Prefabricated lane board

A prefabricated assembly and driveway technology, applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problems of insufficient rigidity of the bridge deck, high initial investment cost, easy deformation, etc., and achieve clear force, simple structure, The effect of novel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

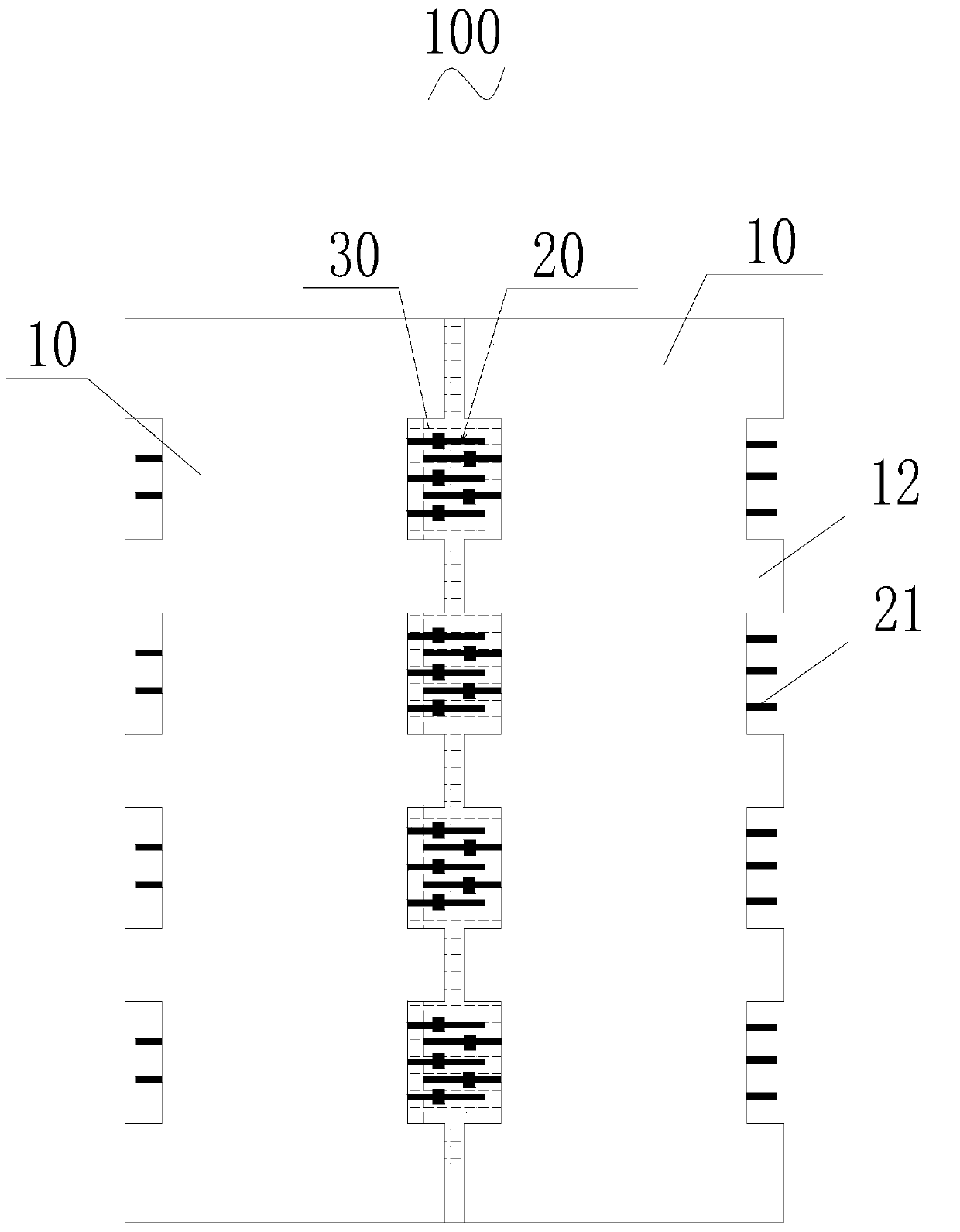

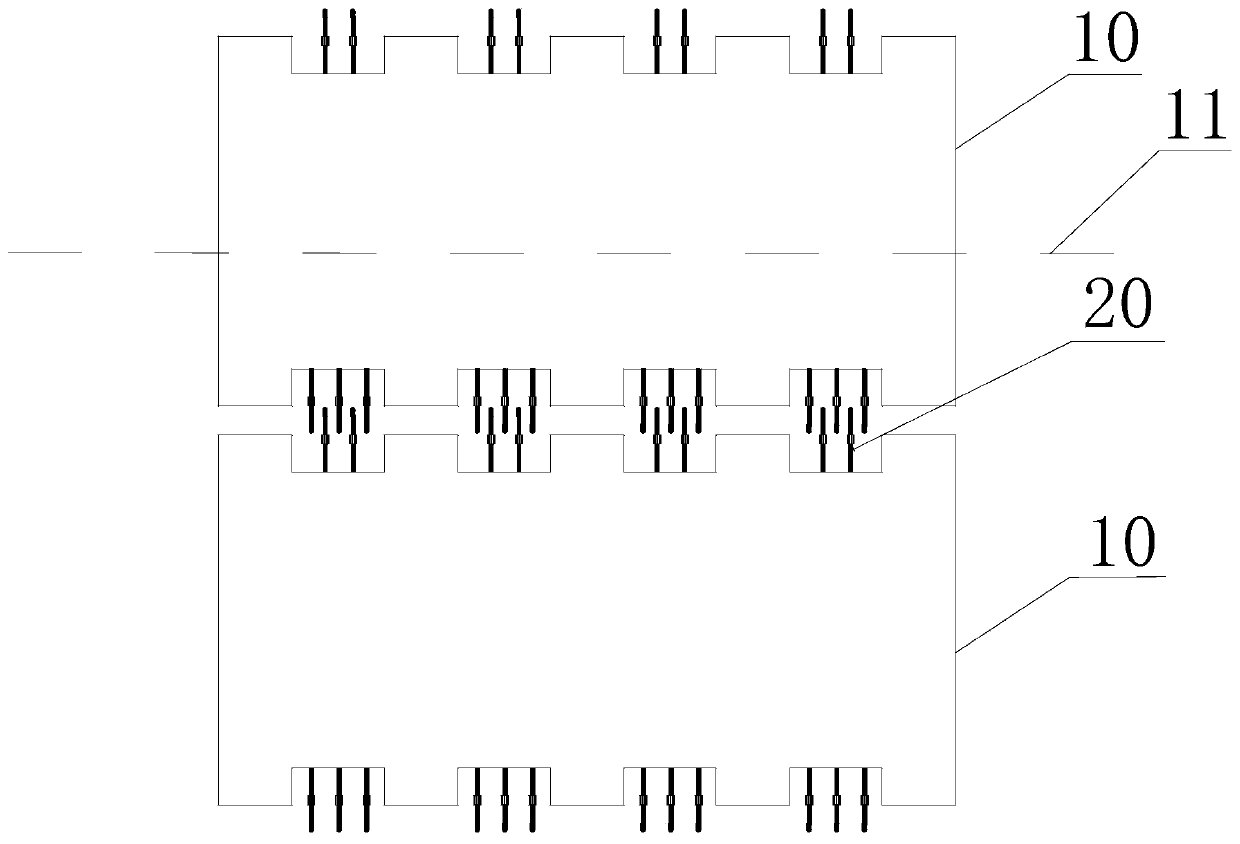

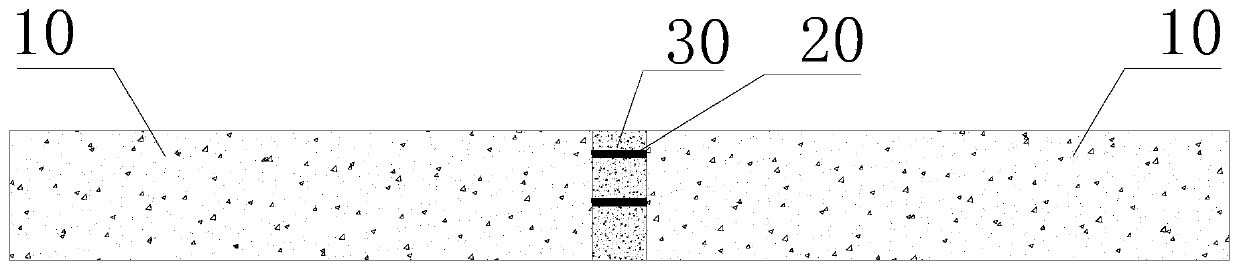

[0046] Such as figure 1 As shown, the present invention firstly provides a prefabricated driveway slab 100 , including a prefabricated driveway slab body 10 , U-shaped steel bars 22 at joints, and cast-in-place materials 30 at joints. in:

[0047] Such as Figure 5 As shown, specifically, the prefabricated driveway slab includes the prefabricated driveway slab body 10, the pre-embedded steel bars 21 at the mortise edge of the prefabricated driveway slab body 10 (it can also be the steel bar configured for the prefabricated driveway slab, and some steel bars are reserved), U-shaped steel bars And the sleeve 23 that connects the U-shaped steel bar. During the actual application process, the prefabricated driveway slab body 10 pre-embeds steel bars 21 at the mortise edge, and the U-shaped steel bars arranged in the joint area of the steel bar skeleton are connected to the embedded steel bars 21 through sleeves 23 . The anchorage length of the U-shaped steel bars connected to t...

Embodiment 2

[0050] On the basis of Embodiment 1, the U-shaped steel bars at the joints are replaced with straight steel bars.

[0051] After completing the above-mentioned implementation process, the following characteristics of the present invention should be reflected:

[0052] 1) Ultra-high-performance concrete has the characteristics of ultra-high strength, ultra-high toughness and high durability, but at present most of domestic research and products adopt high-temperature steam curing to realize the above-mentioned properties, and the construction process is complicated. The ultra-high-performance concrete used in the present invention Concrete can achieve the above properties only by normal temperature curing.

[0053] 2) Compared with the high-performance concrete (HPC), the cast-in-place material 30 in the joint area of the present invention has significantly improved compressive strength of the fiber cement-based composite material, so the self-weight and cross-sectional size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com