Novel fiber bundle central tube type optical cable

A central tube type, optical fiber bundle technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of easy dispersion of optical fiber ribbons, optical fiber attenuation of optical fiber ribbons, etc., and achieve the effects of light weight, high yield, and high fiber density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

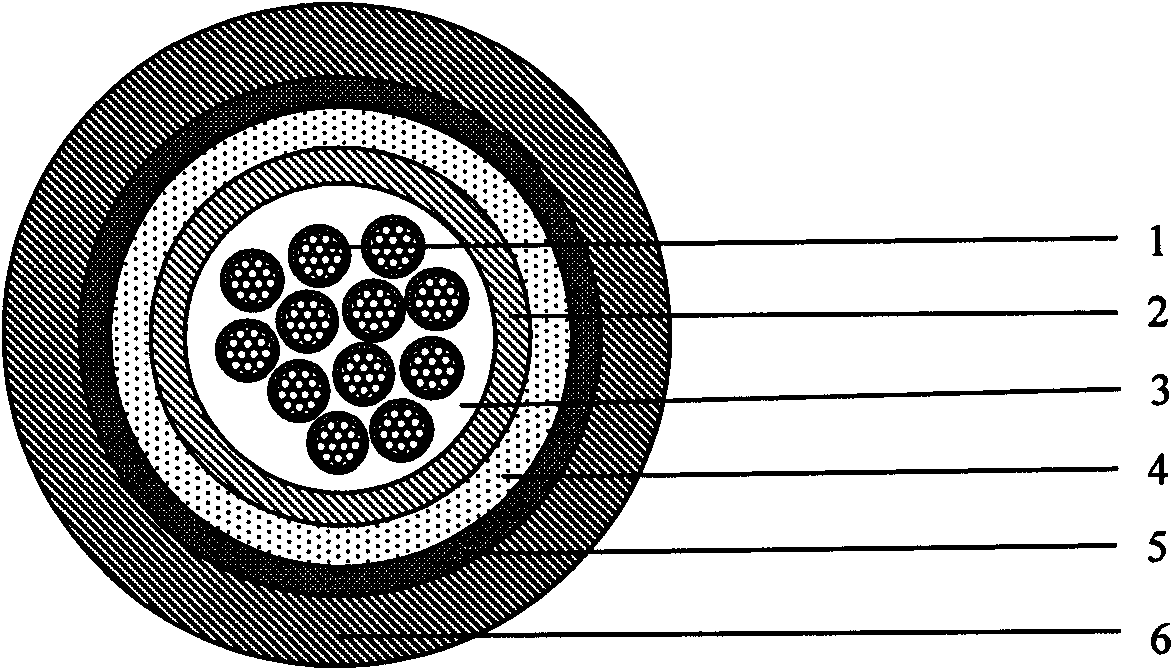

[0035] Such as figure 1 , 5 As shown, the invention includes optical fiber bundle 1, loose tube 2, water-blocking ointment 3, reinforcement 4, metal armor layer 5, outer sheath 6, and 12 fiber optics are produced by UV curing process to fill water-blocking ointment The optical fiber bundle 1 of 11 is placed in the loose tube. The optical fiber bundle 1 is circular in shape and includes 12 optical fibers 12 . The optical fiber bundle central tube type optical cable also includes a loose tube 2, the material of which is polybutylene terephthalate; water-blocking ointment 3, which is filled in the loose tube 2; reinforcement 4, which is aramid fiber ; The outer sheath 6 is made of polyethylene. There is a metal armor layer 5 between the reinforcement 4 and the outer sheath 6, which is an aluminum-plastic composite tape.

