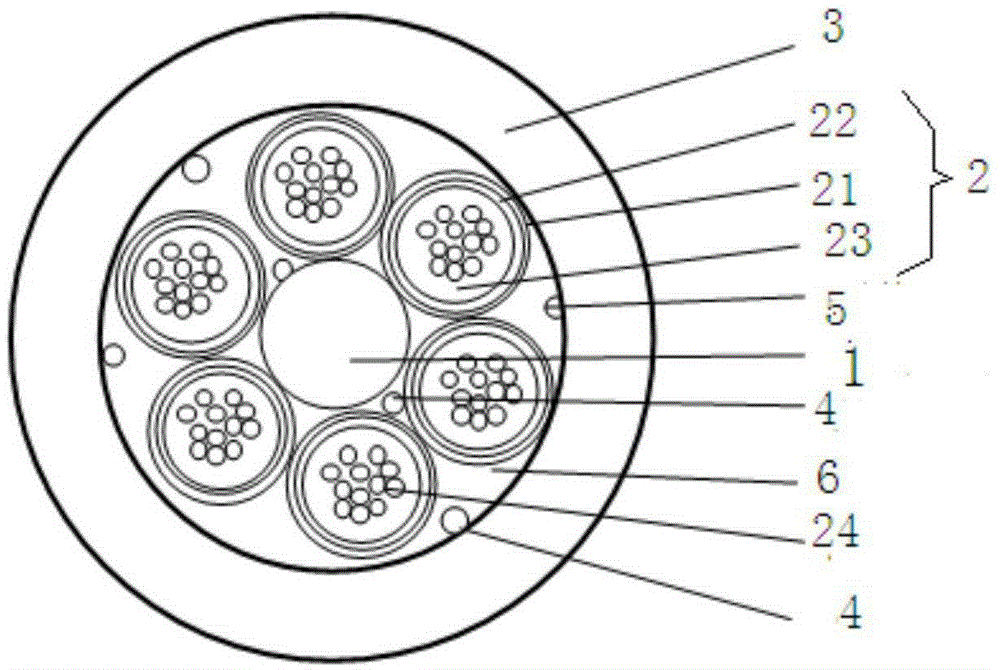

[0044] In embodiment 2, with the process method disclosed in embodiment 1, prepared a kind of micro air-blown optical cable, the structure of this optical cable is as follows figure 2 As shown in , it includes: a central reinforcement 1 arranged in the center, and the outer periphery of the central reinforcement 1 is covered with a number of loose tubes 2, and the loose tube 1 includes: a PBT outer layer 21, a PC inner layer 22 and a A plurality of optical fibers 24 covered by the PC inner layer 22 , and the water blocking material 23 in the loose tube is filled between the PC inner layer 22 and the optical fiber 24 , and the outer sheath 3 is coated on the outside of the plurality of loose tubes 2 .

[0045] The gap between the above-mentioned loose tube 2 and the outer sheath 3 is filled with cable paste 6, and the above-mentioned loose tube 2 and some water-blocking yarns 4 are twisted together by SZ twisting. A tearing rope 5 is arranged inside, and the tearing rope 5 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com