Method for producing a metal component

a metal component and metal technology, applied in the direction of machining electric circuits, electrical machining apparatus, electric circuits, etc., can solve the problems of greater problems and relatively poor machinability of nickel alloy components, and achieve the effect of superior component sections and difficult machinability of component materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

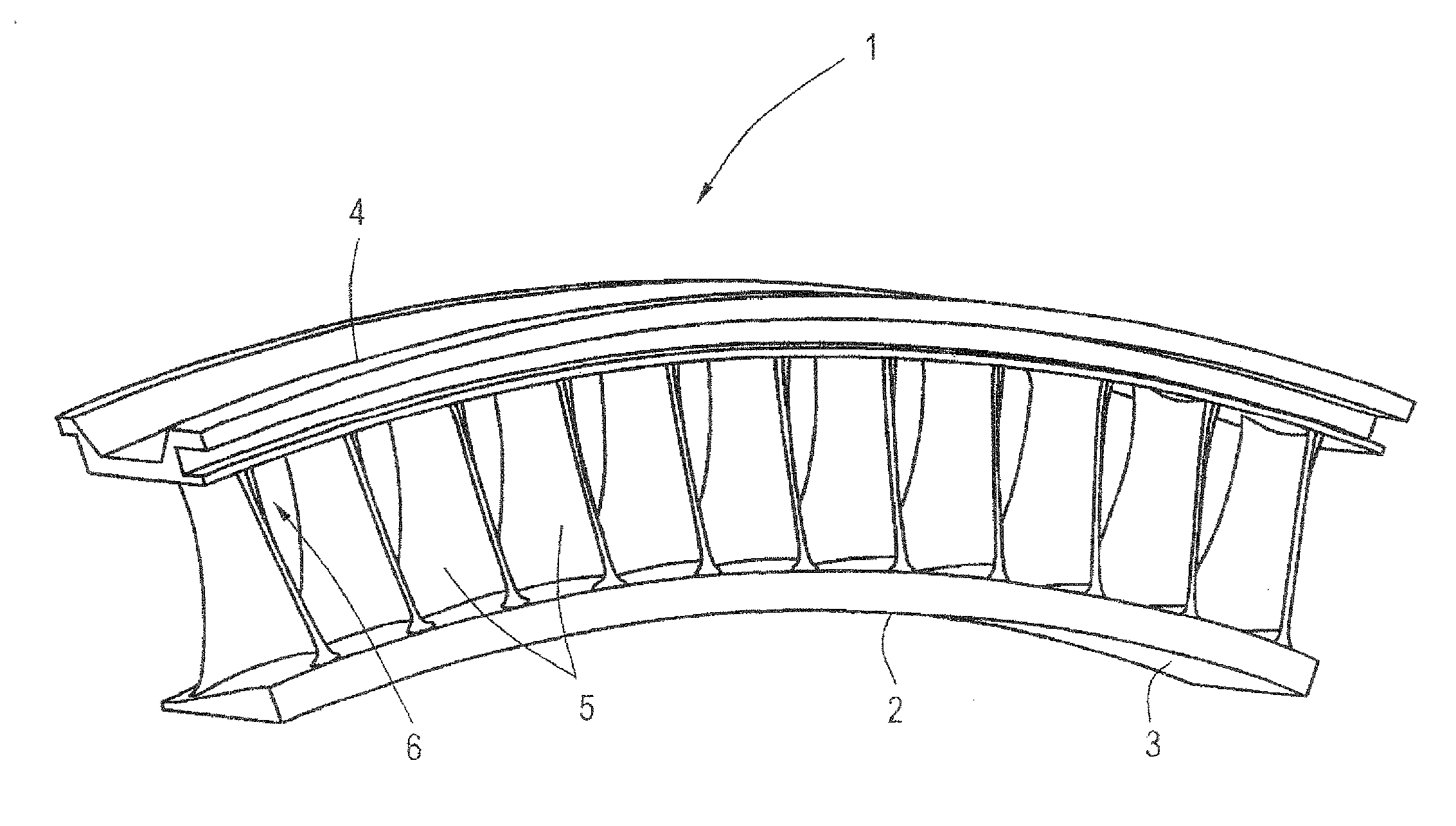

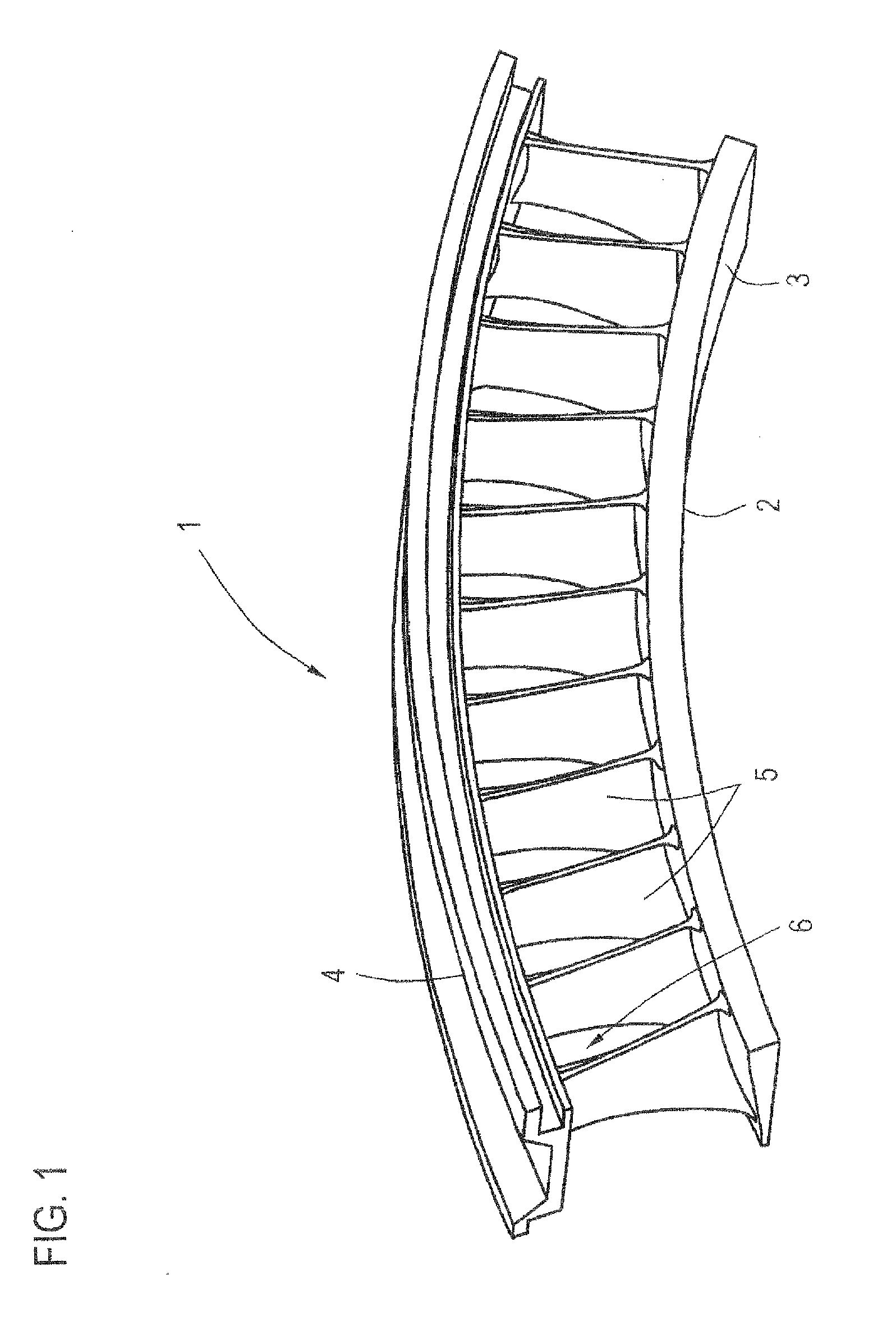

[0027]FIG. 1 shows, in the form of a perspective view, a metal component 1 in the form of a guide vane cluster 2 which for the purpose of forming a complete ring, is assembled with a plurality of such clusters to give a ring shape. Such a guide vane cluster consists of two shrouds 3, 4 and a multiplicity of airfoils 5 extending between said shrouds 3, 4. The shrouds 3, 4 and the airfoils 5 are fashioned from solid material by cutting and / or other removal processes. The airfoils 5 have a complexly twisted geometry and are very closely spaced apart, i.e. there are only very narrow spaces 6 between the individual airfoils 5. The complex geometry consequently results in curved edge regions and curved surfaces in the transition between the airfoils 5 and the shrouds 3, 4 or at the surfaces of the shrouds 3, 4 and at the surfaces of the airfoils 5 themselves, which, after the metal component 1 or its sections (shrouds 3, 4, airfoils 5) have been pre-machined using appropriate working proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com