Multi-piece driver with separately cast hosel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The present invention provides an improvement to the existing art of golf club manufacturing because it employs a separately cast hosel in a golf club head instead of machined or formed hosels. This improvement allows for the use of strong construction materials to support the complex geometry required to combine the hosel with other parts of the golf club head. The invention also allows for high, and efficient, production throughput during golf club manufacturing.

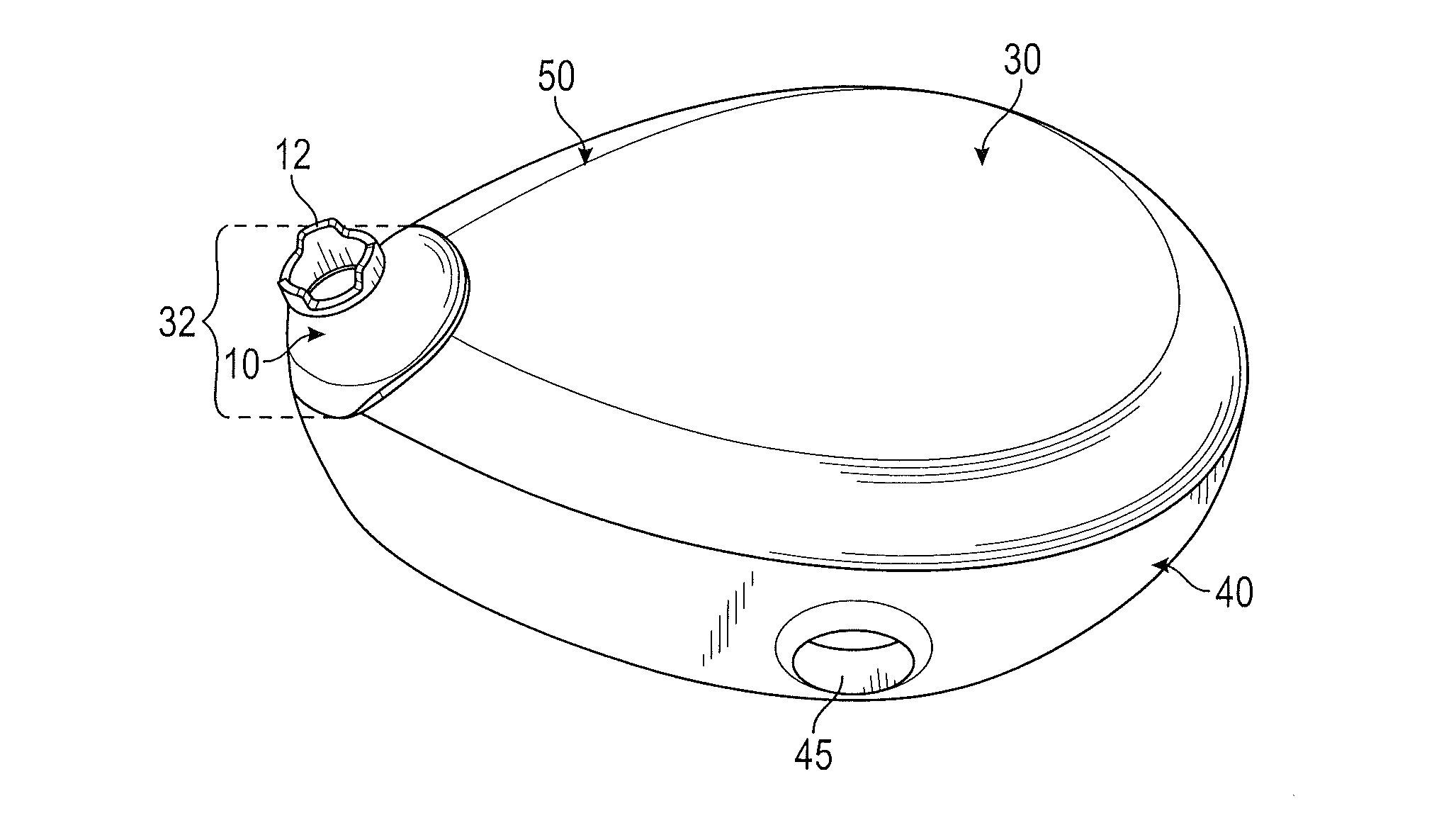

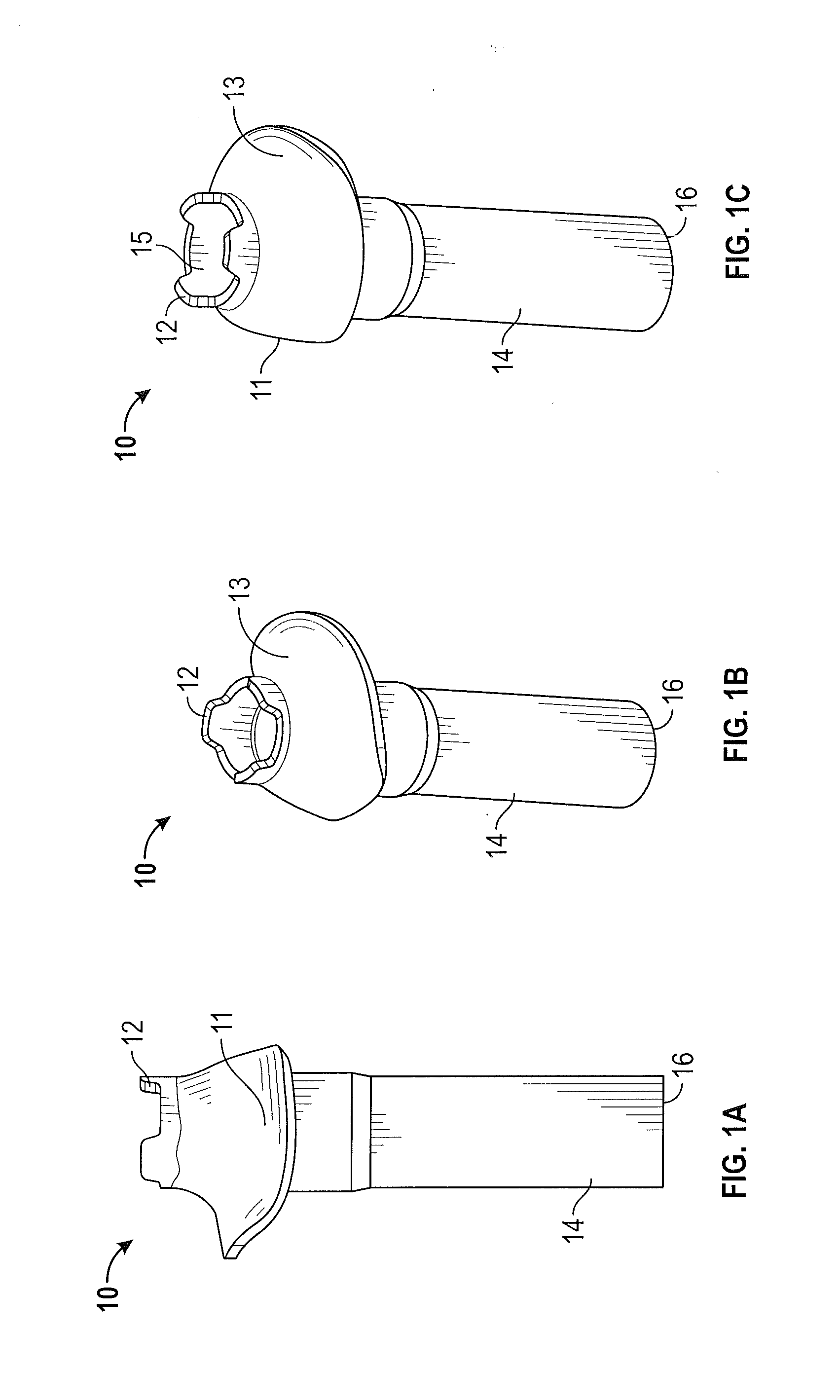

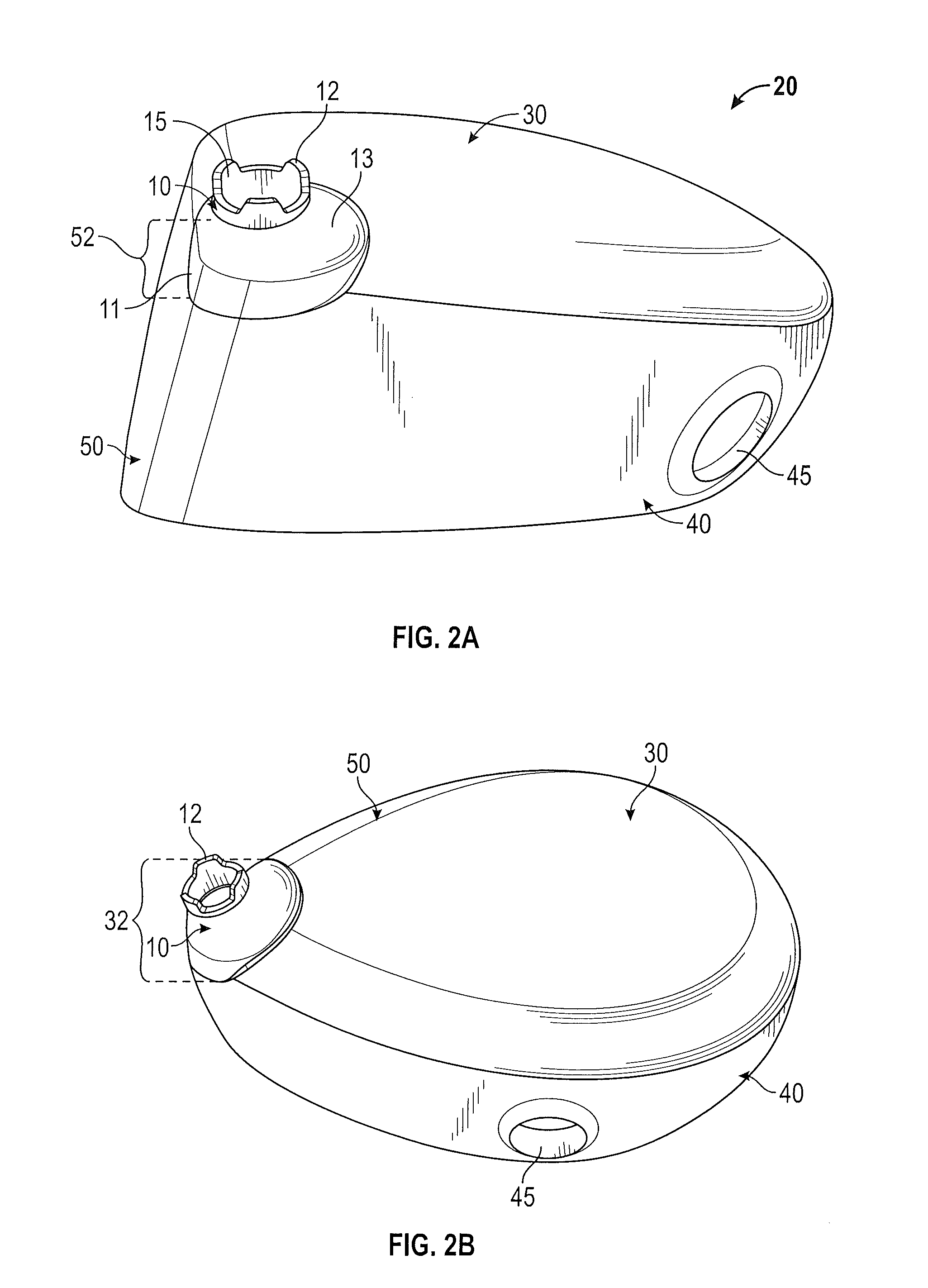

[0019]A preferred embodiment of the present invention is illustrated in FIGS. 1A-2B. As shown in FIGS. 1A-1C, the preferred embodiment includes a cast hosel 10 having a hosel tube 14 having a hosel bore 15 sized to releasably receive a shaft, a face portion 11, a crown portion 13, and a sole portion 16. The hosel bore 15 may further include a flange, such as the one shown in U.S. Pat. Nos. 8,096,895 and 8,002,644. The hosel also includes one or more adjustability features 12 which can be used to allow adjustment or i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com