Patents

Literature

33results about How to "Complex geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation curable resin composition and rapid three dimensional imaging process using the same

ActiveUS20100304088A1High modulusImprove toughnessAdditive manufacturing apparatusOrganic chemistryPolymer scienceIonic polymerization

The invention relates to a radiation curable resin composition comprising a cationically polymerizable component, a cationic photoinitiator, a hydroxy component, an impact modifier and wherein the resin composition after full cure has a modulus of >2 GPa; a yield stress<70 MPa; and a K1c value>1.3 MPa. (m)1 / 2 or an Izod value>0.45 J / cm. The resin composition can preferably be used in the preparation of three dimensional objects.

Owner:STRATSYS INC

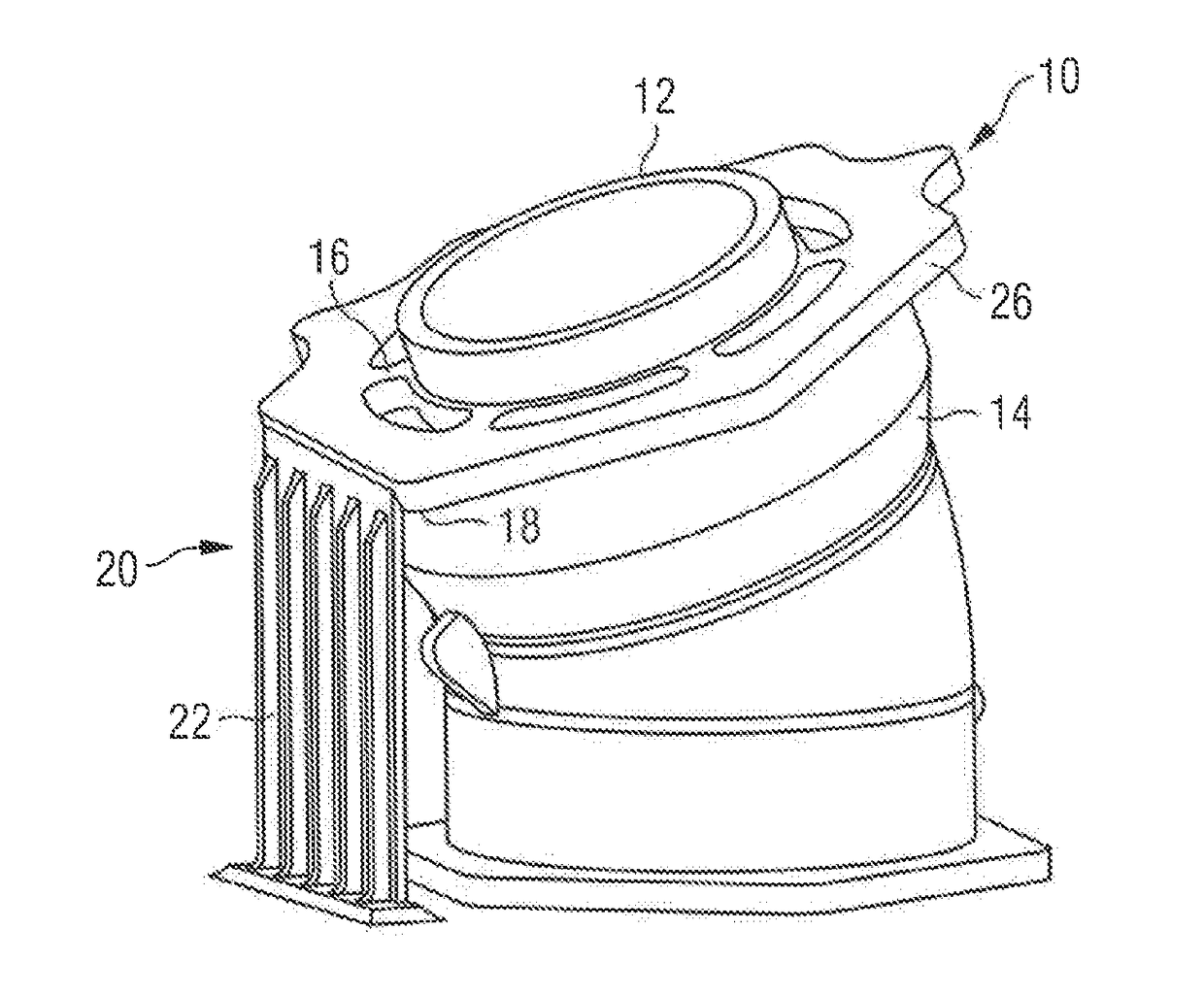

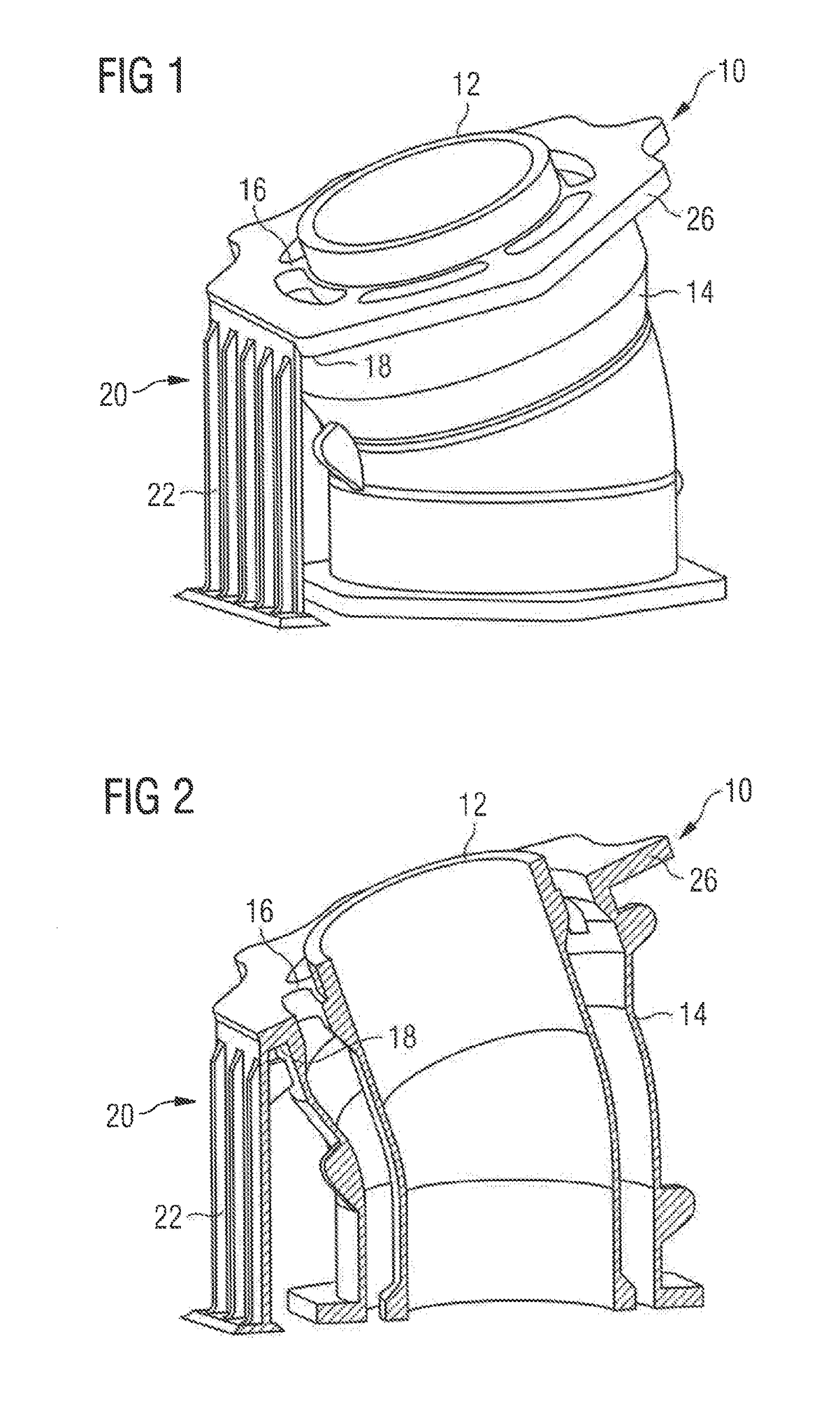

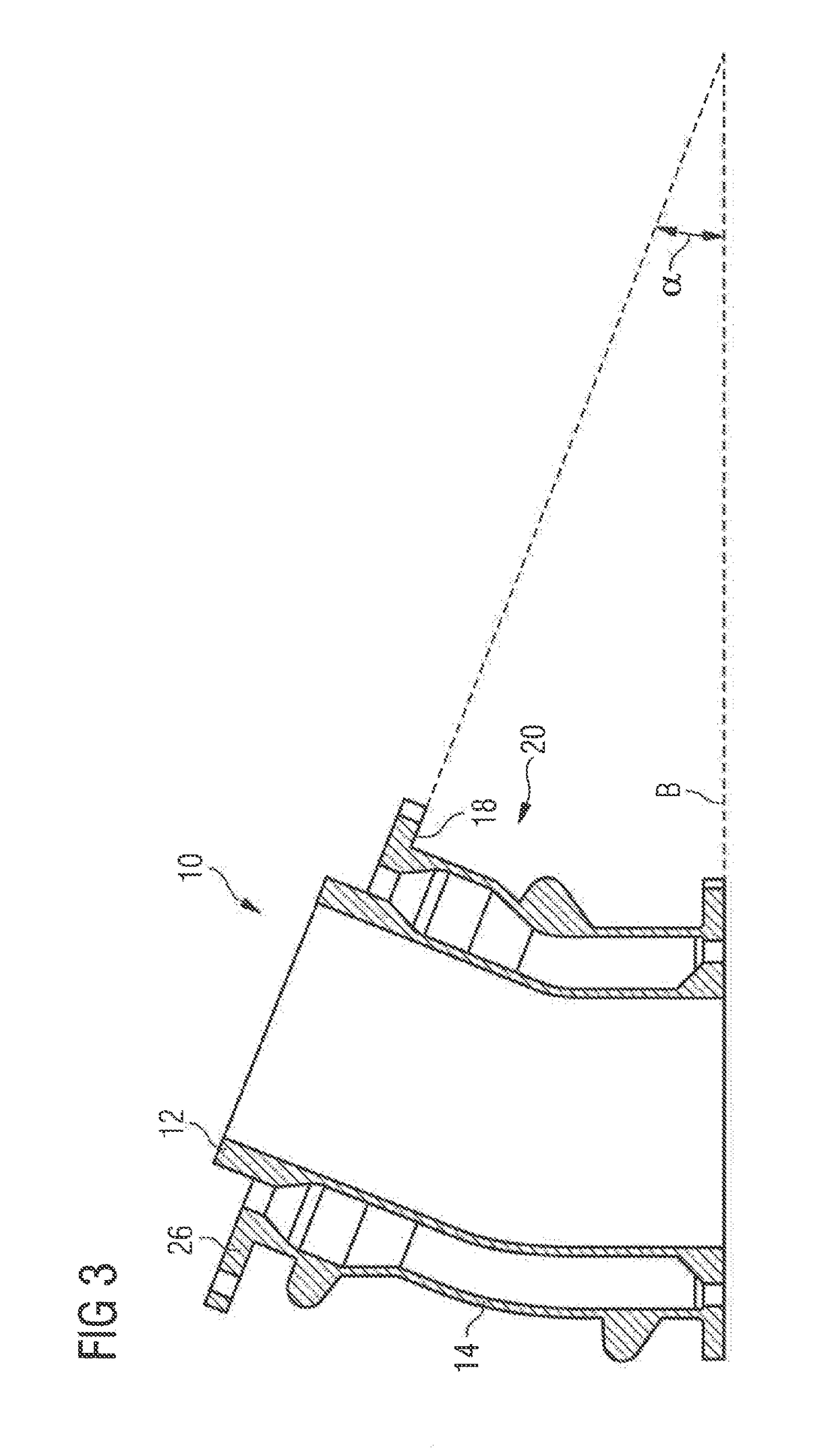

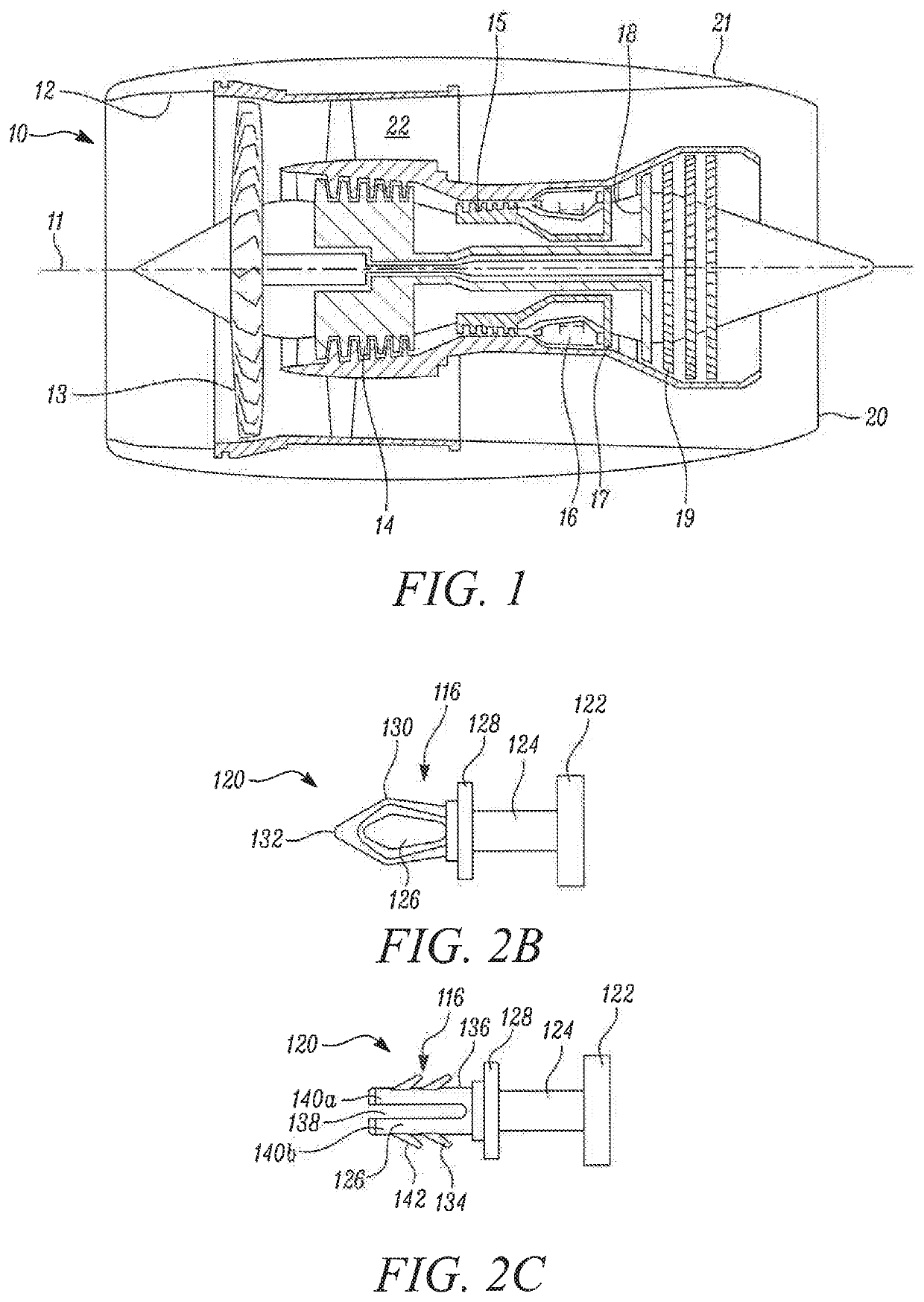

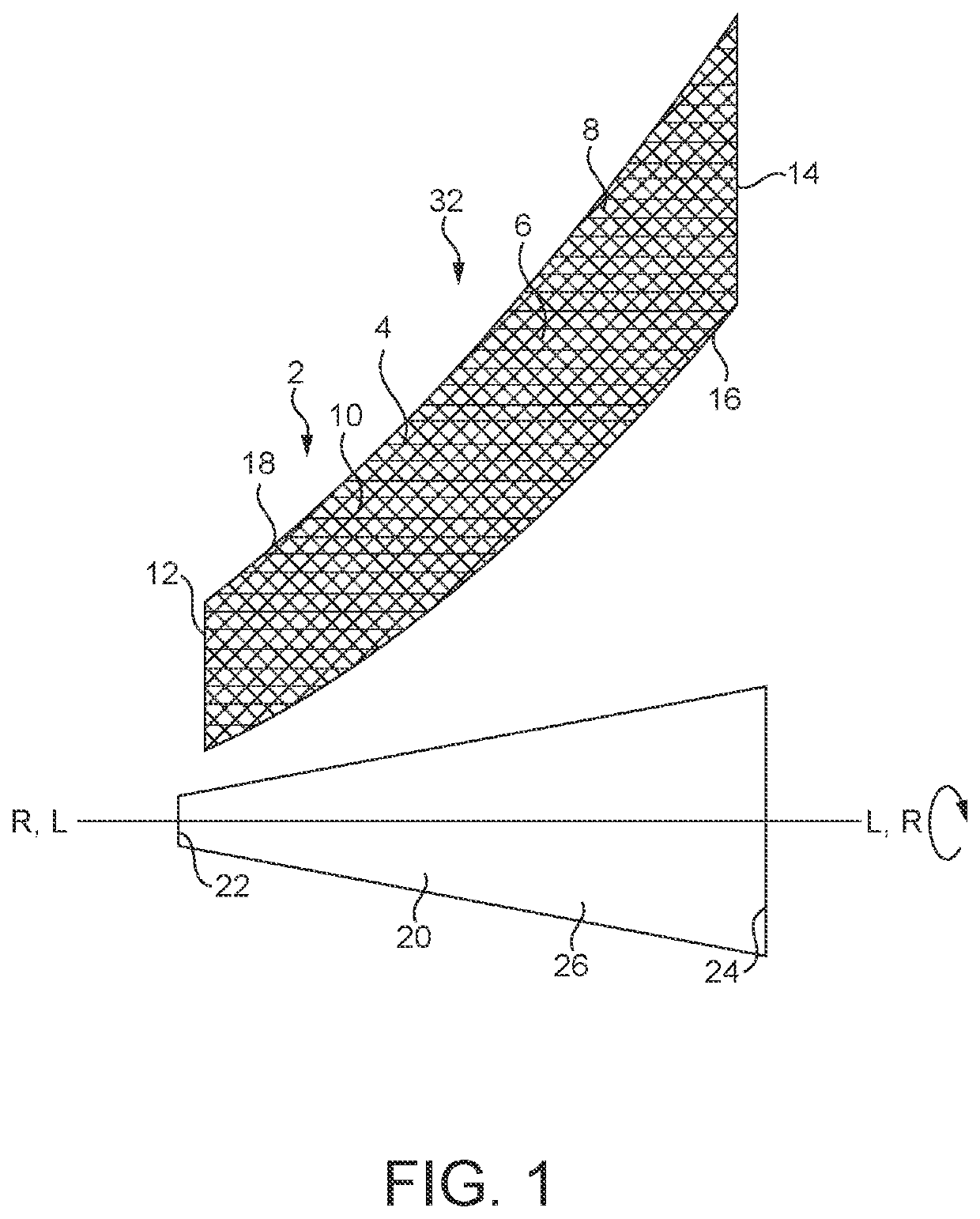

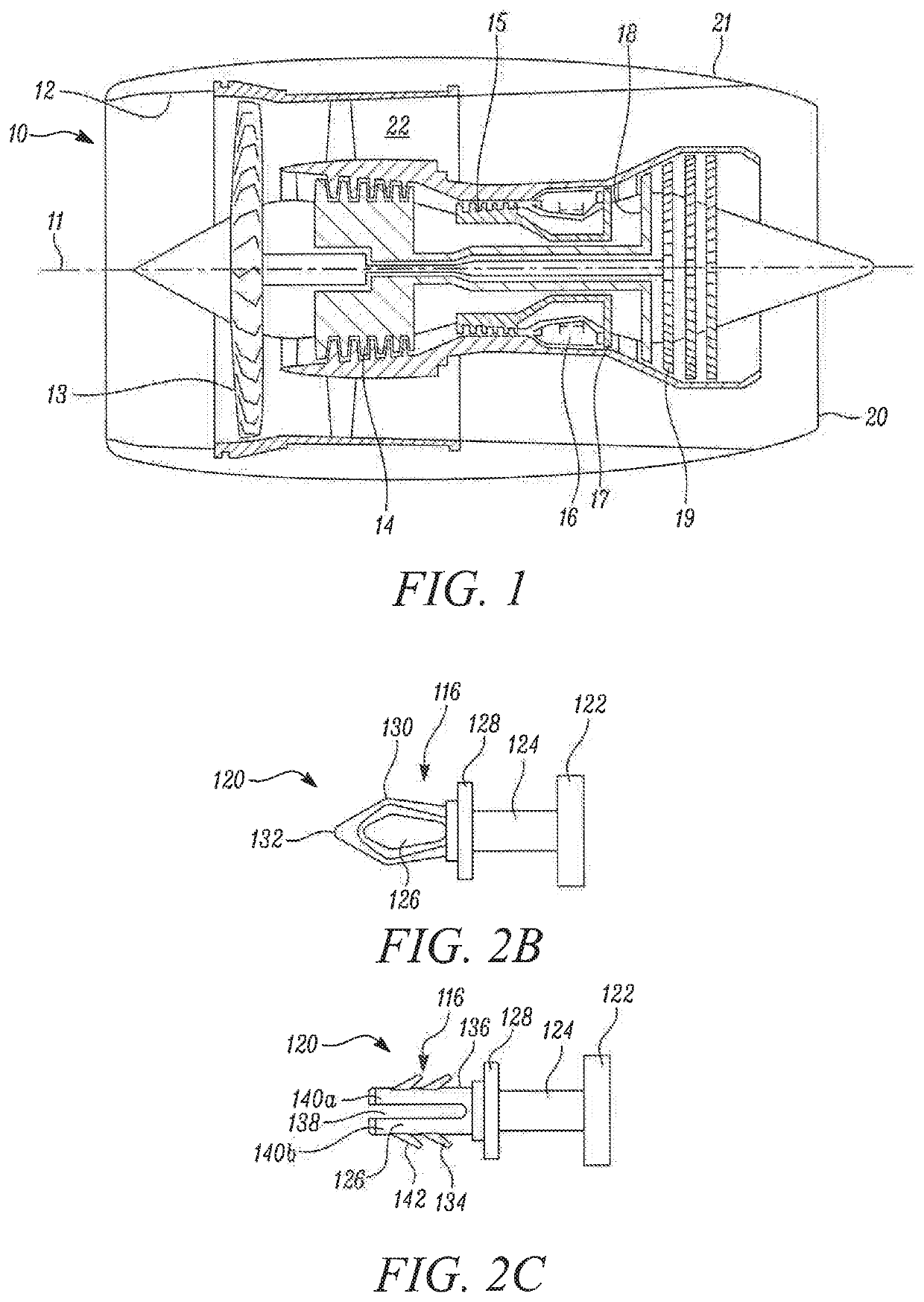

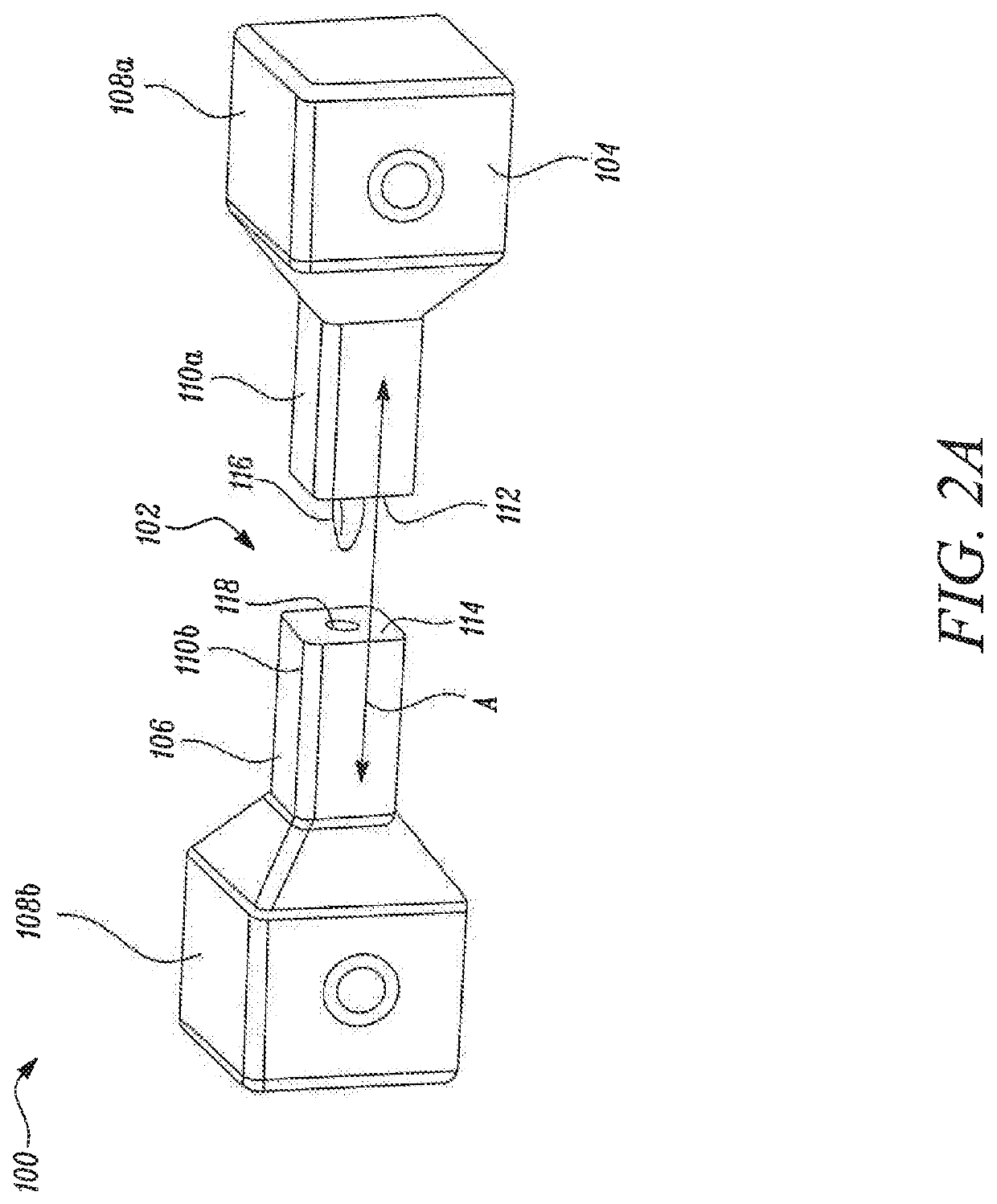

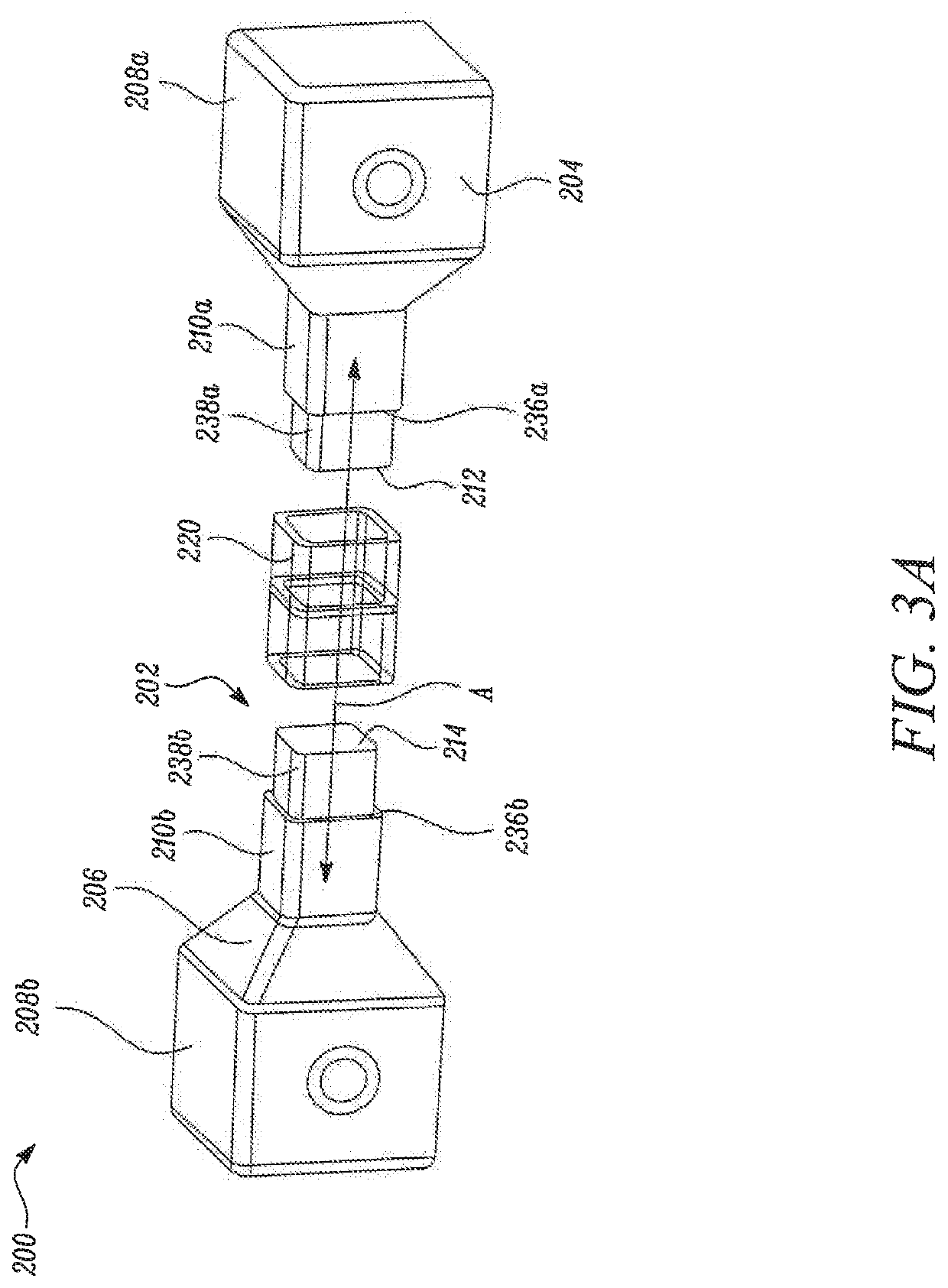

Secondary structures for aircraft engines and processes therefor

InactiveUS20130323473A1Low costMinimizes weightLiquid surface applicatorsAdditive manufacturing apparatusPolymer substrateThree dimensional shape

Processes for fabricating secondary structures of gas turbine engines from polymer-based materials, and secondary structures formed thereby. The processes entail performing an additive manufacturing technique to produce a secondary structure of a gas turbine engine. The additive manufacturing technique directly produces the secondary structure from a polymer-based material to have a complex three-dimensional shape characterized by portions that lie in different planes.

