Micro-nano three-dimensional printing nozzle device

A three-dimensional printing, micro-nano technology, applied in the direction of spraying device, electrostatic spraying device, etc., can solve the problems that cannot meet different precision requirements, and achieve the effect of improving the forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

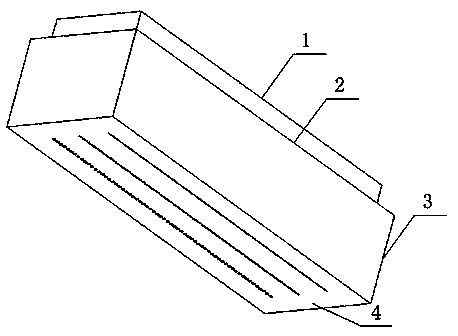

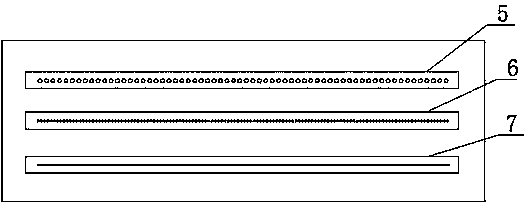

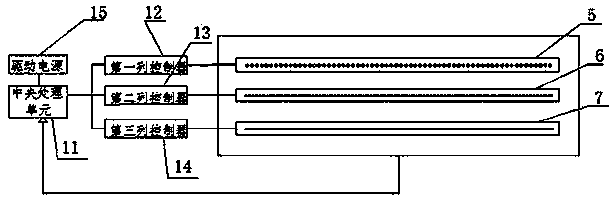

[0031] The structure diagram of the present invention is as figure 1 , 2 As shown in , 3, and 4, the micro-nano three-dimensional printing nozzle device of the present invention includes a controller 1, a material storage box 2, and a nozzle main body 3. The nozzle main body 3 includes three groups of nozzle hole arrays 4 with different diameters, Group A nozzle row 5, Group B nozzle row 6, Group C nozzle row 7, Group A nozzle row 5, Group B nozzle row 6, Group C nozzle row 7 are respectively connected with three nozzles, Described controller 1 comprises central processing unit 11, the first spray hole column controller 12, the second spray hole column controller 13, the 3rd spray hole column controller 14, drive power supply 15, central processing unit 11 by outputting different pulse signal to control and switch the work of the first nozzle row controller 12, the second nozzle row controller 13, and the third nozzle row controller 14, the first nozzle row controller 12, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com