Method for producing a pressure accumulator, and pressure accumulator

A pressure vessel and overpressure technology, which is applied to the pressure vessel, the outer wall of the vessel structure, the installation device of the vessel structure, etc., can solve the problems of high mechanical load, reduce the mechanical load, increase the volume of the vessel, and save reinforcement materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

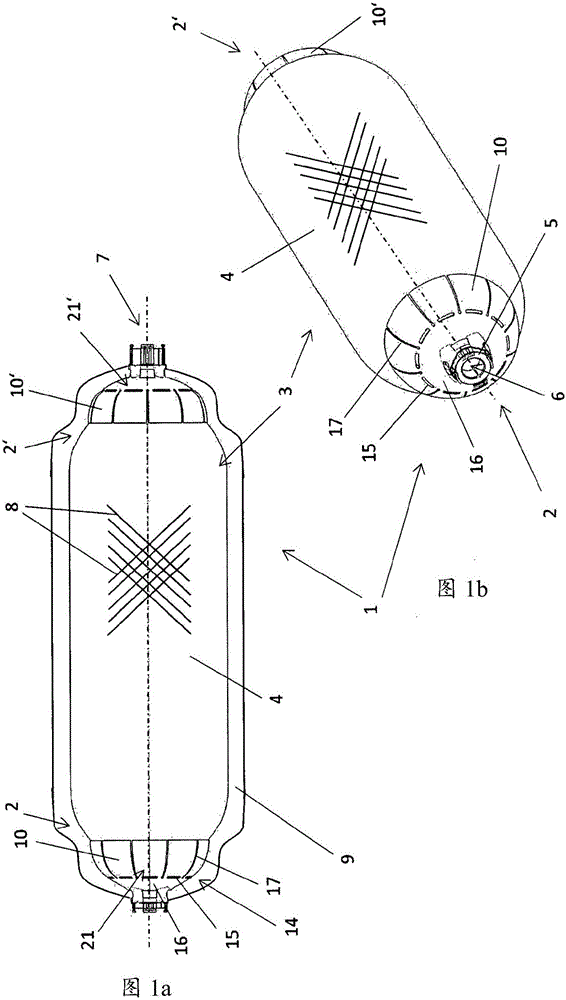

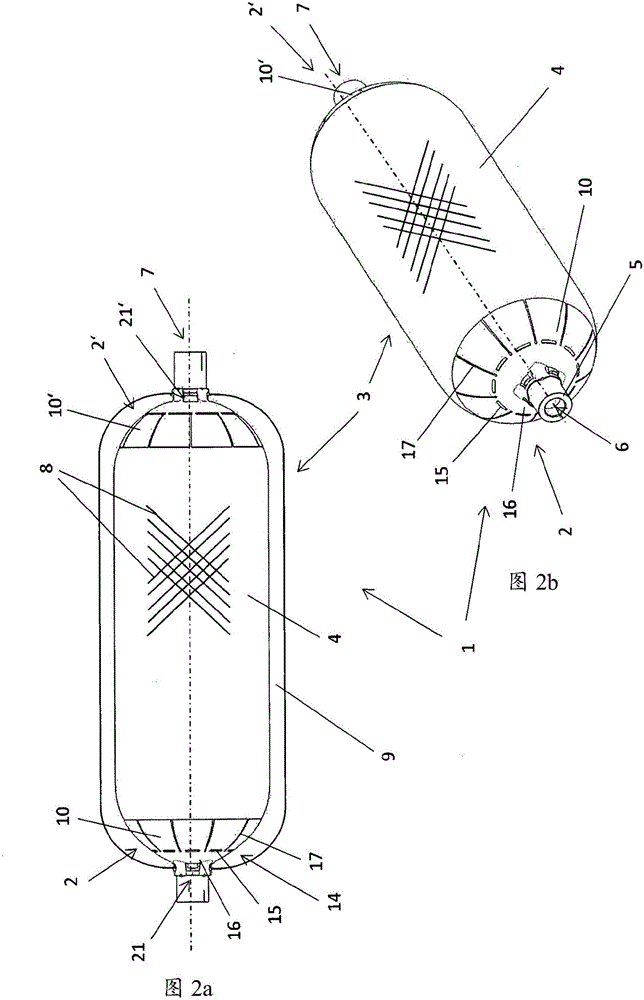

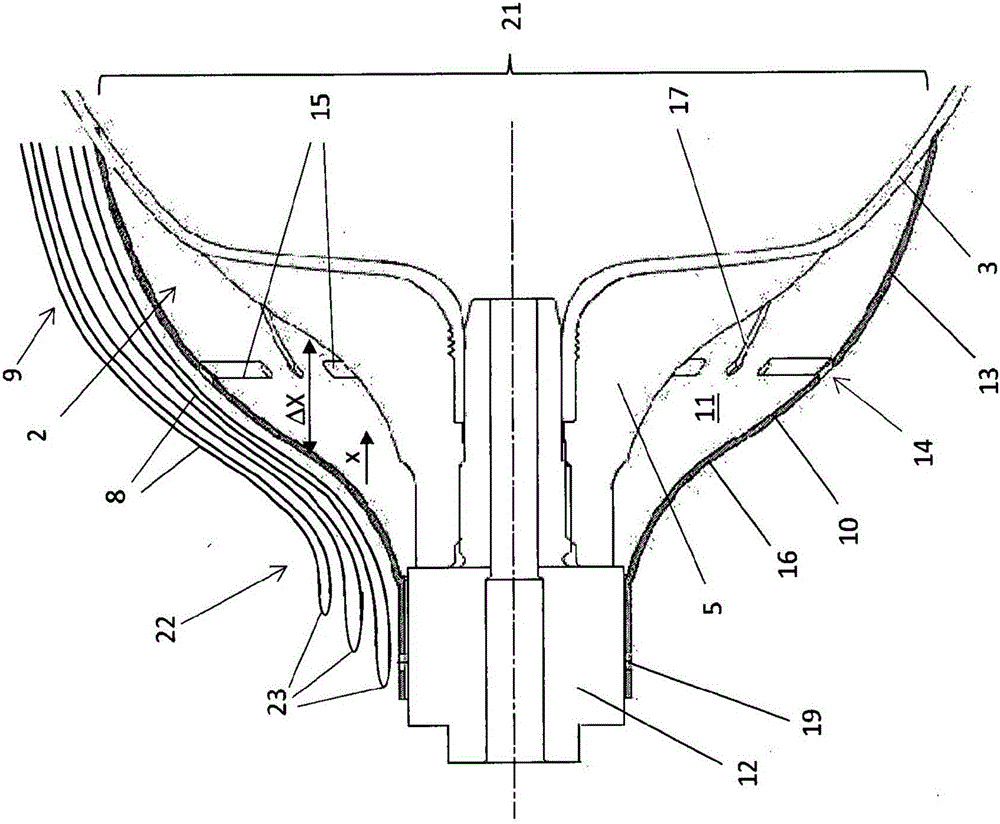

[0020] Figure 1a , 1b as well as Figure 2a , 2b A pressure vessel 1 for storing hydrogen in a motor vehicle is shown. The pressure vessel 1 has an inner liner 3 made of plastic comprising two end caps 2, 2', which has a cylindrical middle section 4. On this intermediate section 4 two end caps 2, 2' are molded on the ends. The end cap 2 of the pressure vessel 1 additionally comprises a pipe connection 5 , also referred to as a head, with an opening 6 for filling or venting hydrogen. The end caps 2' provided on the opposite ends of the pressure vessel 1 additionally comprise so-called blind heads 7, which are only used for mounting the pressure vessel 1 in a vehicle. A braided multilayer reinforcement layer 9 with reinforcement fibers 8 is applied to the inner lining 3 on the outside. In this embodiment the reinforcing fibers 8 are formed as carbon fibers and for the sake of clarity are Figures 1a-2b are only shown individually. Likewise, for a better understandin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com