Owner:GENERAL ELECTRIC CO

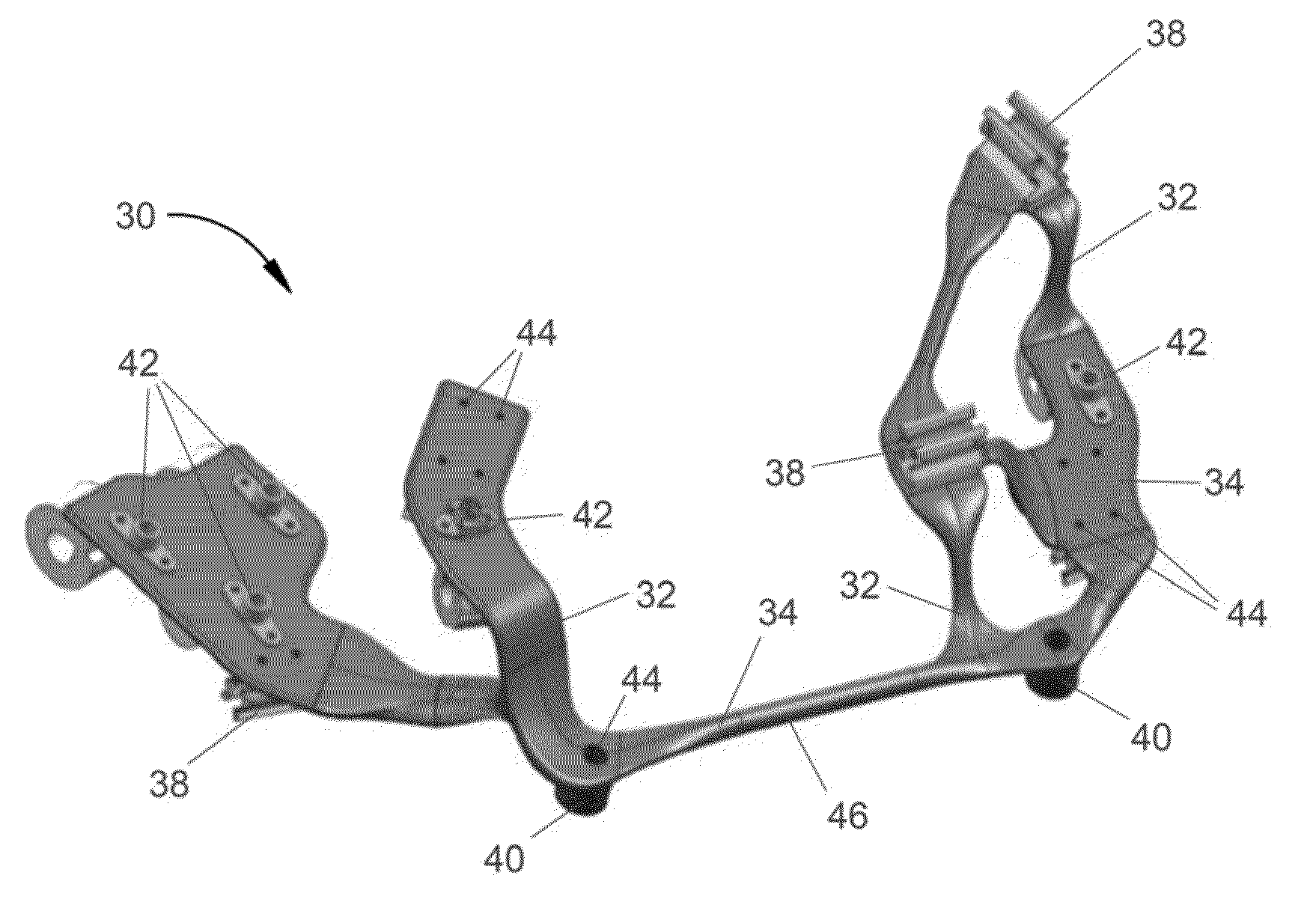

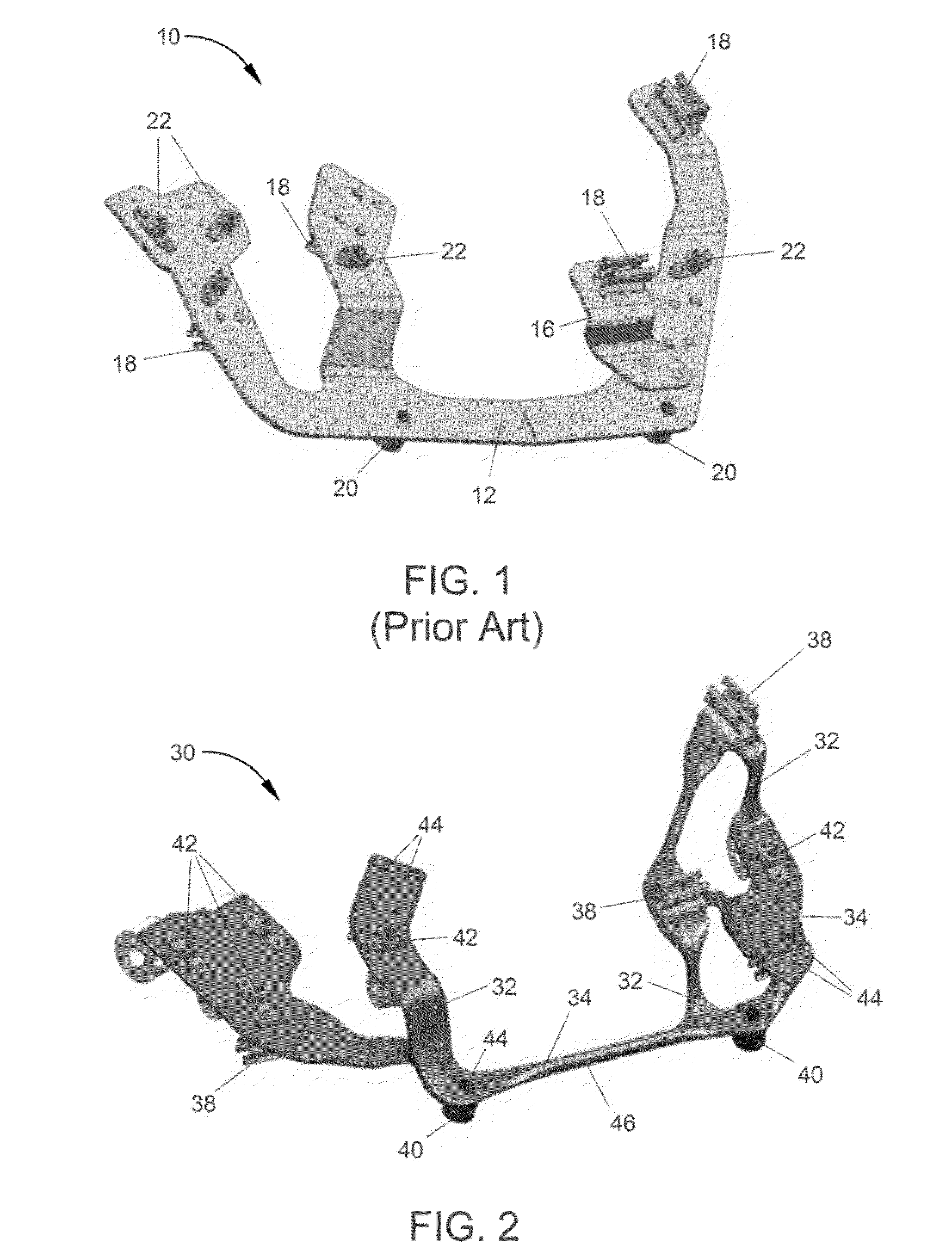

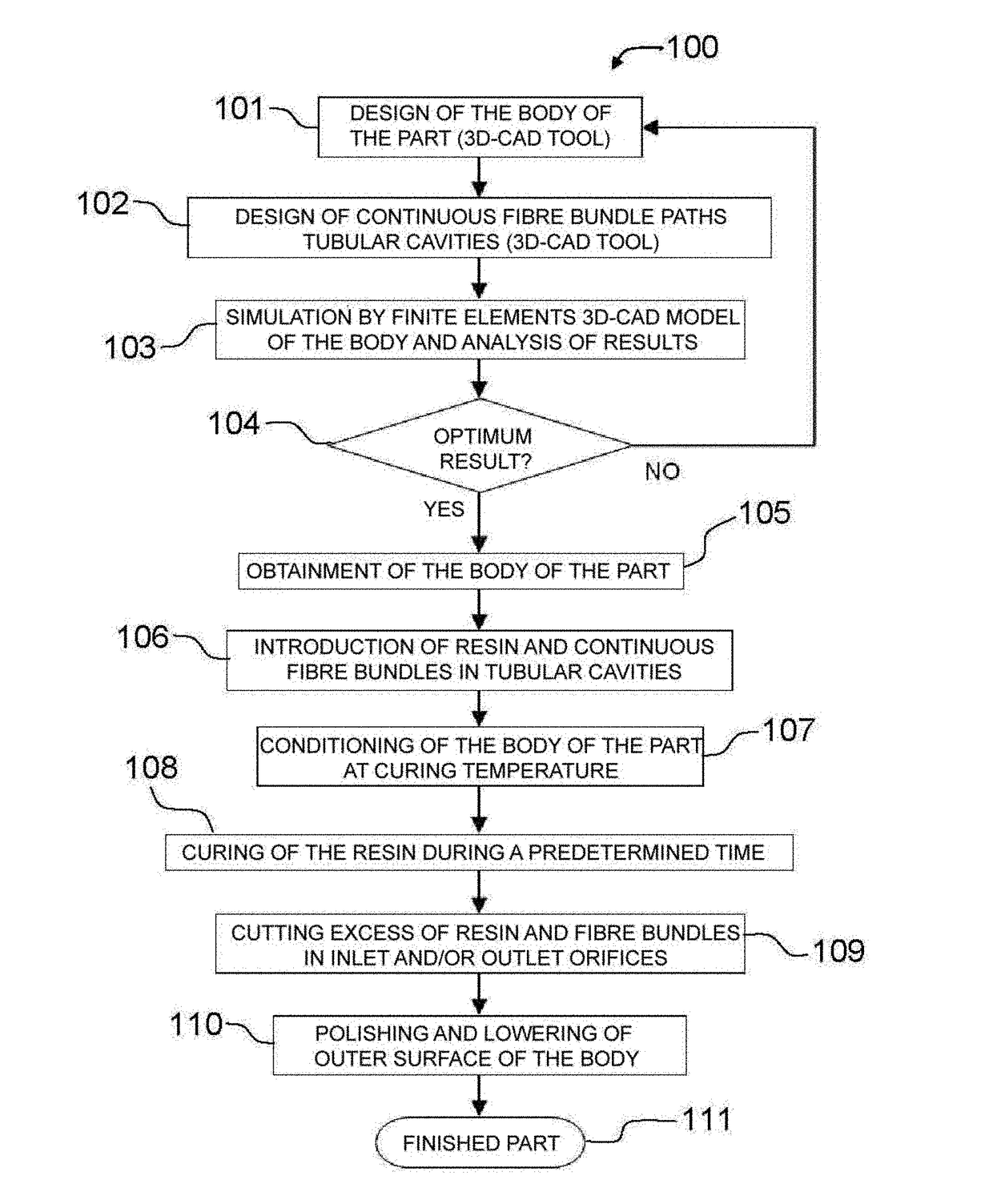

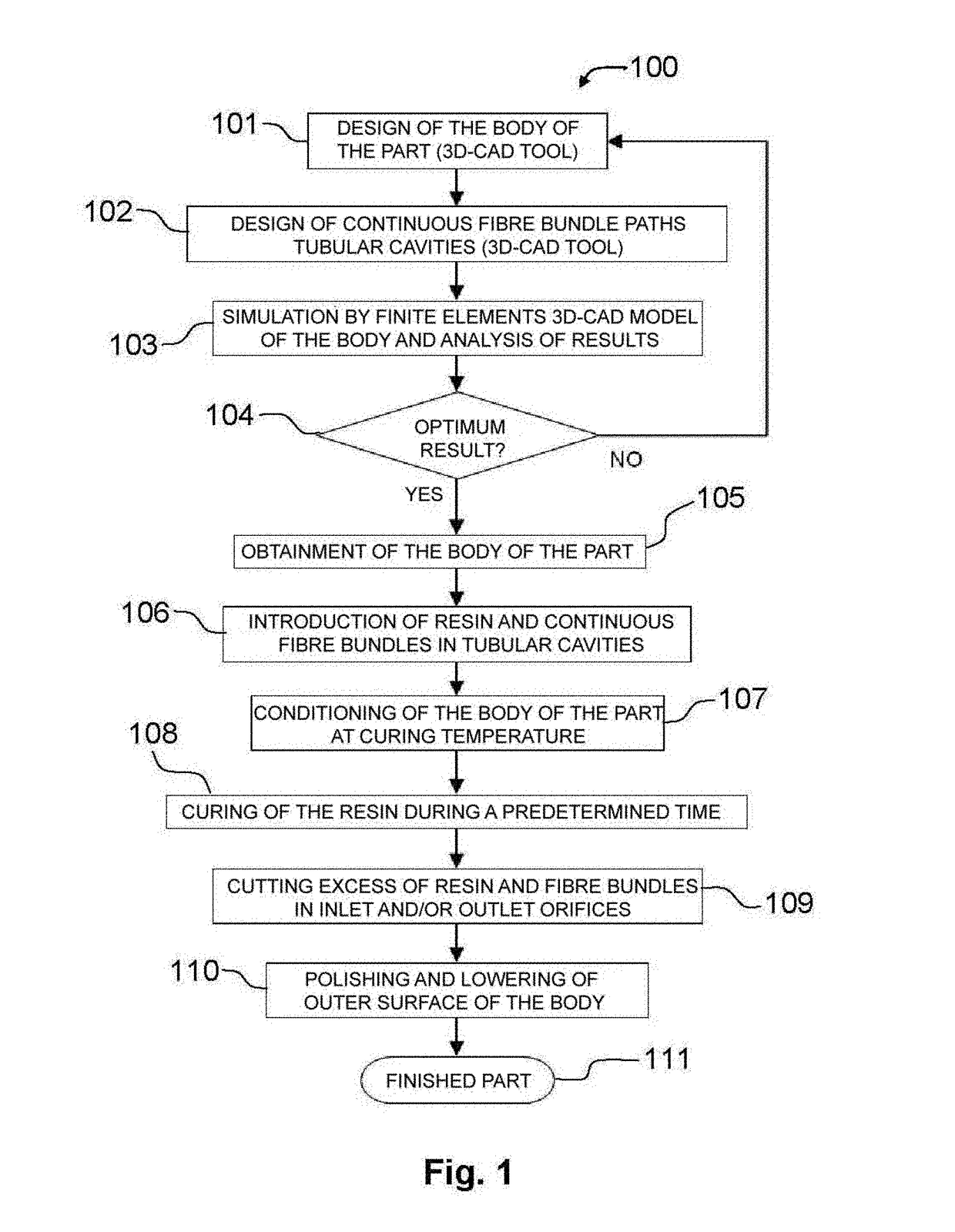

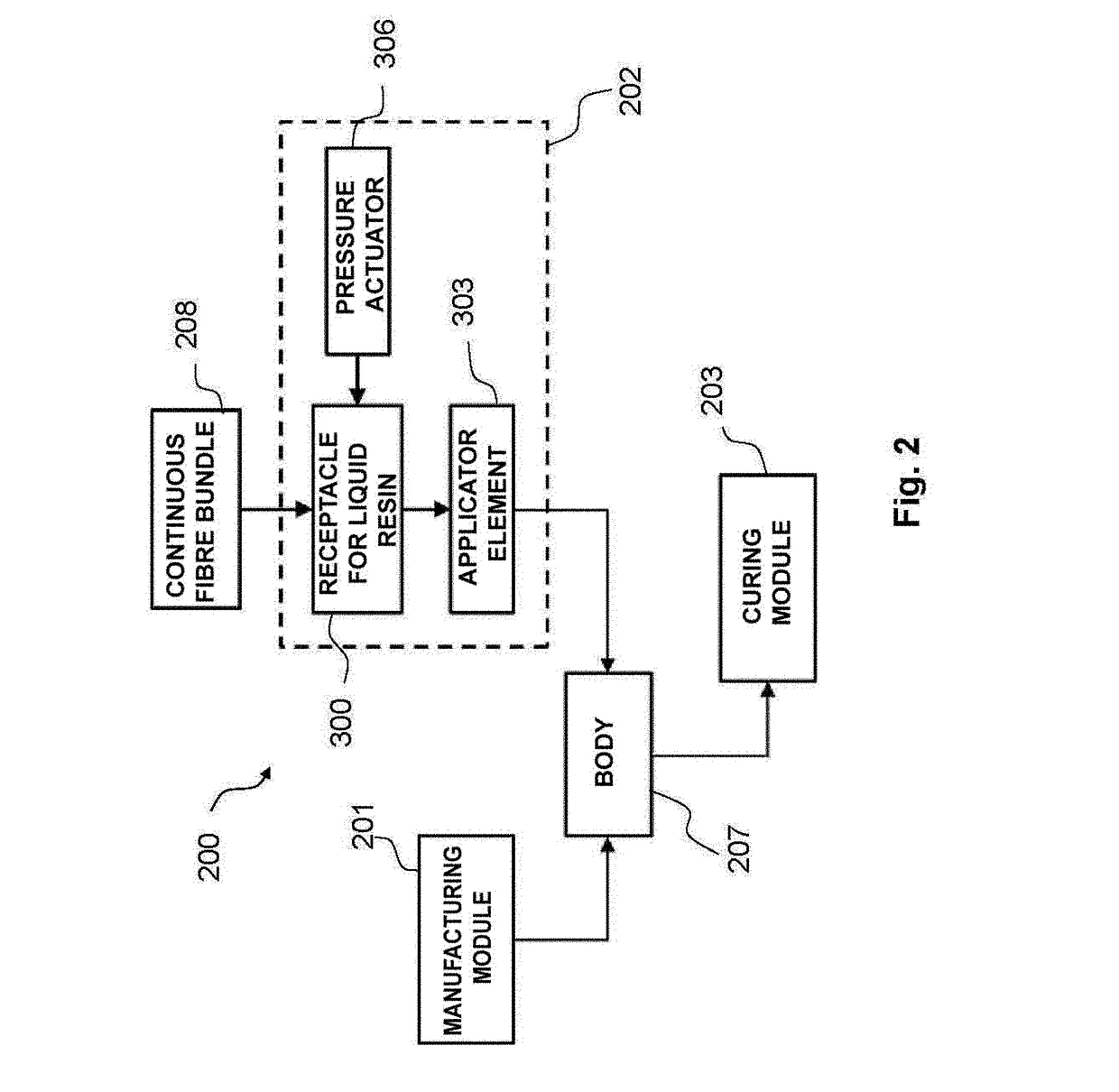

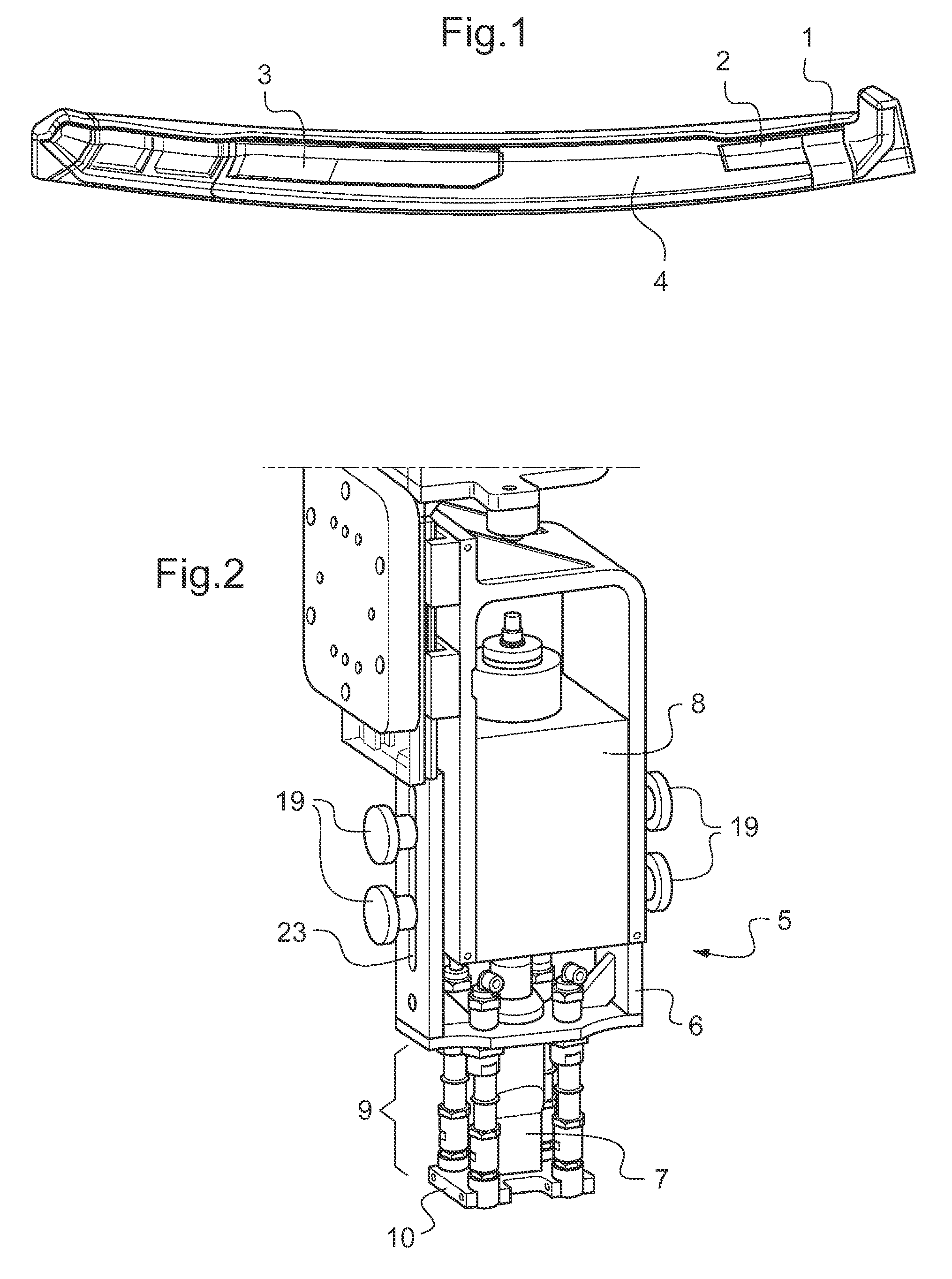

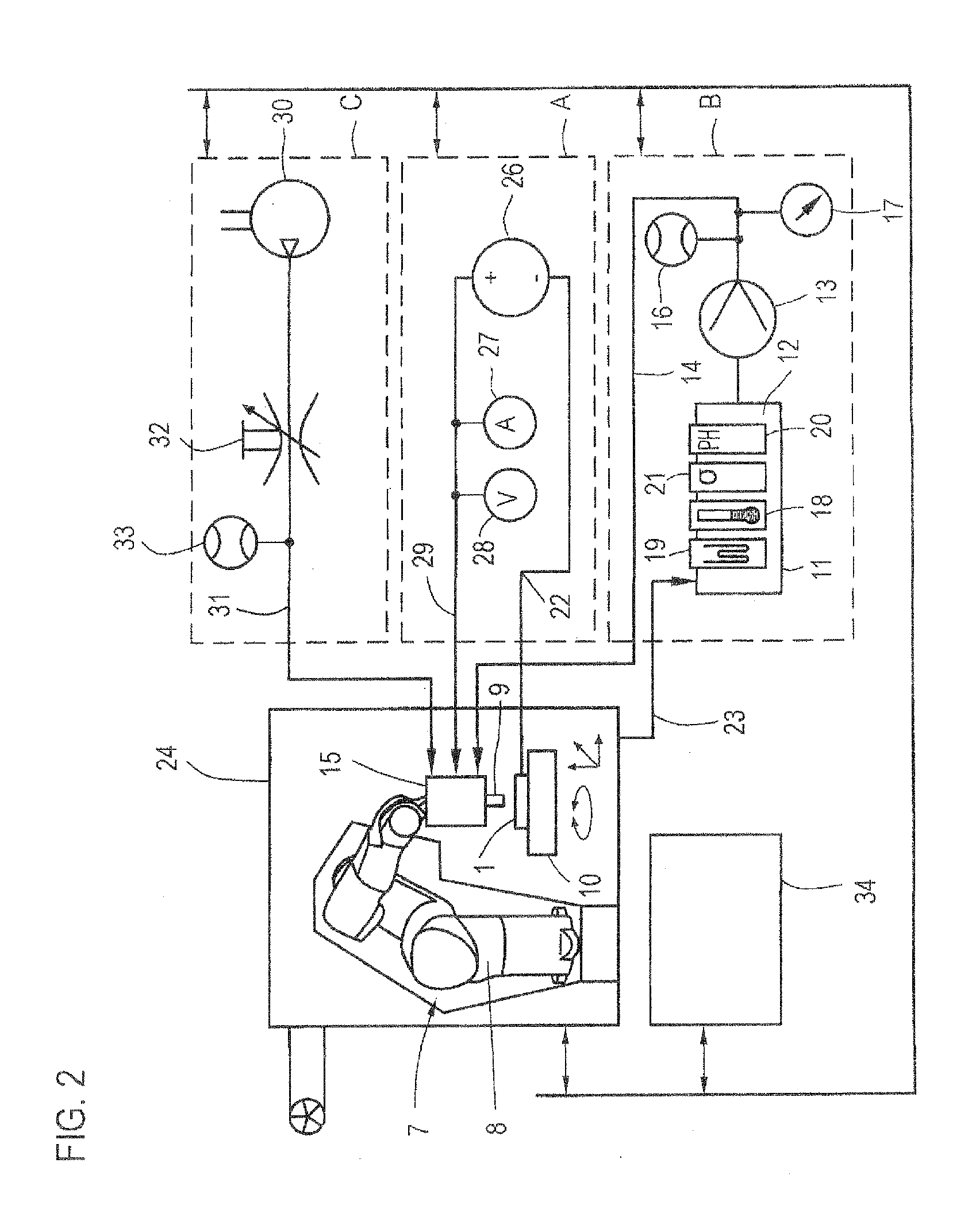

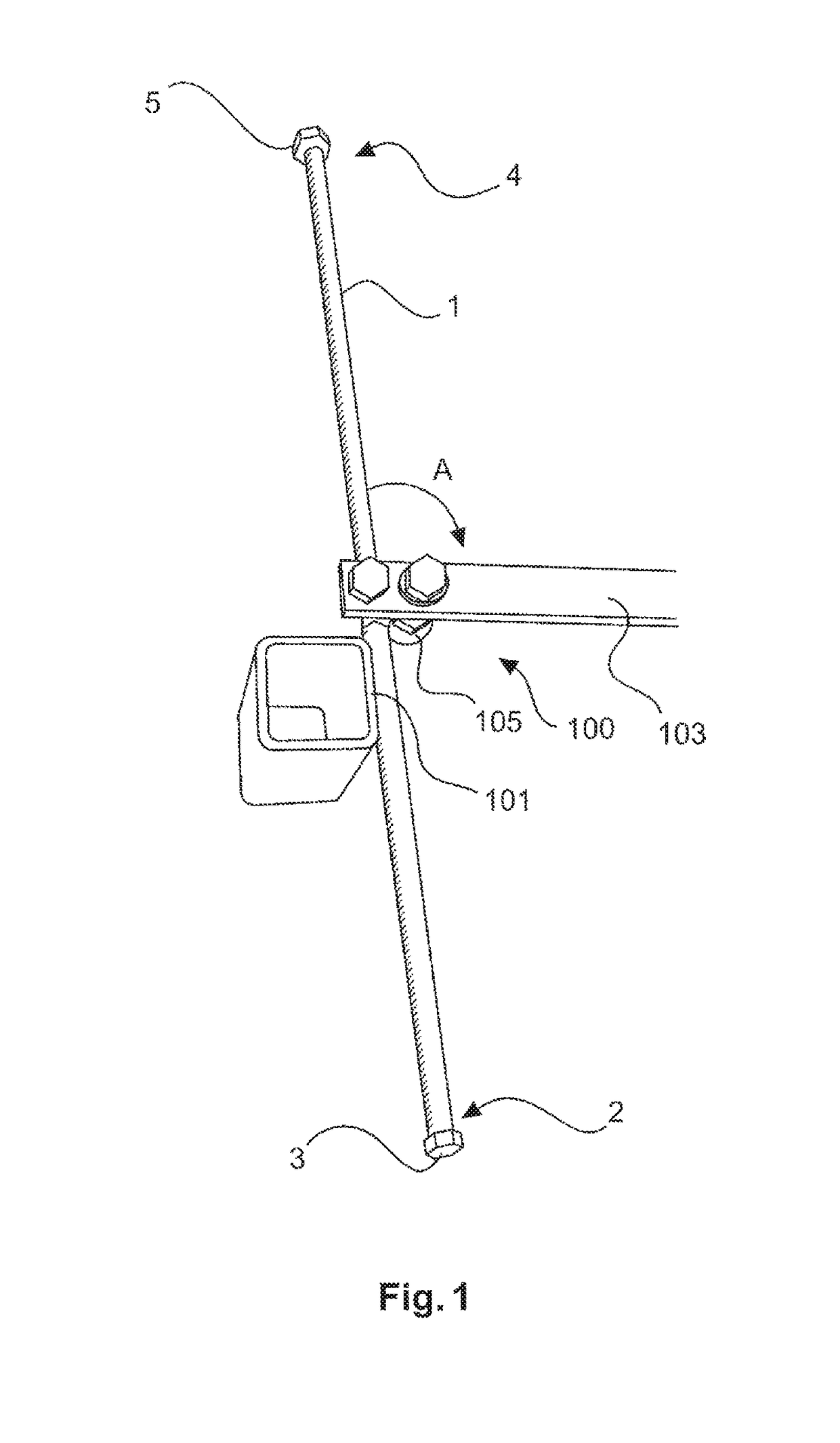

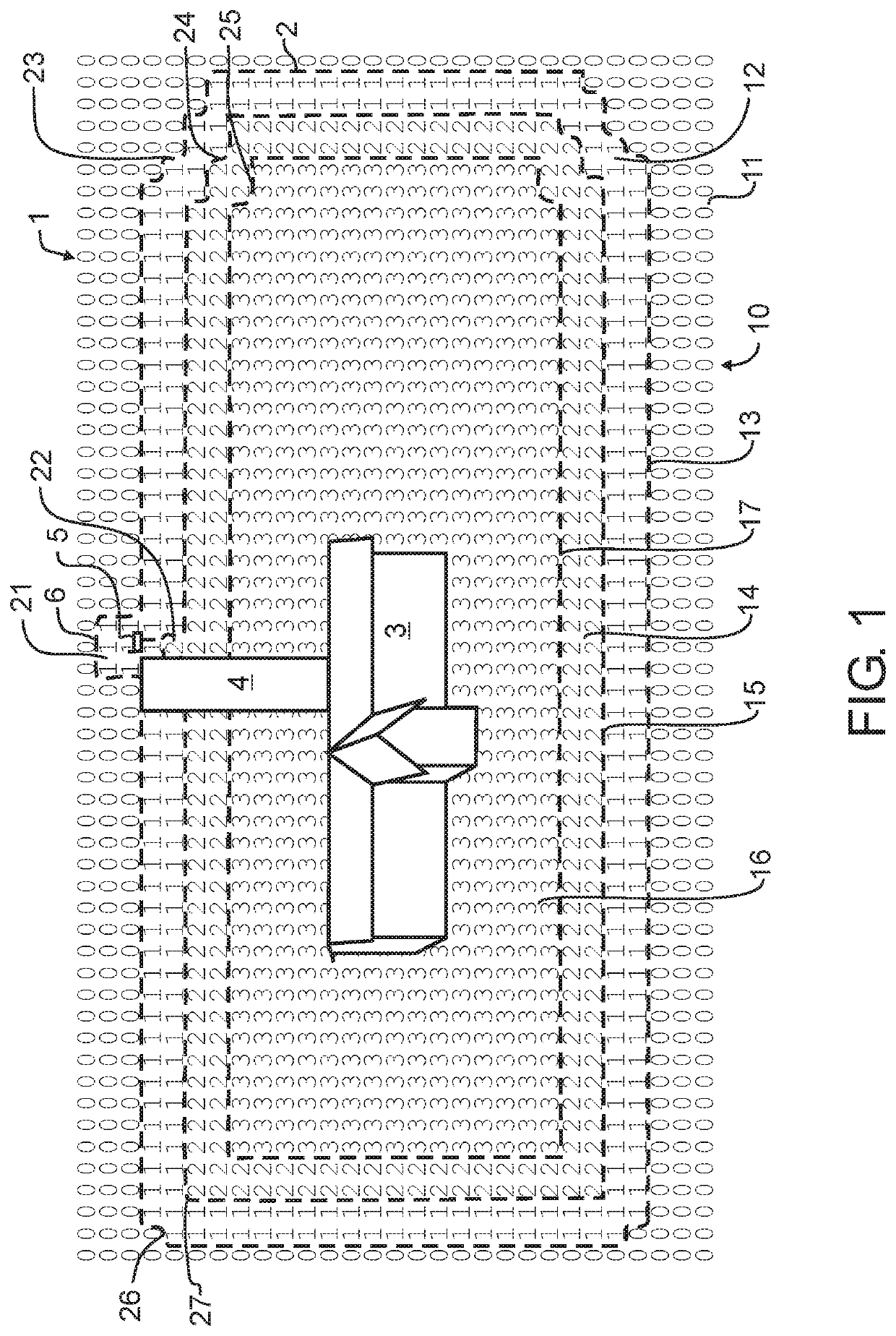

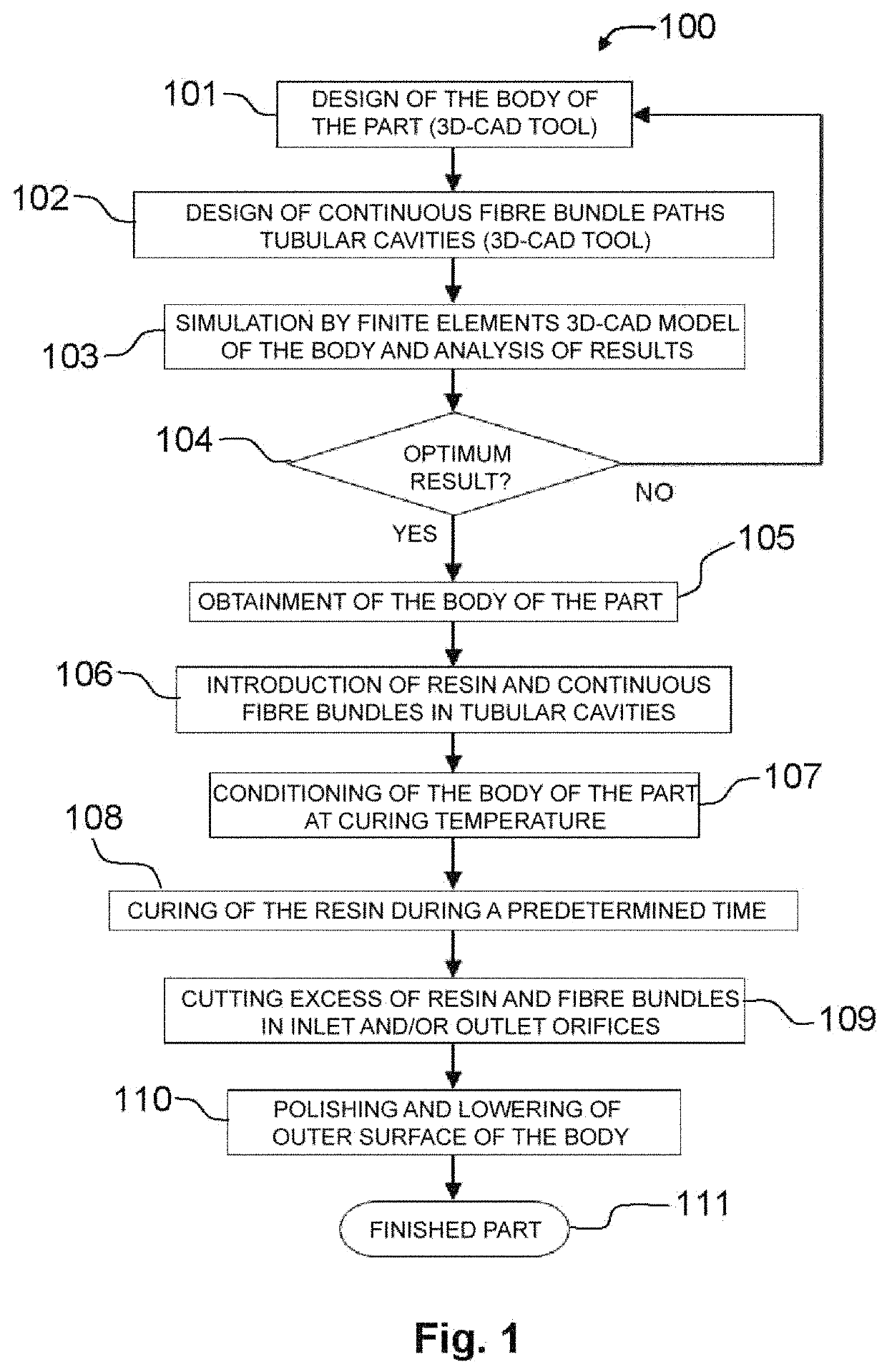

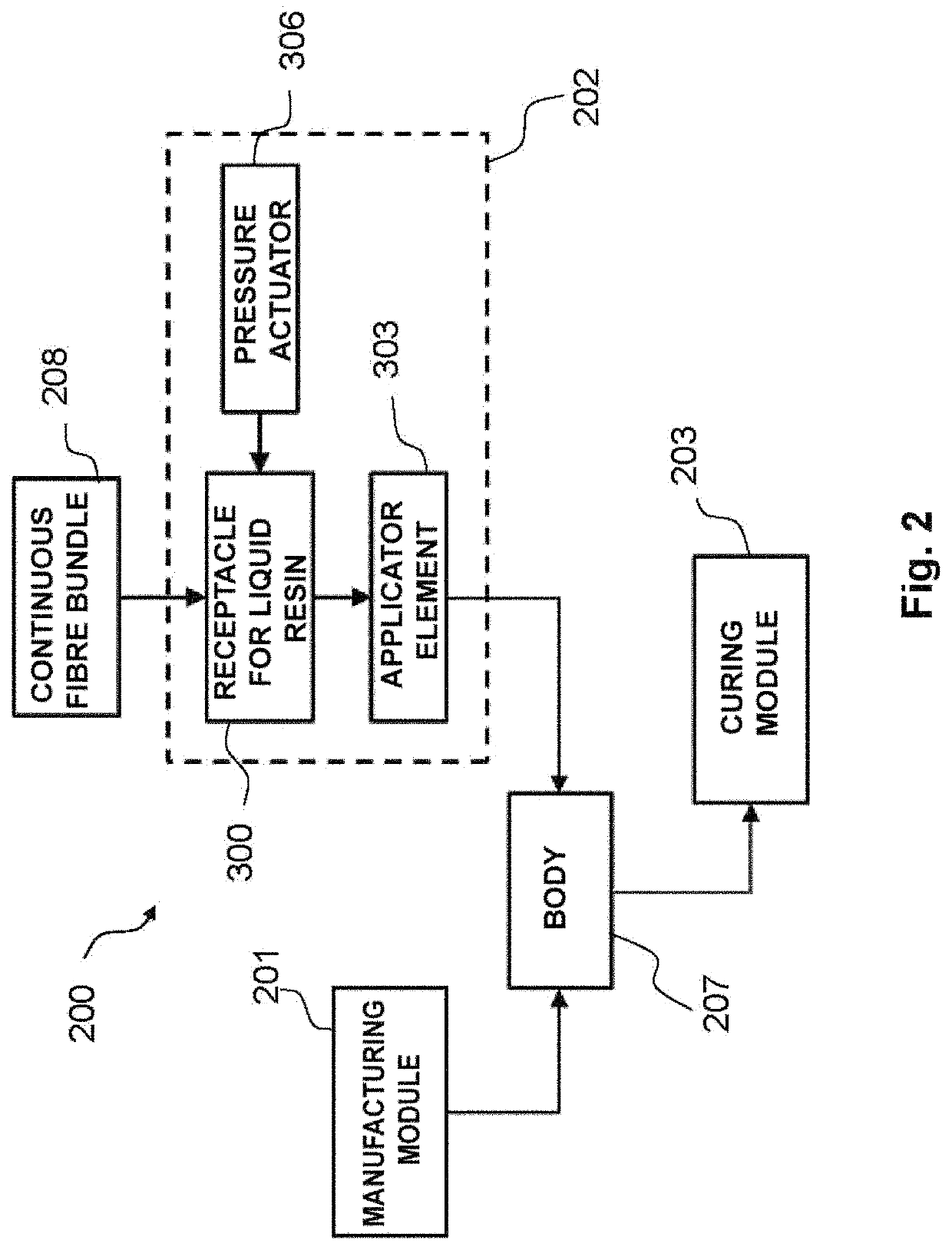

Procedure and system for manufacturing a part made from composite material and part made from composite material obtained by means of said method

ActiveUS20170361497A1Complex geometryEasy to produceAdditive manufacturing apparatus3D object support structuresFiber bundleLiquid state

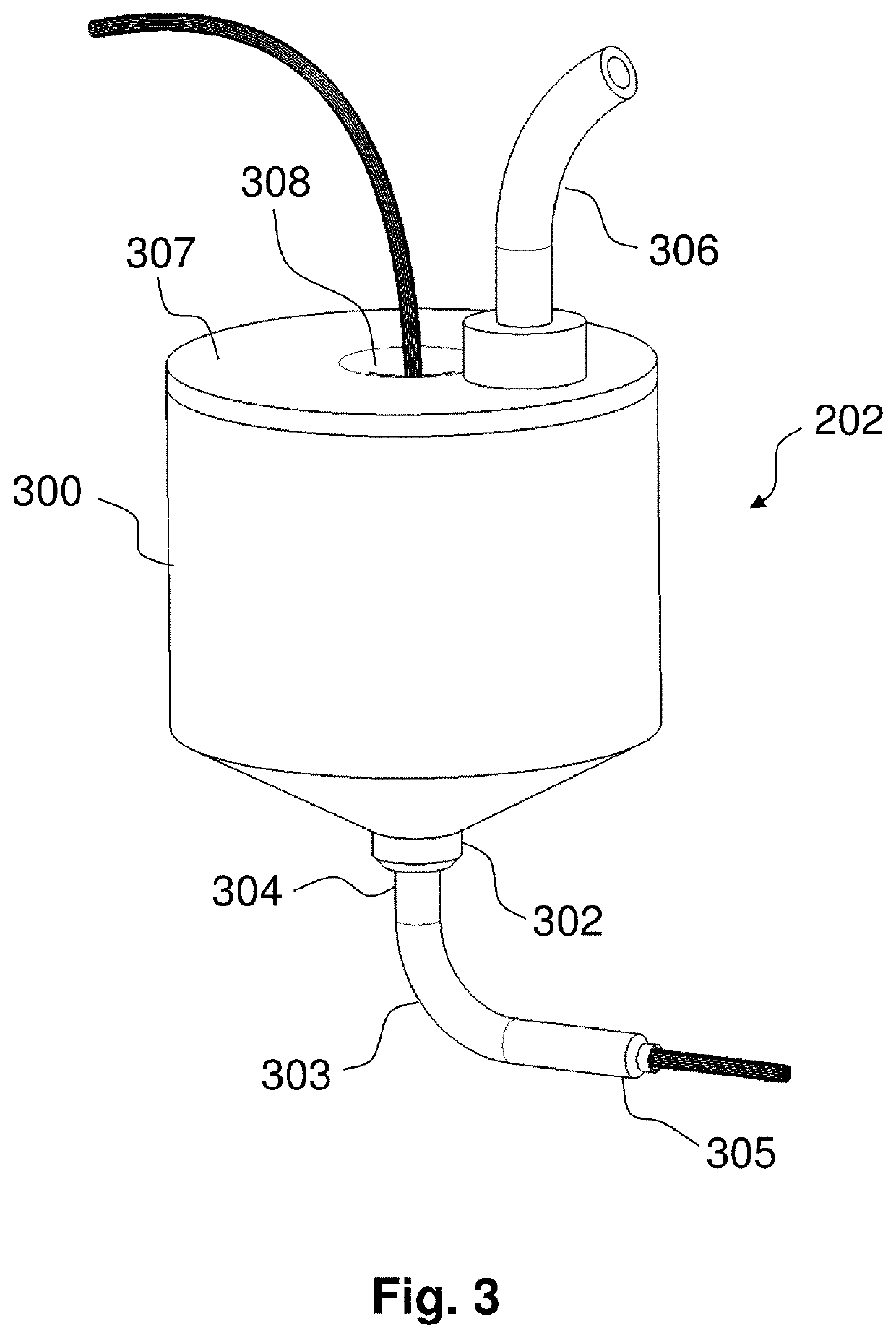

The invention relates to a method for manufacturing a part made from composite material, having a body and one or more continuous fibre bundles in its interior, characterised in that it comprises the stages of: a) obtaining a body that includes one or more tubular cavities in its interior that extend between a first end, disposed on the outer surface of the body and which comprises an inlet orifice, and a second end, opposite to the first end; b) introducing resin in the liquid state and a continuous fibre bundle in the interior of at least one tubular cavity through its inlet orifice; and c) curing the resin until it solidifies, adhering to the body and fixing the continuous fibre bundle. The invention also relates to a system for manufacturing a part made from composite material and to the part made from composite material obtained.

