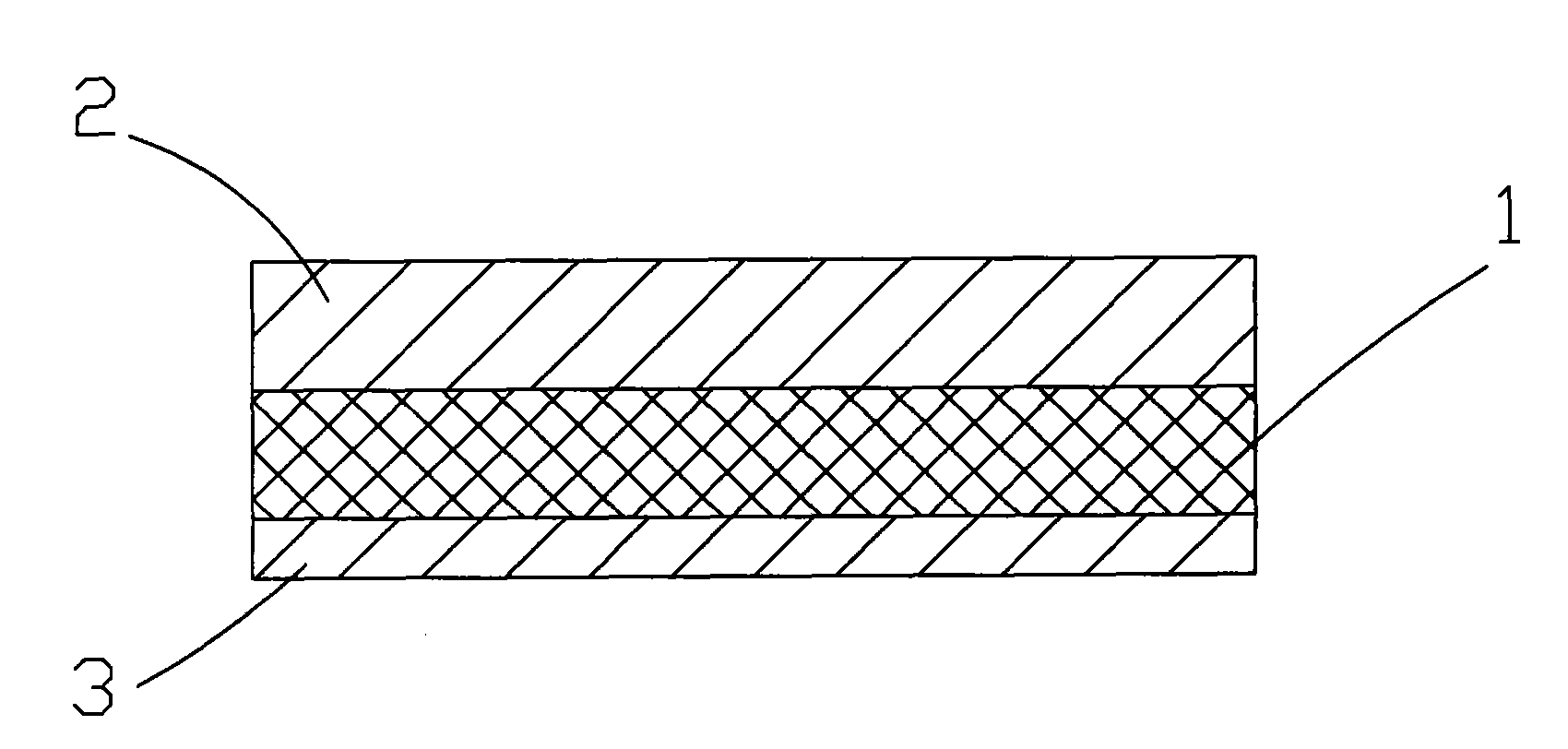

Prepreg having nonsymmetrical resin layer thickness and application thereof

A technology of resin layer thickness and prepreg, which is applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., and can solve problems such as base material white spots and single-panel warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Use ordinary 2116 glass fiber cloth, impregnate FR-4 resin composition, and use subtractive method to produce 2116 prepreg with asymmetric resin layer thickness with a total resin content of 48%. The prepreg with asymmetric resin layer thickness has a resin layer on one side The thickness is 15-18um (side A), and the thickness of the resin layer on the other side is 3-5um (side B). Two sheets are combined, and the copper clad laminates with a thickness of 0.10mm are laminated with the side A facing the rough surface of the copper foil. According to slice analysis, the resin content of the traditional 2 sheets of RC48% reinforcing material layer in contact with the copper foil is less than 5um, and white spots on the base material are prone to appear; while the prepreg with asymmetric resin layer thickness using this special structure has the same total resin content, In the case of the same thickness of the substrate, the problem of white spots on the substrate of the co...

Embodiment 2

[0034] Use ordinary 2116 glass fiber cloth, impregnate FR-4 resin composition, and use the subtractive method to produce 2116 prepreg with asymmetric resin layer thickness with a total resin content of 50%, and the thickness of the resin layer on one side of the prepreg with asymmetric resin layer thickness 18-20um (side A), the thickness of the resin layer on the other side is 5-8um (side B), face the A side with high resin content of the resin layer to the side with copper foil in the inner layer of the printed circuit board, and then press. After slice analysis, the use of this special structure of prepreg can solve the problem of white spots on the substrate and browning white spots on the inner layer of the PCB.

Embodiment 3

[0035] Example 3: Use this special structure prepreg to improve the problem of insufficient glue filling

[0036] Using 1080 glass fiber cloth, impregnated with a high Tg resin composition, a 1080 prepreg with an asymmetric resin layer thickness with a total resin content of 68% is produced, and the resin layer thickness difference between the two sides of the prepreg with an asymmetric resin layer thickness is 15um. The side with high resin content of the resin layer is facing the side with copper foil in the inner layer of the printed circuit board, and then pressed.

[0037] 1. Improve the glue filling problem of thick copper in the inner layer

[0038]With the continuous development of printed circuit board technology, in some specific fields, more and more thick copper (≥2OZ) is used as the inner layer structure. The defect often encountered in the production process of this structure is insufficient glue filling, which is manifested as lack of glue in the copper-free ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com