Cathodic protection monitoring probe, cathodic protection monitoring probe monitoring system, and manufacturing method and monitoring method thereof

A technology of cathodic protection and monitoring probes, which is applied in the field of cathodic protection monitoring probes and cathodic protection monitoring probe monitoring systems, which can solve problems such as difficult monitoring of pipeline cathodic protection potentials, and achieve the effects of ensuring measurement accuracy, avoiding pollution, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

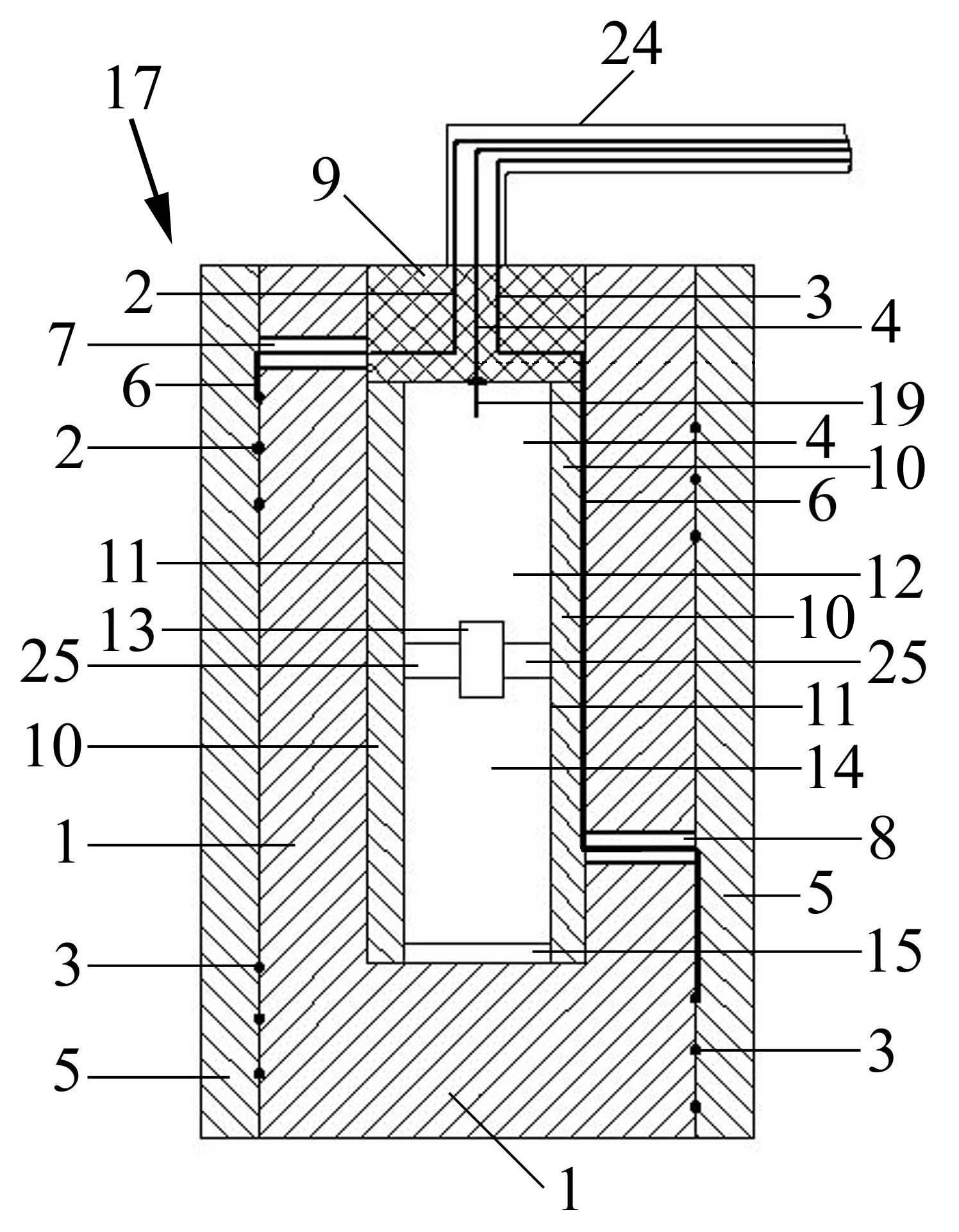

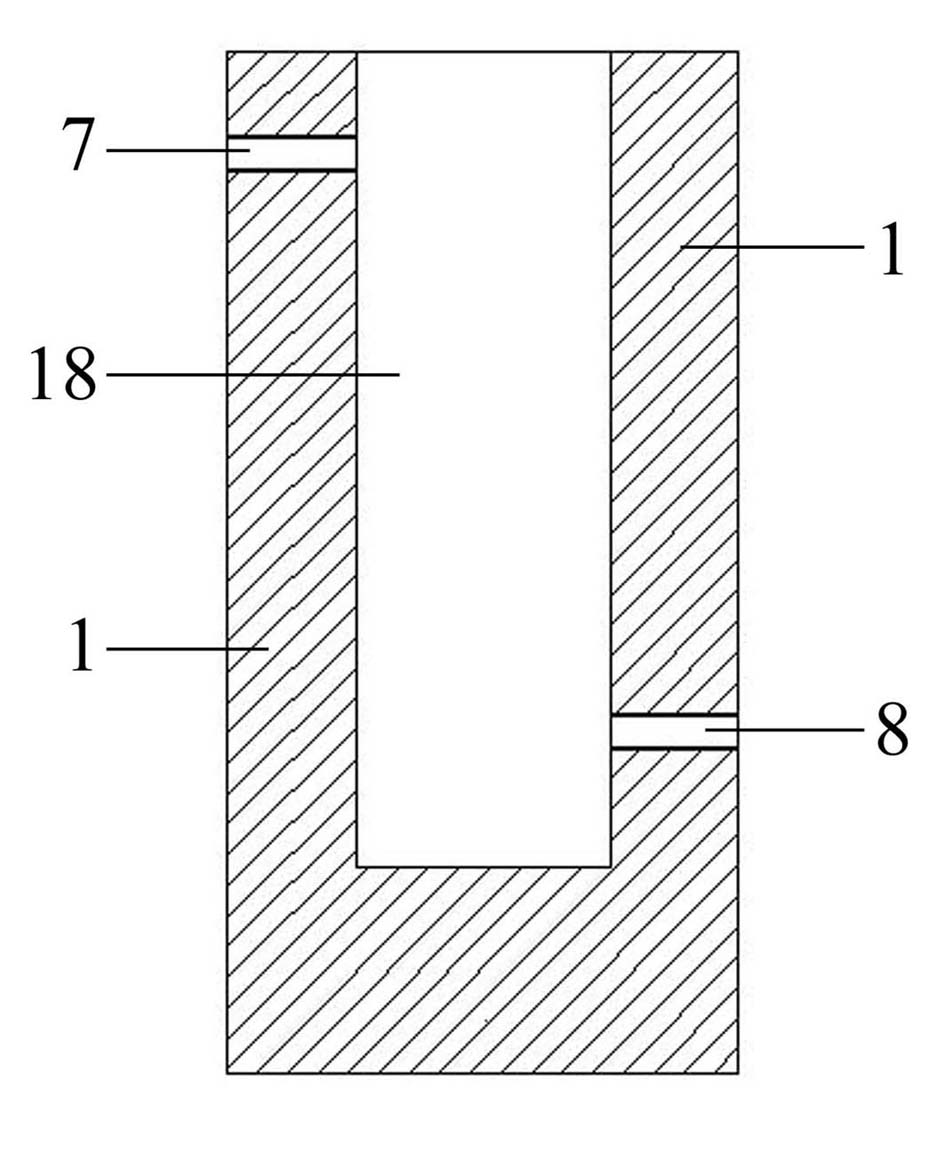

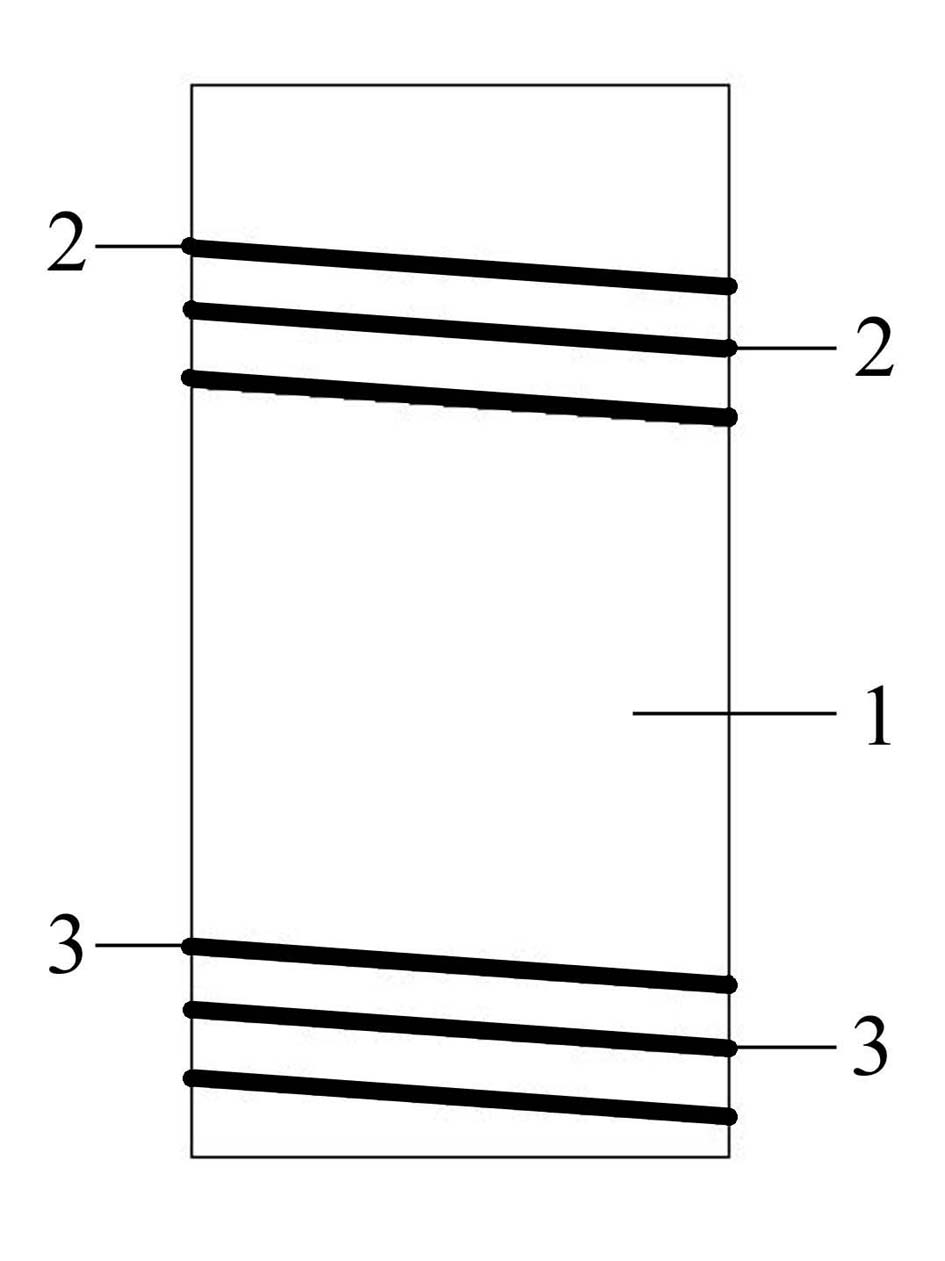

[0126] The main body of the probe (17) is cylindrical as a whole, and is composed of the probe core (1), the self-corrosion electrode (2), the cathode electrode (3), the reference electrode (4), the surface layer (5), the lead wire (6), Composed of electrode threading hole (7), cathode threading hole (8), sealing layer (9), fixed layer (10), probe core cavity (18), reference electrode (19) and lead cable (24), the probe core (1) The overall shape is cylindrical, with a hollow blind hole, and the hollow hole is the probe core cavity (18).