Owner:FUNDACIO EURECAT

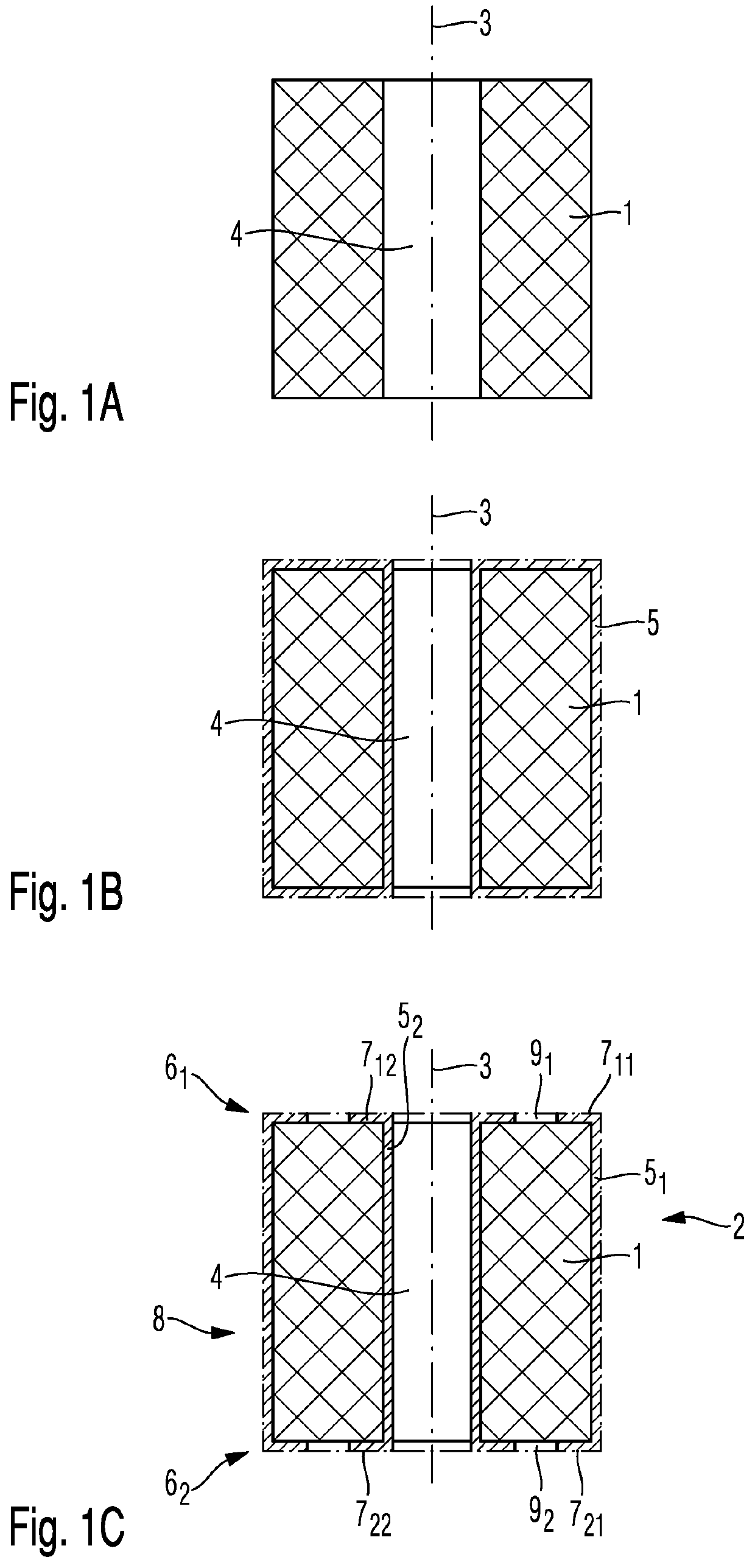

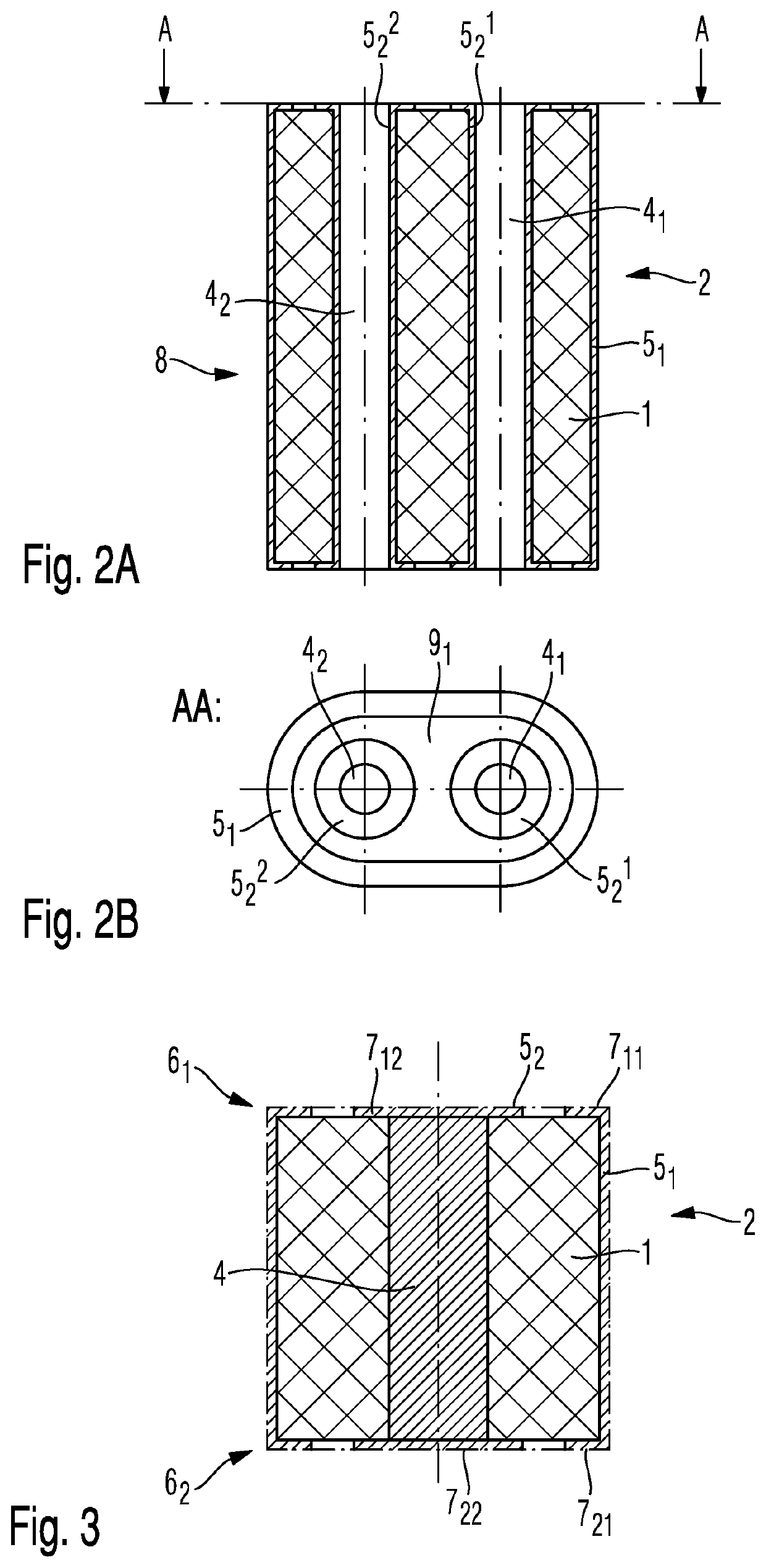

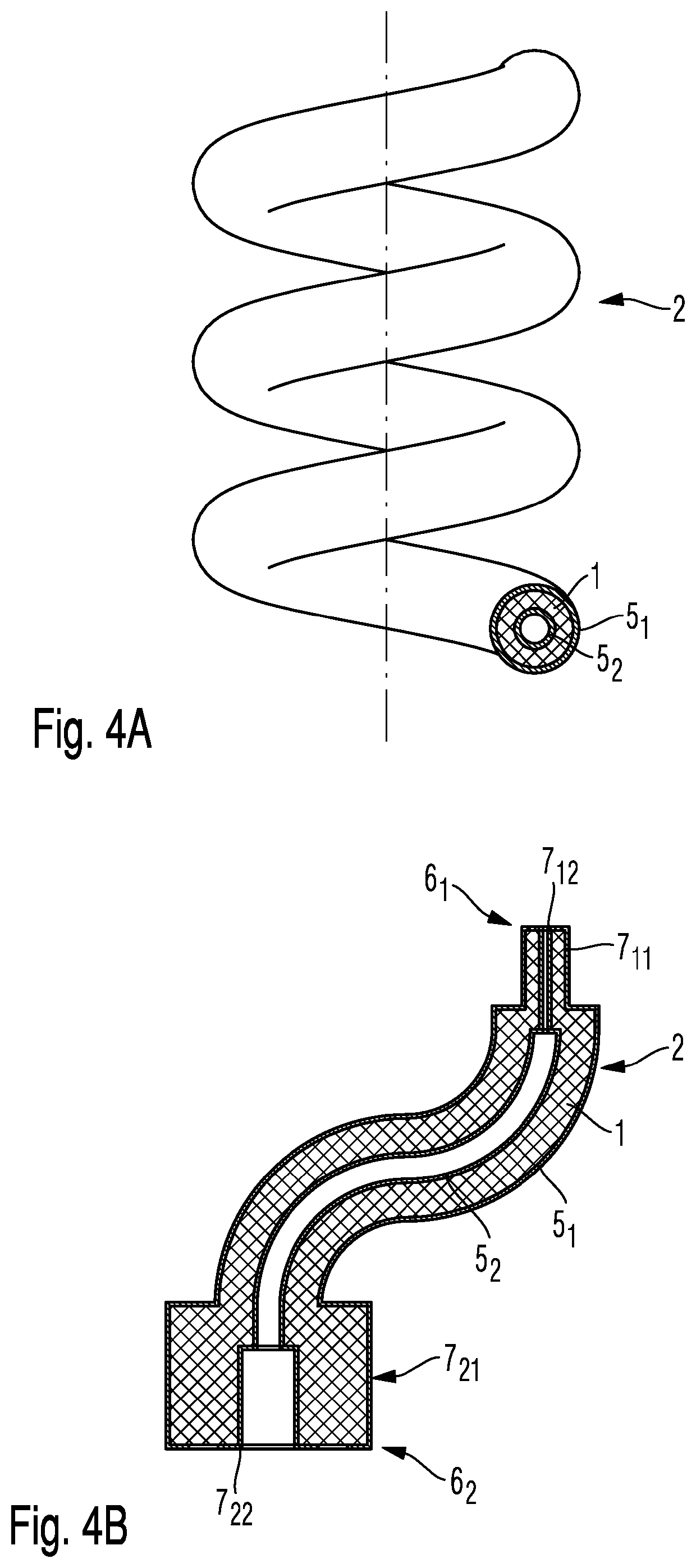

Double-walled pipe element and method for producing a double-walled pipe element

InactiveUS20170219134A1Producible simply and cost-effectivelyProduced simply and cost-effectivelyAdditive manufacturing apparatusPower plant fuel supplyDouble-walled pipeAirplane

Owner:AIRBUS DEFENCE & SPACE

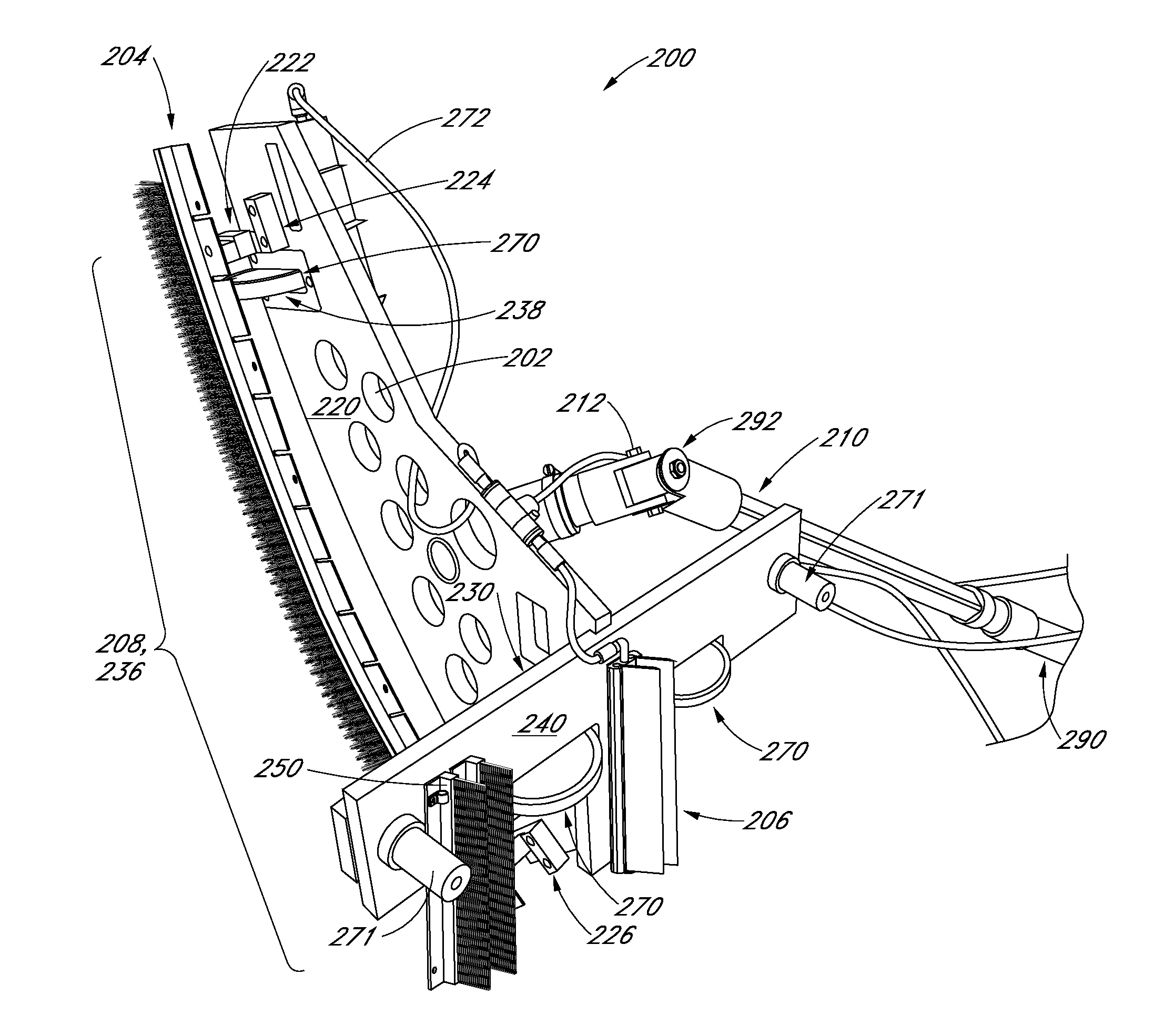

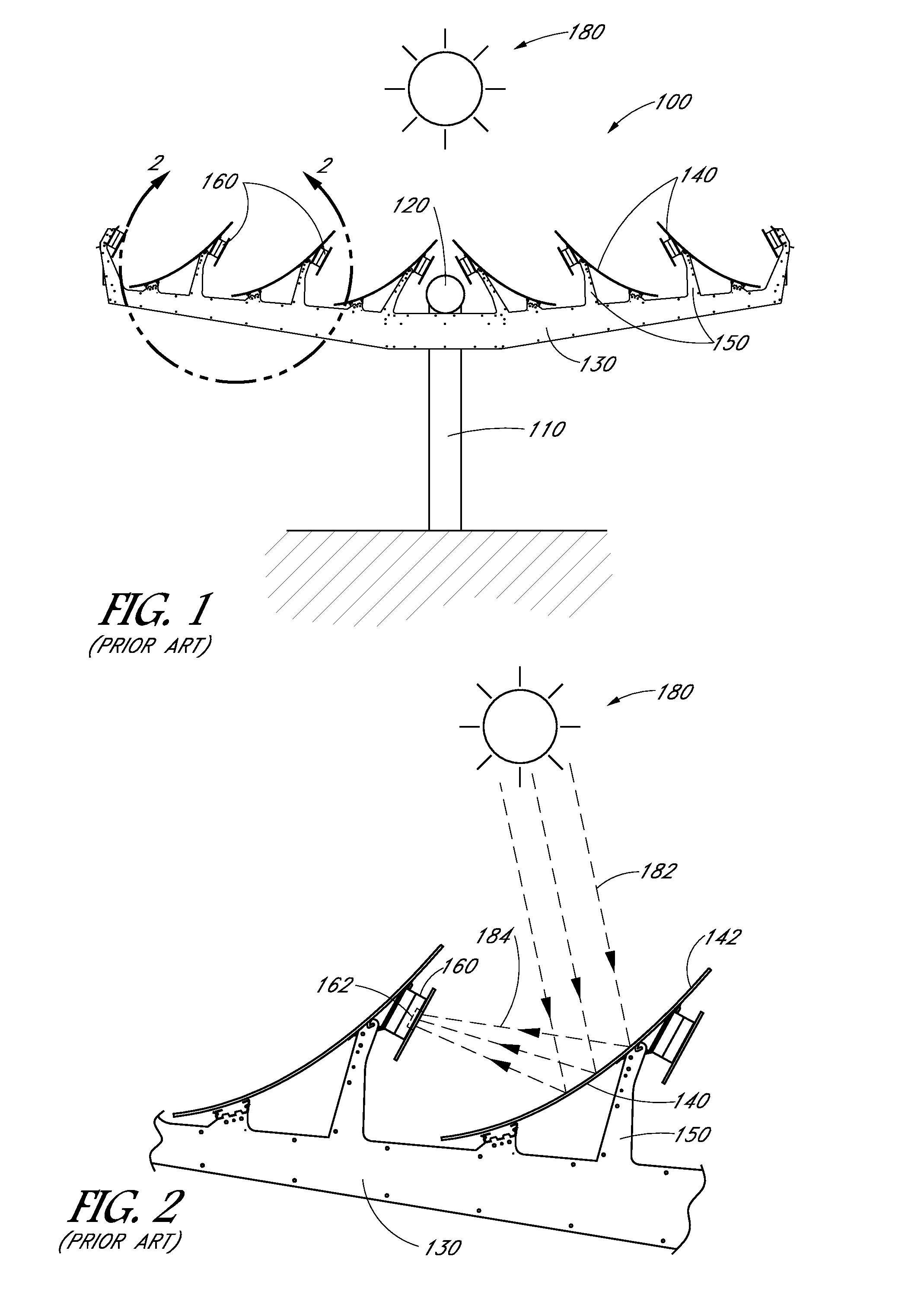

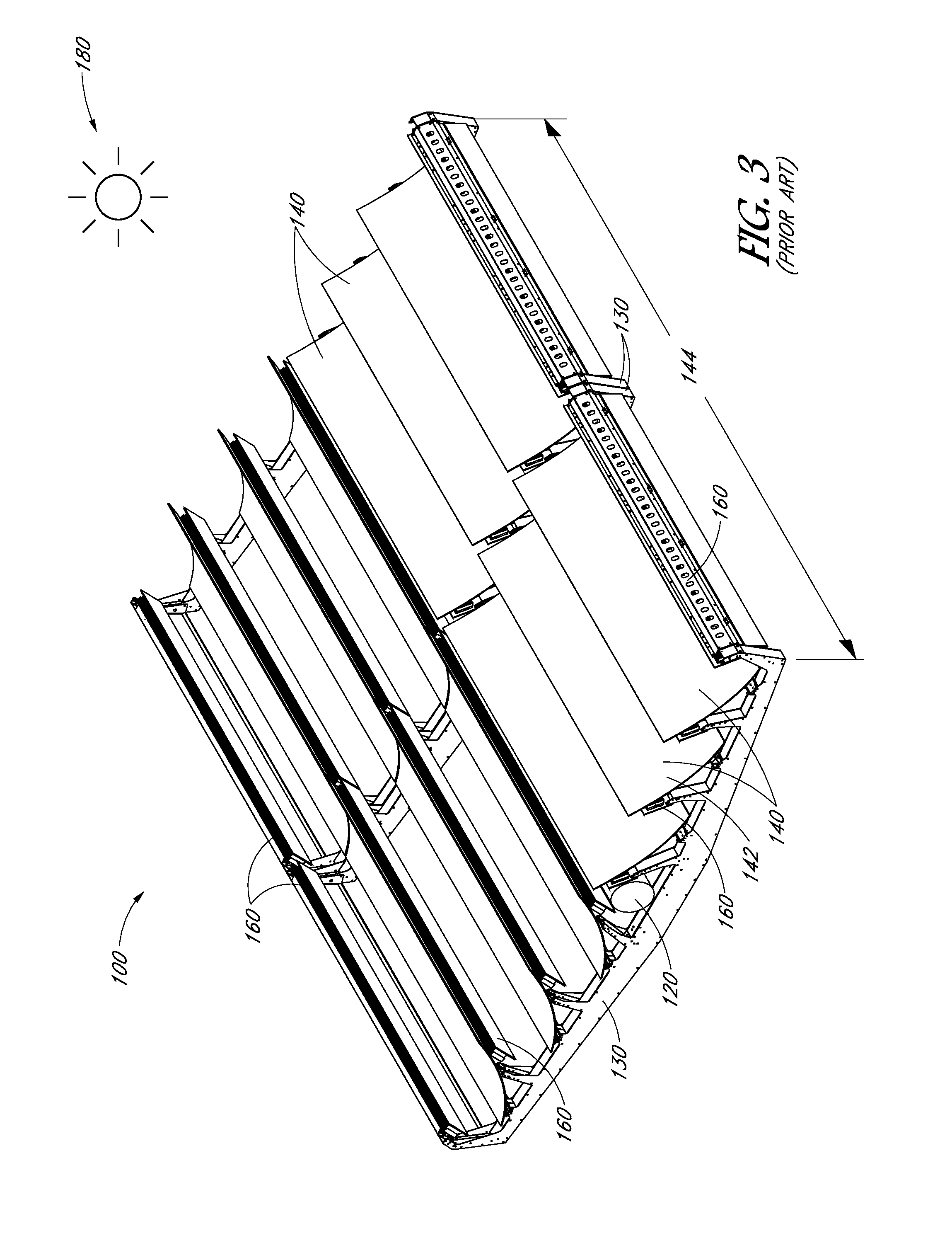

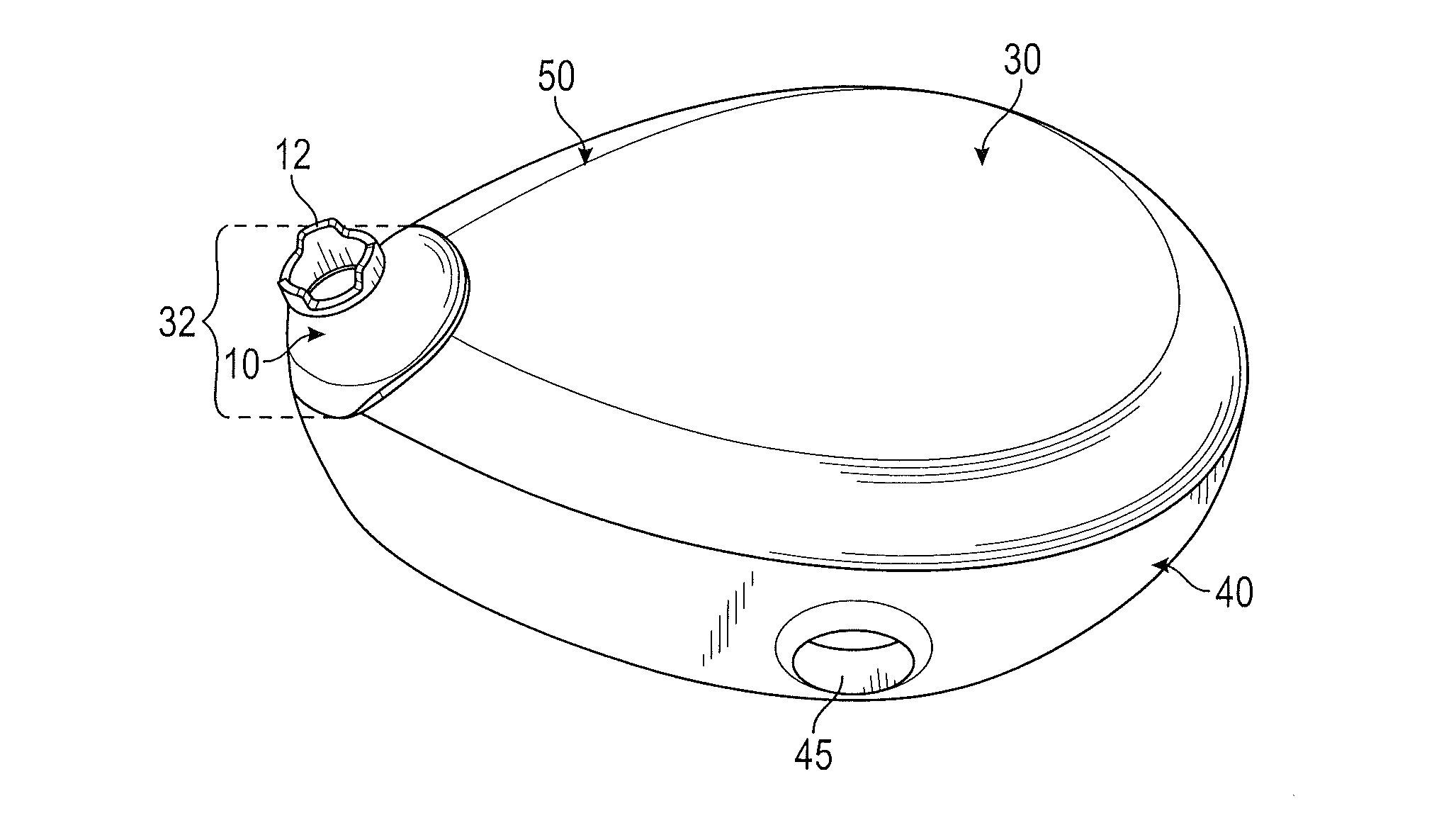

Solar module cleaner

InactiveUS20160178241A1Improve water efficiencyComplex geometrySolar heating energySolar heat devicesEngineeringSolar concentrator

A solar module cleaner can be configured for cleaning reflective surfaces of solar concentrator reflectors. The cleaner can include at least one cleaning module having a cleaning surface extending in a curved configuration corresponding to a curvature of the solar concentrator reflector. The cleaning surface can be configured to displace debris resting on the reflective surface. The cleaner can include fluid delivery devices for discharging a cleaning fluid onto the reflective surface. The cleaner can be configured to clean solar energy receivers associated with a solar concentrator reflector. Additionally, the cleaner can be configured to simultaneously clean a plurality of parallel solar concentrator reflectors. Optionally, the cleaner can be configured to simultaneously clean a plurality of solar energy receivers and a plurality of solar energy concentrators.

Owner:SUNPOWER CORPORATION

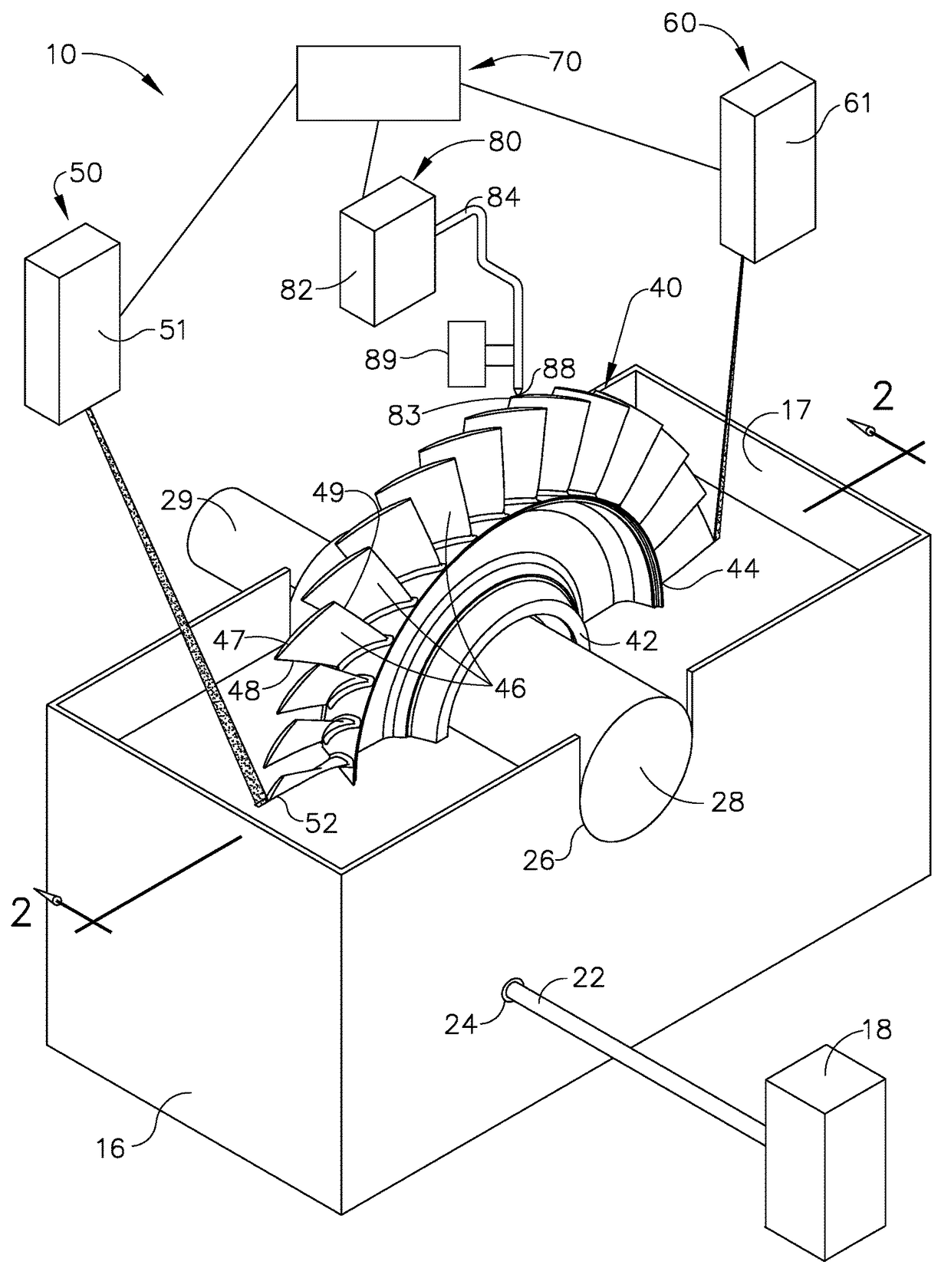

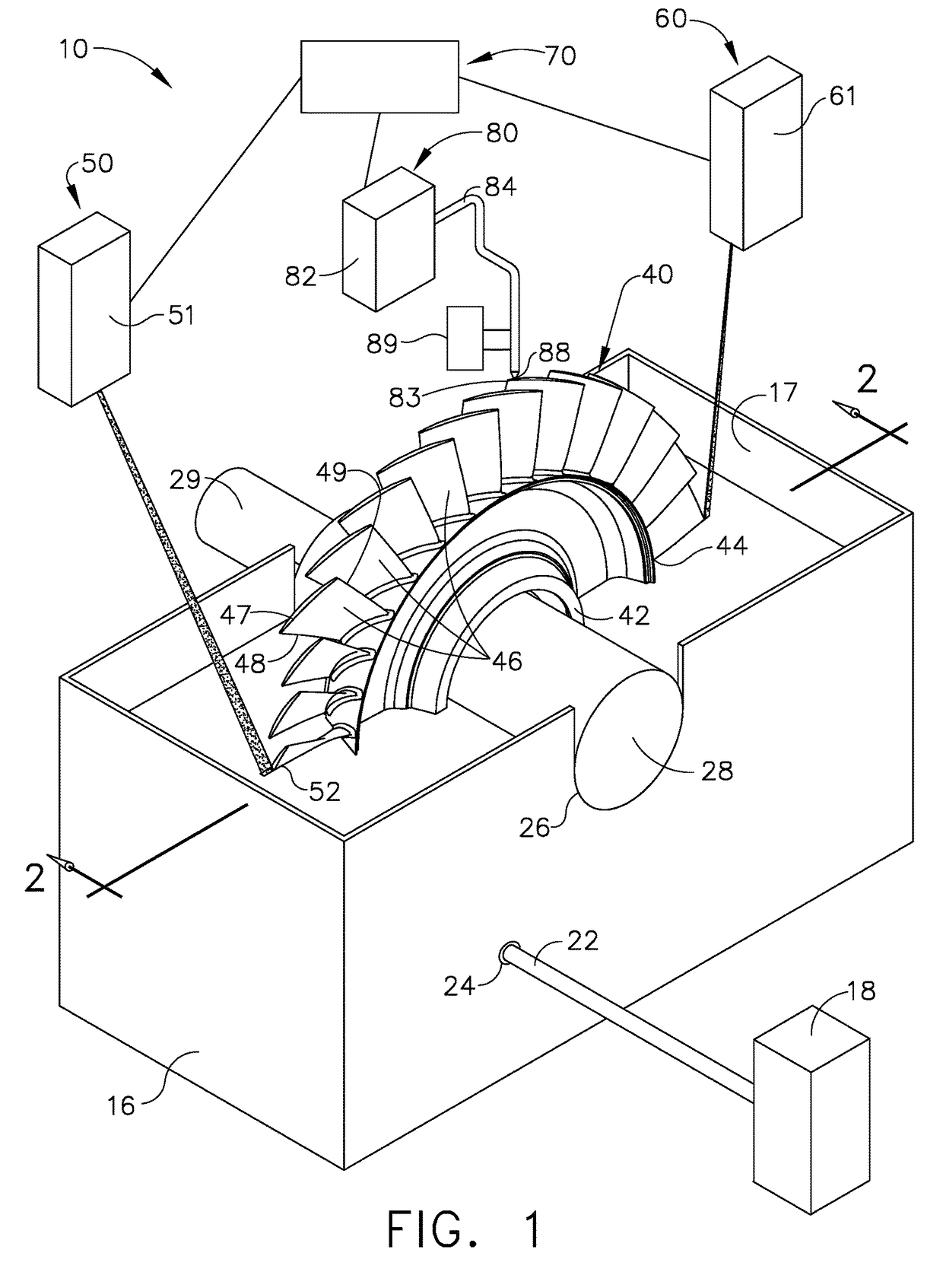

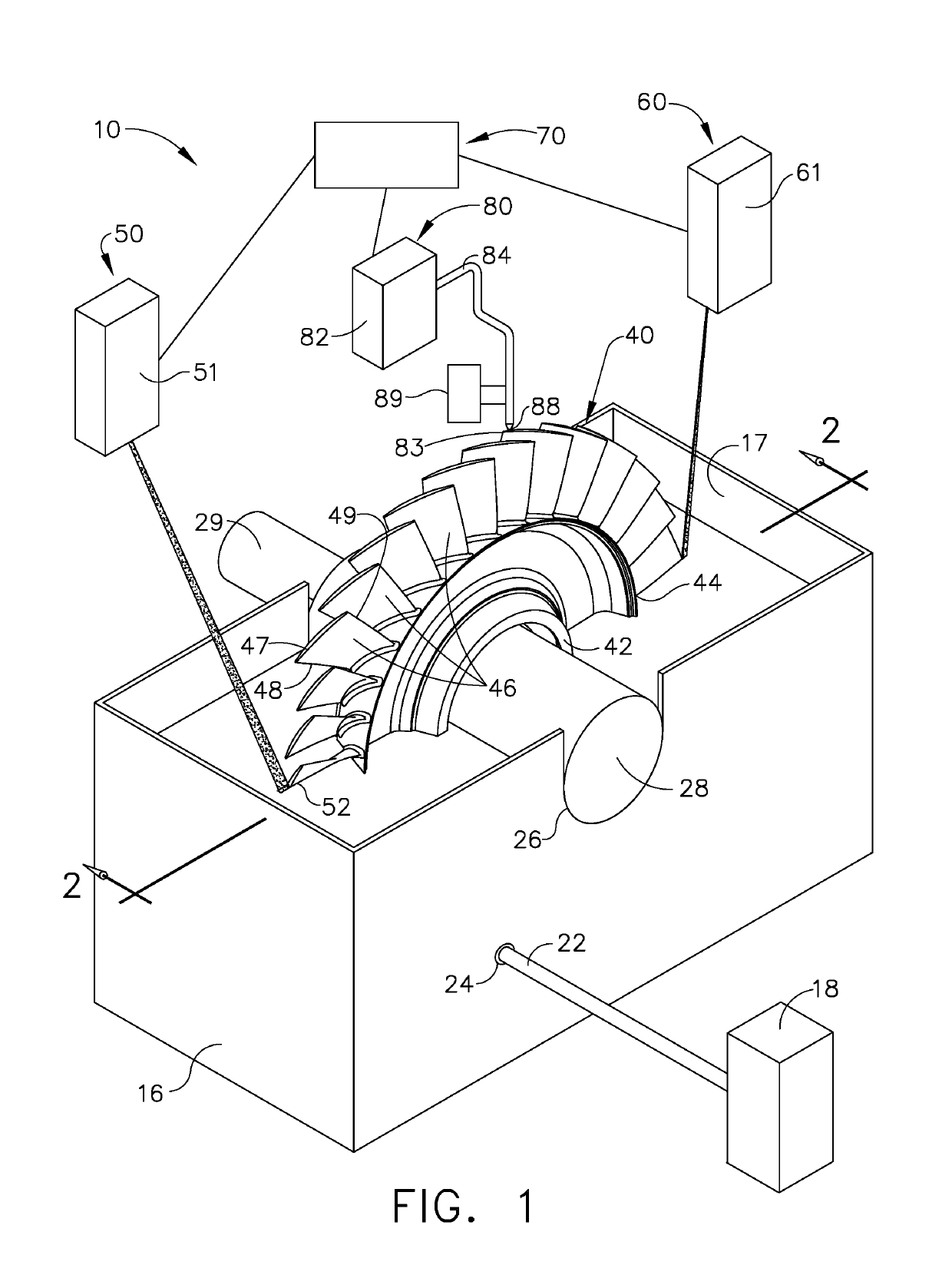

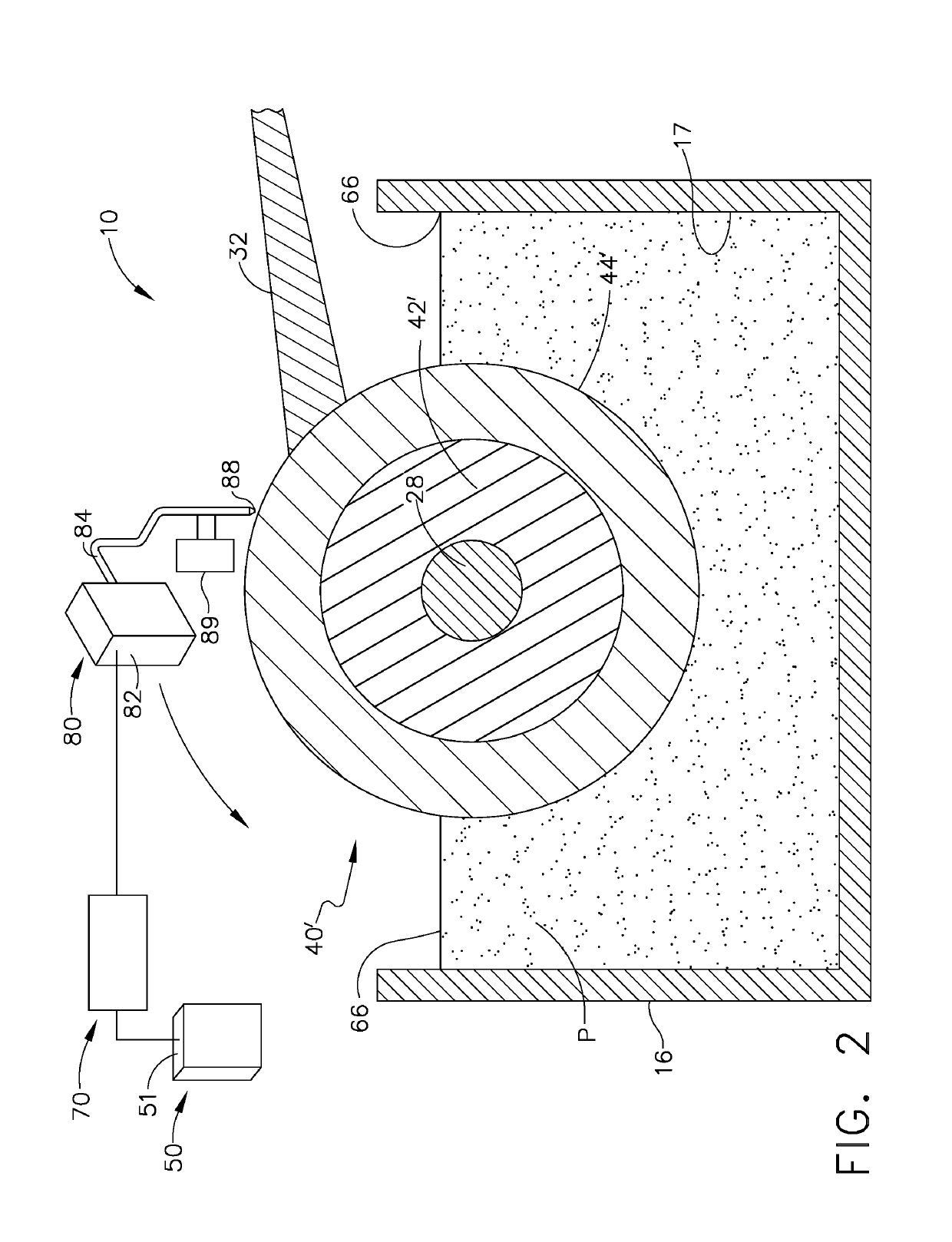

Additive Machine Utilizing Rotational Build Surface

ActiveUS20170291260A1Less spaceEquipment is smallTurbinesManufacturing driving meansBiomedical engineeringEnergy source

An apparatus for manufacturing an axi-symmetric part. The apparatus includes a vessel configured to contain the powder. The vessel is also configured to receive a part such that at least a portion of the part contacts the powder contained within the vessel. A first energy source is configured to generate a first beam of energy. The first beam of energy is configured to melt the powder at a first predetermined location such that the melted powder fuses to the part.

