Planar stereo lithography apparatus and method

A molding device and planar light technology, applied in the field of planar light-curing rapid prototyping devices, can solve the problems of parts production cost, investment cost, expensive system operation and maintenance costs, reduction of warping and deformation of molding materials, and unstable performance of molding materials, etc., to achieve Simplify equipment structure and process, solve warping deformation, and improve surface non-stick performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

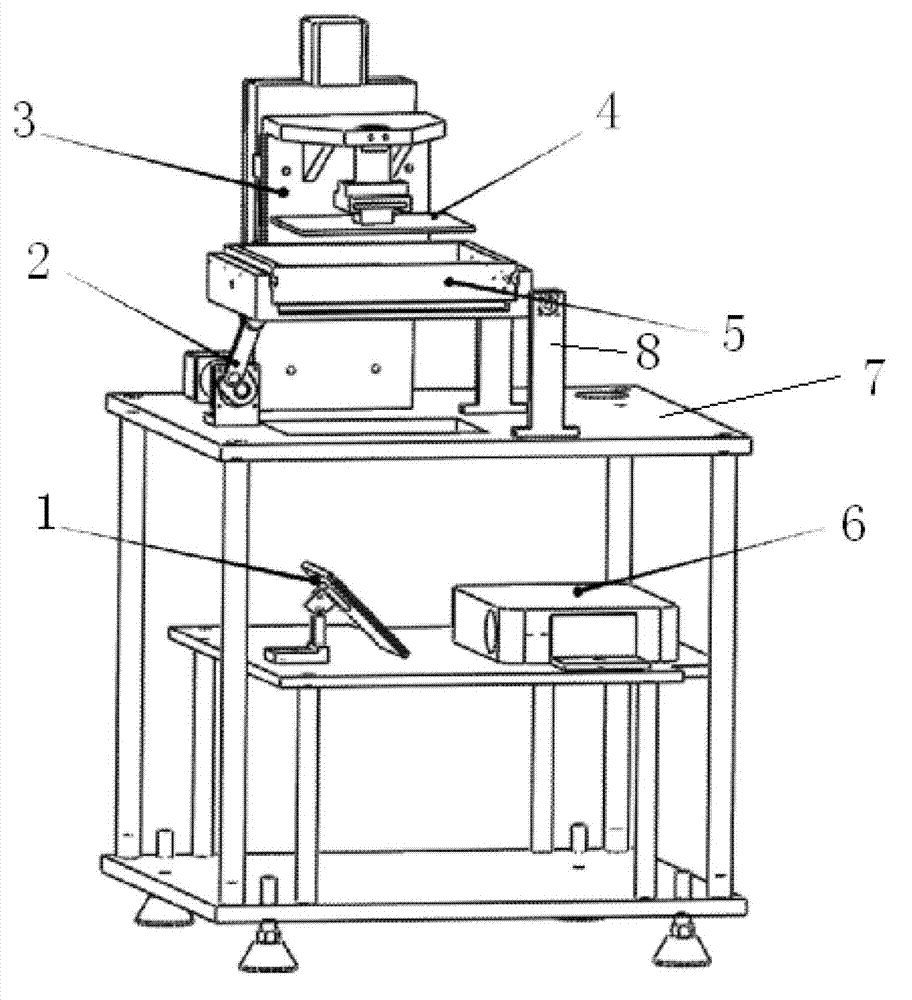

[0030] Digital projection surface curing rapid prototyping device, the device includes: a computer (external), which is equipped with layered data processing software, used to send cross-sectional graphics to the digital projector, and control the graphics projection mode of the projector; A modified digital projector equipped with an ultraviolet lamp head is used to receive image data from a computer, and project graphics onto the surface of the resin liquid according to the set exposure mode; a molding system, including a resin tank , above the resin tank, there is a working platform driven by the lifting system, and the formed entity is hung upside down on the working platform.

