Steel structure anti-corrosion treatment method

A treatment method and technology for steel structures, applied in anti-corrosion coatings, pre-treated surfaces, coatings, etc., can solve the problems of insufficient clean surface treatment of steel structures, shortened service life of steel frame structures, poor corrosion resistance of steel structures, etc., to achieve Increase corrosion resistance, reduce secondary corrosion, and harden the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031]Example 1

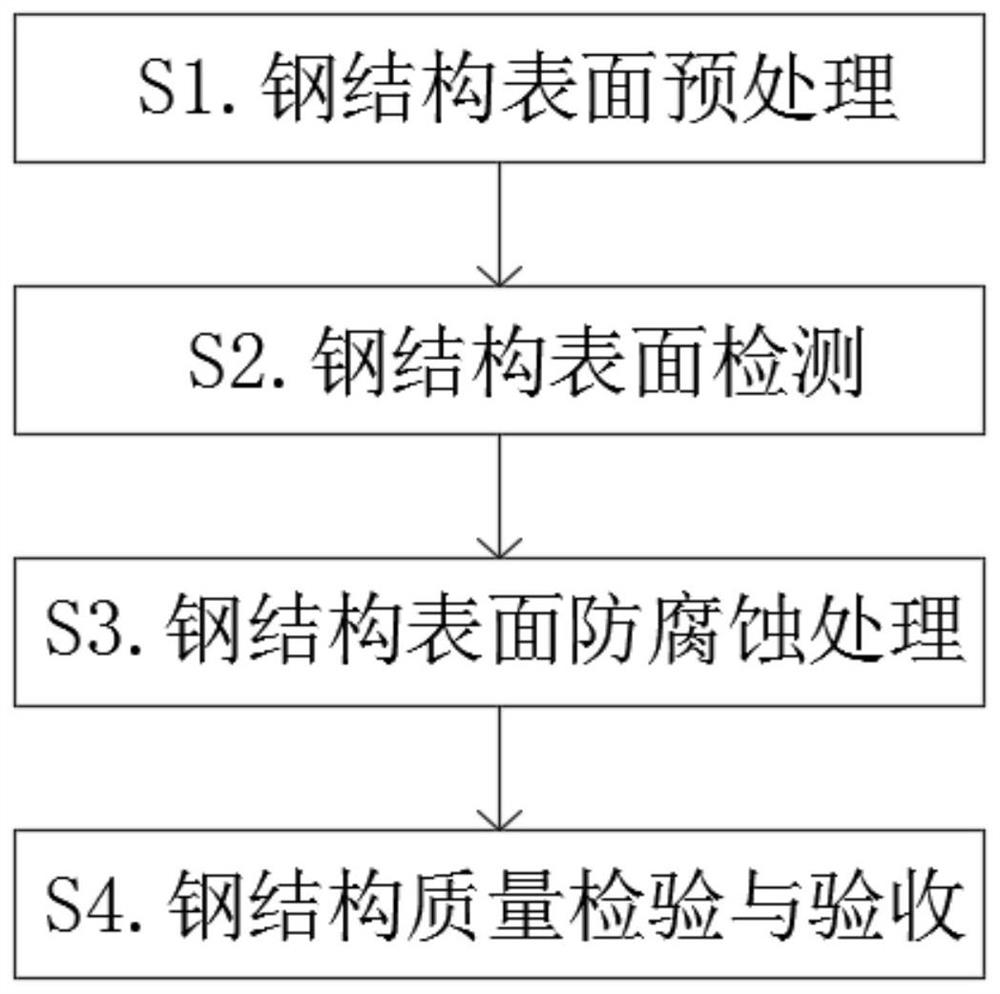

[0032]Seefigure 1, The present invention provides a technical solution: a steel structure anti-corrosion treatment method, including the following steps:

[0033]S1. Surface pretreatment of steel structure: remove grease and rust on the surface of steel structure;

[0034]S2. Steel structure surface inspection: conduct external surface inspection on the steel structure surface, and perform anti-corrosion treatment after passing the test;

[0035]S3. Steel structure surface anti-corrosion treatment: the bottom layer anti-corrosion treatment, the middle layer anti-corrosion treatment and the outer layer anti-corrosion treatment are carried out on the surface of the steel structure;

[0036]S4. Steel structure quality inspection and acceptance: the steel structure treated by S3 is subject to quality qualification inspection, and the inspection is passed and accepted.

[0037]In this embodiment, preferably, the specific operation of removing grease and rust on the surface of the steel s...

Example Embodiment

[0053]Example 2

[0054]Seefigure 1, The present invention provides a technical solution: a steel structure anti-corrosion treatment method, including the following steps:

[0055]S1. Surface pretreatment of steel structure: remove grease and rust on the surface of steel structure;

[0056]S2. Steel structure surface inspection: conduct external surface inspection on the steel structure surface, and perform anti-corrosion treatment after passing the test;

[0057]S3. Steel structure surface anti-corrosion treatment: the bottom layer anti-corrosion treatment, the middle layer anti-corrosion treatment and the outer layer anti-corrosion treatment are carried out on the surface of the steel structure;

[0058]S4. Steel structure quality inspection and acceptance: Carry out quality qualification inspection on the steel structure treated by S3, and accept it after passing the inspection.

[0059]In this embodiment, preferably, the specific operation of removing grease and rust on the surface of the steel s...

Example Embodiment

[0075]Example 3

[0076]Seefigure 1, The present invention provides a technical solution: a steel structure anti-corrosion treatment method, including the following steps:

[0077]S1. Surface pretreatment of steel structure: remove grease and rust on the surface of steel structure;

[0078]S2. Steel structure surface inspection: conduct external surface inspection on the steel structure surface, and perform anti-corrosion treatment after passing the test;

[0079]S3. Steel structure surface anti-corrosion treatment: the bottom layer anti-corrosion treatment, middle layer anti-corrosion treatment and outer layer anti-corrosion treatment are carried out on the surface of steel structure;

[0080]S4. Steel structure quality inspection and acceptance: Carry out quality qualification inspection on the steel structure treated by S3, and accept it after passing the inspection.

[0081]In this embodiment, preferably, the outer surface inspection in the S2 is weld inspection and outer surface integrity inspec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com