Owner:GENERAL ELECTRIC CO

Powder mixture for manufacture of a battery electrode, a respective battery electrode and a method for manufacturing same

ActiveUS20100330432A1Outstanding shapingImprove mechanical stabilityElectrode rolling/calenderingFilling tube/pocket electrodesPowder mixtureMetallurgy

A method for manufacturing of a powder mixture for a battery electrode that includes suspending of particles of at least one binder within an inert solvent producing a first suspension, slowly suspending of particles of an active material within the first suspension producing a second suspension, drying of the second suspension producing a granulate material. Further relates to a respective powder mixture, an electrode and a method of manufacturing the electrode.

Owner:LITRONIK BATTERIETECHNOLOGIE GMBH

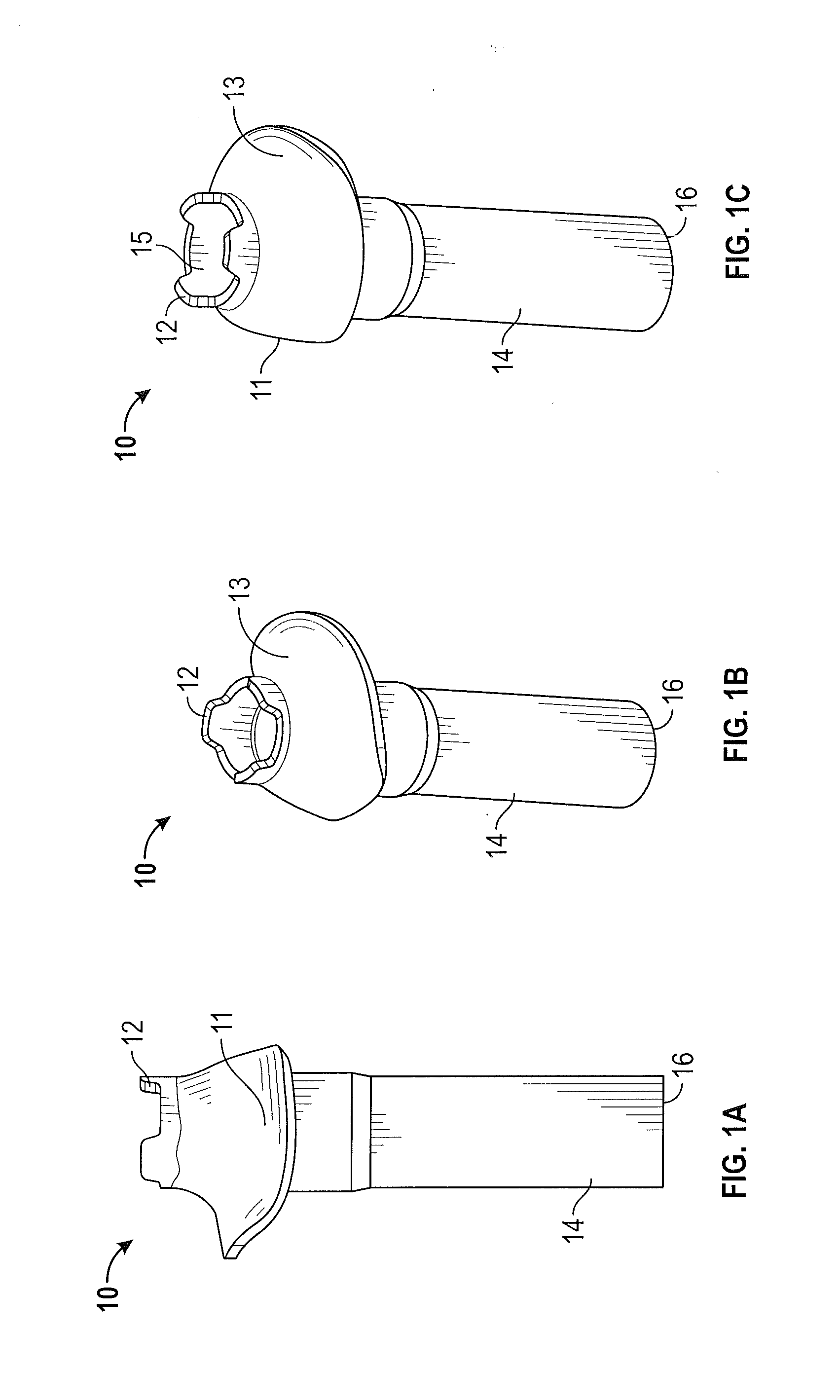

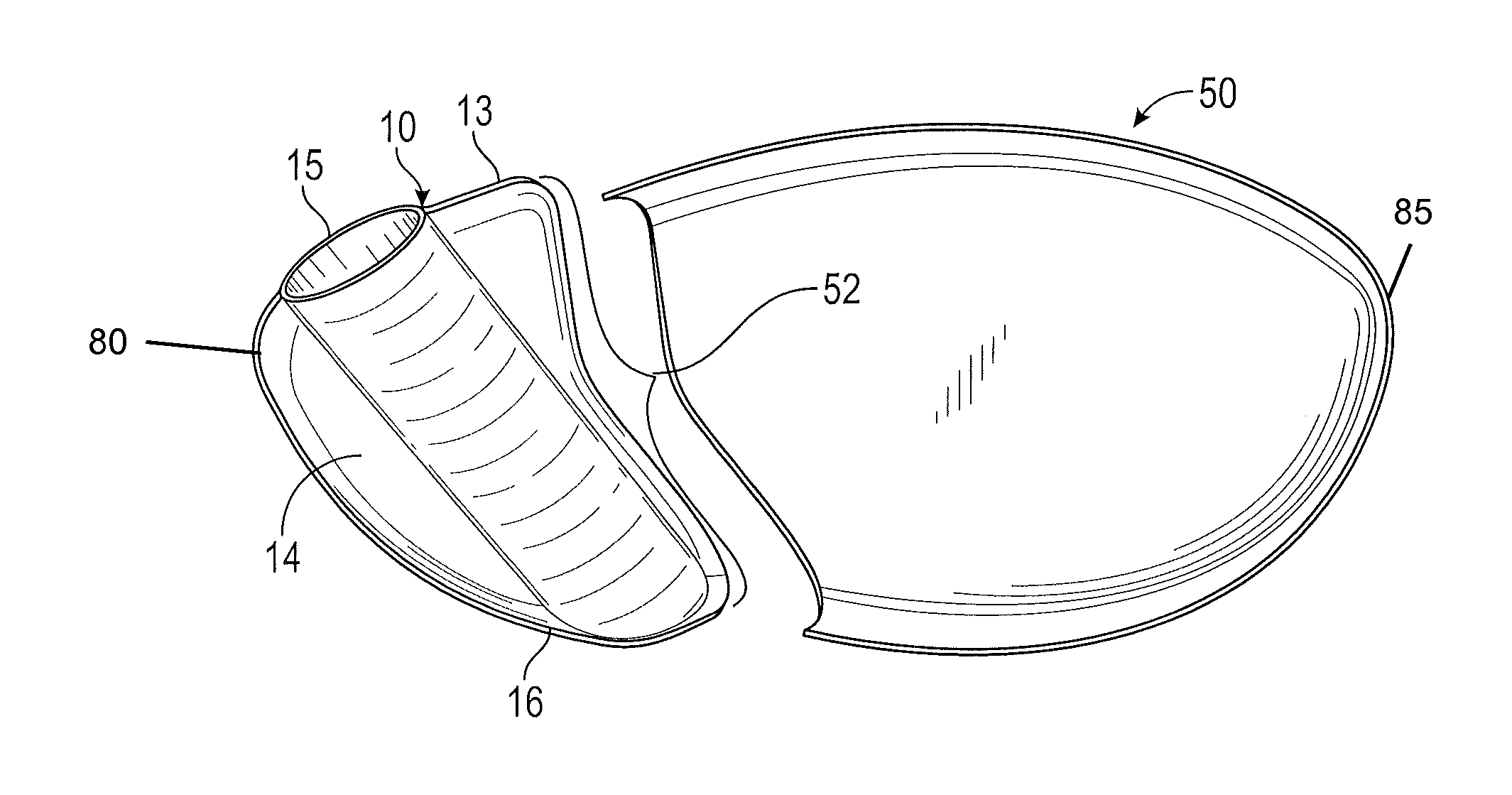

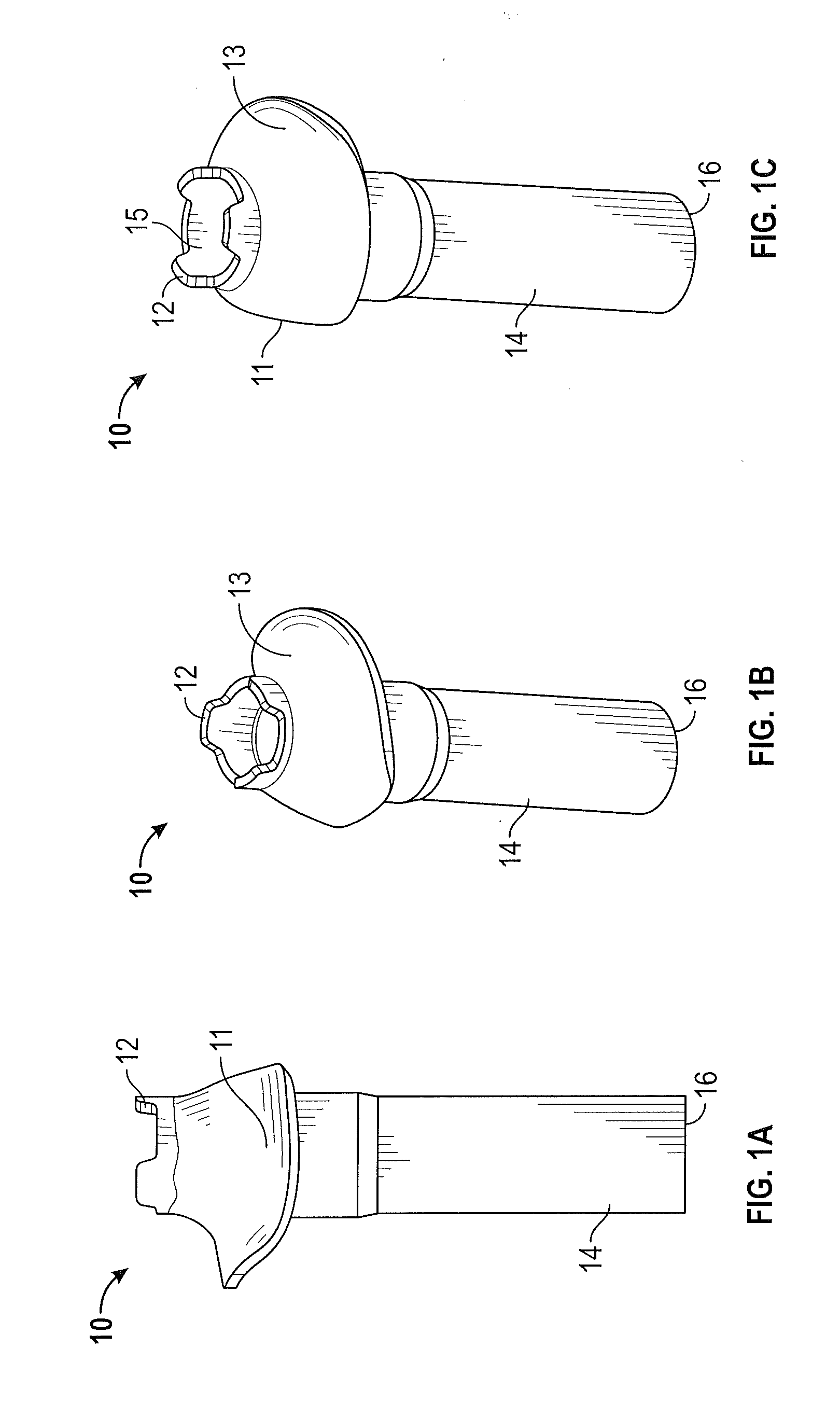

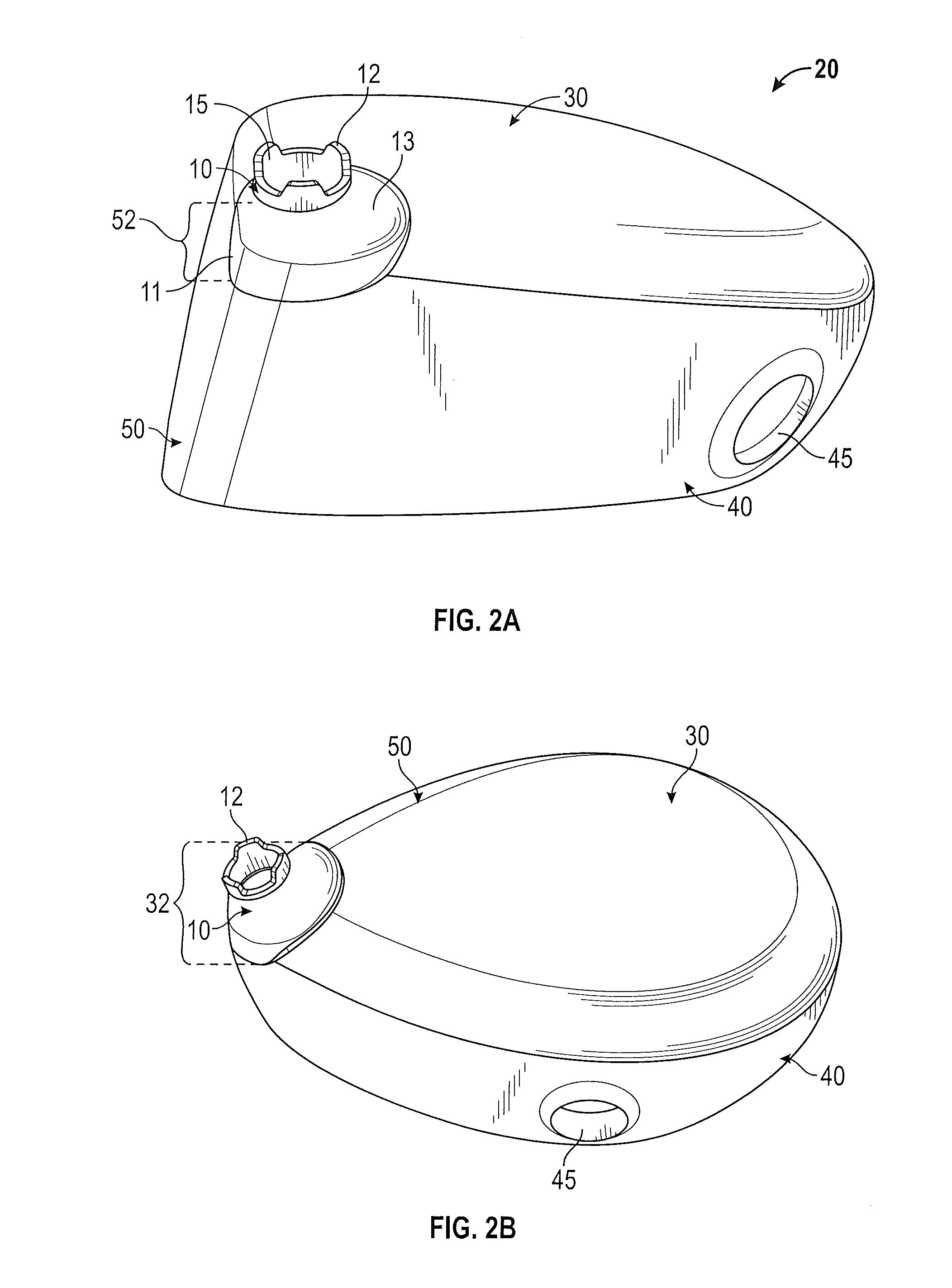

Multi-piece driver with separately cast hosel

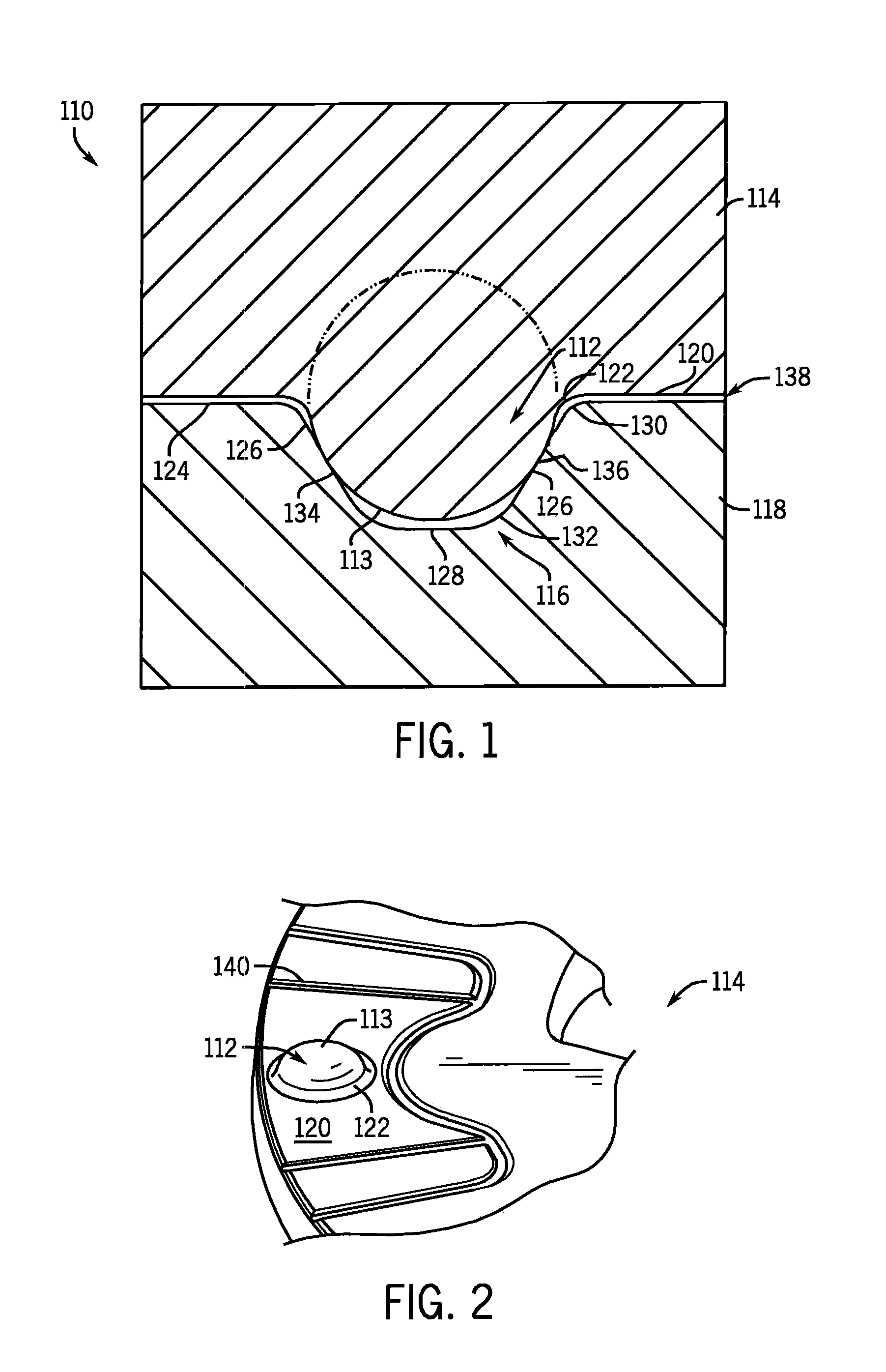

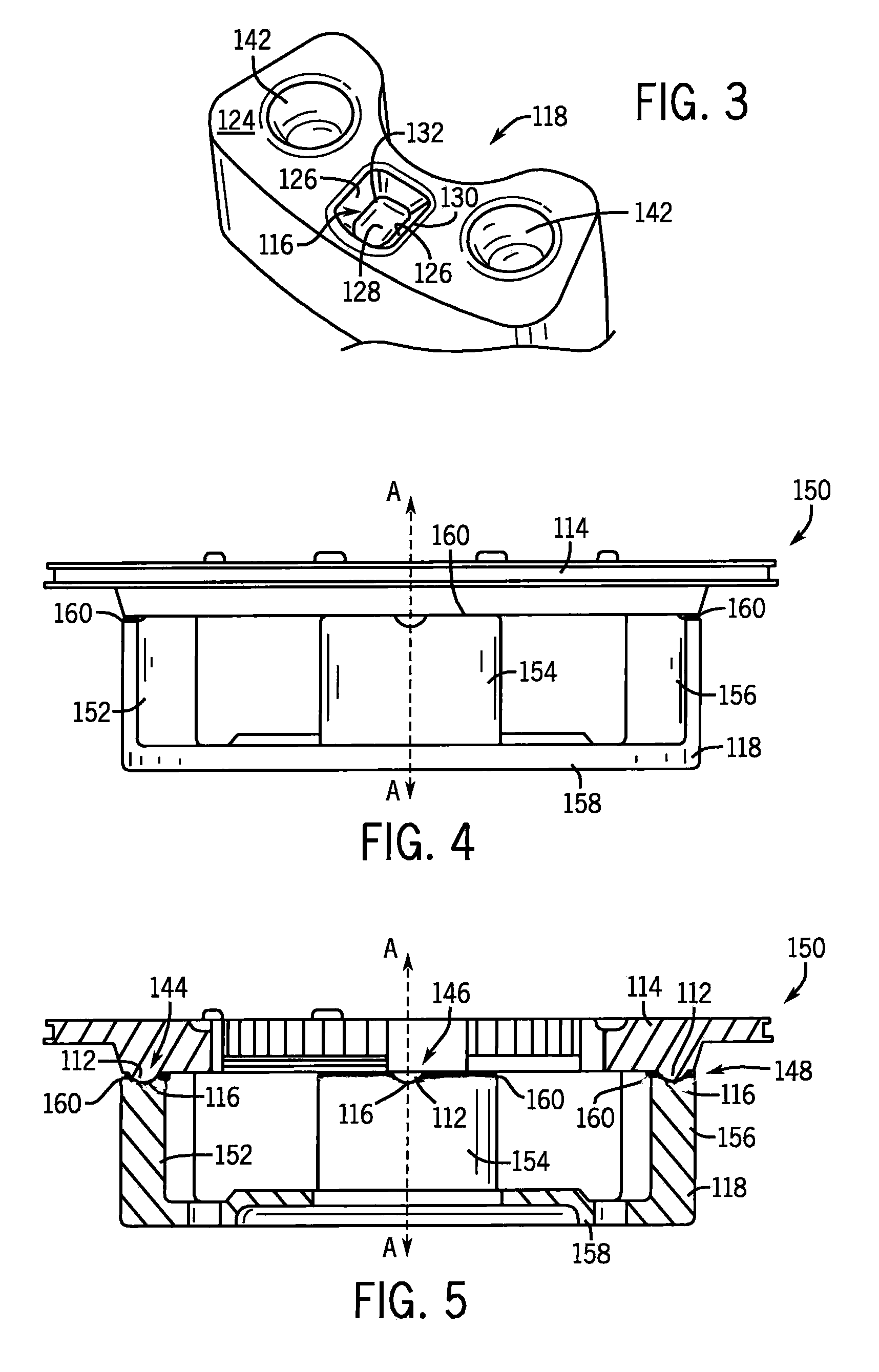

InactiveUS20130190103A1Complex geometryLess featureSensing record carriersGolf clubsMetallic materialsGolf club

The present invention is directed to a multi-piece golf club head having a metal hosel with adjustability features that is cast separately from a face component, sole, and crown, and then is permanently affixed to those other parts after casting is complete. The face component, sole, and crown may be composed of any suitable materials, but preferably each of the face component, the sole, and the crown are stamped from a metal material and are welded to the hosel.

