Nonwoven fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

2. First Embodiment

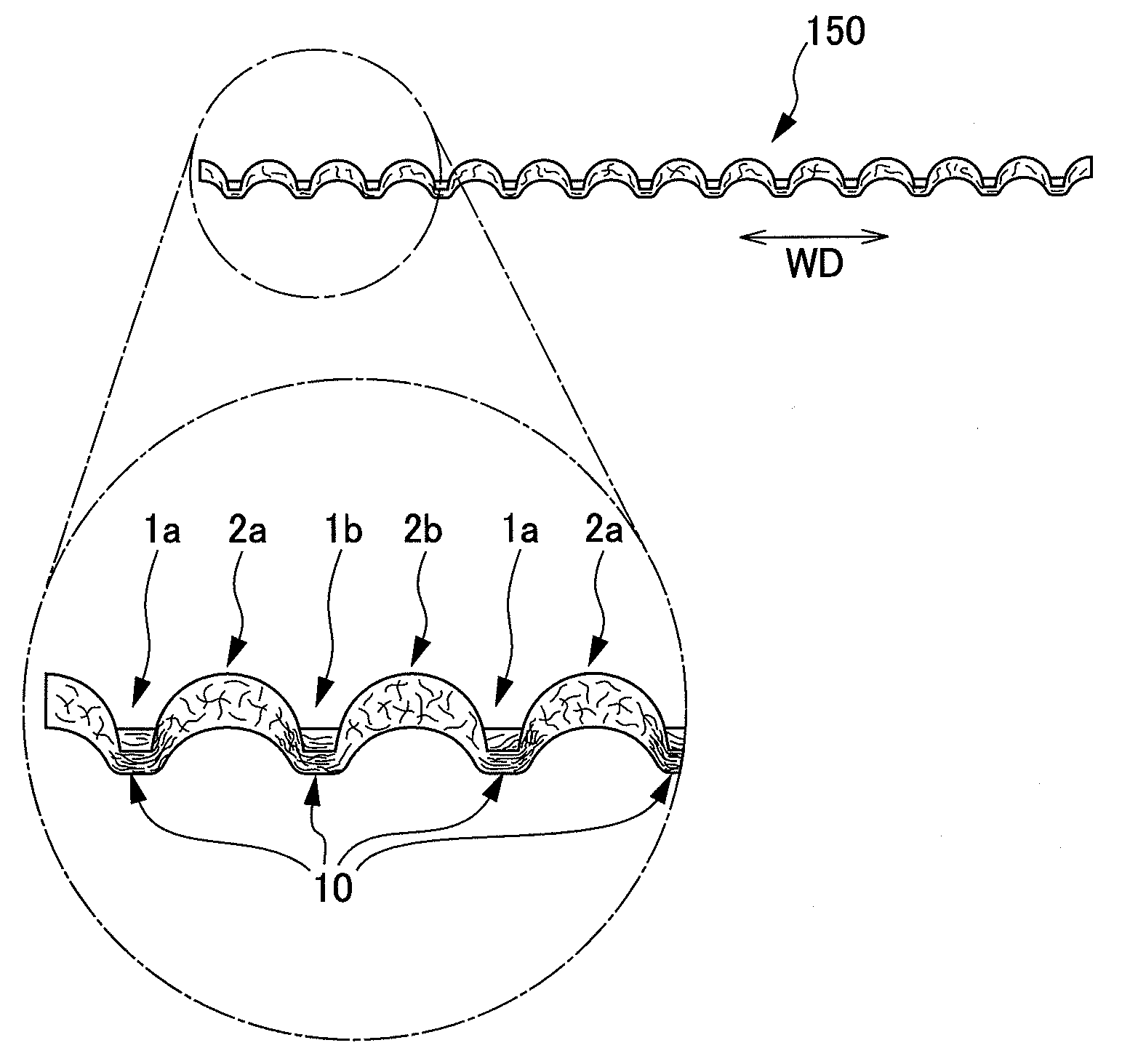

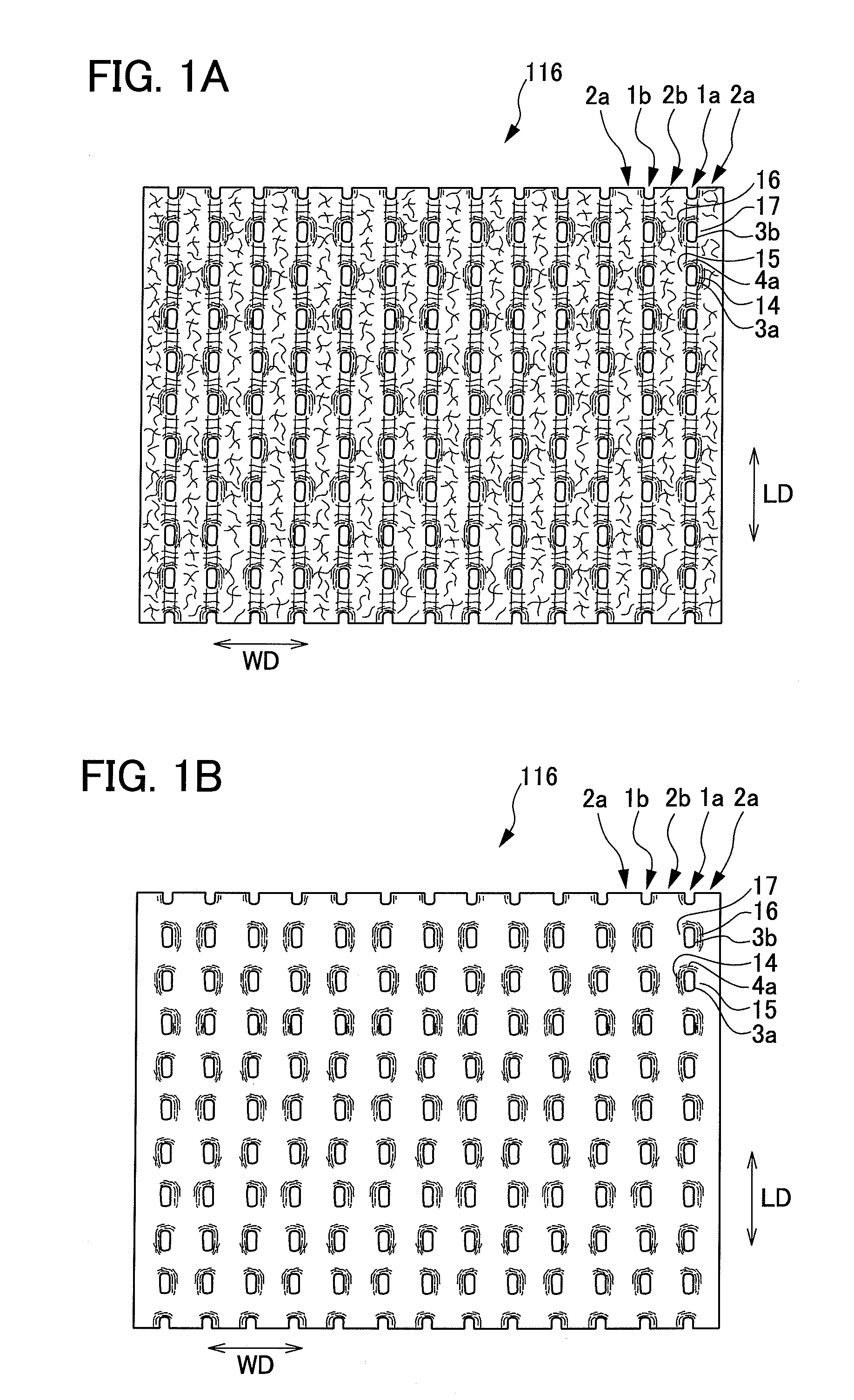

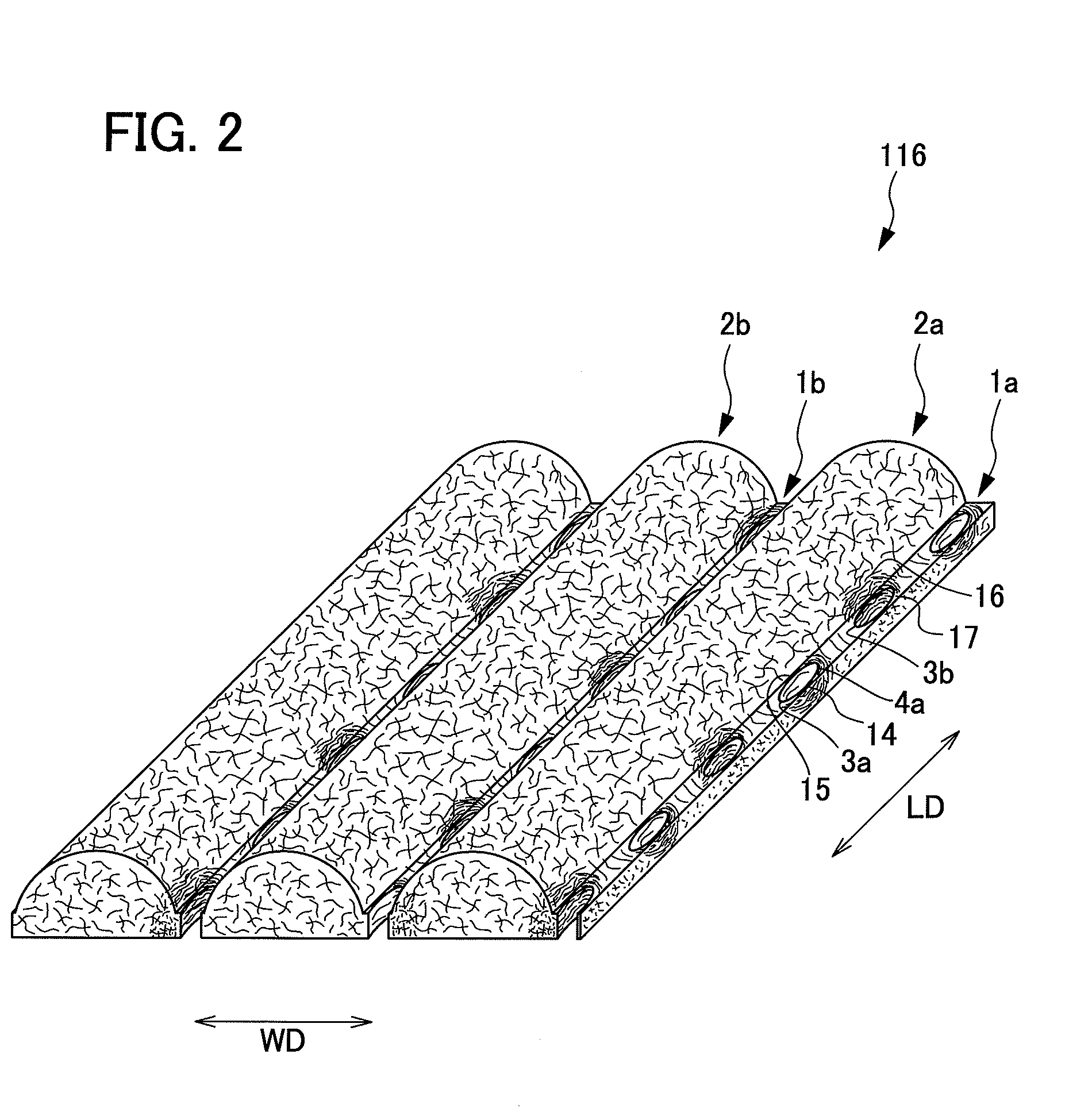

[0050]A first embodiment in the nonwoven fabric of the present invention will be described with reference to FIG. 1A to 4.

[0051]In the following, groove portions 1a and 1b are examples of a groove portion 1, as shown in FIGS. 1A and 1B and FIG. 2. Raised ridge portions 2a and 2b are examples of a raised ridge portion 2 as a convex portion. A Second opening 3b adjacent to a predetermined first opening 3a in the longitudinal direction (LD) being the machine direction (hereinafter in some cases, the first openings 3a and 3b are referred to simply as the openings 3a and 3b) are examples of a plurality of openings 3.