[0127] The upper part of the probe core (1) is provided with an electrode threading hole (7), and the electrode threading hole (7) runs through the cylinder wall of the probe core (1) and communicates with the probe core cavity (18). The lower part of the probe core body (1) is provided with a cathode threading hole (8), and the cathode threading hole (8) runs through the cylinder wall of the probe core body (1) and communicates with the pro...

Embodiment 2

[0137] The main body of the probe (17) is set next to the pipeline (21) under the ground surface (23). The pipeline (21) is connected to each other to form a pipeline. At least 2 sets of probe bodies (17) are arranged around the pipeline (21), and the probe bodies (17) are buried in parallel along the periphery of the pipeline (21). (17) generates a small voltage drop in the soil between the pipeline (21).

[0138] The probe main body (17), wiring test box (16), main controller (30), engineering anode electrode (20) and pipeline electrode (29) constitute the cathodic protection monitoring probe monitoring system, and the lead cable (24) of the probe main body (17) ) is connected to the terminal (27) on one of the terminal blocks (26) of the wiring test box (16), the yellow wire of the self-corrosion electrode (2) at one end of the lead cable (24), The green lead wire of the cathode electrode (3) and the red lead wire of the reference electrode (4) are respectively connected w...

Embodiment 3

[0147] The probe embedding point is provided with two sets of probe bodies (17) around the pipeline (21), and at least two sets of probe bodies (17) are buried in one probe embedding point connected to the wiring test box (16), and one set of probe bodies (17) One end of the lead cable (24) is connected to the terminal post (27) on one of the terminal blocks (26) of the connection test box (16), and the self-corrosion electrode (2) at one end of the lead cable (24) The yellow wire of the cathode electrode (3) and the red wire of the reference electrode (4) are respectively connected to the terminal (27) on one of the terminal blocks (26); the other group of probe main body ( 17) One end of the lead cable (24) is connected to the terminal post (27) on one of the terminal blocks (26) of the connection test box (16), and the self-corrosion electrode at one end of the lead cable (24) The yellow wire of (2), the green wire of the cathode electrode (3) and the red wire of the refere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com