Owner:CALLAWAY GOLF CO

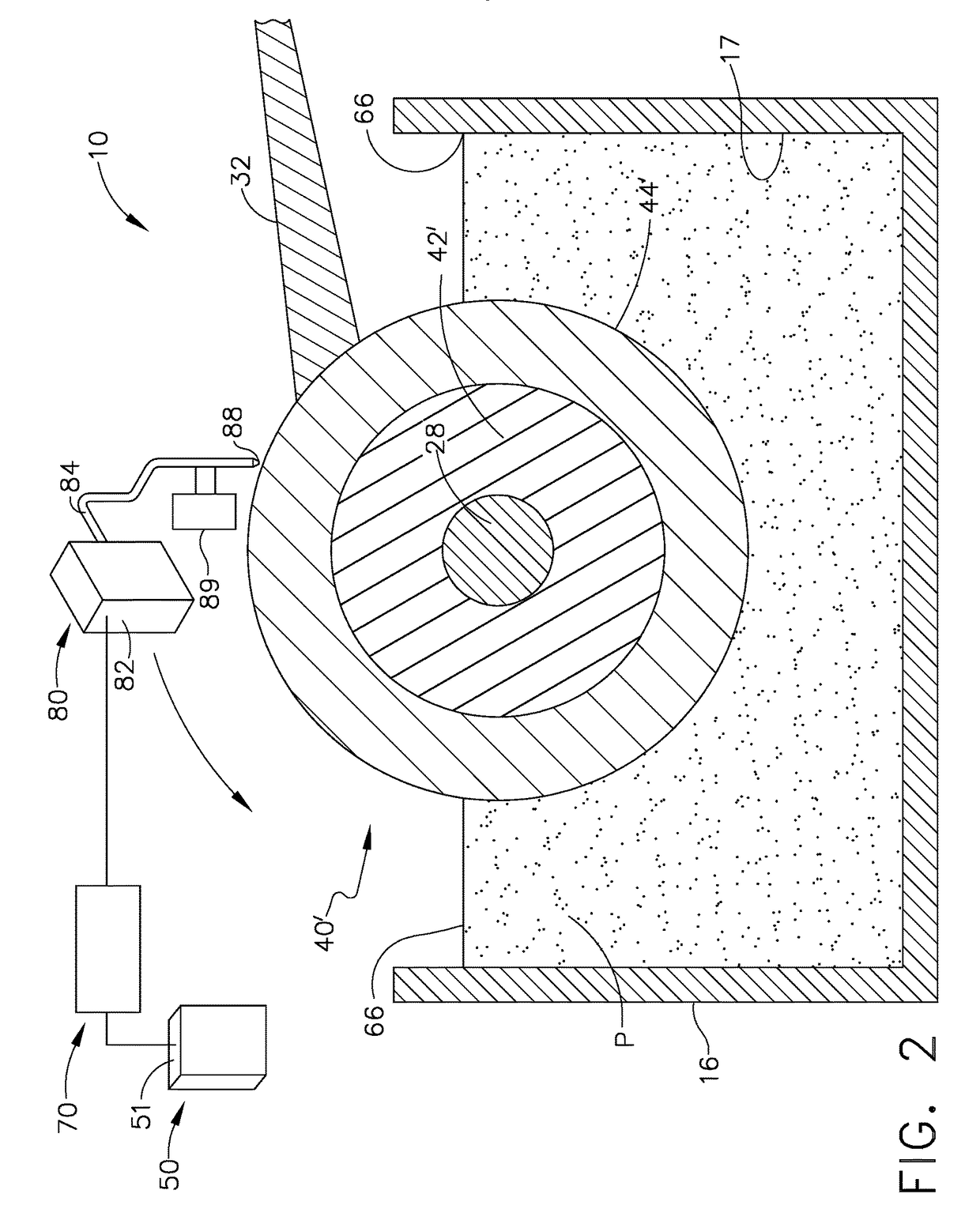

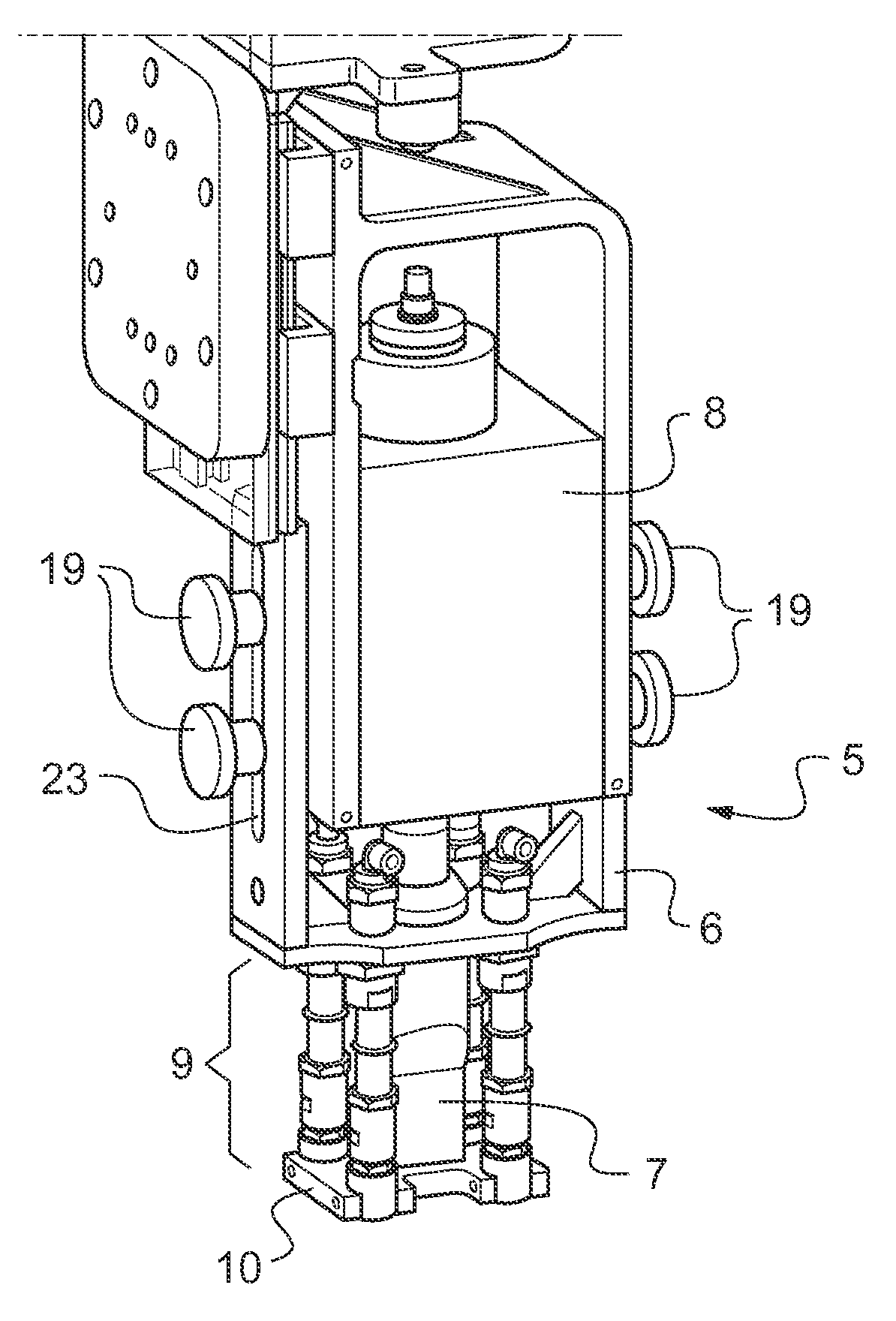

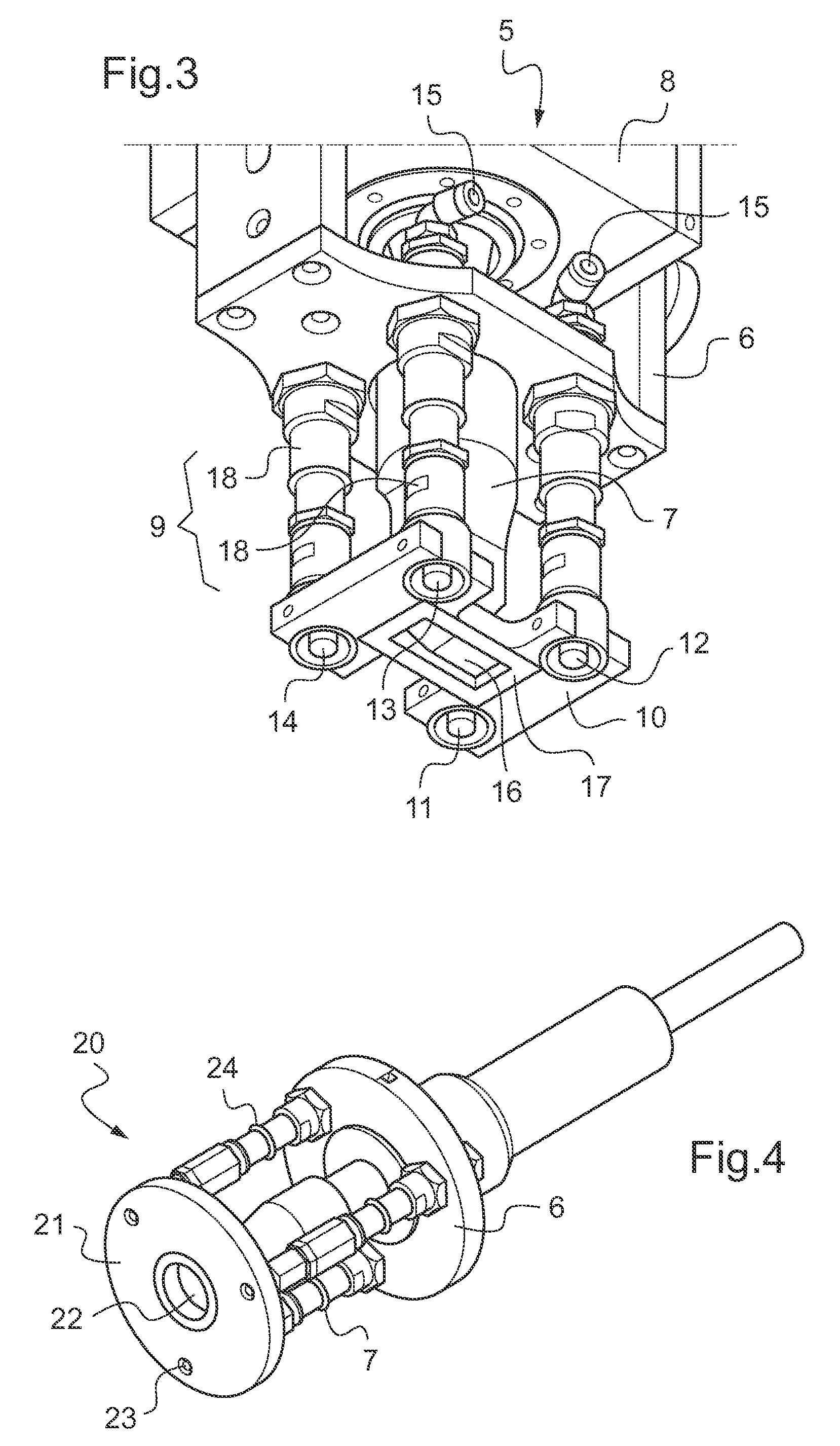

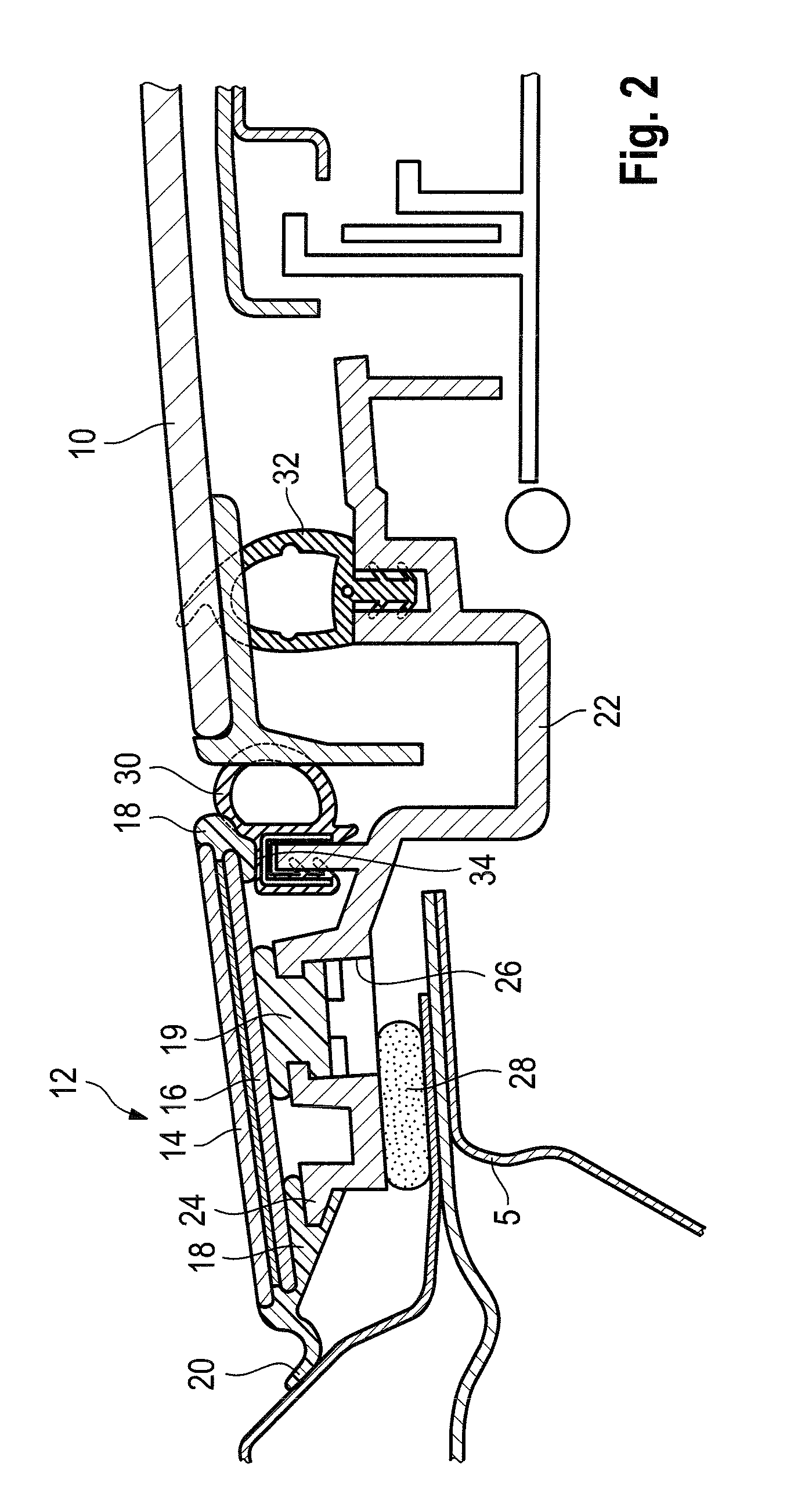

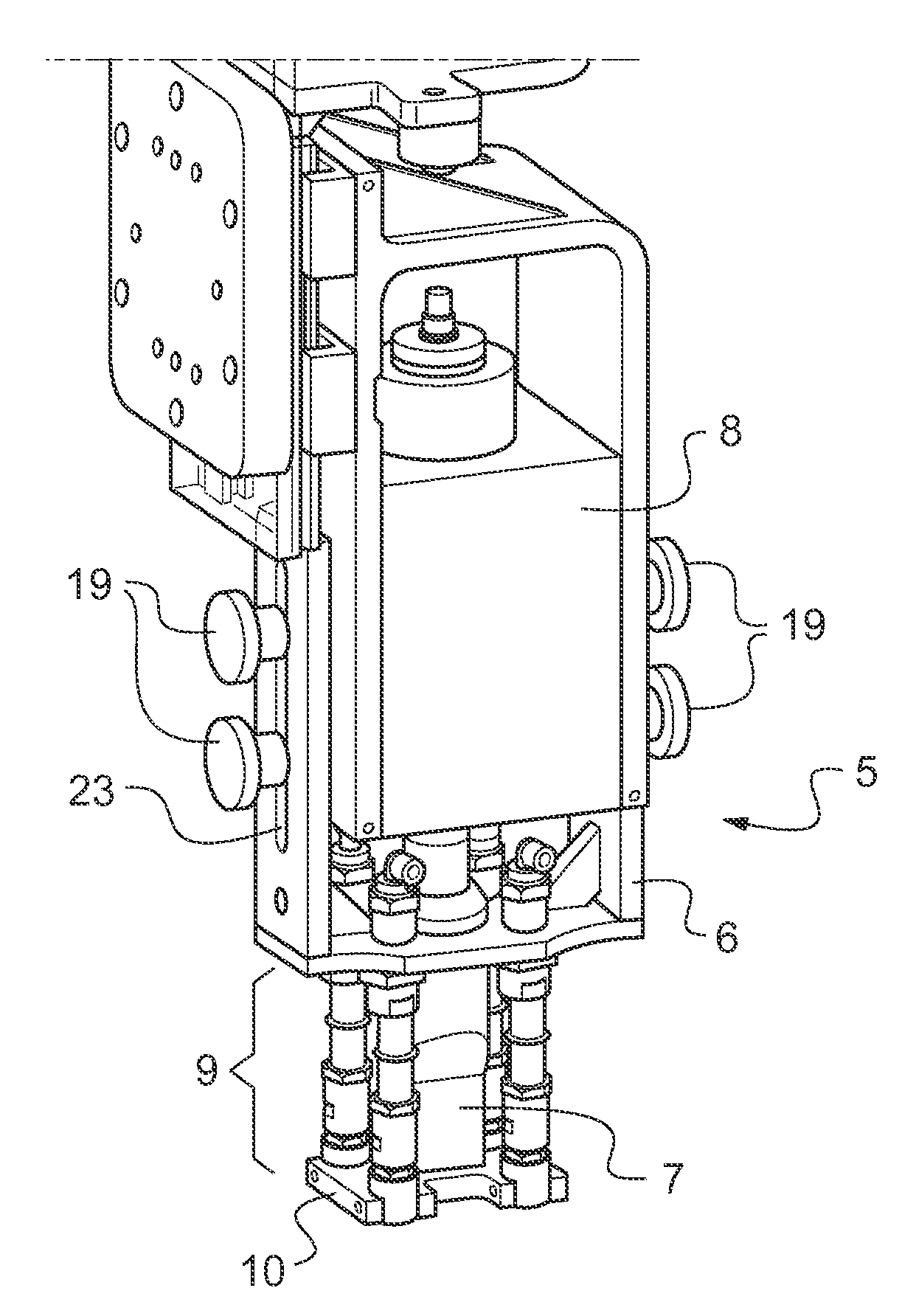

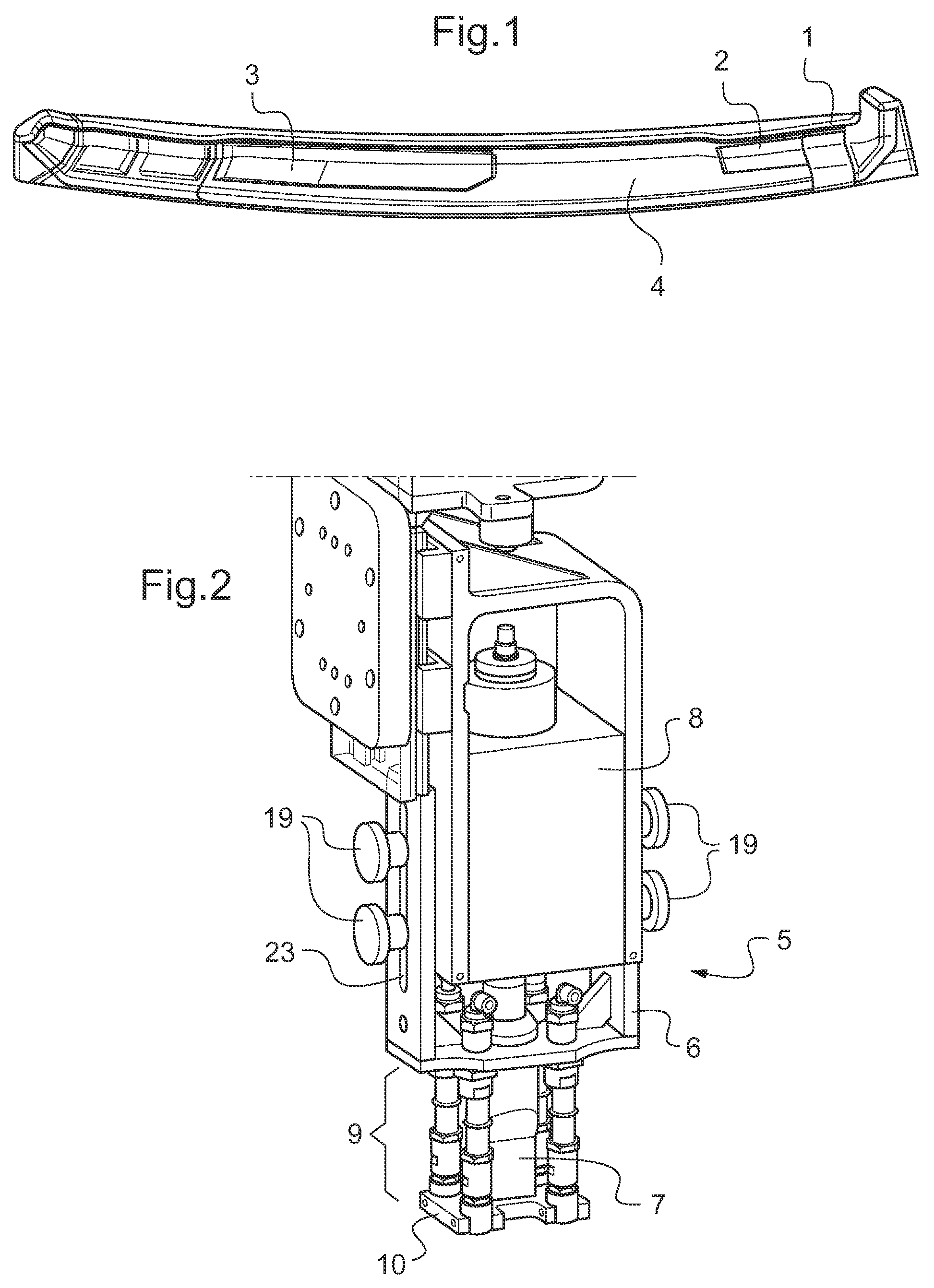

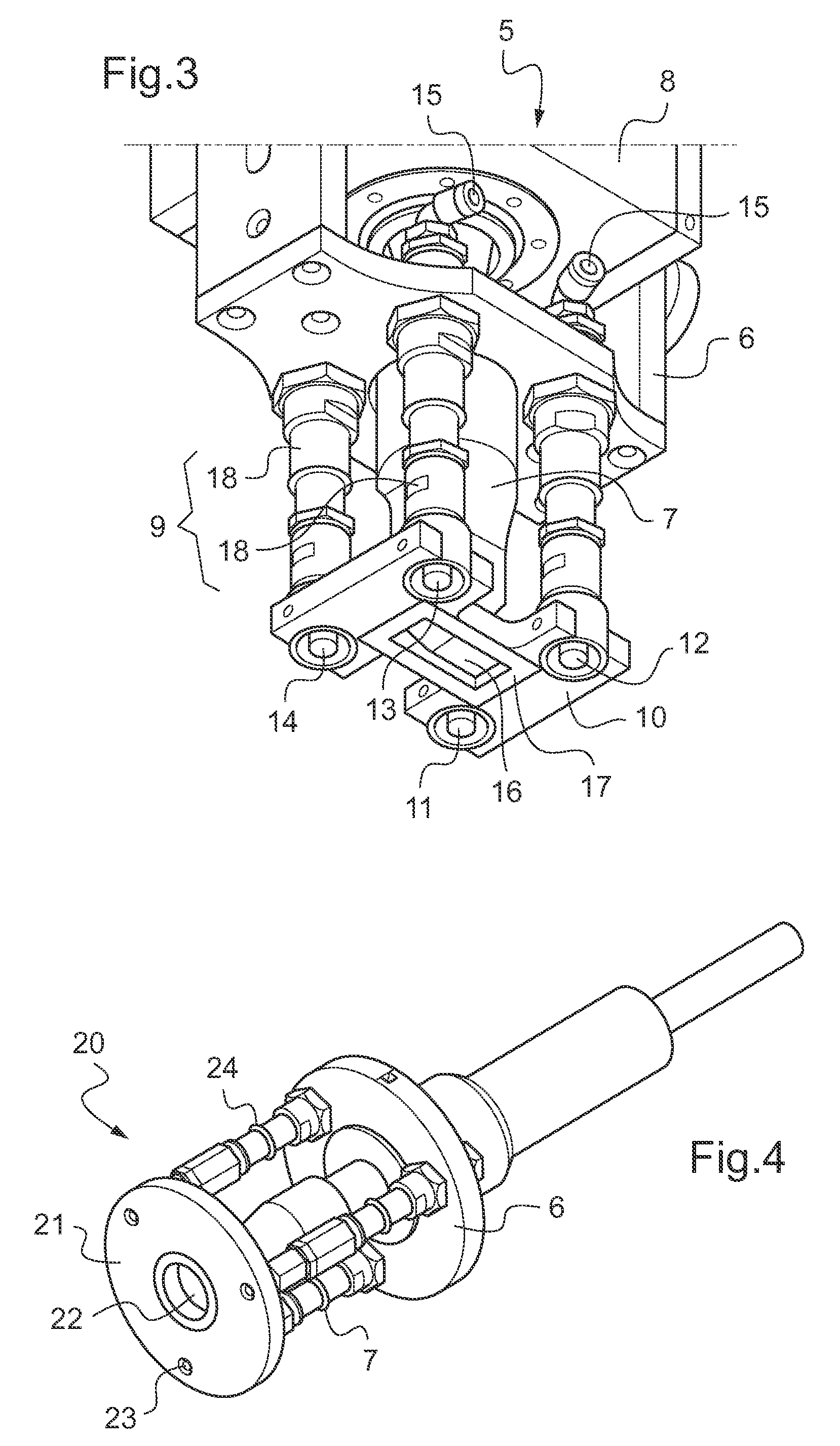

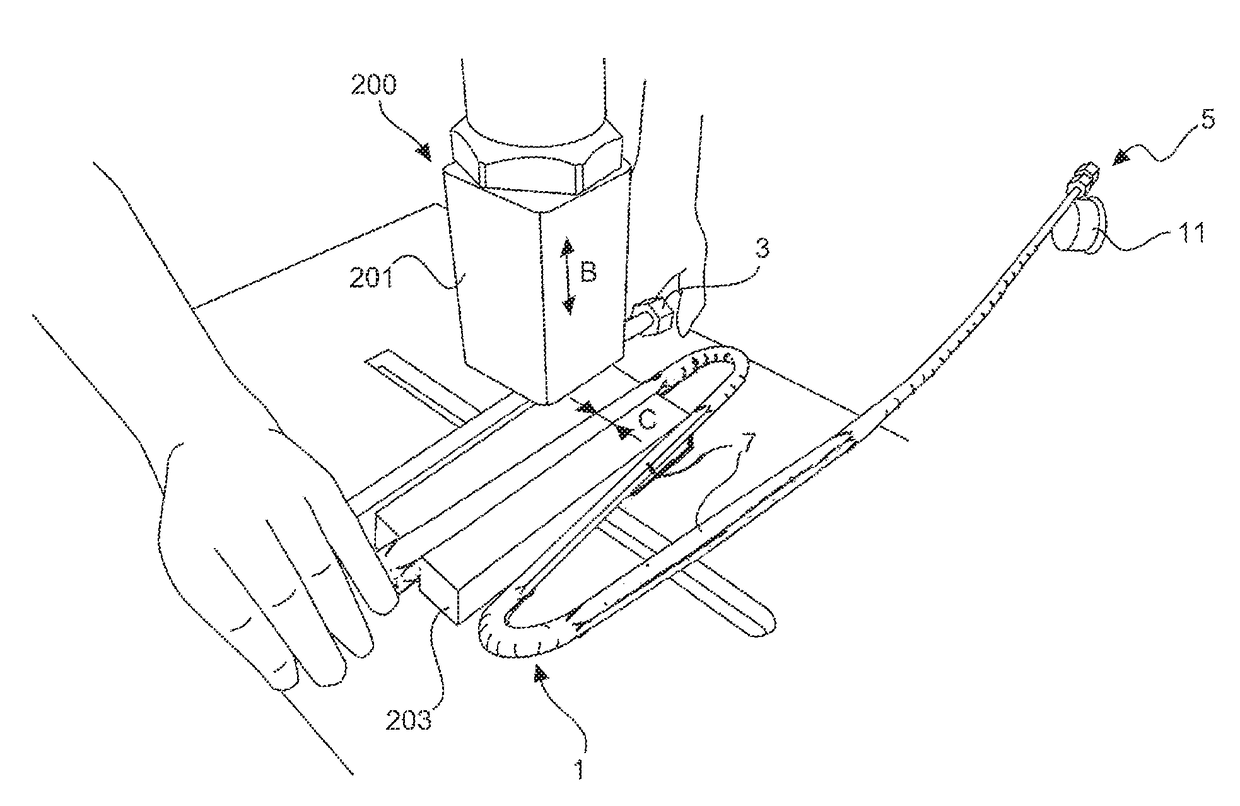

Ultrasonic welding device and method of operating said device

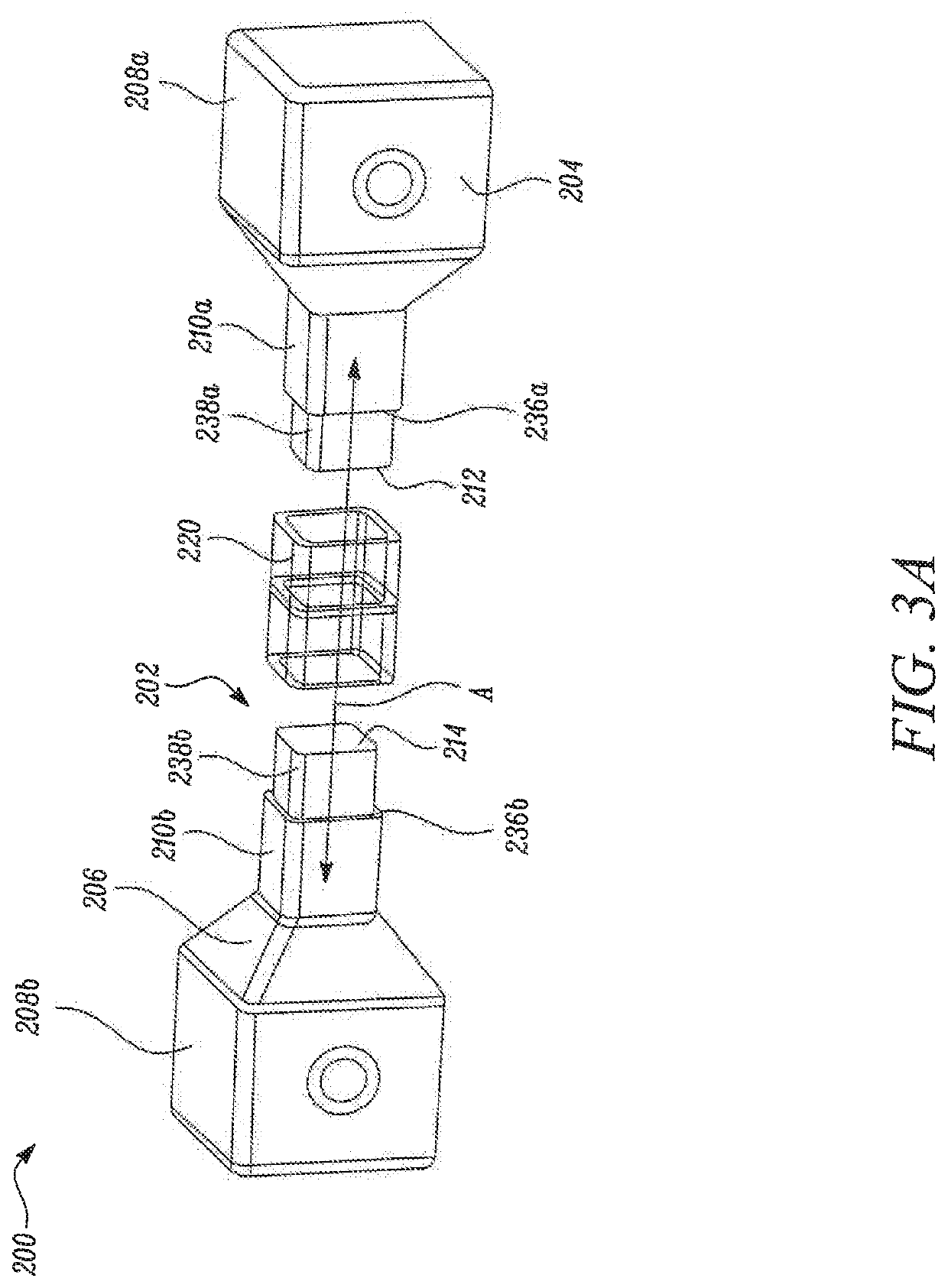

ActiveUS20130263999A1Avoid restrictionsLack of reproducibilityLaminationLamination apparatusUltrasonic weldingEngineering

The invention is related to an ultrasonic welding device (5) comprising: an adapter frame (6); an ultrasonic horn (7) driven by a adapter frame mounted converter (8). A pick member (9) comprises grippers (11-14). Passive clamping means are provided with a press pad (10). Control means and activation means (15) are provided for controlled activation of the pick member (9) and the ultrasonic horn (7). The invention is further related to a method of operating said device.

