Cathodic protection system for underground storage tank

a protection system and underground storage technology, applied in the field of cathodic protection system and method, can solve the problems of system adverse effects, corrosion on the outer surface of both buried and above-ground pipelines, and common metal surfaces,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

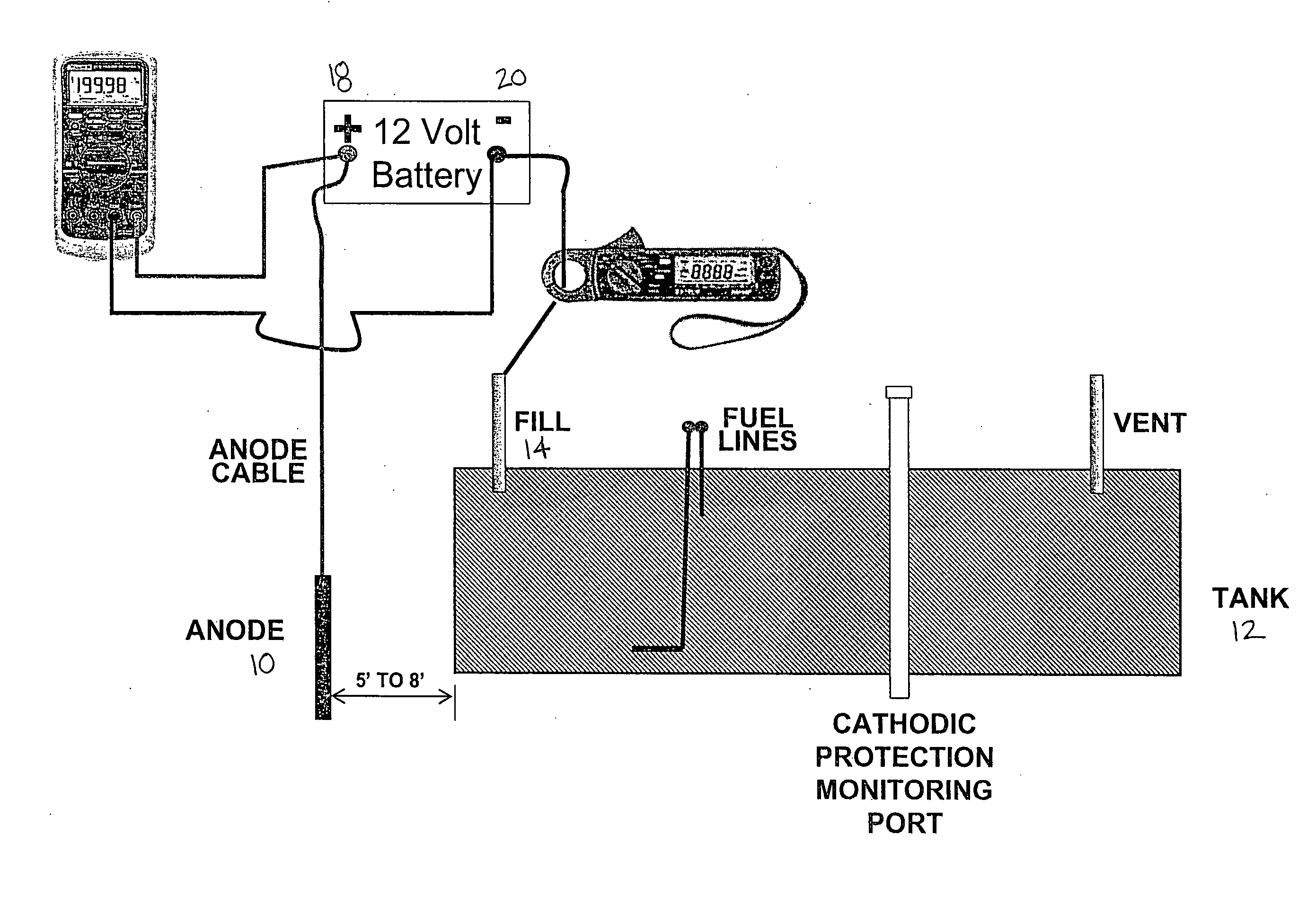

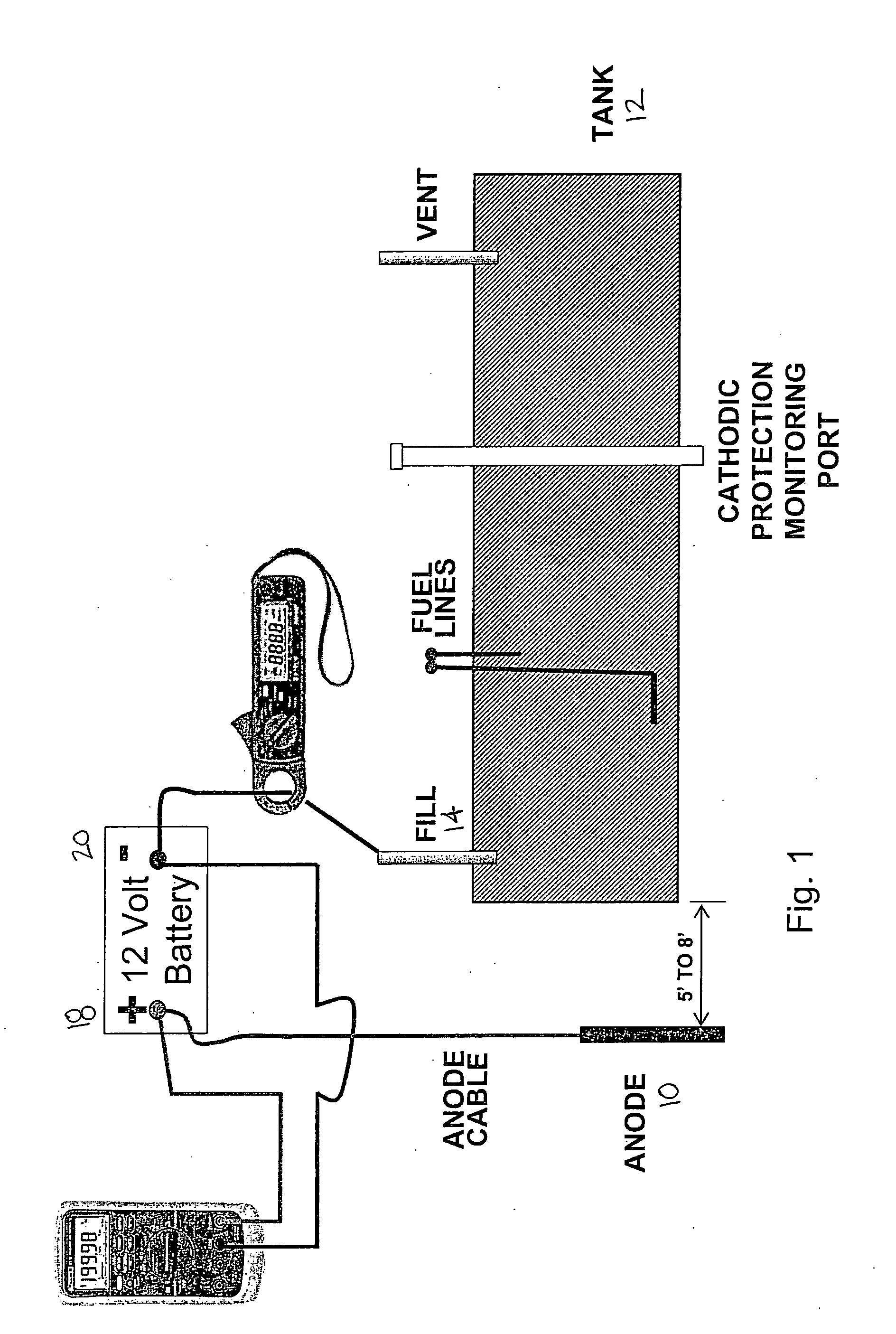

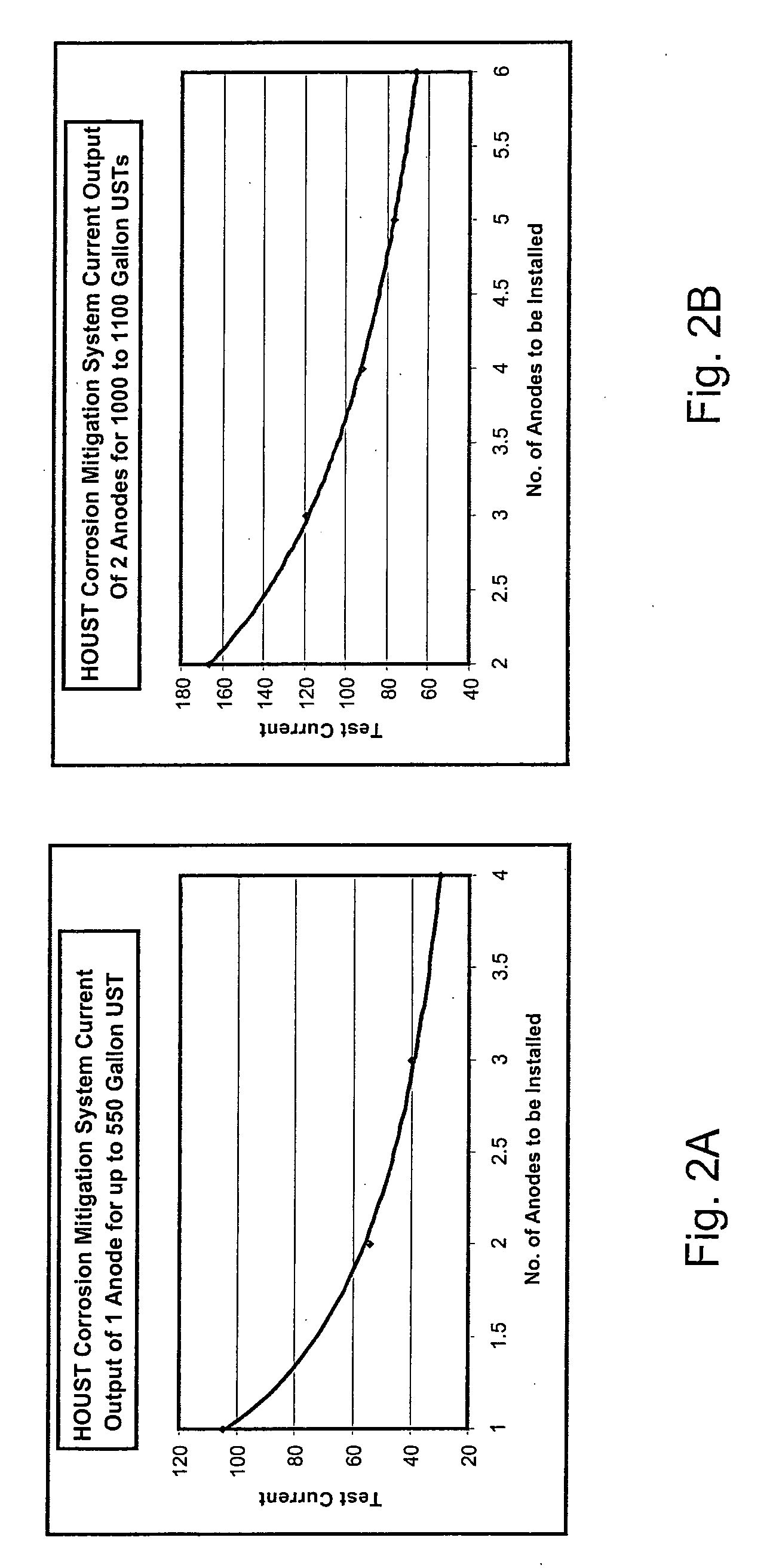

[0017] The present exemplary embodiments relate to a system and method for providing impressed current cathodic protection to an underground storage tank or pipe. By way of example, the exemplary embodiments will be described with reference to an underground heating oil storage tank for home or residential use, which applicants envision as the primary market for the present invention. However, the invention is in no way limited to such tanks but in fact can be extended to any underground storage tank or pipe for holding or transporting a material. For convenience, applicants may make reference herein when describing the present embodiments to a HOUST system, which is an acronym for Home Oil Underground Storage Tank. The present described embodiments can be employed in conjunction with both new and existing HOUST systems. In addition, although the described embodiments make reference to underground tanks, above ground metallic structures in need of cathodic protection are also amenab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com