Preparation method of carbon fiber trim strip for automobile

A carbon fiber and decorative strip technology, applied in the field of automobile interior decoration, can solve the problems such as performance can not meet the requirements of the whole vehicle, high price, etc., and achieve the effect of improving the grade and product competitiveness, less equipment investment, and improving the feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

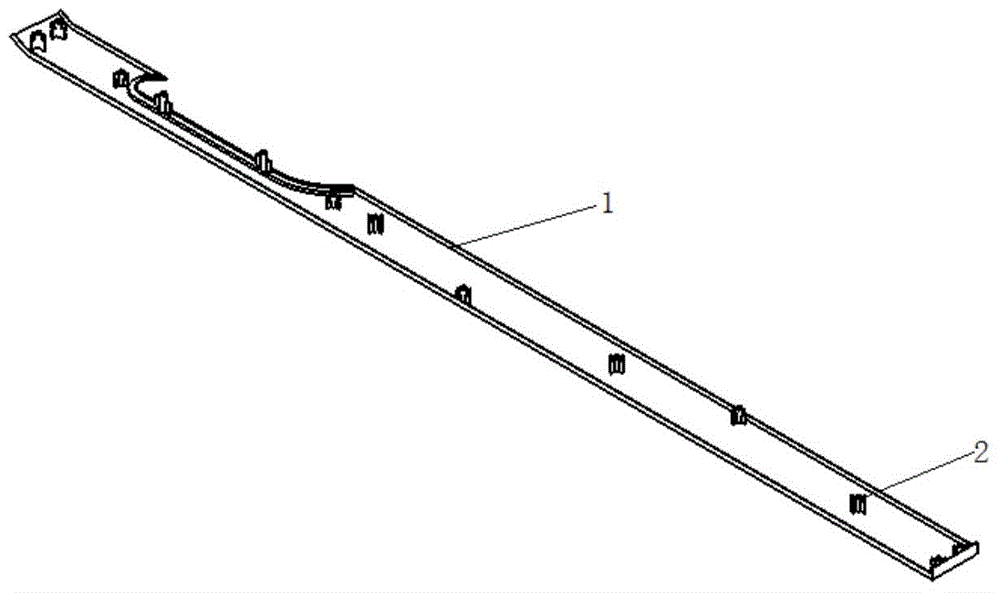

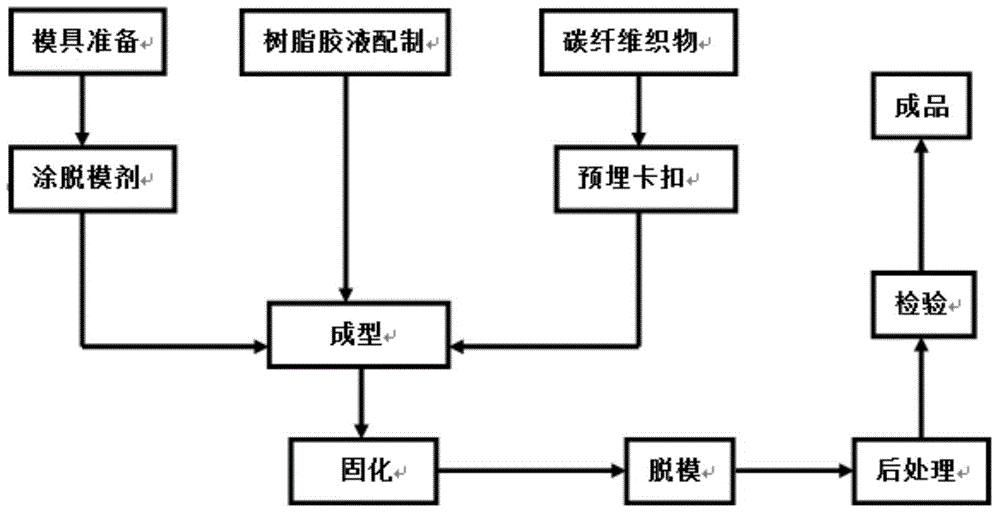

[0021] A method for preparing carbon fiber decorative strips for automobiles includes the following steps:

[0022] (1) Clean the mold surface, and evenly coat the mold release agent on the mold;

[0023] (2) Brush the resin mixture containing the curing agent, (the weight ratio of curing agent to resin is 5:5), and pave a layer of tailored carbon fiber fabric (T300 carbon fiber fabric, thickness: 0.25 ~ 0.3mm.) , Squeeze the fabric to make it evenly dipped and flatten out bubbles, then paint the resin mixture containing curing agent, pave the second layer of carbon fiber fabric, and embed the buckle 2 according to the designed position; the resin is EPON135 epoxy resin; The curing agent model is EPON1366;

[0024] (3) Repeat step (2) to lay a total of four layers of carbon fiber fabric to obtain the decorative strip carbon fiber fabric body, cut the opening, and the buckle 2 exposes the effective installation distance; the weight ratio of the carbon fiber fabric in the obtained car...

Embodiment 2

[0028] A method for preparing carbon fiber decorative strips for automobiles includes the following steps:

[0029] (1) Clean the mold surface, and evenly coat the mold release agent on the mold;

[0030] (2) Brush the resin mixture containing curing agent, pave a layer of tailored carbon fiber fabric (Toray T300 carbon fiber fabric, thickness: 0.25 ~ 0.3mm.), squeeze the fabric to make it evenly dipped to eliminate air bubbles Afterwards, paint the resin mixture containing curing agent, pave the second layer of carbon fiber fabric, and embed the buckle 2 according to the designed position; the resin is EPON135 epoxy resin; the curing agent model is EPON1366, the weight ratio of curing agent to resin 5.5: 4.5

[0031] (3) Repeat step (2) to lay a total of four layers of carbon fiber fabric to obtain the decorative strip carbon fiber fabric body, cut the opening, and the buckle 2 exposes the effective installation distance; the weight ratio of the carbon fiber fabric in the obtained ...

Embodiment 3

[0035] A method for preparing carbon fiber decorative strips for automobiles includes the following steps:

[0036] (1) Clean the mold surface, and evenly coat the mold release agent on the mold;

[0037] (2) Brush the resin mixture containing curing agent, pave a layer of tailored carbon fiber fabric (Toray T300 carbon fiber fabric, thickness: 0.25 ~ 0.3mm.), squeeze the fabric to make it evenly dipped to eliminate air bubbles Afterwards, paint the resin mixture containing curing agent, pave the second layer of carbon fiber fabric, and embed the buckle 2 according to the designed position; the resin is EPON135 epoxy resin; the curing agent model is EPON1366, the weight ratio of curing agent to resin 6:4.

[0038] (3) Repeat step (2) to lay a total of four layers of carbon fiber fabric to obtain the decorative strip carbon fiber fabric body, cut the opening, and the buckle 2 exposes the effective installation distance.

[0039] (4) Heat curing and molding; the initial heating tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com