Owner:AIRBUS HELICOPTERS DEUT GMBH

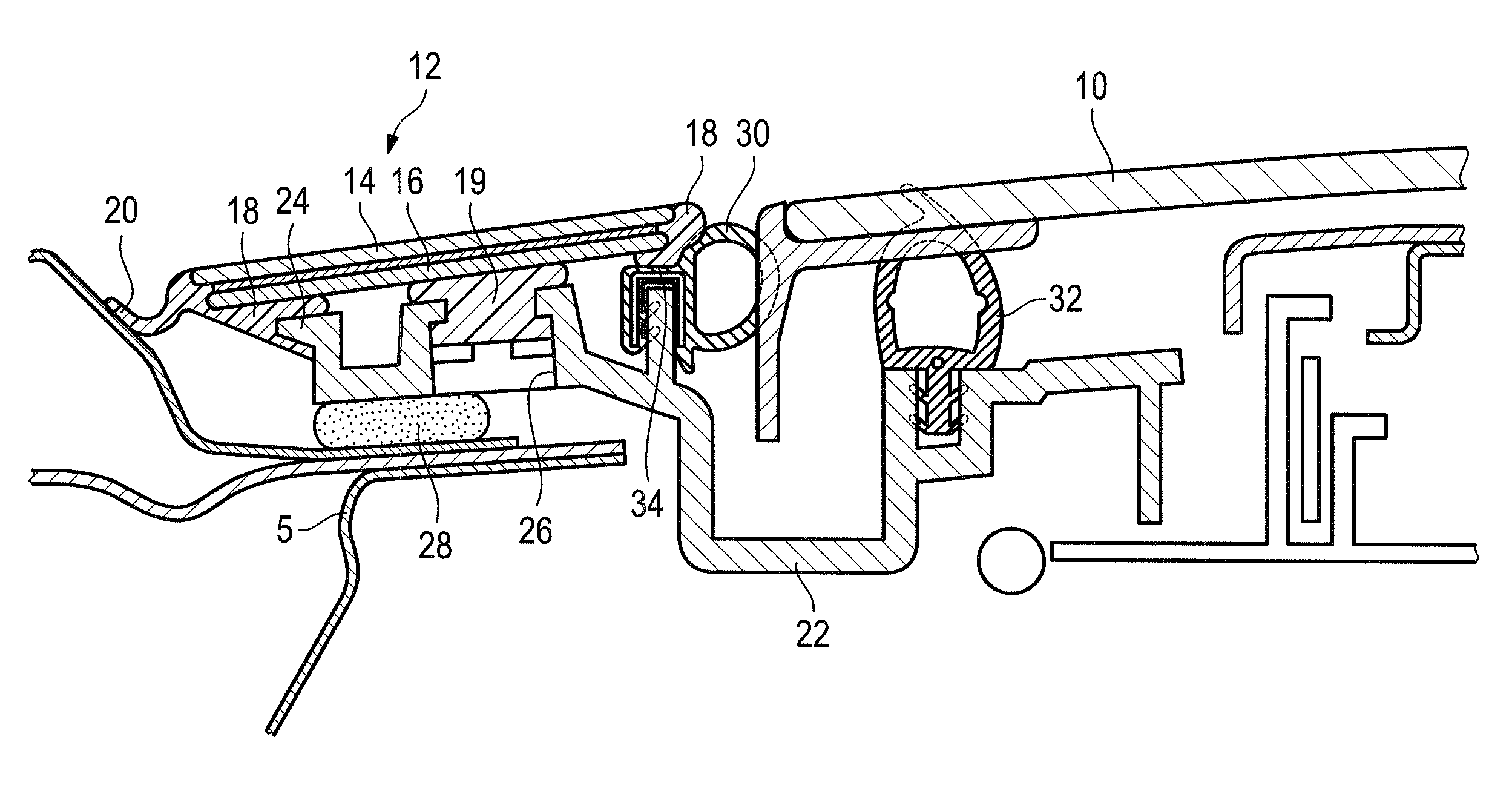

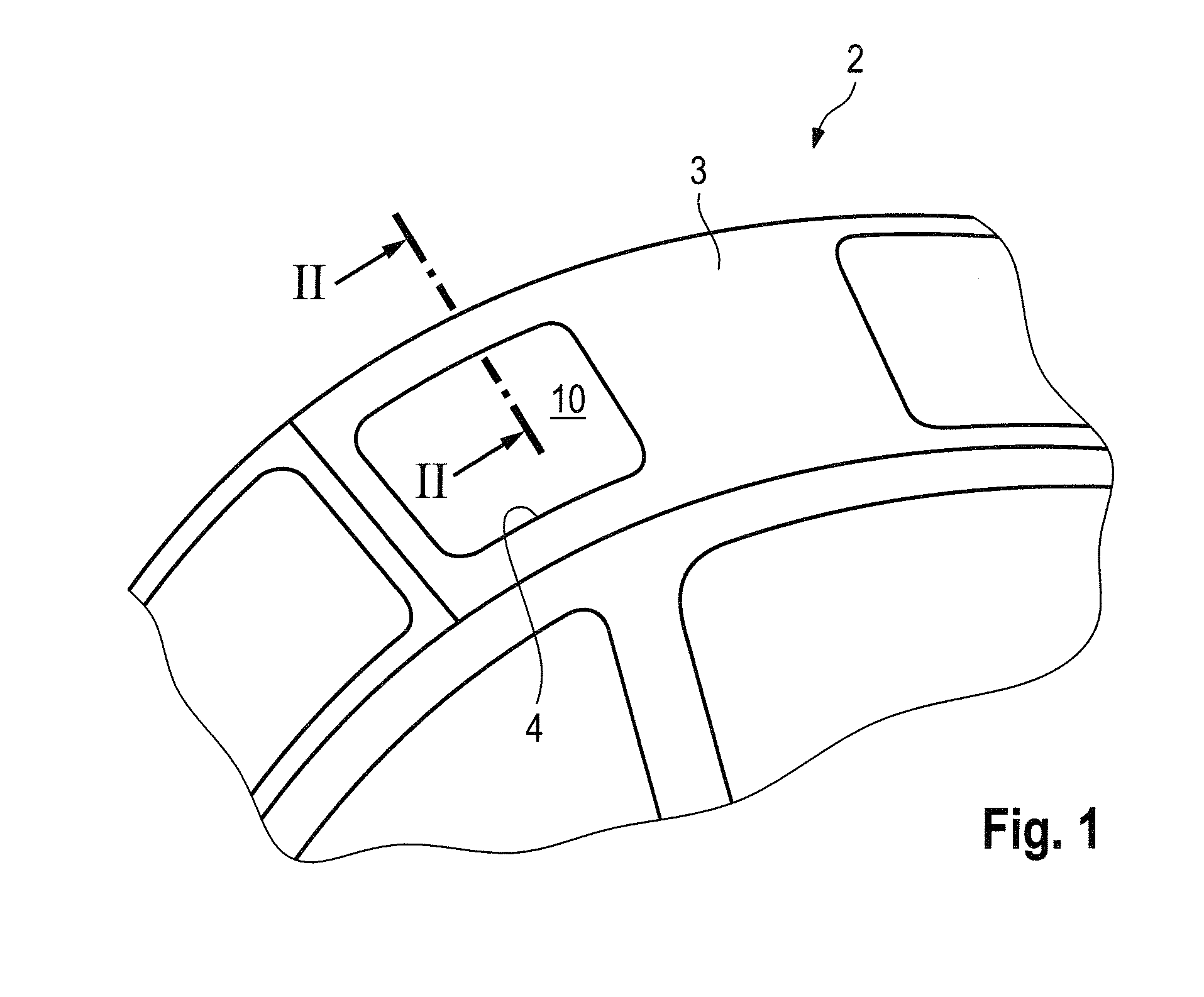

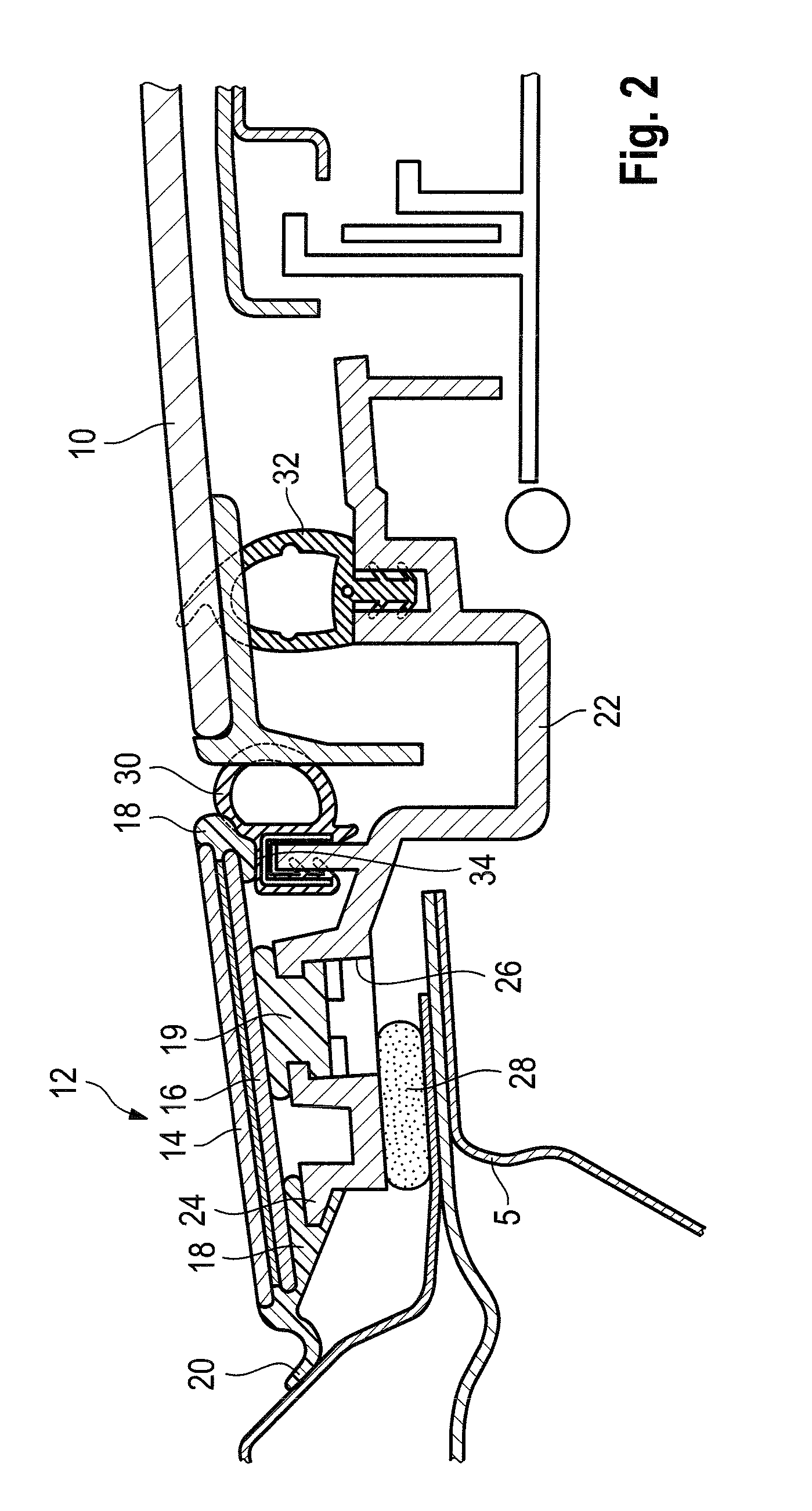

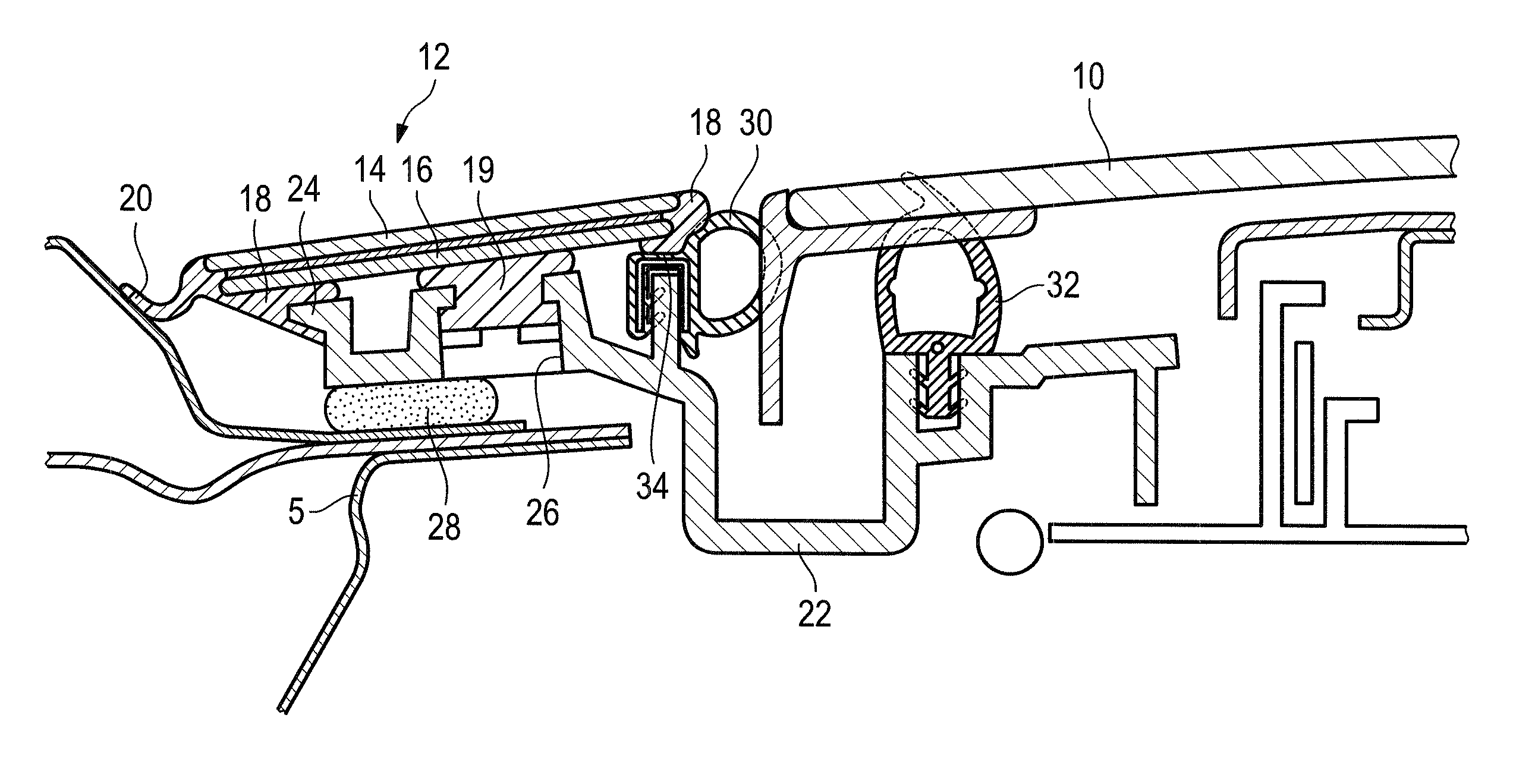

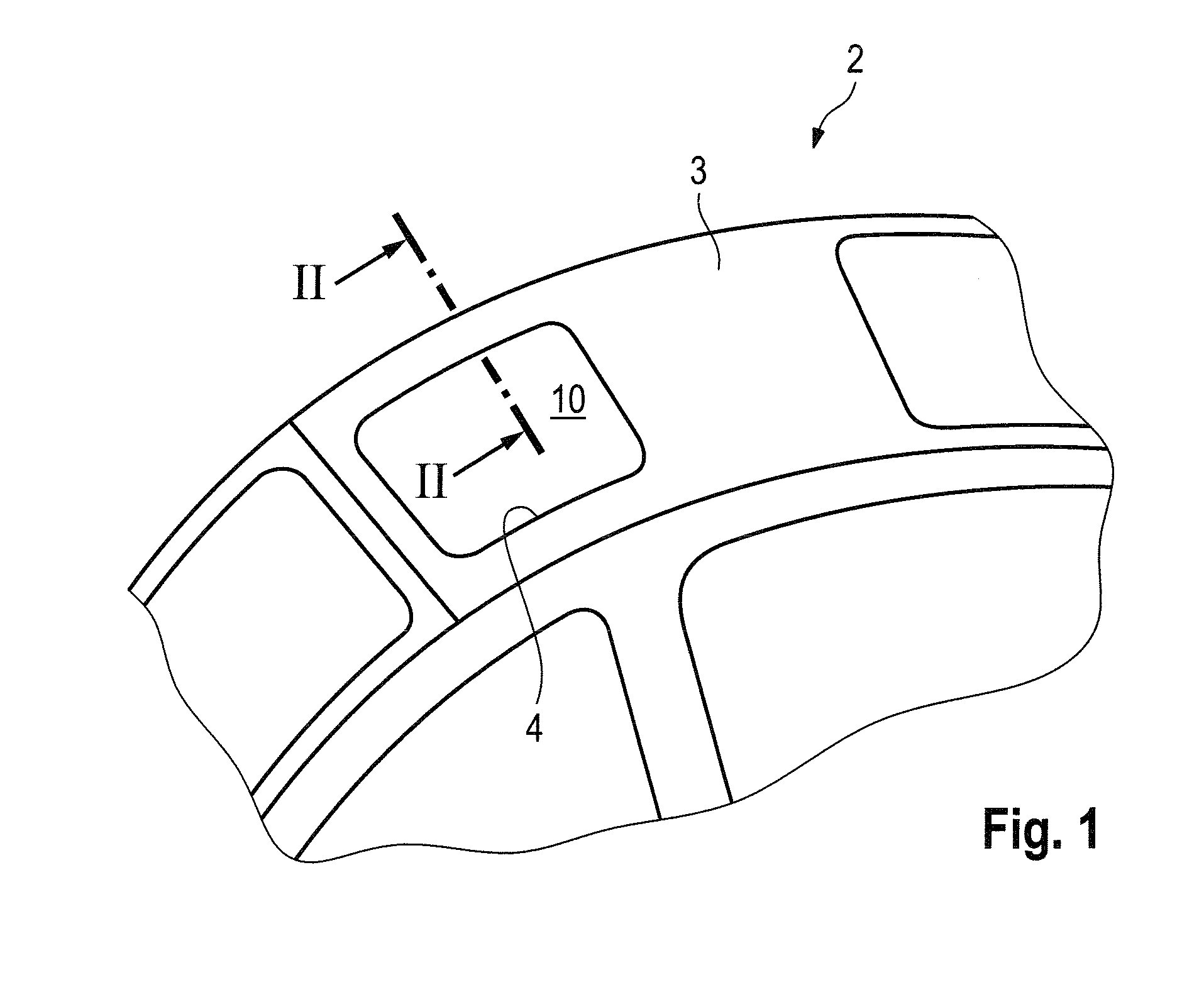

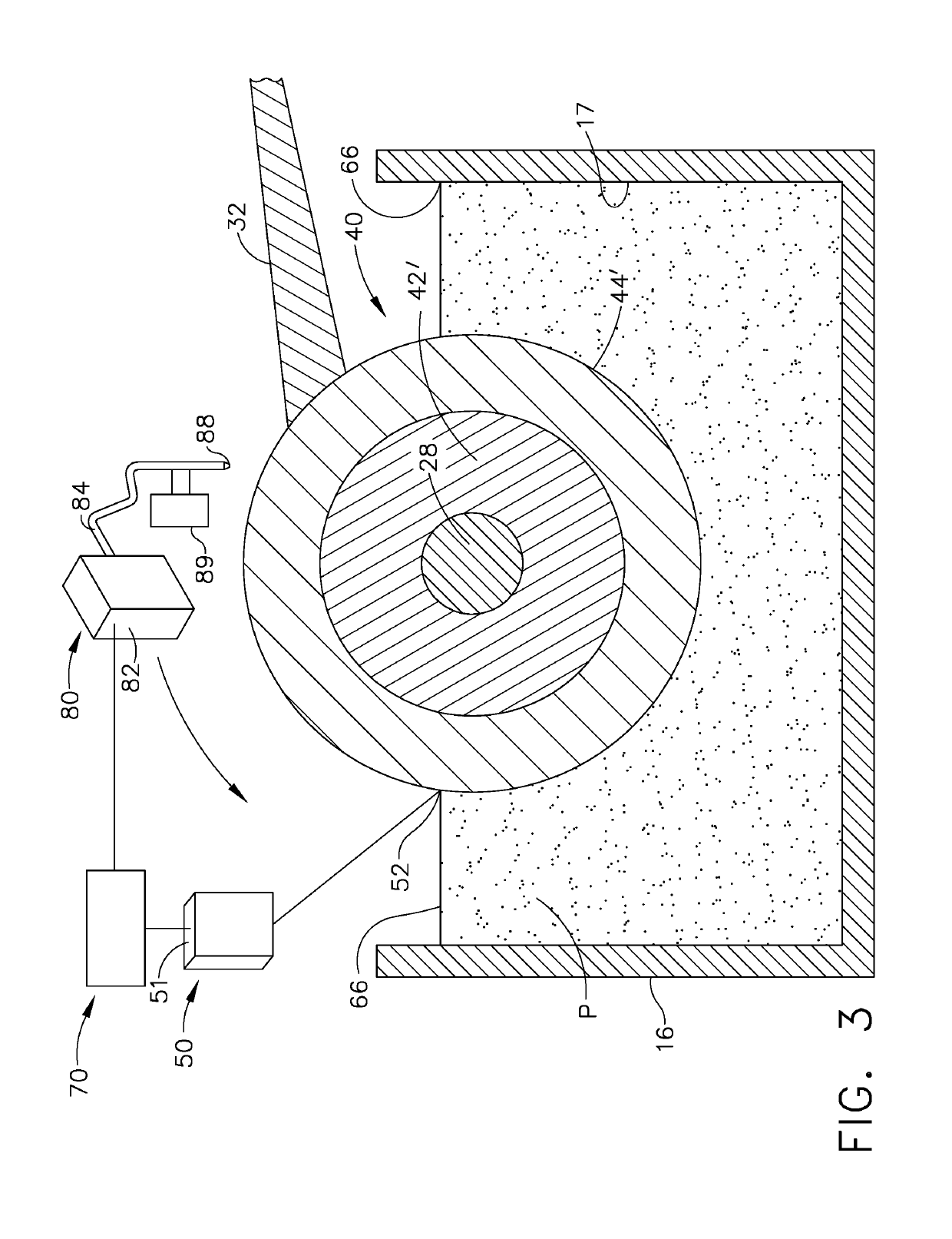

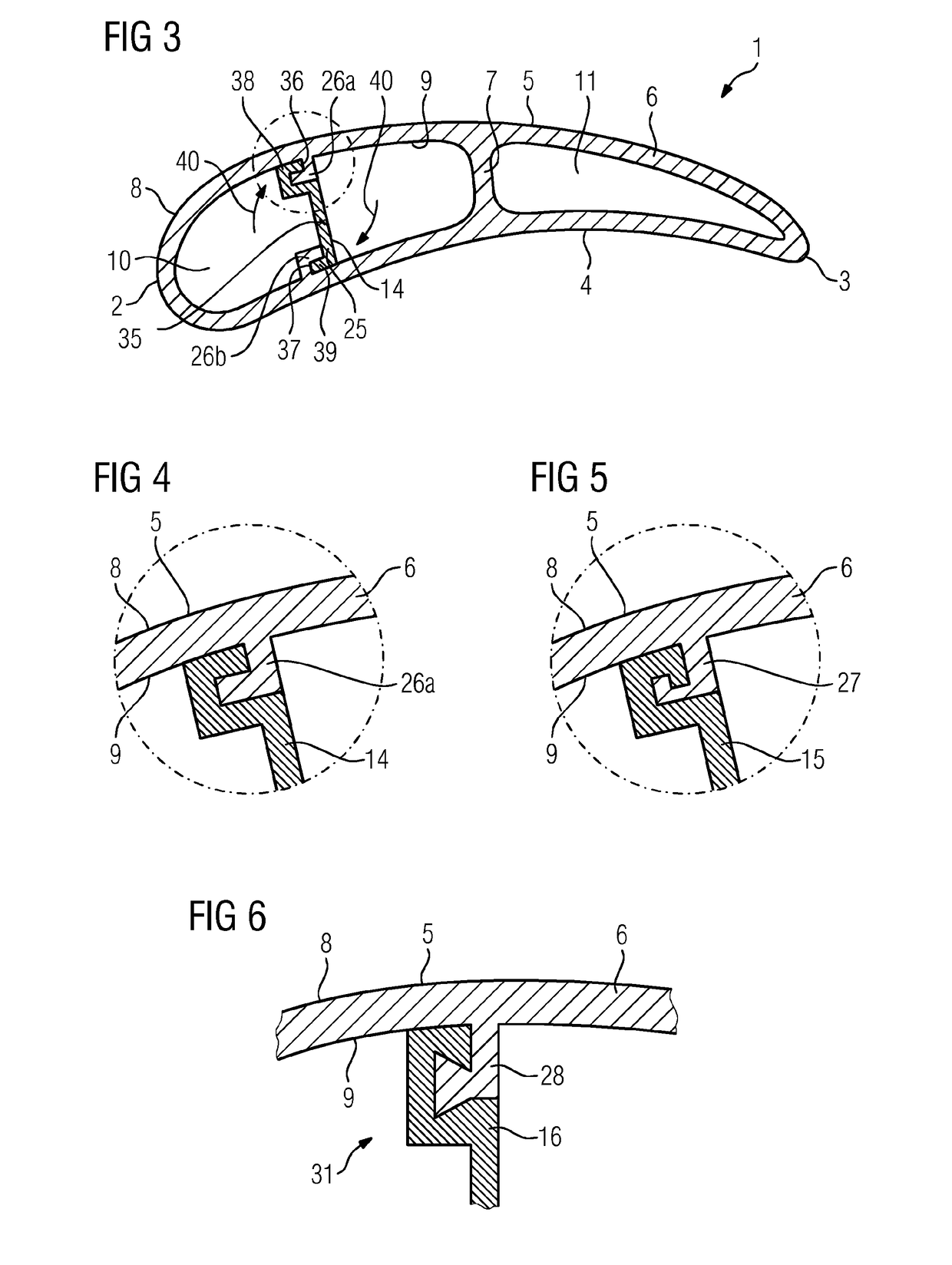

Method of attaching functional components to a roof element of a vehicle, and vehicle roof element

A method of attaching functional components to a roof element of a vehicle, including applying a curable material in a low-viscosity state which is molded in sections by means of a first mold surface, wherein a second mold surface is used which serves for shaping further sections of the curable material, an opening remaining accessible towards the environment through which the curable material can be introduced.

Owner:ROOF SYST GERMANY

Method of attaching functional components to a roof element of a vehicle, and vehicle roof element

ActiveUS9308804B2Complex geometryHigh positioning accuracyEngine sealsVehicle sealing arrangementsEngineeringMechanical engineering

Owner:ROOF SYST GERMANY

Method for enhancing the operational life of production parts in the oil and gas industry

InactiveUS20170253977A1Extended service lifeIncrease corrosion ratePressure inorganic powder coatingLoss rateEpoxy

A method for improving the operational life of production parts, such as steel sucker rods, couplings, pump parts, and tubes, for use in underground recovery or production of oil and gas, includes coating the steel production parts with a layer of corrosion resistant alloy (CRA) to reduce a loss rate of the steel by improving corrosion resistance and mitigate pitting. In one embodiment, the corrosion resistant alloy is a nickel-based alloy. In other embodiments, the steel production parts can either be coated with an epoxy / phenolic layer, or coupled with a sacrificial anode. The coating process can implemented by any one of the following processes: cold spray coating; electroless corrosion resistant coating; flow forming; and electrochemical machining.

Owner:NEW MEXICO JUNIOR COLLEGE RES FOUND LLC

Method for producing a metal component

InactiveUS20120024717A1Great sectionDifficult to processCellsMachining electric circuitsThree dimensional shapeManipulator

Method for machining a metal component which has a three-dimensional shape produced by removing and / or shaping material, wherein one or more superior component sections are electrochemically finish-machined by means of a nozzle-like cathode, via which an electrolyte is delivered into the working region, and wherein the cathode or the metal component is moved freely in space by means of a manipulator element.

Owner:LEISTRITZ TURBOMASCHEN TECHN

Multi-piece driver with separately cast hosel

ActiveUS20150011325A1Without requiring additional material cost and tool wear expenseLess brittleSensing record carriersGolf clubsMetallic materialsGolf Ball

The present invention is directed to a multi-piece golf club head having a metal hosel with adjustability features that is cast separately from a face component, sole, and crown, and then is permanently affixed to those other parts after casting is complete. The face component, sole, and crown may be composed of any suitable materials, but preferably each of the face component, the sole, and the crown are stamped from a metal material and are welded to the hosel.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Method for enhancing the operational life of production parts in the oil and gas industry

InactiveUS20150299863A1Extended service lifeIncrease corrosion rateEnvelopes/bags making machineryLiquid surface applicatorsEpoxySpray coating

A method for improving the operational life of production parts, such as steel sucker rods, couplings, pump parts, and tubes, for use in underground recovery or production of oil and gas, includes coating the steel production parts with a layer of corrosion resistant alloy (CRA) to reduce a loss rate of the steel by improving corrosion resistance and mitigate pitting. In one embodiment, the corrosion resistant alloy is a nickel-based alloy. In other embodiments, the steel production parts can either be coated with an epoxy / phenolic layer, or coupled with a sacrificial anode. The coating process can implemented by any one of the following processes: cold spray coating; electroless corrosion resistant coating; flow forming; and electrochemical machining.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Ultrasonic welding device and method of operating said device

ActiveUS9216540B2Avoid restrictionsLack of reproducibilityLaminationLamination apparatusUltrasonic weldingEngineering

Owner:AIRBUS HELICOPTERS DEUT GMBH

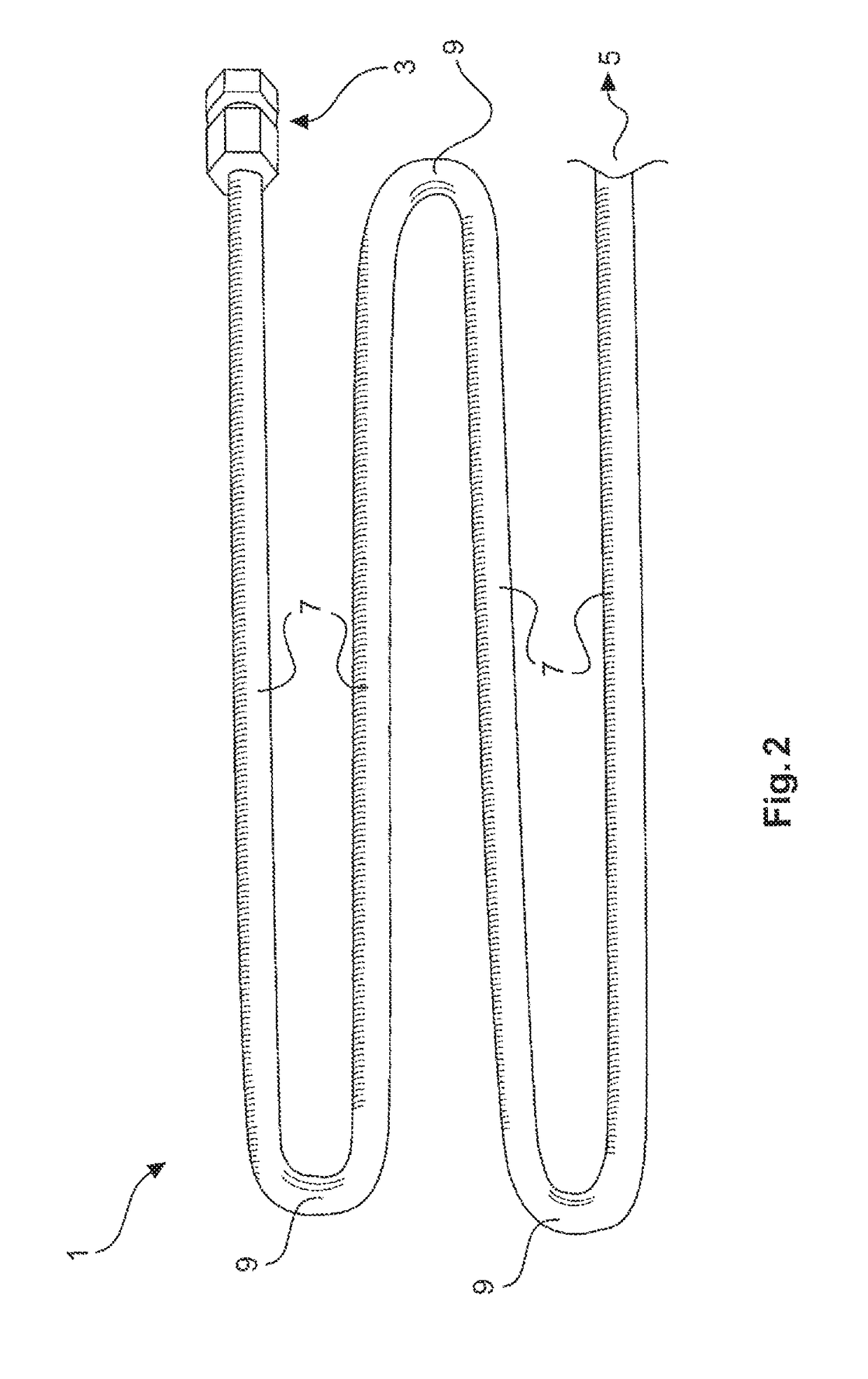

Method for forming a tubular body, undulating tubular body and use of same

InactiveUS20180021830A1Increase flexibilitySufficient incompressibilityRigid pipesBiomedical engineering

Owner:WOBBEN PROPERTIES GMBH

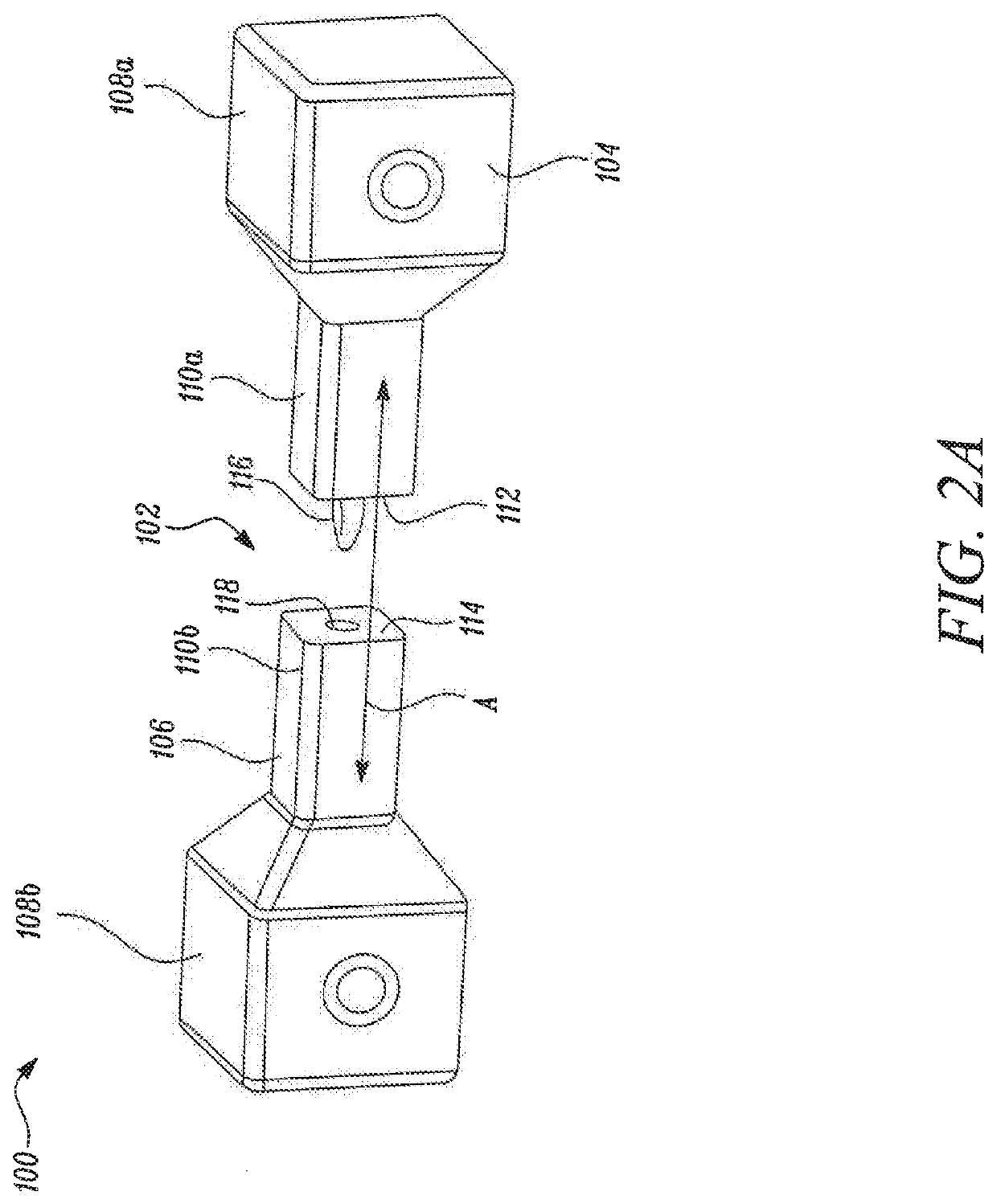

Investment casting pattern

ActiveUS20190388961A1Low efficiencyShort lifeAdditive manufacturing apparatusFoundry mouldsInvestment castingMaterials science

An investment casting pattern including: a consumable body formed of: a first body portion; and a second body portion; and a fastener arranged to form an interface between the first body portion and the second body portion, and to locate the first body portion relative to the second body portion, wherein the fastener is formed of a different material than the first body portion and the second body portion.

Owner:ROLLS ROYCE PLC +1

Brazed component and method of forming a brazed joint therein

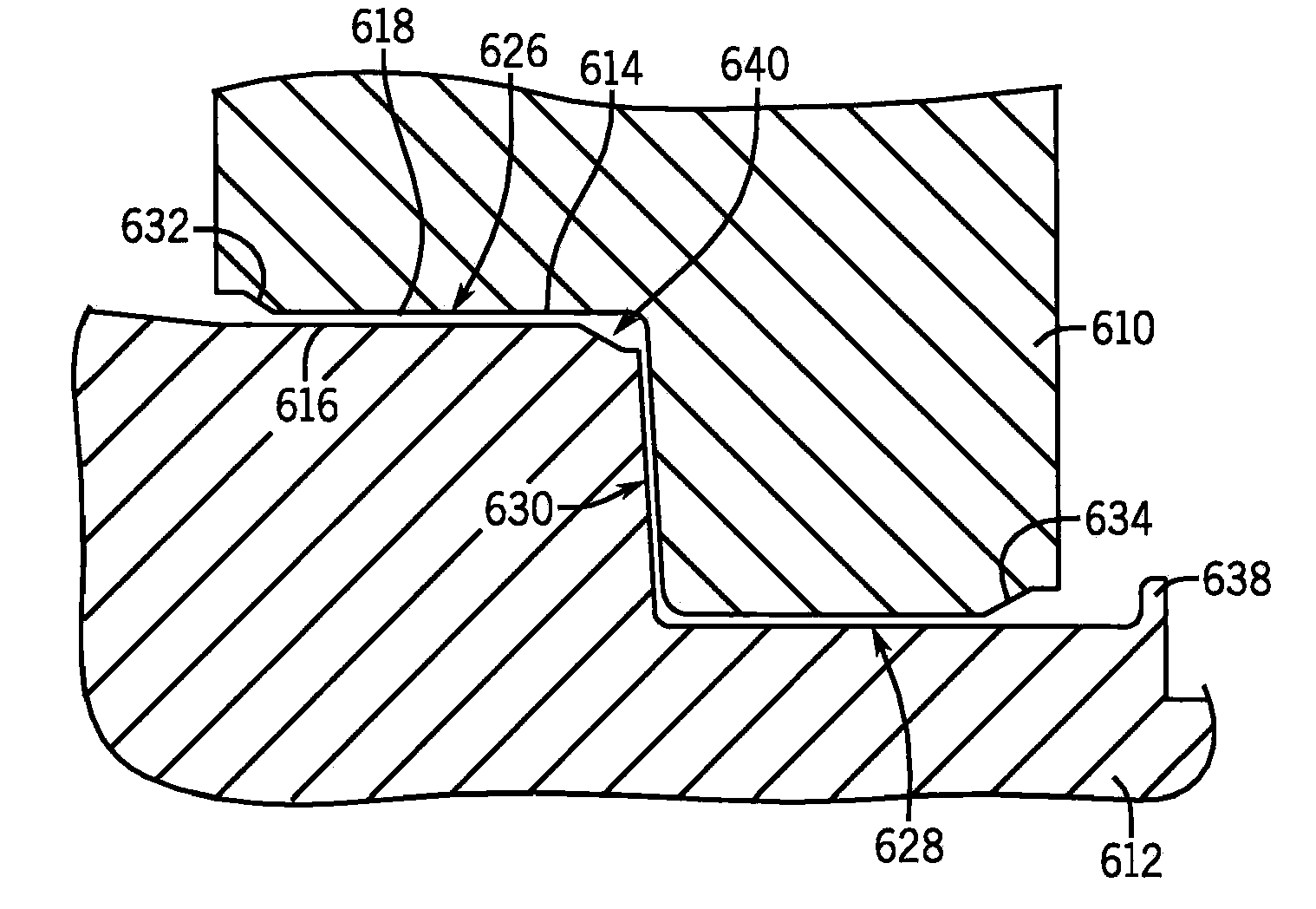

ActiveUS8753753B2Avoid actionIncrease the gapLayered productsBuilding componentsEngineeringMechanical engineering

A brazed part, and methods of forming a brazed joint therein, are disclosed. The brazed part includes two or more components that are brazed together. Using the method of locating the parts herein disclosed, an inter-component gap between the components may be formed. Flow control features formed along the inter-component gap may then be used to assist in the retention of the braze material between the components during brazing.

Owner:SKN SINTER METALS LLC (US)

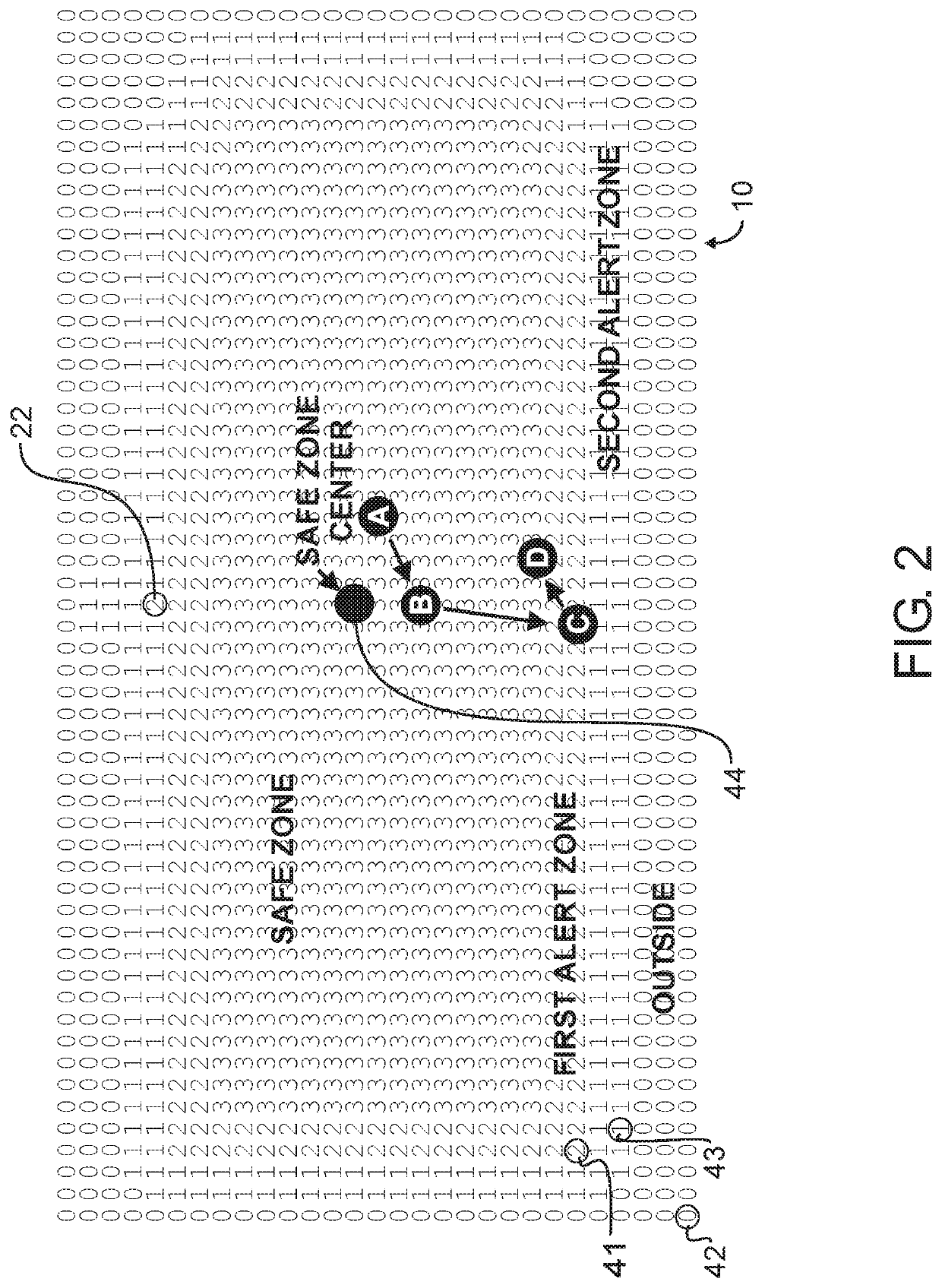

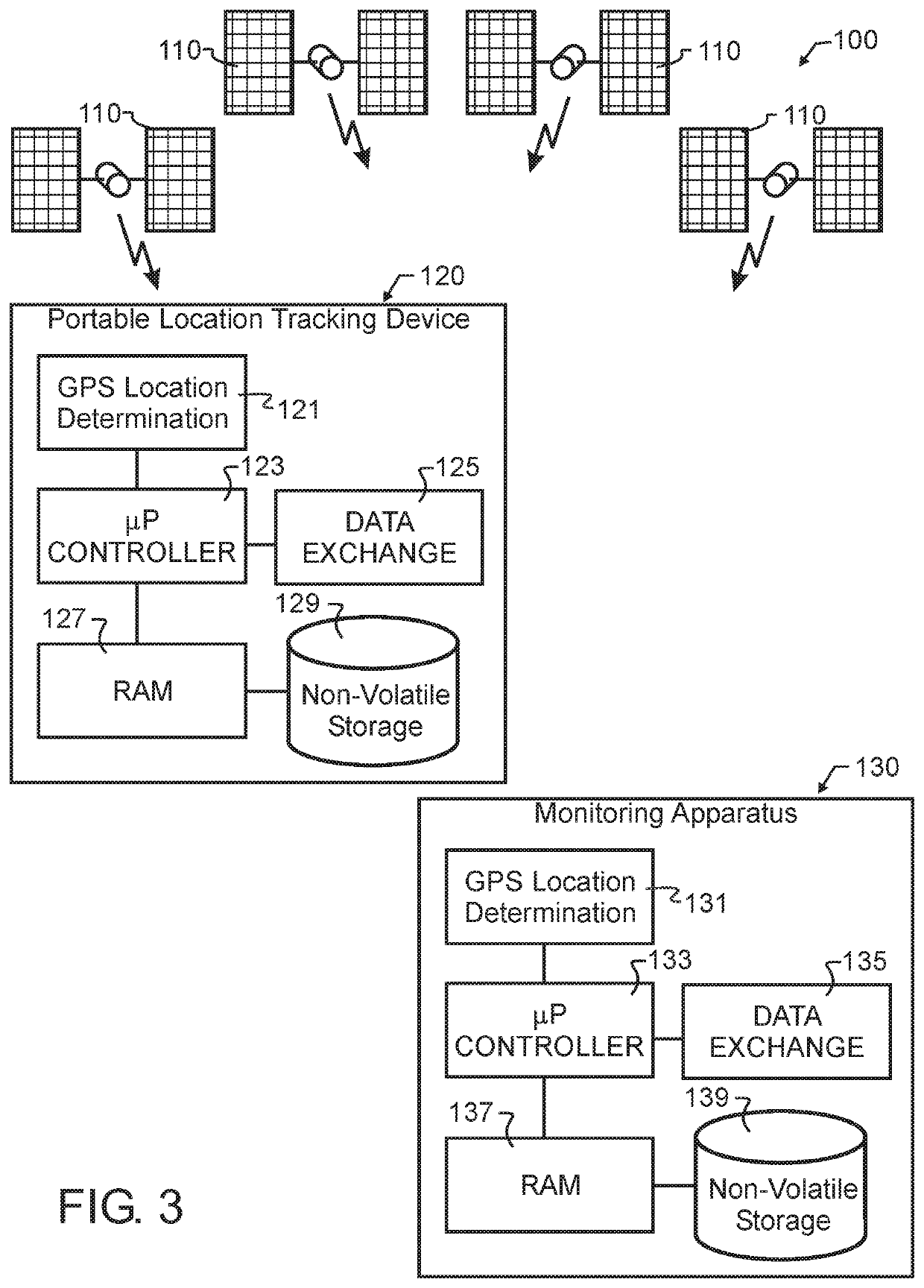

Wireless Location Assisted Zone Guidance System Incorporating Secure Transmission of Location

ActiveUS20210190503A1Simple and efficient set-upSimple and efficient and operationNavigational calculation instrumentsPosition fixationSecure transmissionLocation tracking

A fully self-contained portable location tracking device autonomously compares a current location with a latitude-longitude map stored in memory. The latitude-longitude map stores guidance zone values indicative of a predetermined safe zone, progressive alert zones, and a predetermined reference point. The guidance zone values represent actions to be taken based upon current GC location. When initiated by some combination of current location or zone value, location history, and time, or when otherwise queried, the tracking device transmits the offset from reference location, rather than actual current location data, to at least one wireless communications monitoring apparatus. The monitoring apparatus also stores a copy of the latitude-longitude map and reference point. Using the received offset, the monitoring apparatus knows both the location of the location tracking device and the actions to be taken based upon current location.

