Method and device for leaching high-quality lignite wax

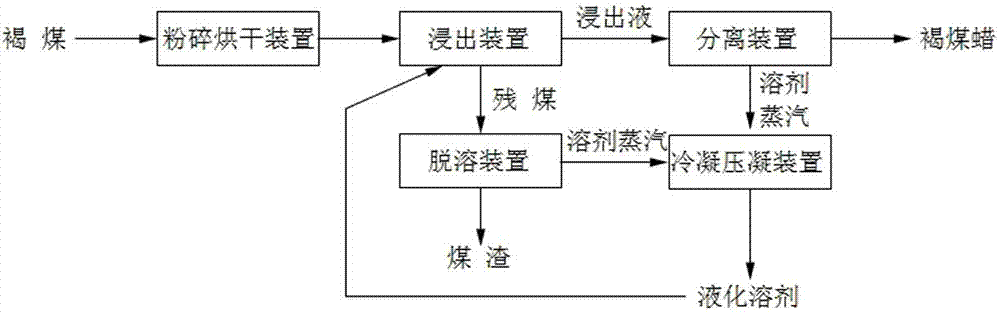

A montan wax, high-quality technology, applied in the field of coal chemical industry, can solve the problems of affecting the health of operators, high consumption of stripping steam, poor solvent selectivity, etc., to reduce processing costs, reduce wax production rate, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

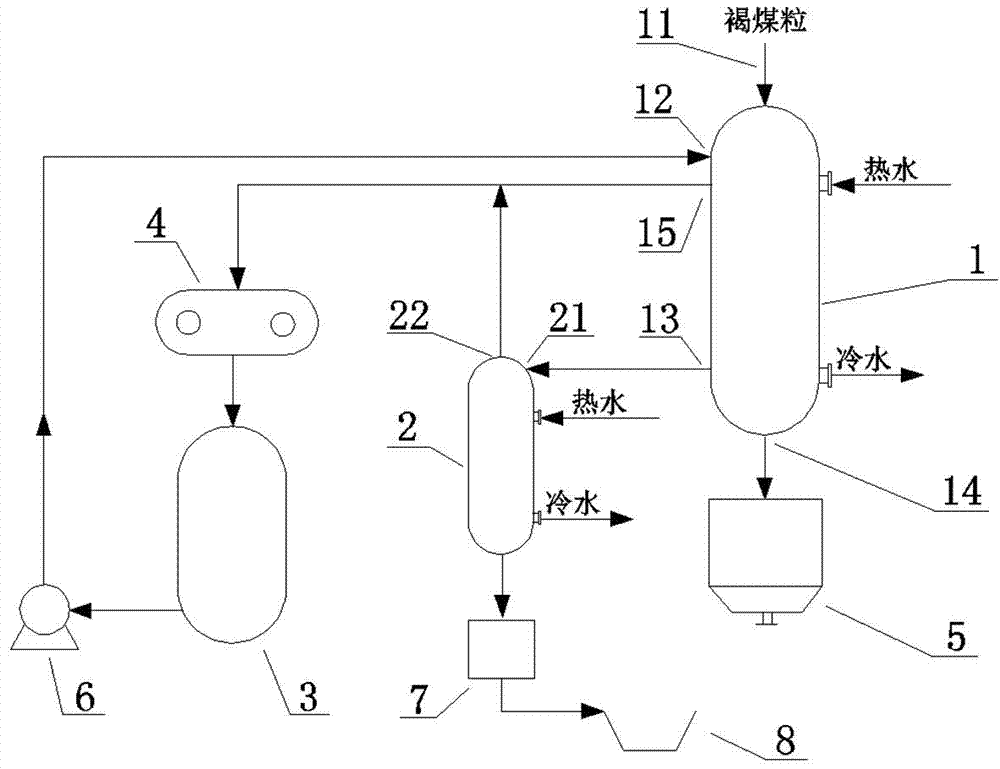

[0030] The preparation device of the present invention also includes a solvent condensing device 4, the extractor 1 and the upper part of the wax liquid evaporation tank 2 are respectively provided with steam outlets 15, 22, and the steam outlets 15 and 22 pass through the solvent condensing device 4 and the solvent Storage tank 3 is connected.

[0031] The discharge port 14 communicates with the residual coal bunker 5, and the residual coal bunker 5 is provided with a heating device and / or a vacuum extraction device and a steam outlet 51, and the steam outlet 51 communicates with the solvent storage tank 3 through the solvent condensation device 4 .

[0032] Working principle and working process of the present invention:

[0033] Such as figure 2 As shown, the lignite is crushed, screened and dried to obtain qualified coal (1-8mm, moisture 15-25%), which is fed into the extractor 1 from the lignite feeding port 11 . The linear alkane solvent is pumped into the extractor...

Embodiment 1

[0038] Such as figure 1 As shown, the lignite produced in Zhaotong, Yunnan Province was taken, and after crushing, it was screened and intercepted through sieves with apertures of 2.0 mm and 5.0 mm to obtain lignite particles with a particle size of 2.0 to 5.0 mm, which were dried to a moisture content of 25%; 500 kg of dried lignite particles were placed in Add 1000L of No. 4 solvent oil into the leaching tank, keep the indoor temperature at 25°C and keep the pressure at 1MPa in the tank, soak the lignite for 3 hours, separate and filter to obtain the leaching solution and residual coal; put the separated leaching solution into the separation device, and heat the leaching solution to 40 The low boiling point No. 4 solvent oil is evaporated at ℃, and the montan wax is separated from the solvent; the montan wax is cooled and formed to obtain 24.8kg of the montan wax product, wherein the resin content accounts for 14.57%, and the asphalt content accounts for 2.29%; the residual w...

Embodiment 2

[0040]Take lignite produced in Yuezhou, Qujing, Yunnan, crush it, and sieve it through sieves with apertures of 1.0mm and 3.0mm to obtain lignite particles with a particle size of 1.0-3.0mm, and dry them to a moisture content of 15%; take 500kg of dried lignite particles and place them in a leaching tank 2000L of liquefied natural gas was added, and hot water was introduced into the tank wall to maintain a temperature of 35°C in the tank and a pressure of 0.5 MPa. After soaking the lignite for 4 hours, the leachate and residual coal were separated and filtered; the separated leachate was placed in a separation device, The decompression in the separation device is reduced to 50KPa (vacuum degree), so that the low boiling point liquefied natural gas in the leaching liquid is evaporated, and the montan wax is separated from the solvent; The content accounts for 1.29%; the residual coal after waxy leaching is placed in a desolventizer, and the residual coal is heated to 30°C to eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com