Method for forming a tubular body, undulating tubular body and use of same

a tubular body and undulating technology, applied in the field of forming a tubular body, to achieve the effect of high flexibility and complexity in forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

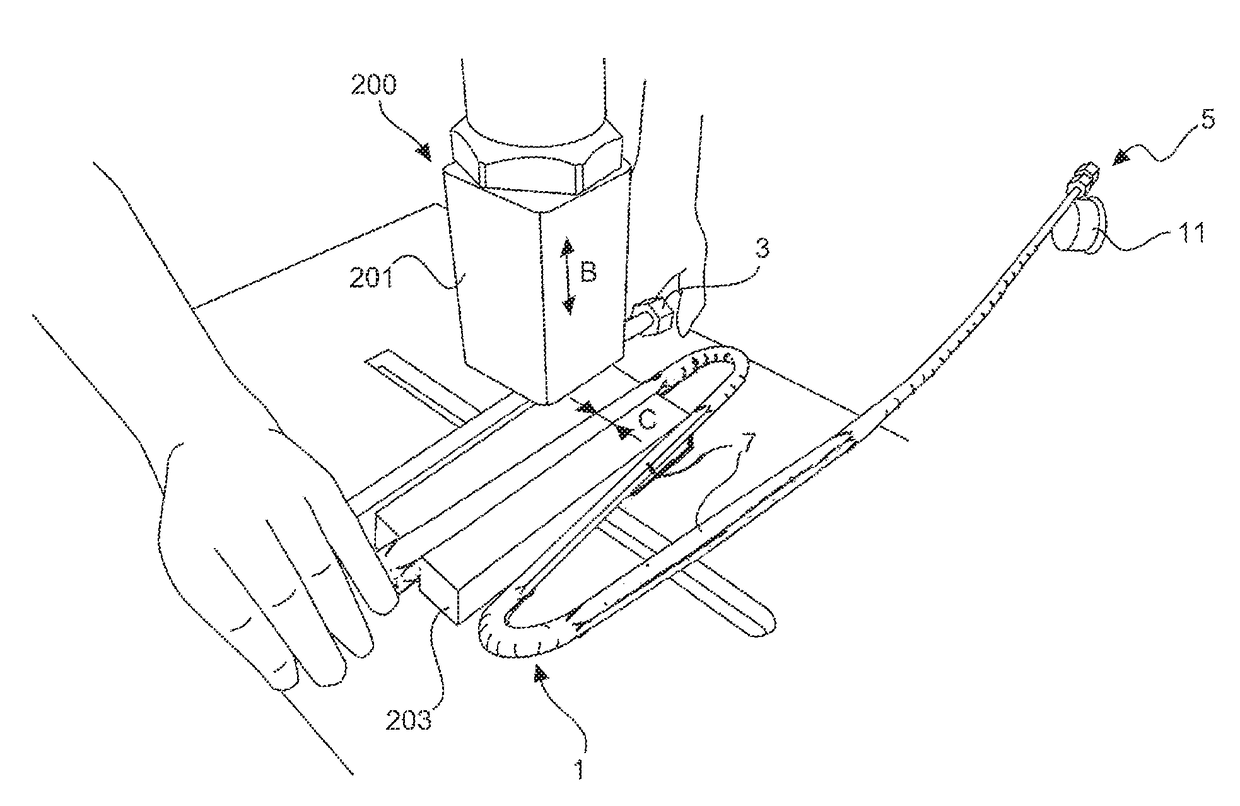

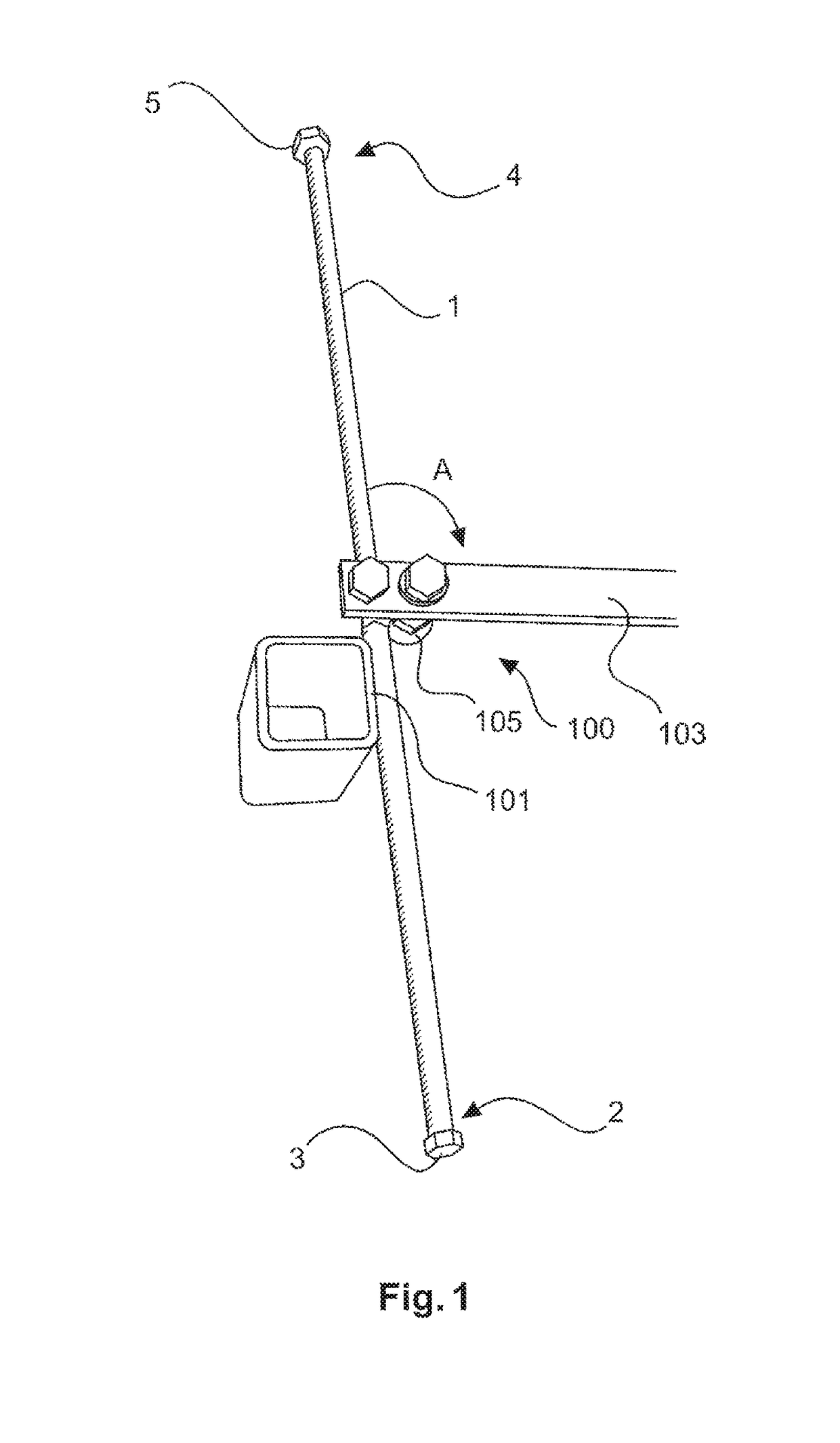

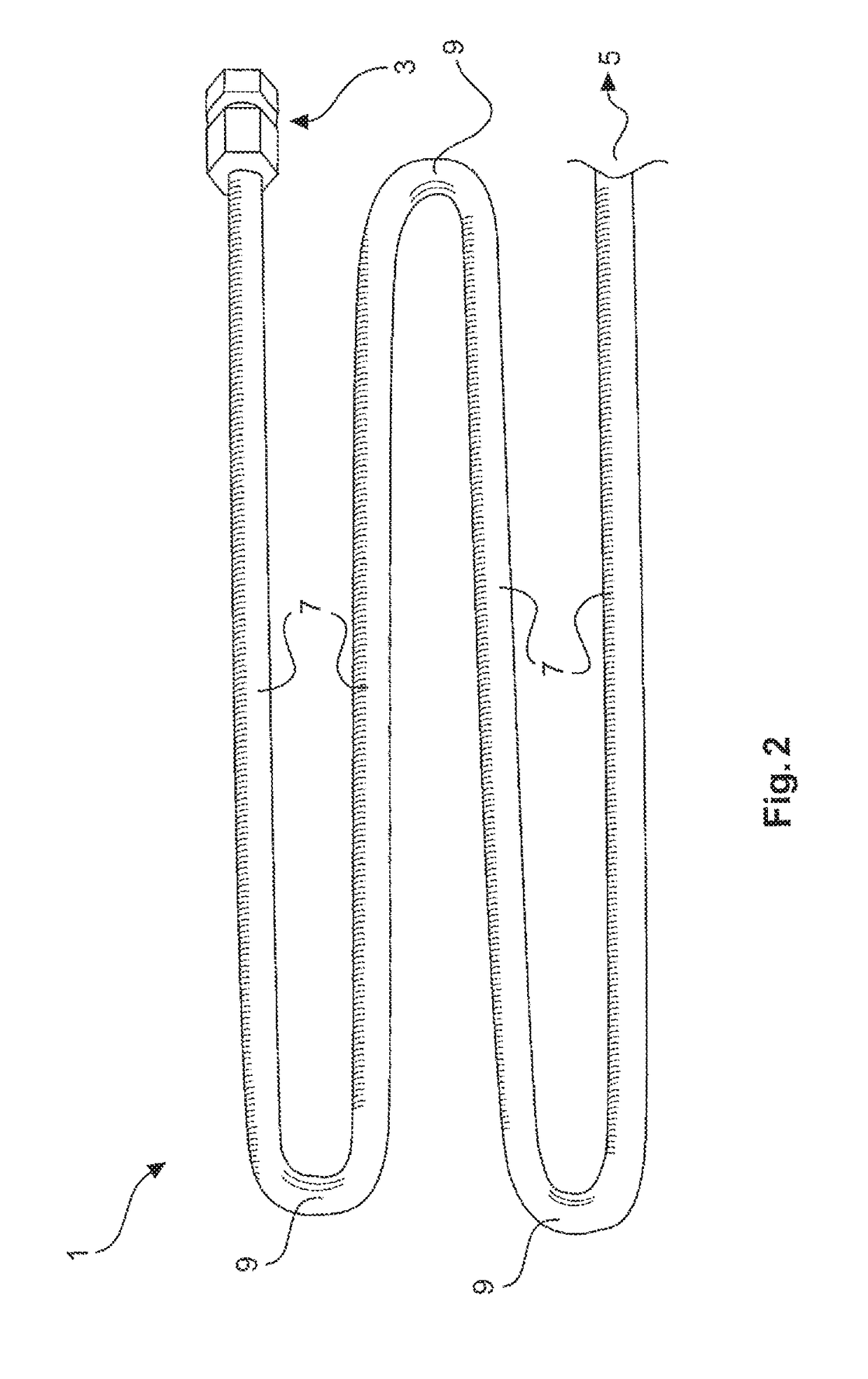

[0032]In its undeformed state, the tubular body 1 shown in FIGS. 1-3 has a substantially cylindrical cross section and is uncurved, as can be seen in FIG. 1. To prepare the forming step, the tubular body 1 is closed pressure tightly in a first end segment 2 by means of a closure 3, e.g., a blind plug. A second closure 5 is fitted in an opposite, second end segment 4. The second closure 5 is designed as a check valve with an excess pressure limiter, for example.

[0033]The tubular body 1 is filled with liquid, preferably via the second closure 5, and pressurized, e.g., with a pressure in a range of from 50 to 200 bar. The tubular body is then closed pressure tightly by means of the optionally provided check valve, wherein the optionally provided pressure limiter is designed to discharge liquid from the interior of the tubular body 1 if a predetermined pressure within the tubular body 1 is exceeded.

[0034]It is then possible to carry out the forming step with the filled and closed and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com