Embodiment 2

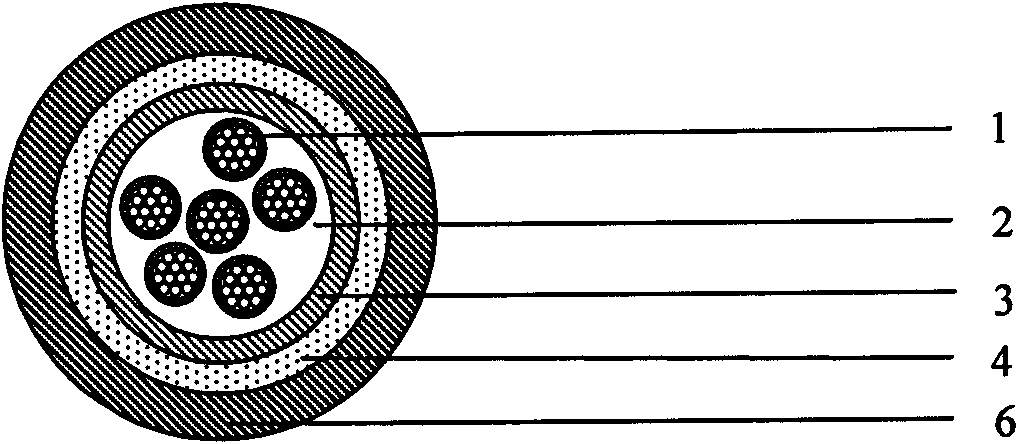

[0037] Such as figure 2 , 5 As shown, the invention includes an optical fiber bundle 1, a loose tube 2, a water-blocking ointment 3, a reinforcing member 4, an outer sheath 6, and 6 optical fiber bundles produced by an ultraviolet curing process for filling an optical fiber with a water-blocking ointment 11. in the loose tube. The optical fiber bundle 1 is circular in shape and includes 12 optical fibers 12 . The optical fiber bundle central tube type optical cable also includes a loose tube 2, the material of which is polycarbonate; water-blocking ointment 3, which is filled in the loose tube 2; reinforcement 4, which is glass fiber; outer sheath 6, which The material is low-smoke halogen-free plastic LSZH.

Embodiment 3

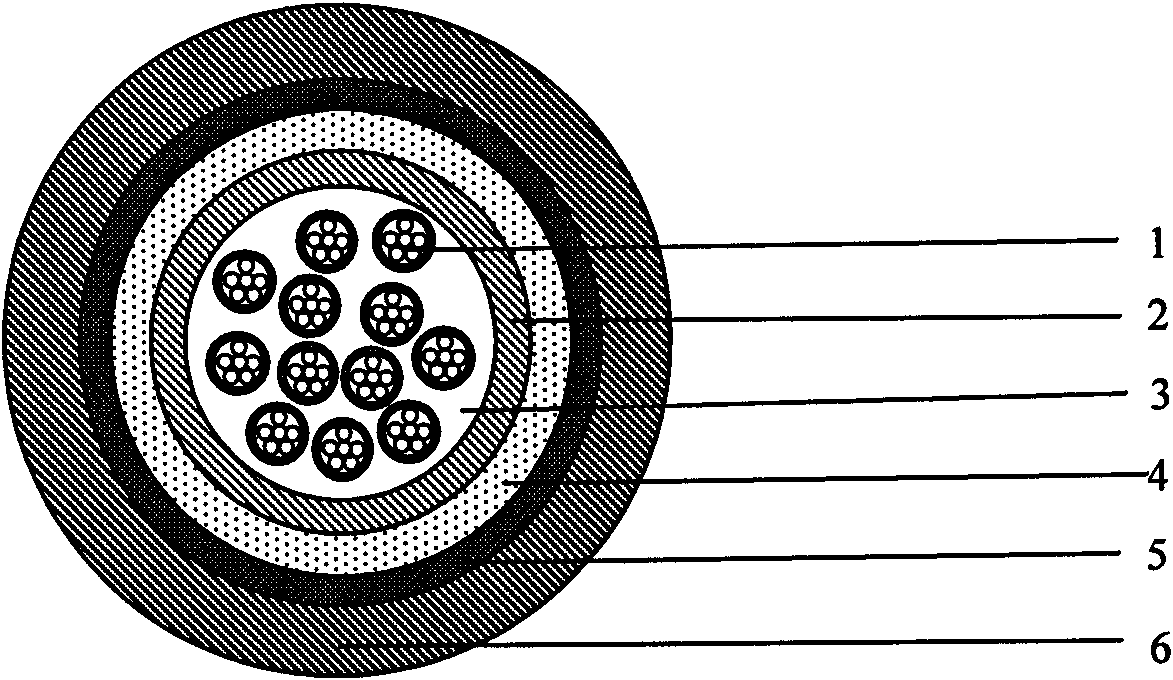

[0039] Such as image 3 , 6 As shown, the invention includes optical fiber bundle 1, loose tube 2, water-blocking ointment 3, reinforcement 4, metal armor layer 5, outer sheath 6, and 12 fiber optics are produced by UV curing process to fill water-blocking ointment The optical fiber bundle 1 of 11 is placed in the loose tube. The optical fiber bundle 1 is circular in shape and includes six optical fibers 12 . The optical fiber bundle central tube optical cable also includes a loose tube 2, which is made of polycarbonate; water-blocking ointment 3, which is filled in the loose tube 2; a reinforcement 4, which is aramid fiber; an outer sheath 6, Its material is polyurethane. There is a metal armor layer 5 between the reinforcement 4 and the outer sheath 6, which is a steel-plastic composite tape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com