Closely arranged frame bridge structure of high speed railway switch area

A high-speed railway and bridge structure technology, applied in bridges, bridge parts, bridge applications, etc., can solve problems affecting construction quality, project duration and project investment, construction quality is difficult to fully guarantee, bridge height and length increase, etc., to achieve construction Convenience and quickness, fast construction turnover, and clear effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

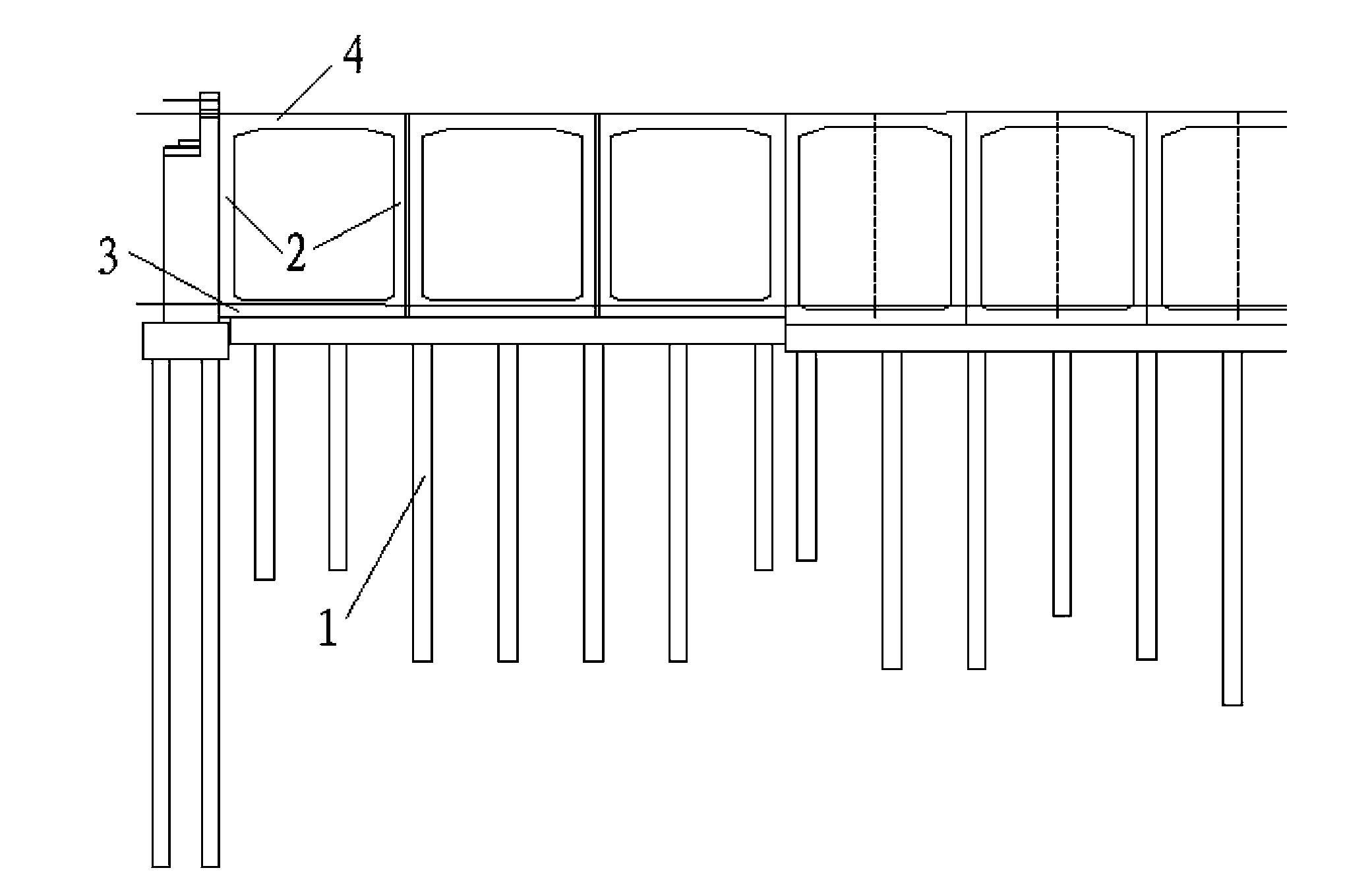

[0010] Such as figure 1 The close-packed frame bridge structure in the high-speed railway turnout area includes the bottom plate, side wall and driving roof on the foundation. The bottom plate, side wall and driving roof form a number of close-packed frames. The aperture of the frame perpendicular to the turnout area is 8-10m. The gap between the frames along the direction of train travel is 2cm.

[0011] The present invention adopts a frame with an aperture of 8-10m to be laid perpendicular to the main line of the turnout area, and the high-speed train runs on the top of the frame plate, and the gap between the frames along the line direction is 2cm, which not only meets the requirements of the high-speed turnout on the longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com