Owner:GPSIP

Additive machine utilizing rotational build surface

ActiveUS10239157B2Less spaceEquipment is smallTurbinesManufacturing driving meansBiomedical engineeringEnergy source

An apparatus for manufacturing an axi-symmetric part. The apparatus includes a vessel configured to contain the powder. The vessel is also configured to receive a part such that at least a portion of the part contacts the powder contained within the vessel. A first energy source is configured to generate a first beam of energy. The first beam of energy is configured to melt the powder at a first predetermined location such that the melted powder fuses to the part.

Owner:GENERAL ELECTRIC CO

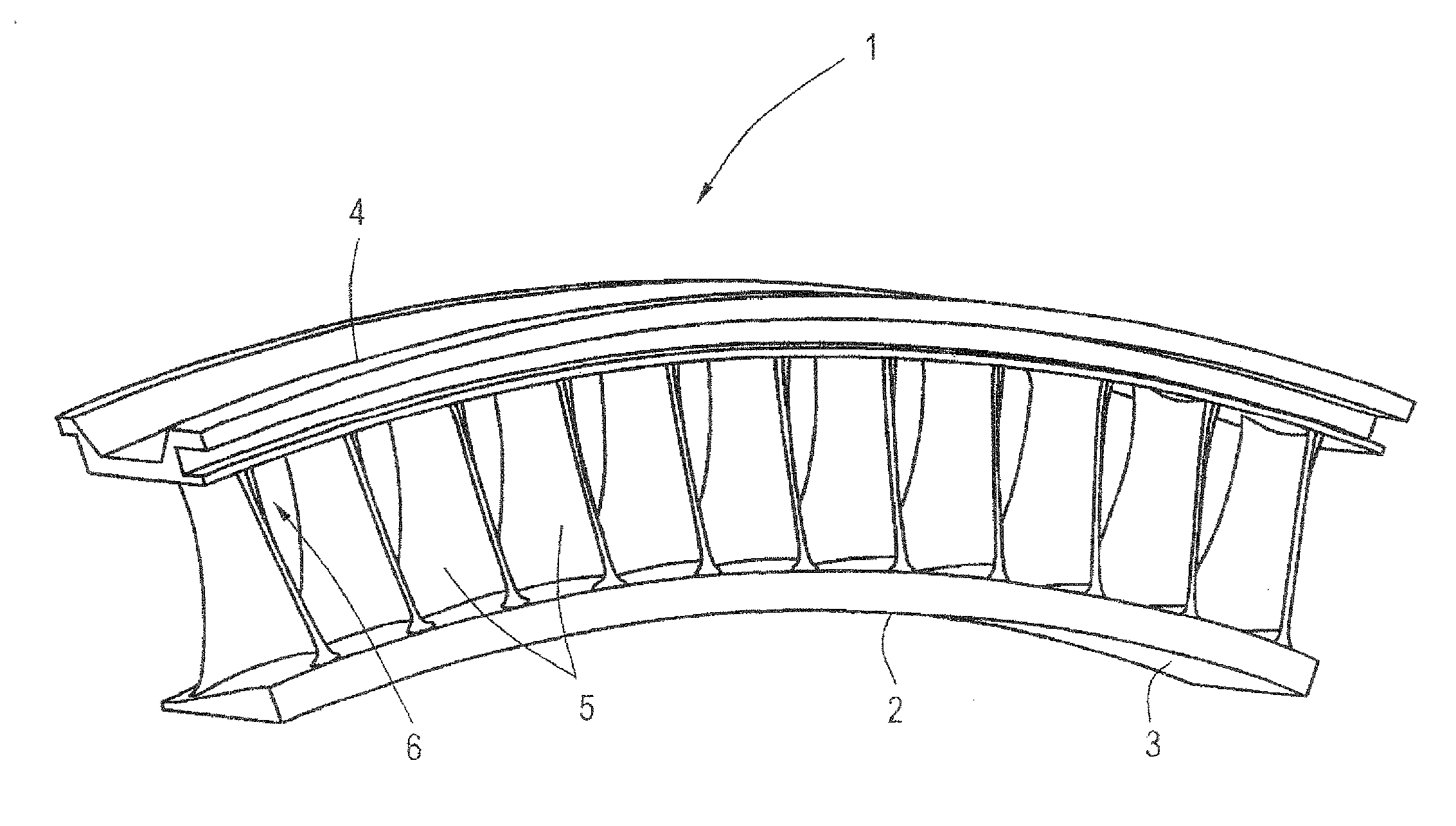

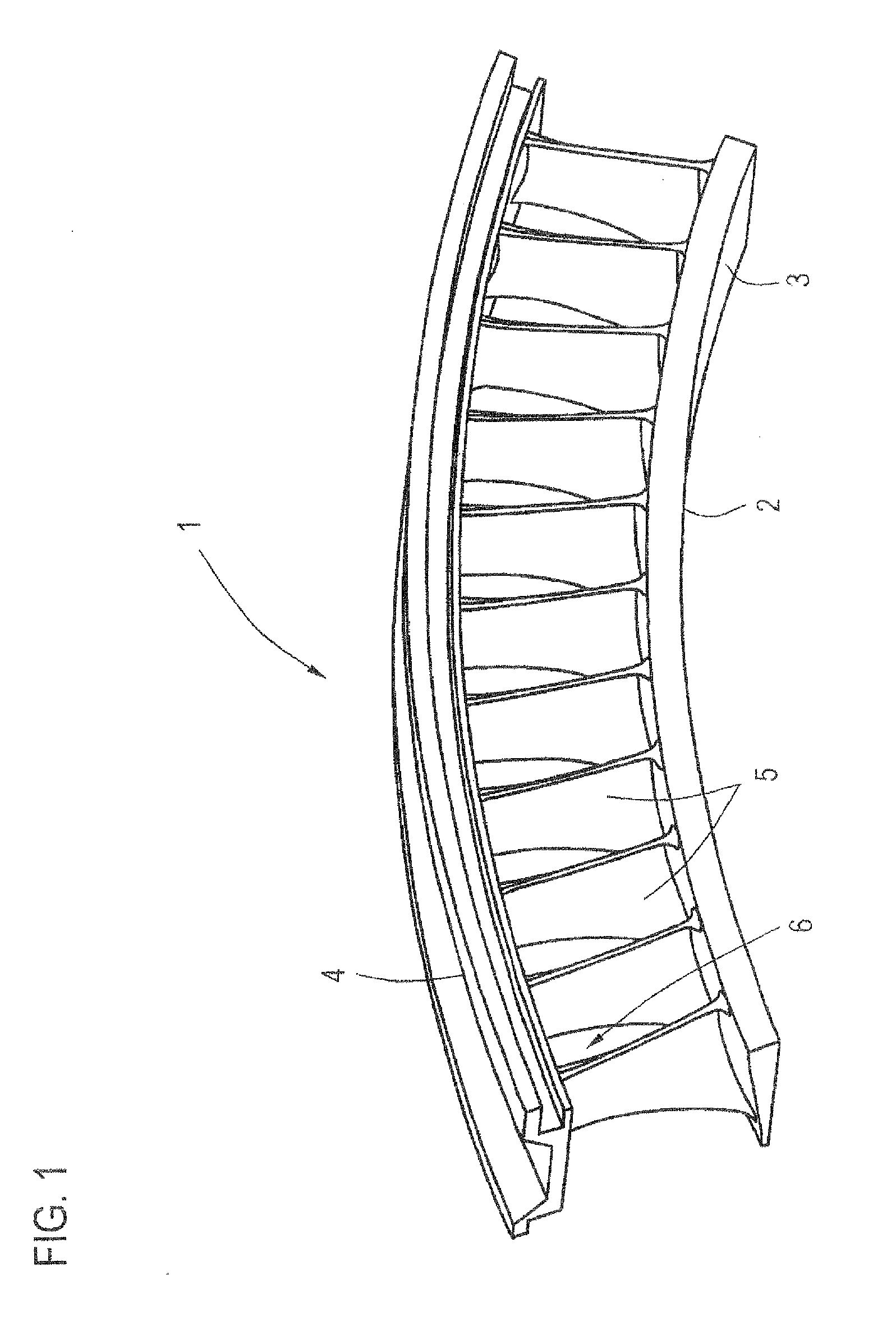

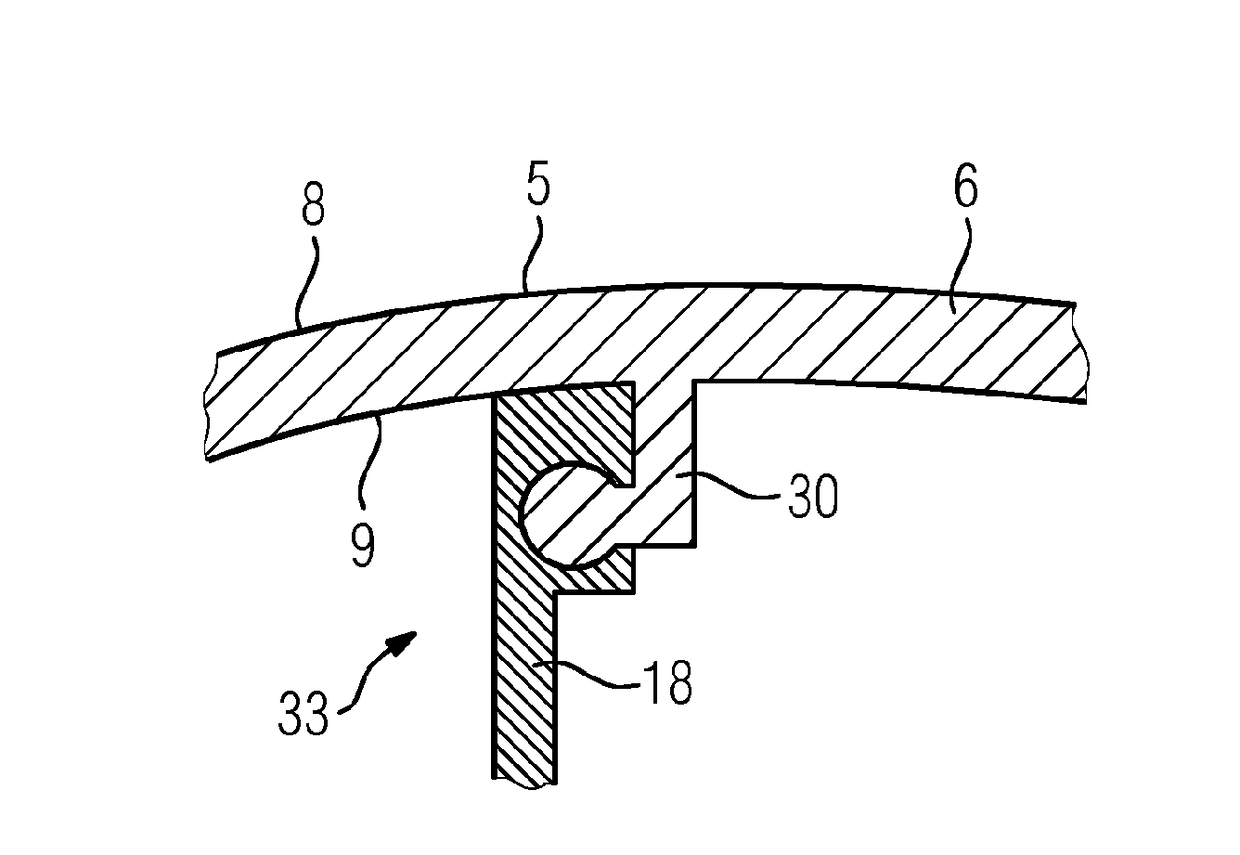

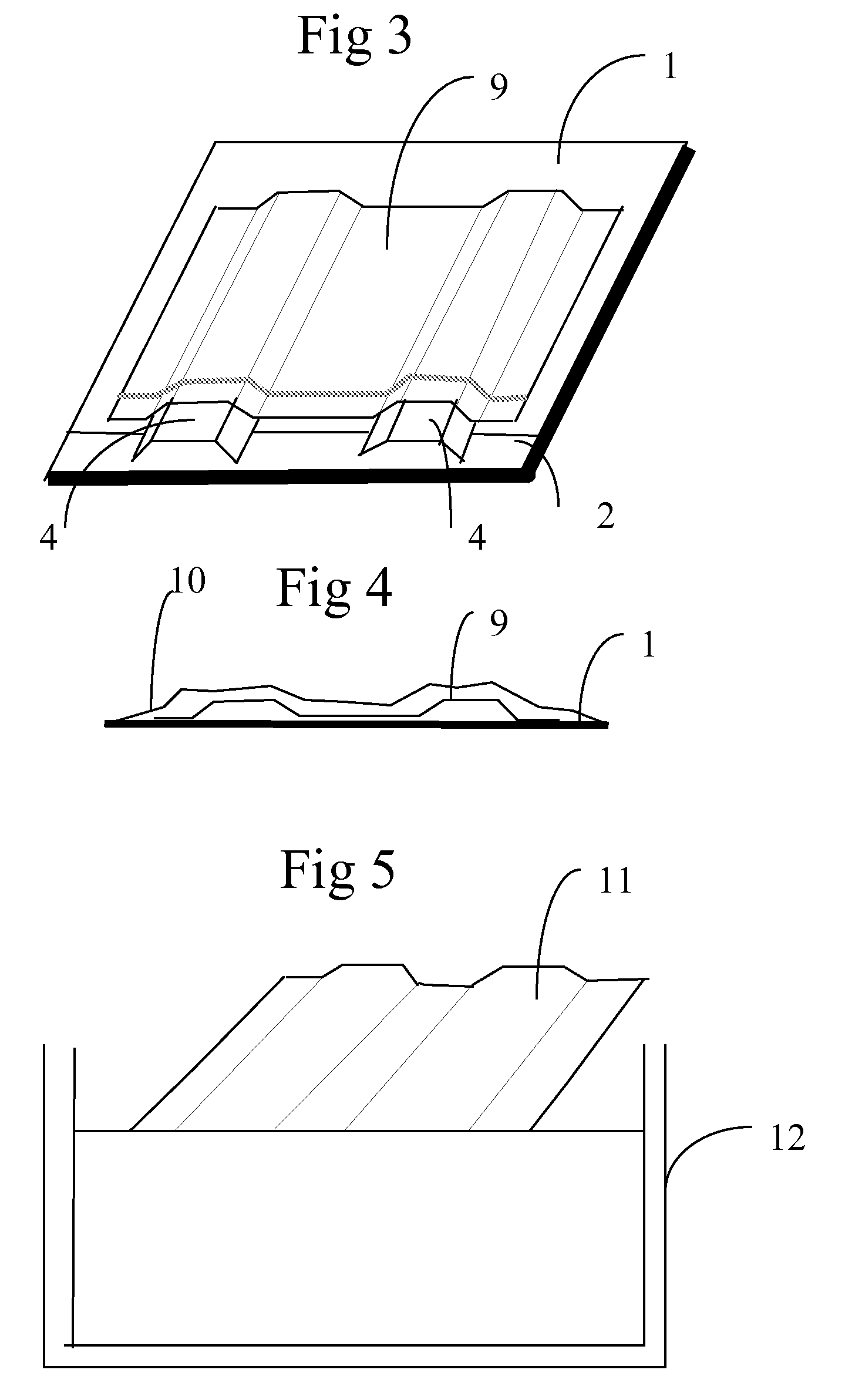

Hollow blade body, insertion rib, and hollow blade

InactiveUS20170314400A1Strong stiffeningConnection securityEngine fuctionsBlade accessoriesEngineeringMechanical engineering

A hollow blade body for a hollow blade, has a blade wall which has a pressure side which has at least one first blade connection element on the inner side thereof, and a suction side which has at least one second blade connection element diametrically opposite to the first blade connection element on the inner side thereof, wherein the first blade connection element can be engaged with at least one first rib connection element which is arranged on a first longitudinal end of an insertion rib, and the second blade connection element can be engaged with at least one second rib connection element which is arranged on a second longitudinal end of the insertion rib facing away from the first longitudinal end in such a way that the insertion rib is fixed on the hollow blade body and effects a stiffening of the hollow blade.

Owner:SIEMENS AG

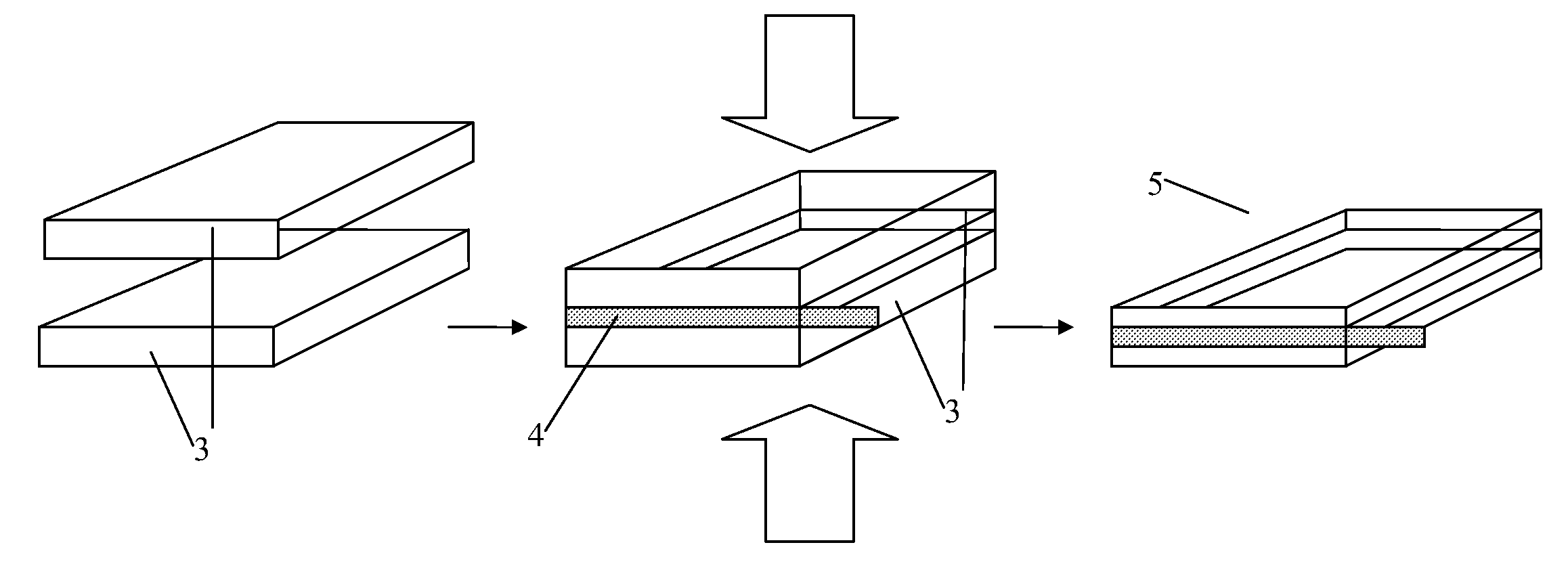

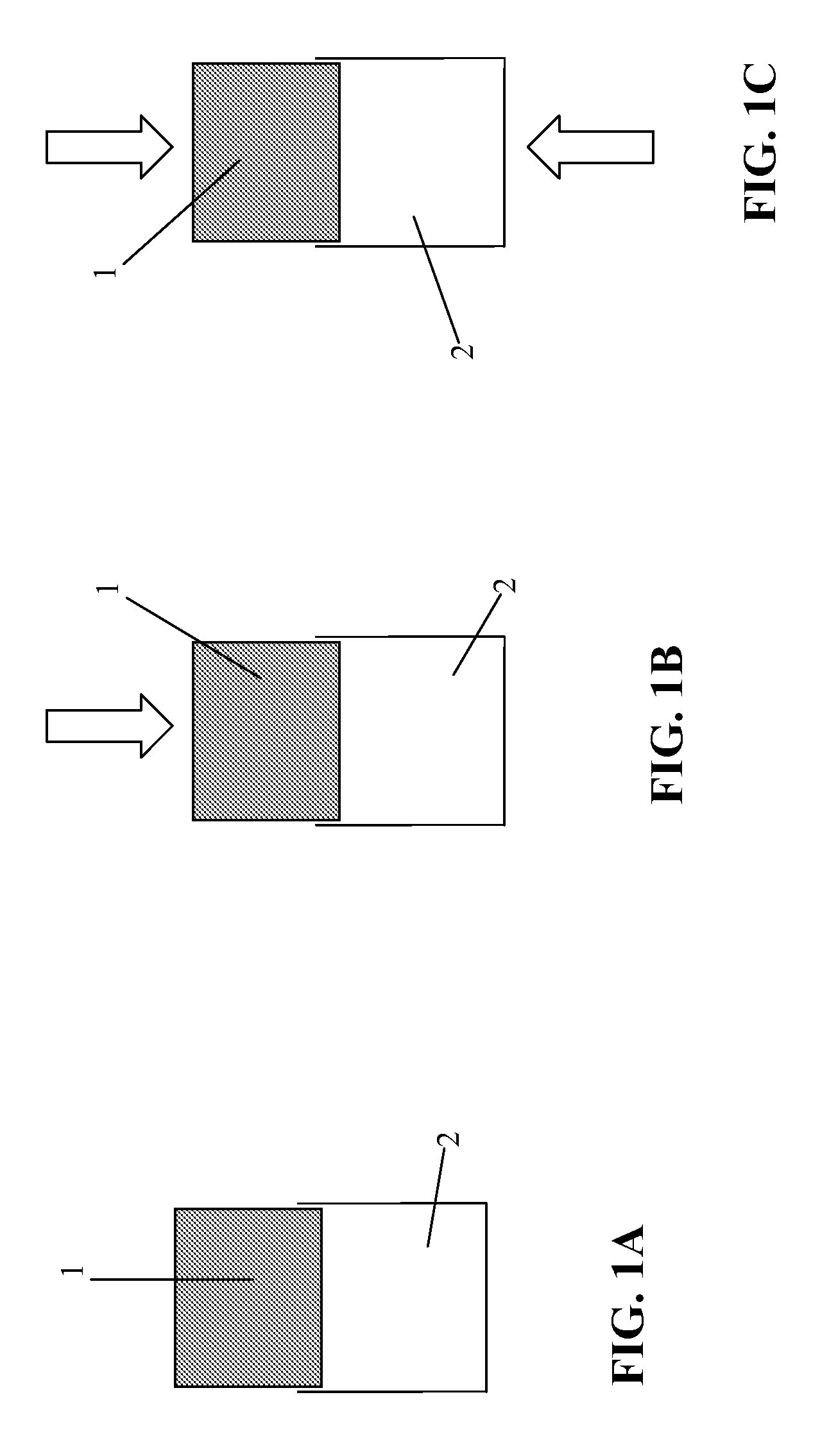

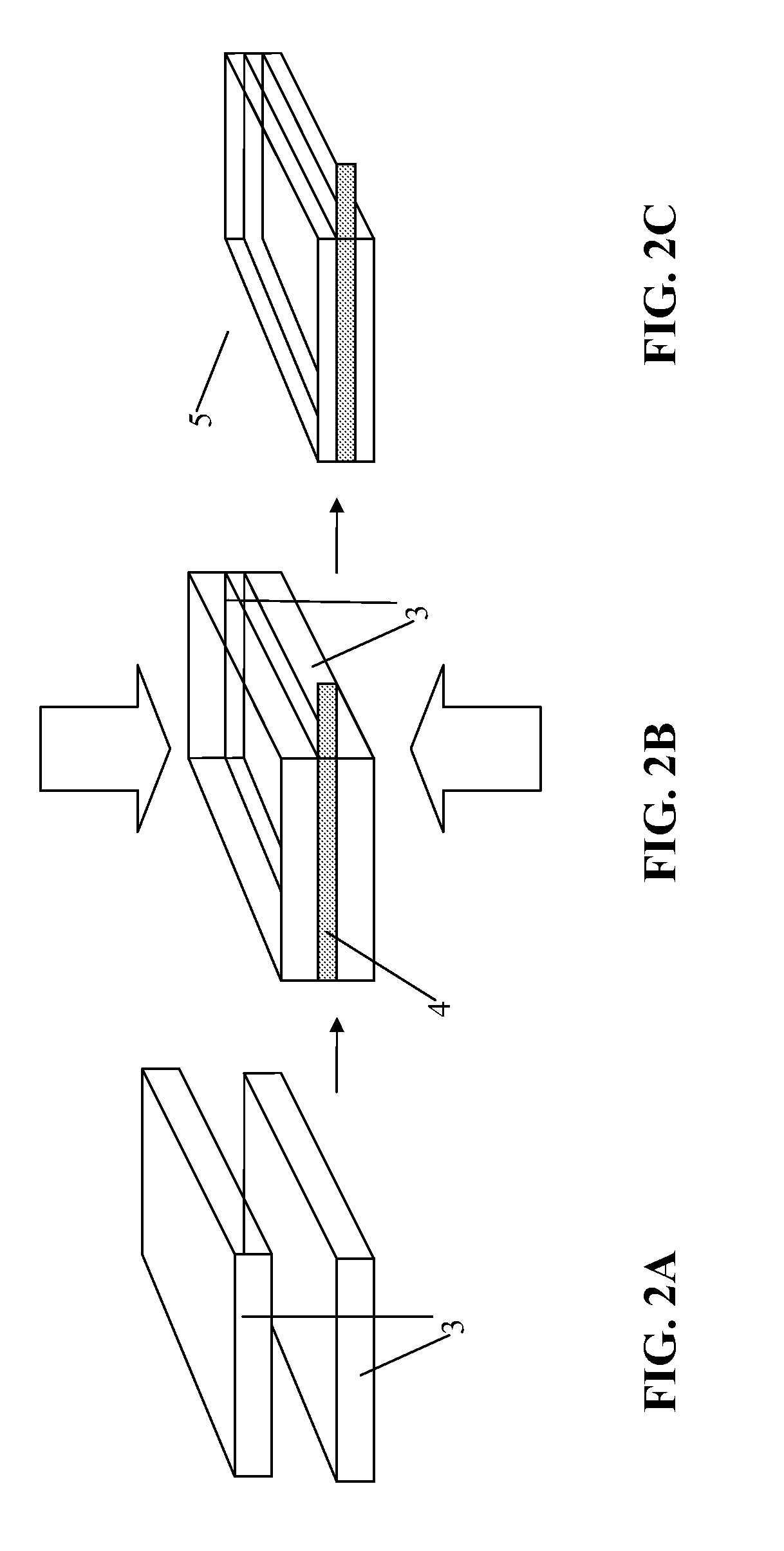

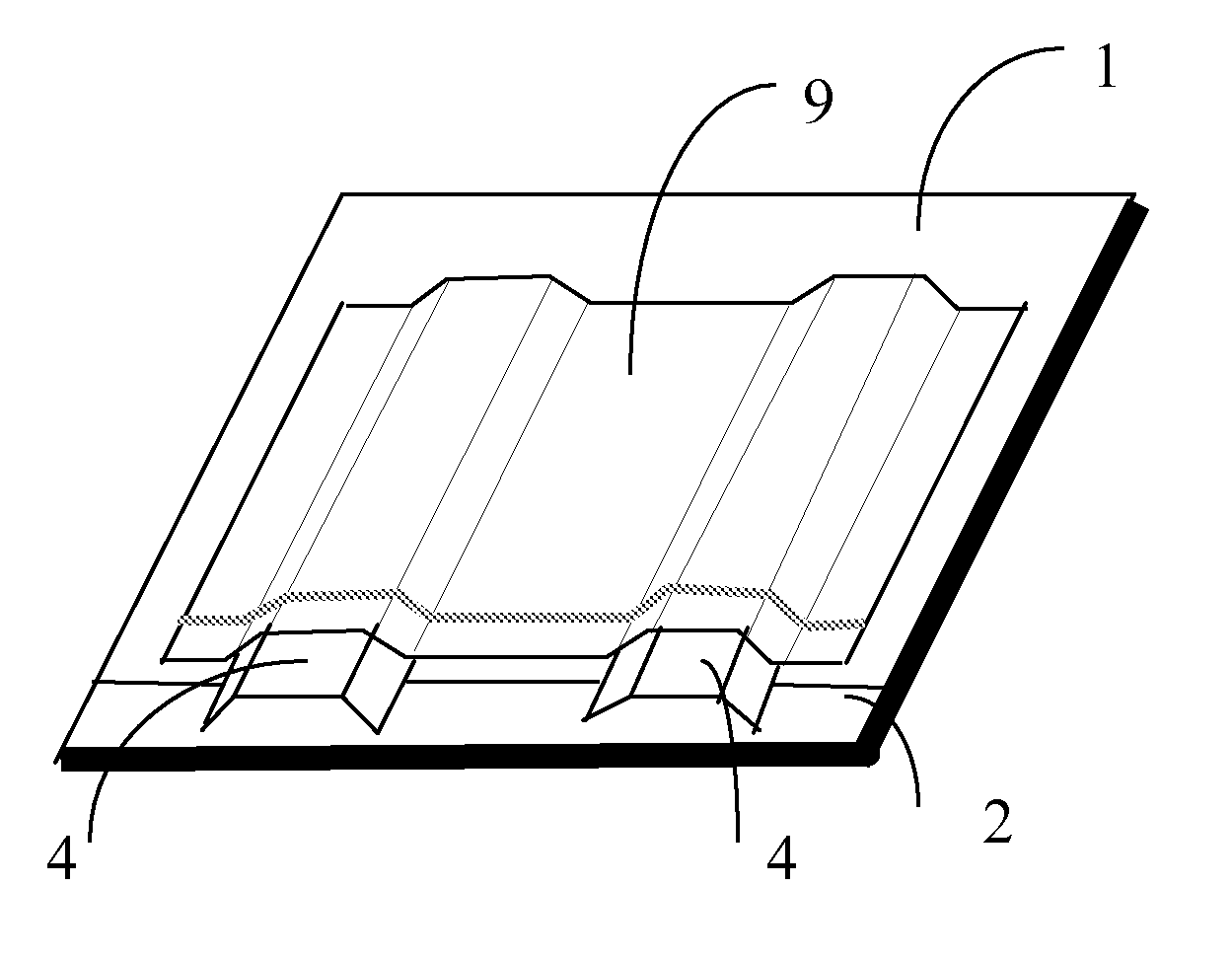

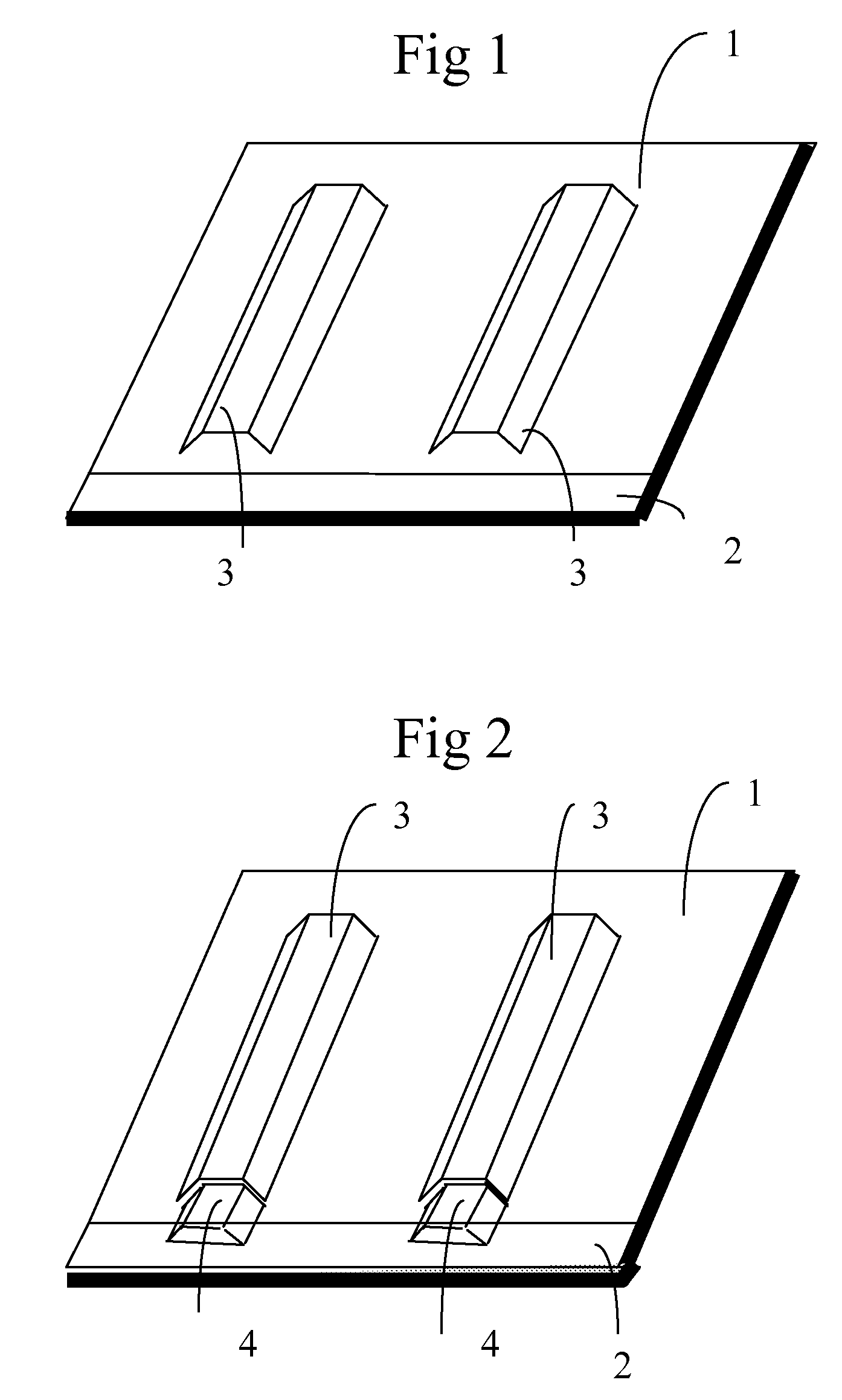

Method for the manufacture of a composite article

InactiveUS8632710B2Reduction factorMinimized tensionLaminationWood working apparatusComposite plateMaterials science

The present invention relates to a method for the manufacture of a composite article comprising a composite plate (1) and at least one fitting (4). The method is characterized by the steps of arranging at least one former on said composite plate (1), arranging at least one fitting (4) on said composite plate (1), producing a lay-up by applying a composite material layer (9) least partly covering an external surface of the former and of the fitting, and curing the layup in a curing process. After curing, said composite material layer (9) forms the walls of a stiffener and at least partly encloses the fitting so as to support it in a predetermined position.

Owner:SAAB AB

Method for producing at least one high-frequency contact element or a high-frequency contact element arrangement and associated apparatuses

PendingUS20200403364A1Cheap productionOptimized in of electrical propertyContact member manufacturingCoupling contact membersPhysicsConductive coating

The present invention relates to a method for producing at least one high-frequency contact element or a high-frequency contact element arrangement comprising at least one such high-frequency contact element. The method includes producing a basic body part of each high-frequency contact element from a dielectric material by means of an additive manufacturing method, wherein the basic body part has a bushing between a first end and a second end of a longitudinal extent of the basic body part. In addition, the method includes coating the dielectric basic body part with an electrically conductive layer and removing the electrically conductive layer in a region surrounding the bushing at the first end and at the second end of the basic body part so as to form an electrically conductive coating on the outer conductor side and an electrically conductive coating on the inner conductor side. The present invention also relates to a high-frequency contact element or a high-frequency contact element arrangement.