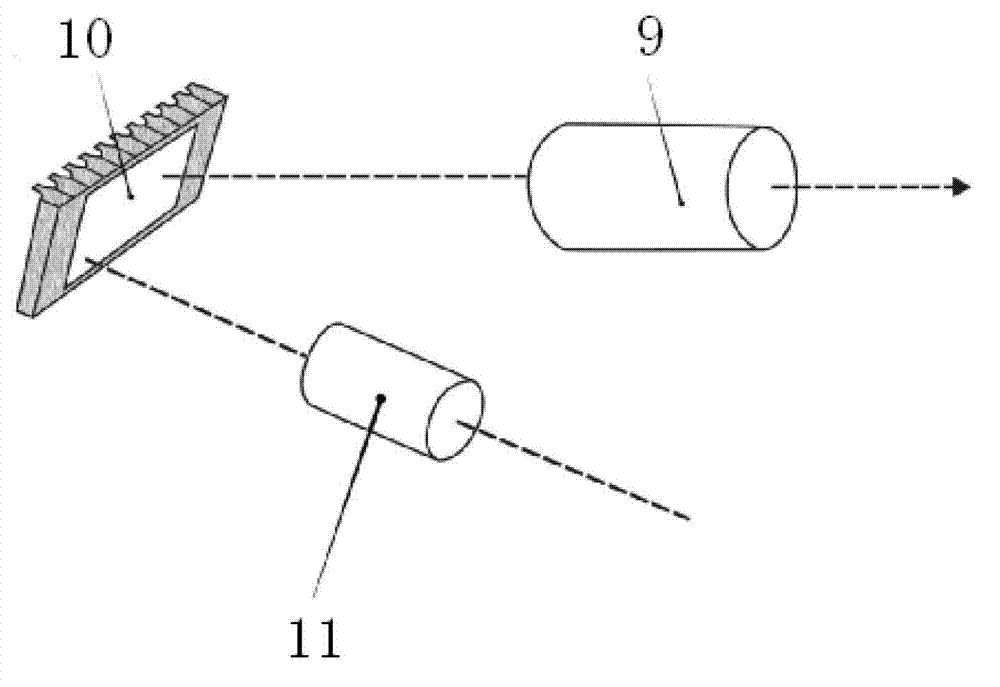

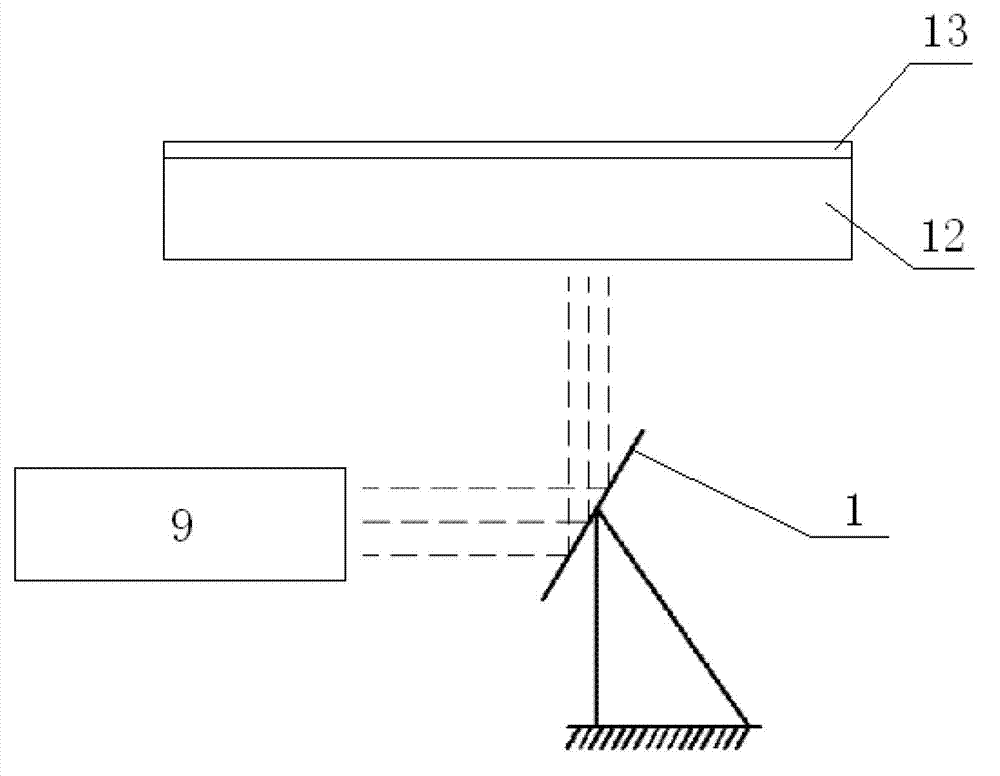

[0031] The digital projection technology is used to generate the layer profile of the solid part. Using the method of down-illumination and the shallower resin tank, the glass that can pass through ultraviolet light is used as the bottom plate of the resin tank. After one layer is cured, the light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com