1-1. Shape

[0052]As shown in FIGS. 1A, 1B, or FIG. 2, a nonwoven fabric 116 in the first embodiment is a nonwoven fabric where the groove portions 1a and 1b are used as a unit, and a plurality of units are arranged side by side. The groove portions 1a and 1b are examples of a groove portion 1 as a concave portion. That is, the nonwoven fabric 116 has on one ...

second embodiment

3-1. Second Embodiment

[0143]The second embodiment in the nonwoven fabric of the present invention will be described with reference to FIGS. 9A and 9B and FIG. 10.

3-1-1. Nonwoven Fabric

[0144]As shown in FIGS. 9A, 9B, and 10, a nonwoven fabric 140 in the second embodiment is different from the first embodiment in having a second connecting part 4b formed between a third opening 3c adjacent to a first opening 3a on the opposite side of a second opening 3b adjacent to a first opening 3a. The nonwoven fabric 140 is also different from the first embodiment in that one side edge portion 16 in the second opening 3b, a first connecting part 4a, one side edge portion 14 in the opening 3a, the second connecting part 4b, the third opening 3c, and one side edge portion 18 in the third opening 3c are continued in a zigzag pattern. The nonwoven fabric 140 is identical with the first embodiment in groove portions 1a and 1b, the raised ridge portions 2a and 2b, the openings 3a and 3b, one side edge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com