Owner:ROSENBERGER HOCHFREQUENZTECHNIK GMBH & CO KG

Fibre-Reinforced Composite Tubular Shafts and Manufacture Thereof

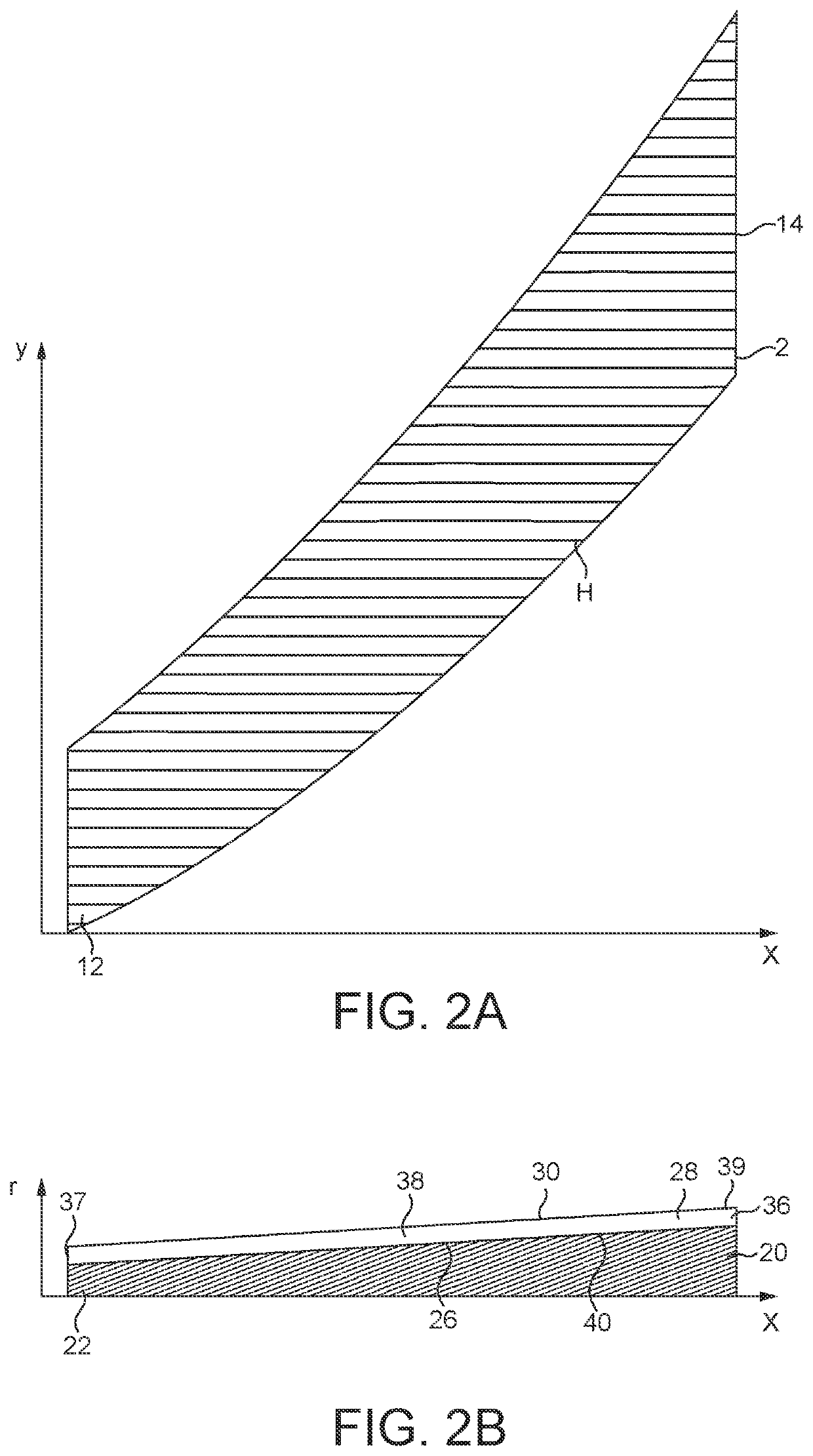

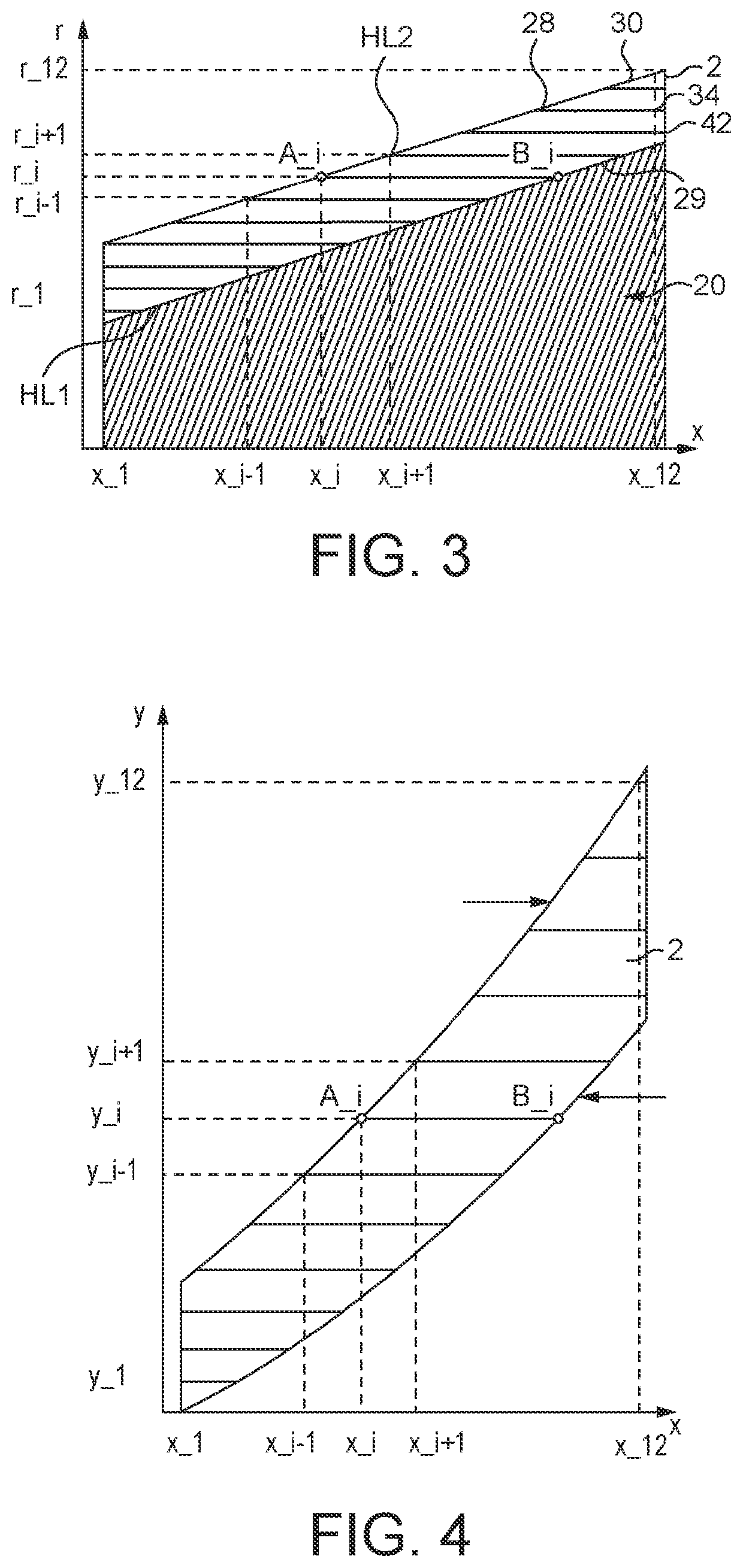

PendingUS20220242062A1Highly consistently and accurately alignedIncrease flexibilityShaftsRotary machine partsResin matrixEngineering

An elongate tubular shaft body having a stack of wrapped layers of fibrous reinforcement in a resin matrix, a portion of the stack of wrapped layers circumferentially surrounding a first surface part of a fibrous layer has a non-constant width which varies non-linearly with a change in radius of an inner elongate circumferential surface in the portion, and wherein the fibrous reinforcement has fibres that are, along the length of the elongate tubular body, constantly oriented with respect to a cylindrical coordinate system about the longitudinal axis of the elongate tubular body, the fibre orientation in any said portion being independent of the geometry of the inner and outer elongate circumferential surfaces of that portion.

Owner:NORTH THIN PLY TECH

Procedure and system for manufacturing a part made from composite material and part made from composite material obtained by means of said method

ActiveUS10967542B2Complex geometryEasy to produceAdditive manufacturing apparatus3D object support structuresFiber bundleLiquid state

The invention relates to a method for manufacturing a part made from composite material, having a body and one or more continuous fibre bundles in its interior, characterised in that it comprises the stages of: a) obtaining a body that includes one or more tubular cavities in its interior that extend between a first end, disposed on the outer surface of the body and which comprises an inlet orifice, and a second end, opposite to the first end; b) introducing resin in the liquid state and a continuous fibre bundle in the interior of at least one tubular cavity through its inlet orifice; and c) curing the resin until it solidifies, adhering to the body and fixing the continuous fibre bundle. The invention also relates to a system for manufacturing a part made from composite material and to the part made from composite material obtained.

Owner:FUNDACIO EURECAT

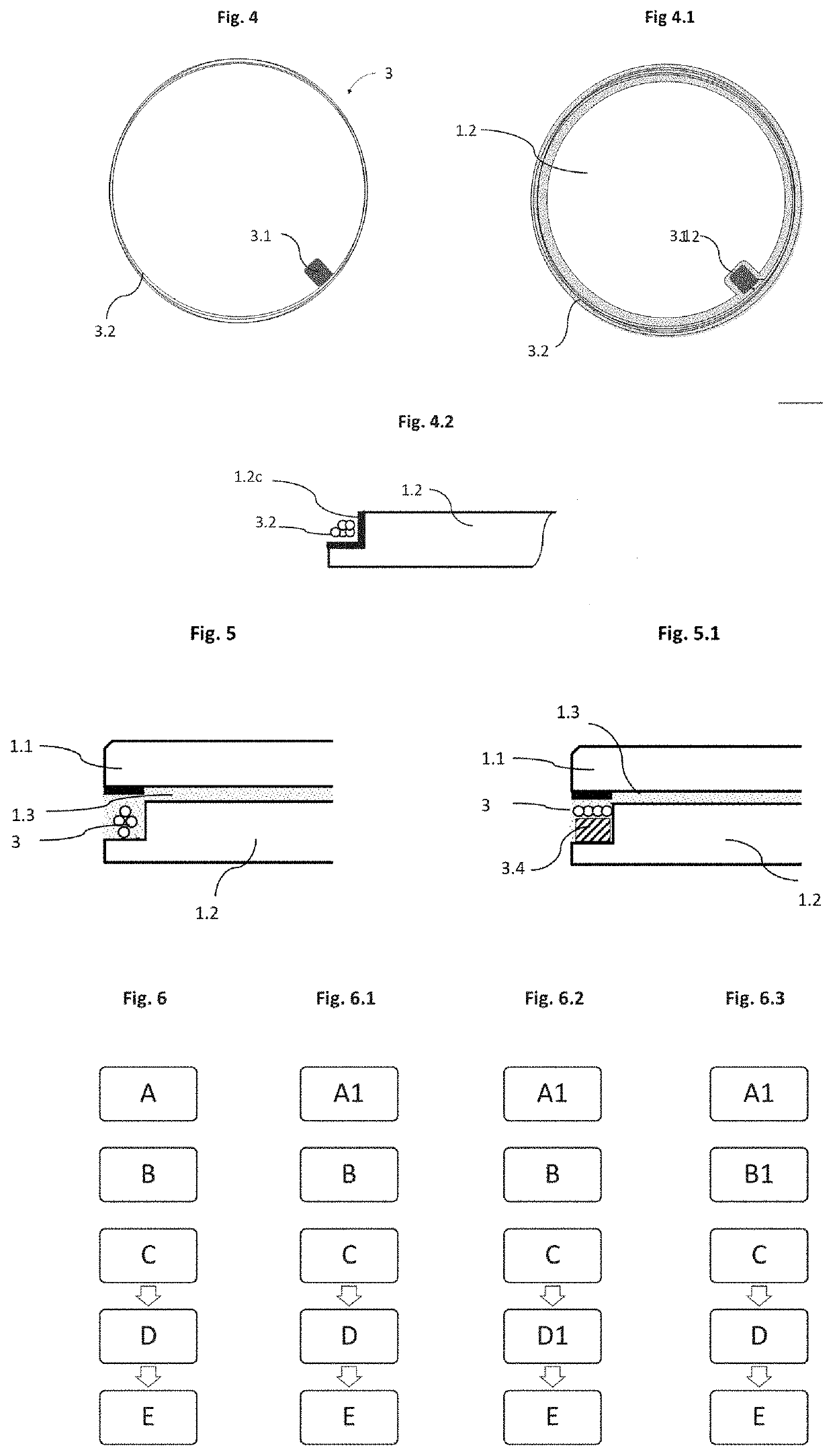

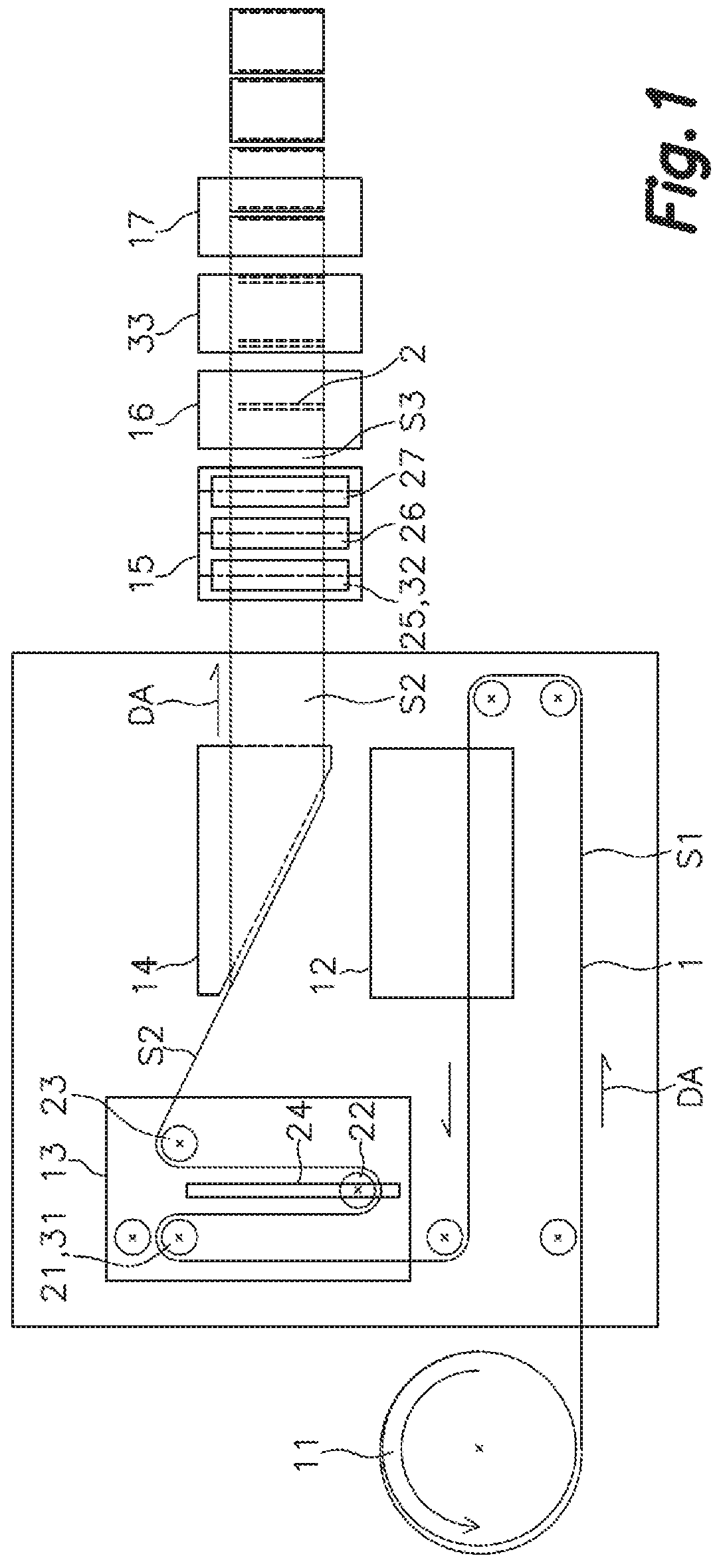

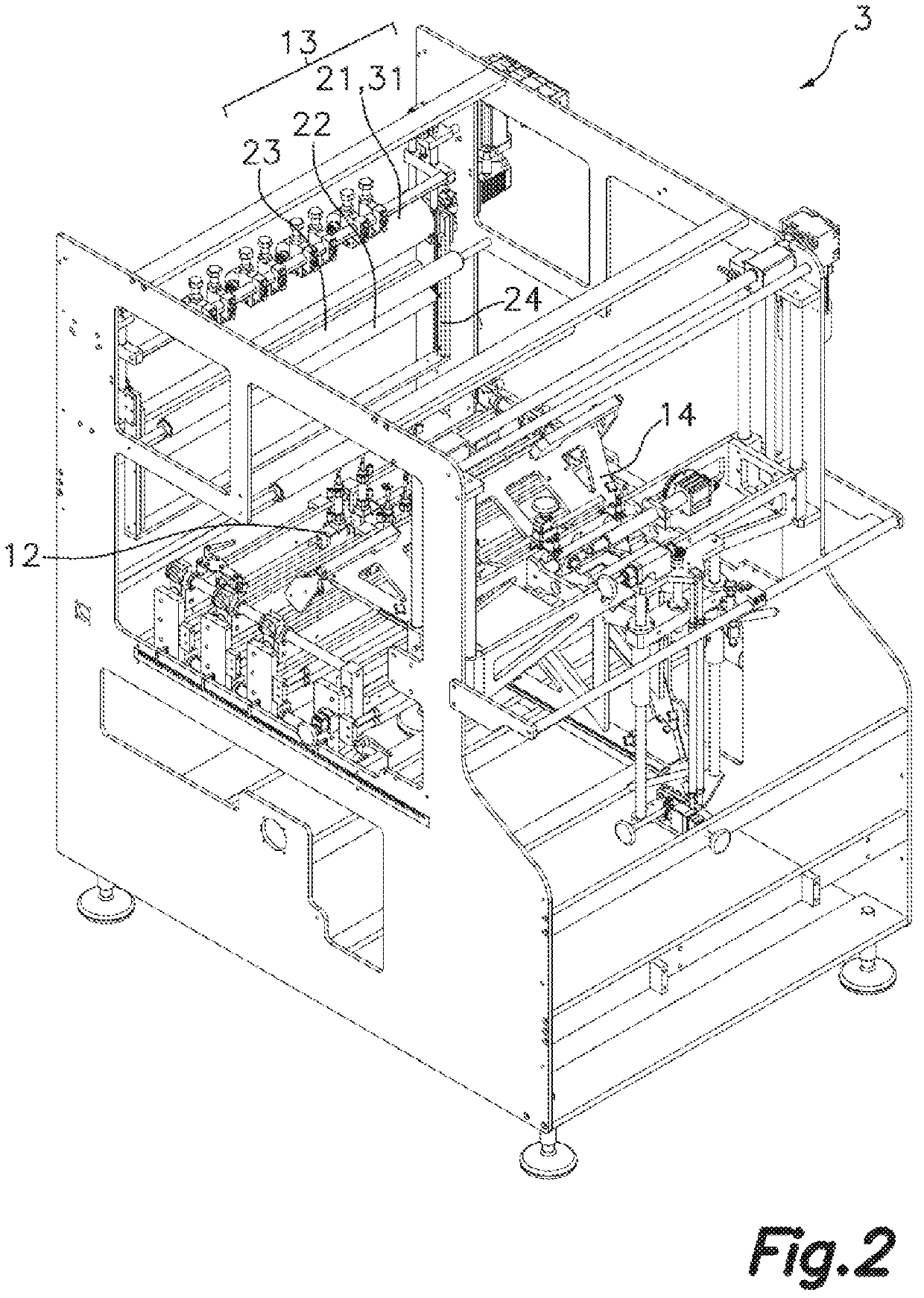

Flexible package-forming machine for horizontal packaging and method of manufacturing flexible packages

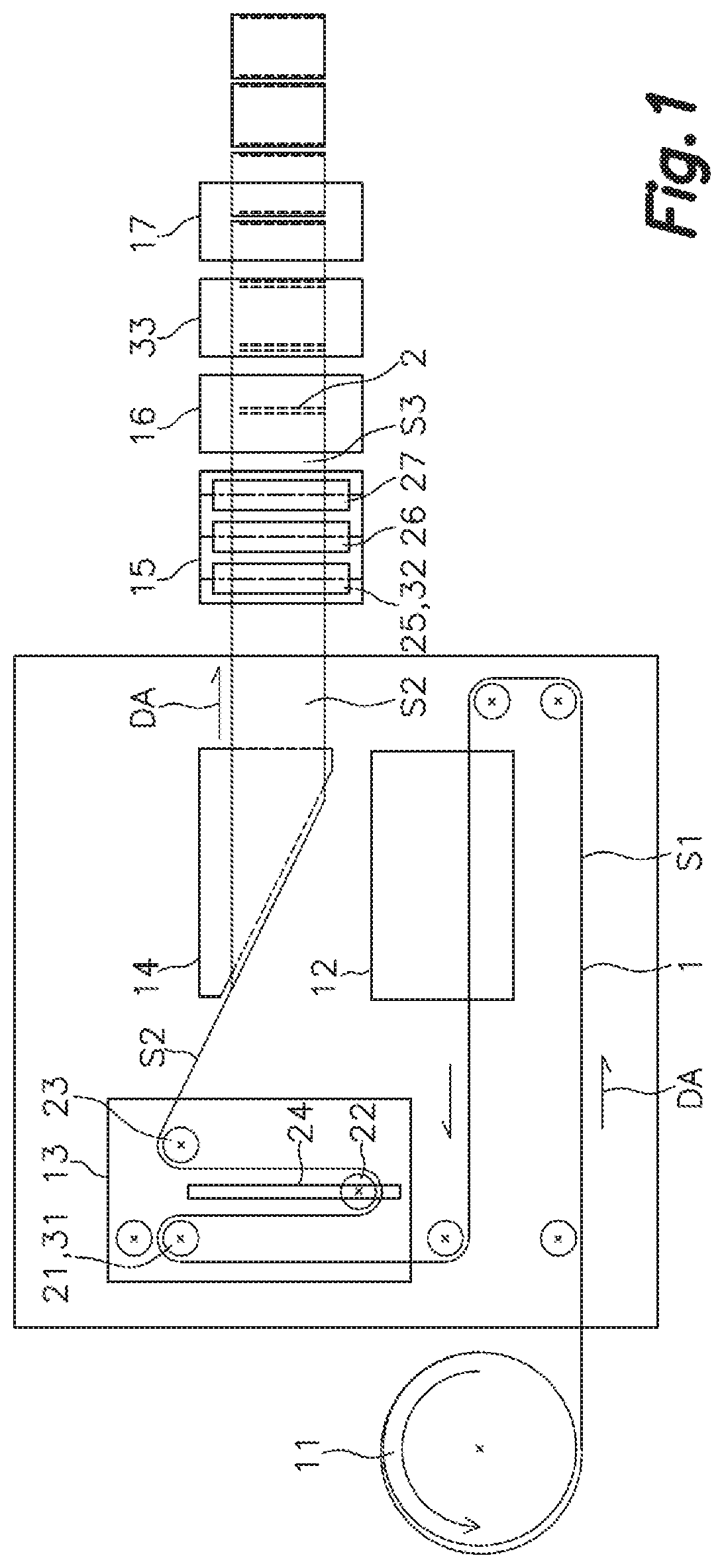

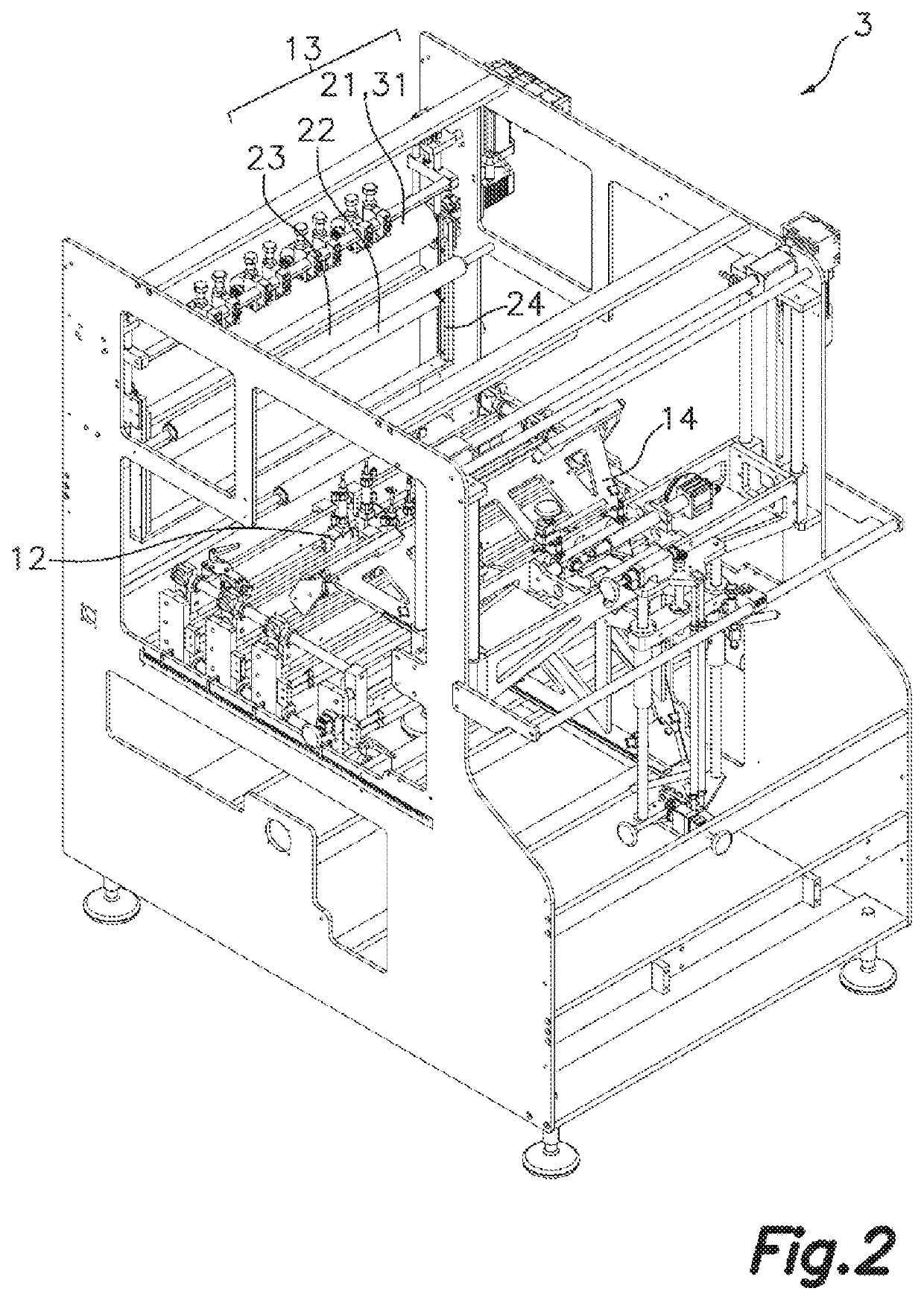

ActiveUS20200047446A1Easy to foldComplex geometryBag making operationsPaper-makingMolding machineMechanical engineering

The present invention relates to a flexible package-forming machine for horizontal packaging and method of manufacturing flexible packages. The proposed forming machine consists of an unwinding unit (11), a perforating unit (12), a folding unit (14), a welding unit (16), and a cutting unit (17), wherein a compensating unit (13) is further included intercalated between the perforating unit (12) and the folding unit (14), linking a section with intermittent forward movement (S1) of the flexible band (1) where the flexible band moves in an intermittent manner and including the perforating unit, and a section with continuous forward movement (S2) where the flexible band moves in a continuous manner and including the folding unit, flexible band being accumulated in said compensating unit during the forward movement of the section with intermittent forward movement (S1) and the accumulation being reduced during breaks in the forward movement of the section with intermittent forward movement.

Owner:MESPACK SL

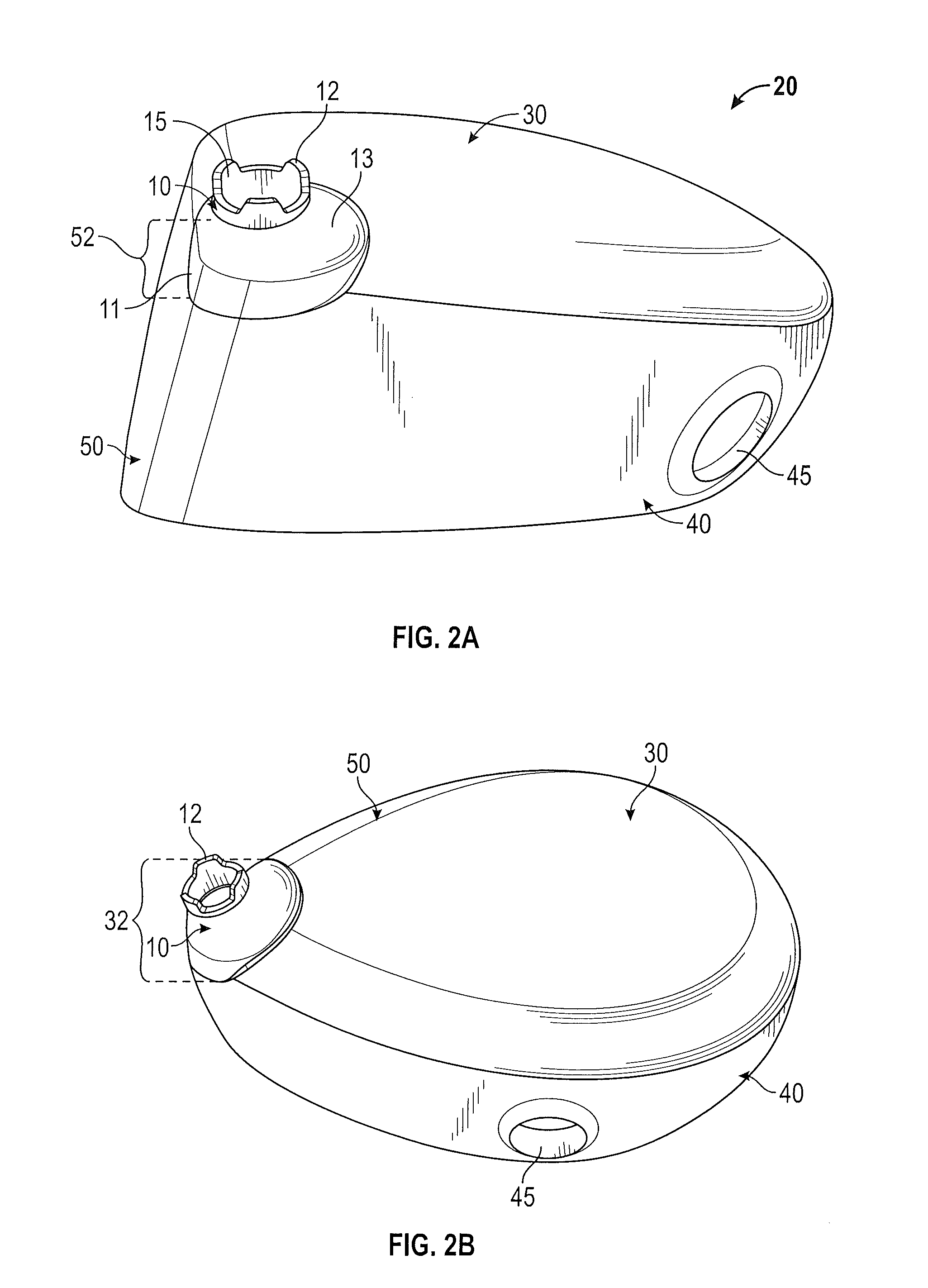

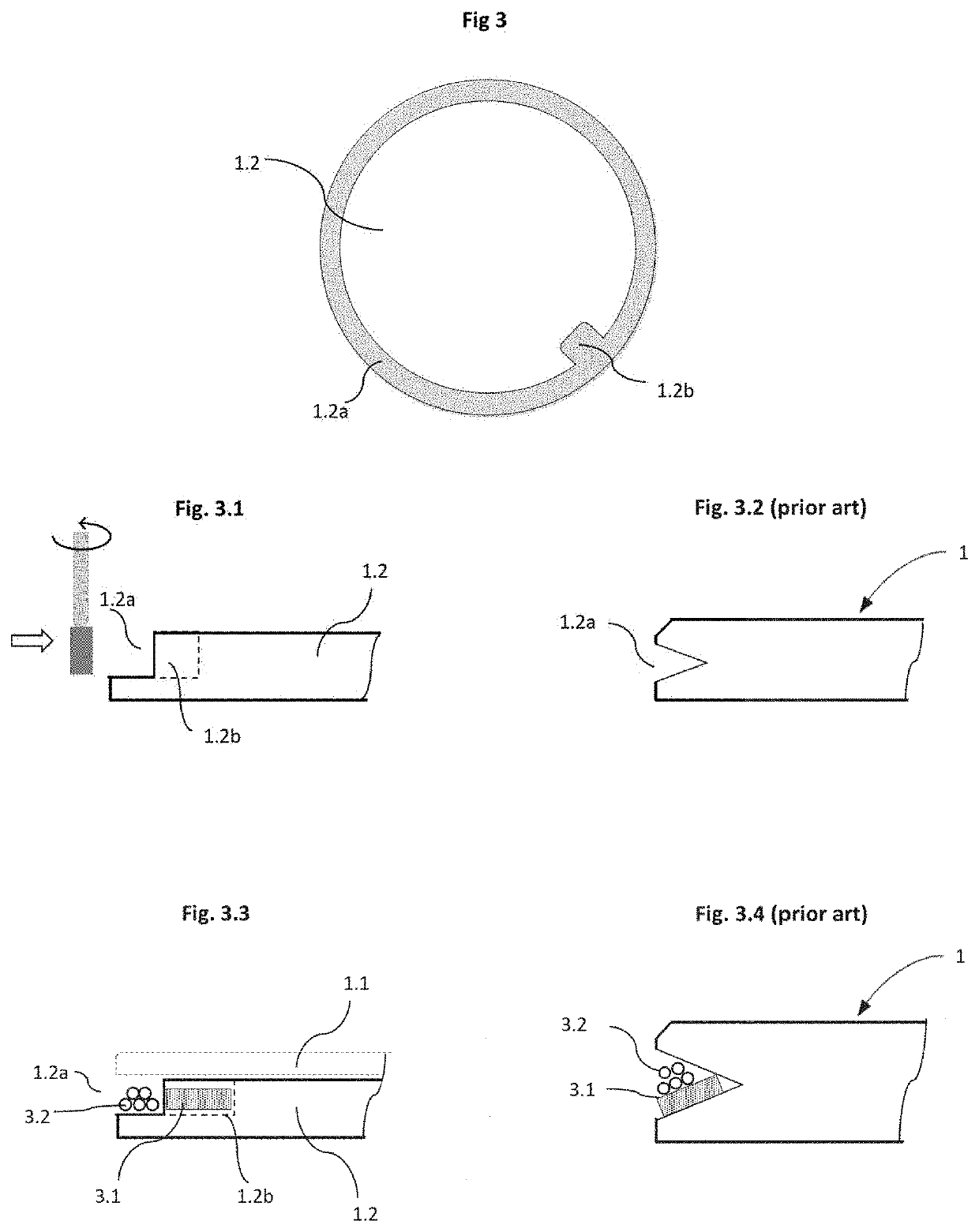

Watch glass containing a near-field communication (NFC) module and method of producing such a glass

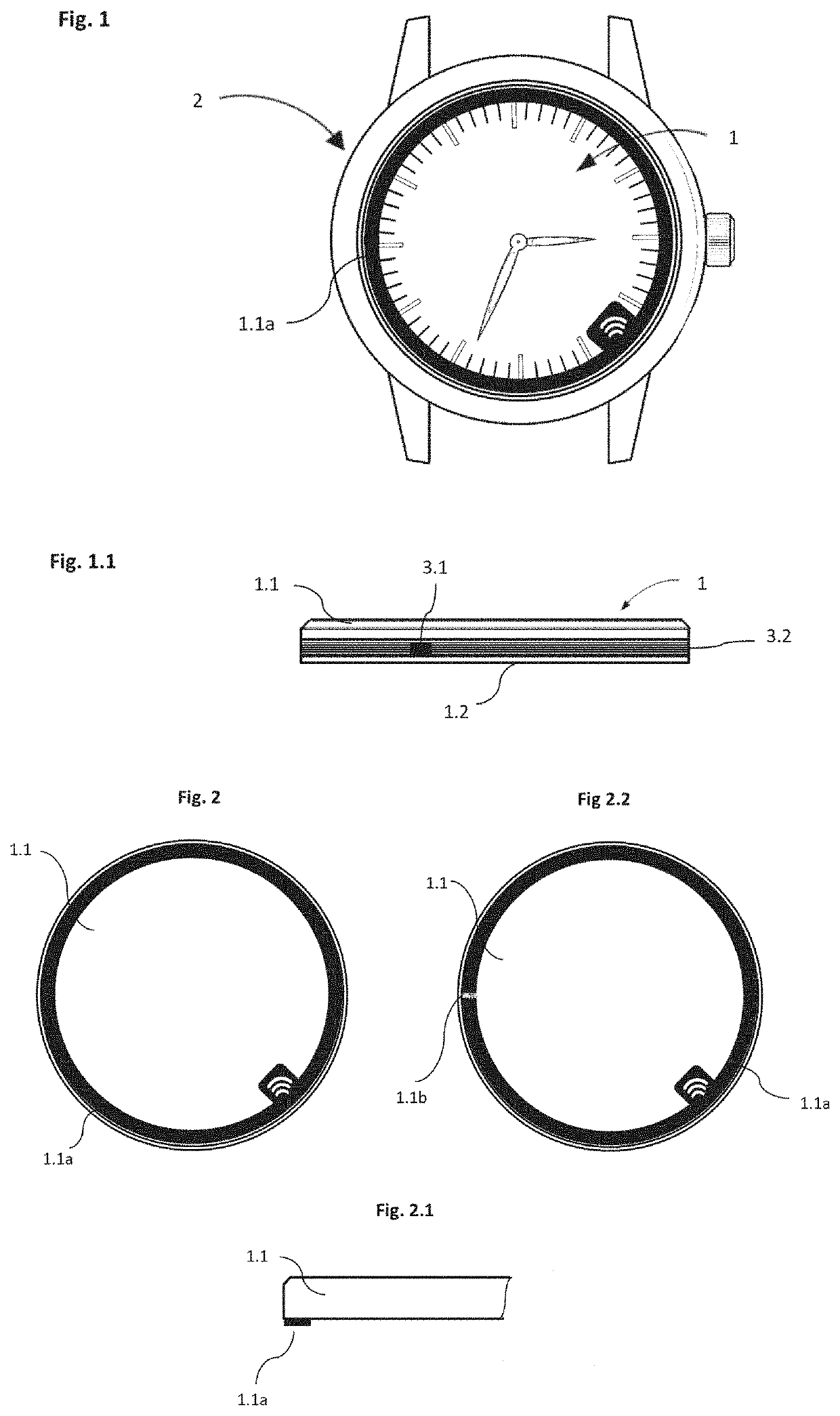

PendingUS20220206443A1Reliable data communicationEasily and quickly integrated into watchAntenna adaptation in movable bodiesNear-field for read/write/interrrogation/identification systemsTelecommunicationsWatch glass

The invention relates to a watch glass (1) comprising an near field communication (NFC) module (3) which comprises at least one microcircuit (3.2) connected to an antenna (3.1). The invention also relates to a watch (2) equipped with such a glass (1). The invention also relates to a method of producing such a watch glass (1).

Owner:WINWATCH

Flexible package-forming machine for horizontal packaging and method of manufacturing flexible packages

ActiveUS11351748B2Complex geometryMore edgeBag making operationsPaper-makingMolding machineMechanical engineering

Owner:MESPACK SL

Investment casting pattern

ActiveUS10758967B2Reducing efficiency and lifeReduce in quantityAdditive manufacturing apparatusFoundry mouldsInvestment castingEngineering

Owner:ROLLS ROYCE PLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com